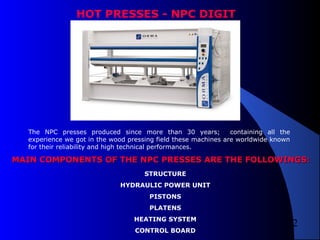

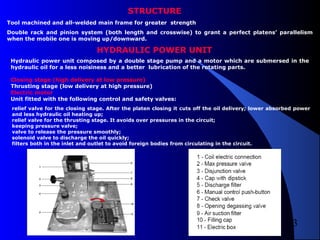

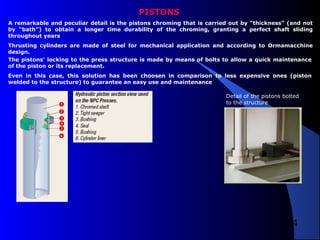

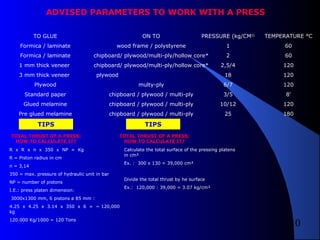

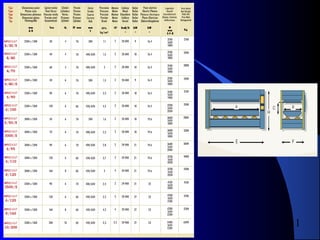

This document provides information about Ormamacchine, an Italian manufacturer of automatic pressing plants. It discusses their NPC line of hot presses, including key components like the structure, hydraulic power unit, pistons, platens, heating systems, and control board. Parameters for common gluing applications are also listed, along with tips for calculating a press's total thrust. Ormamacchine has over 40 years of experience and produces 900 plants annually with 150 employees across 5 production units in Italy.