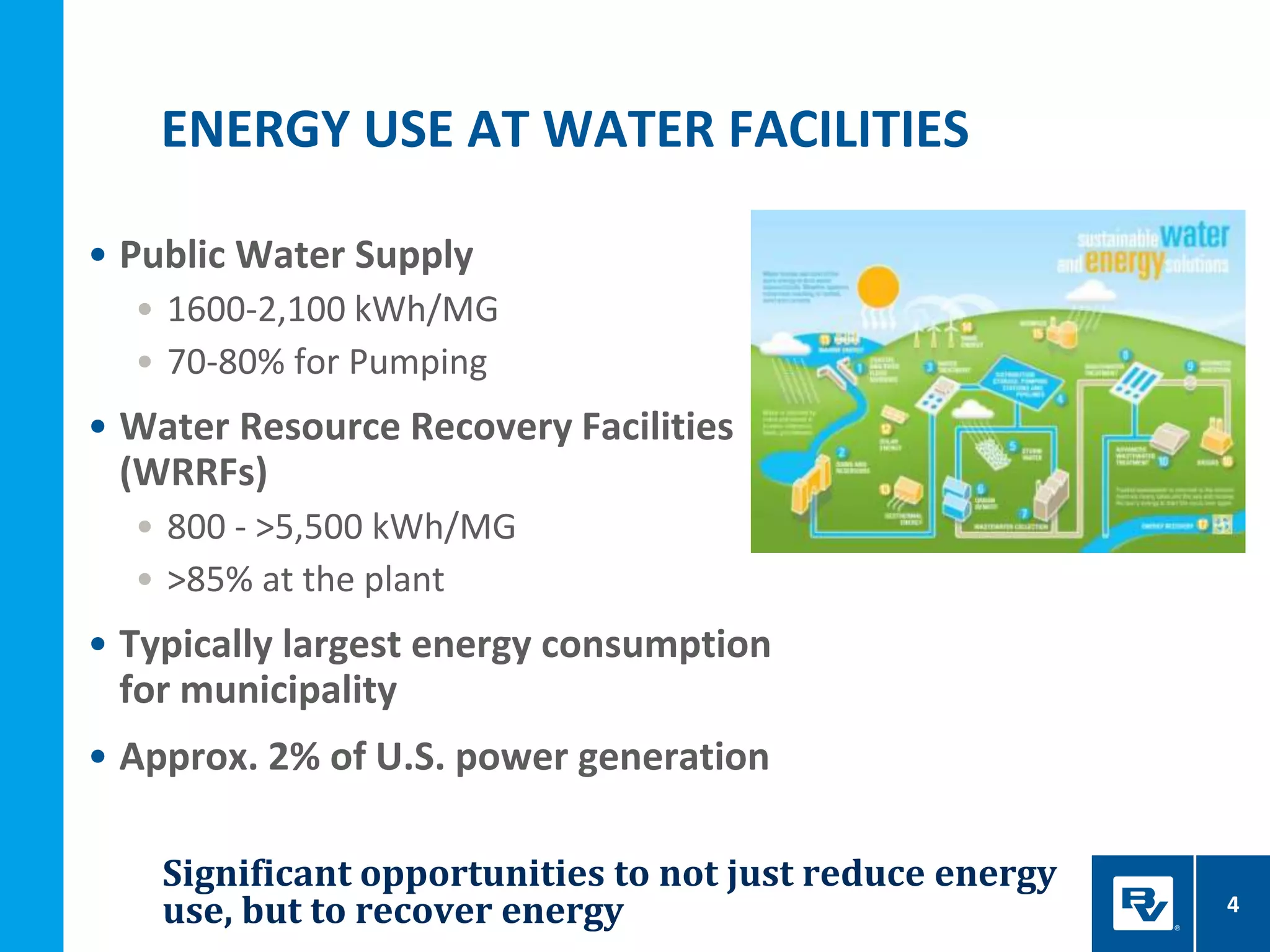

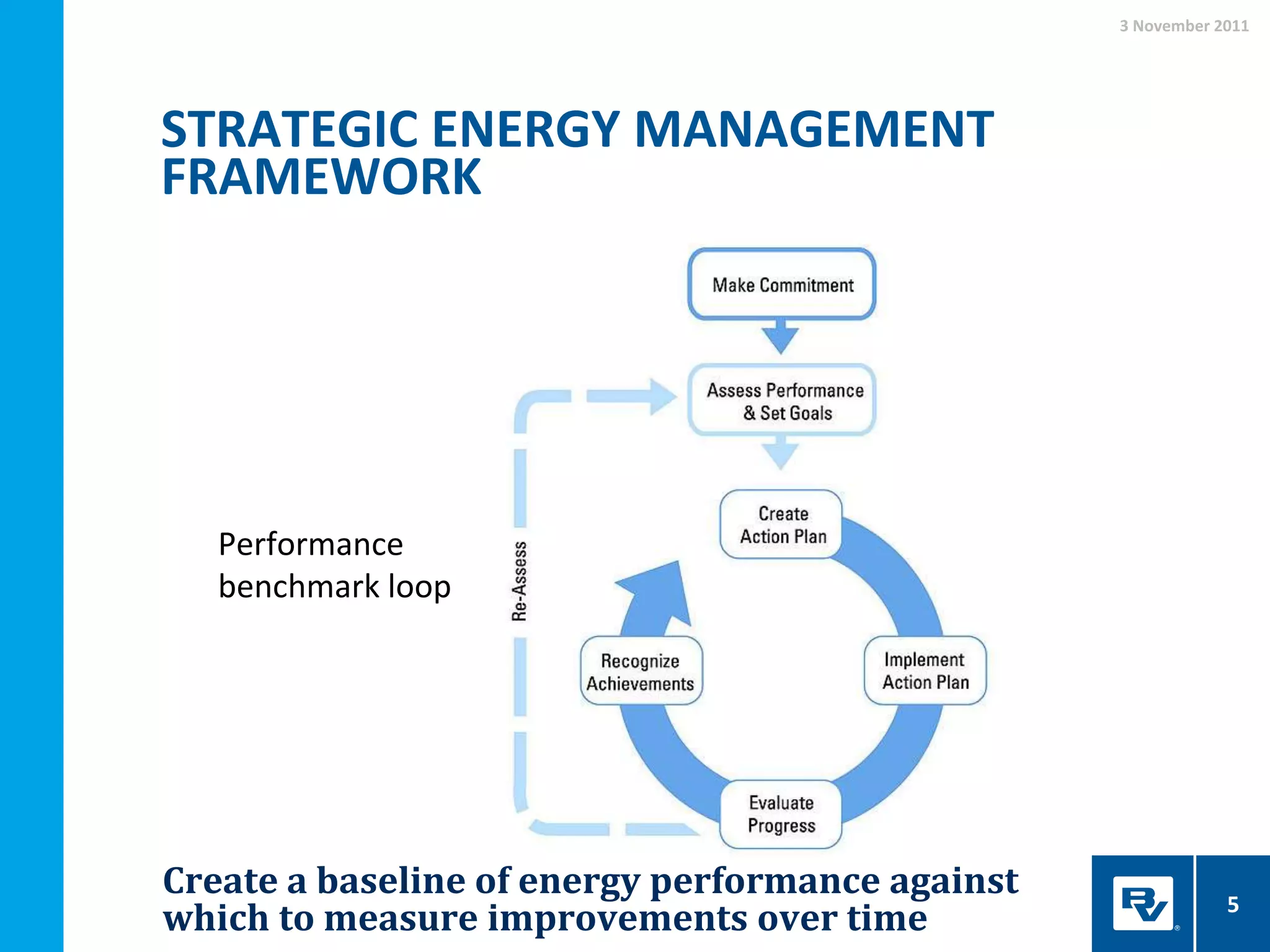

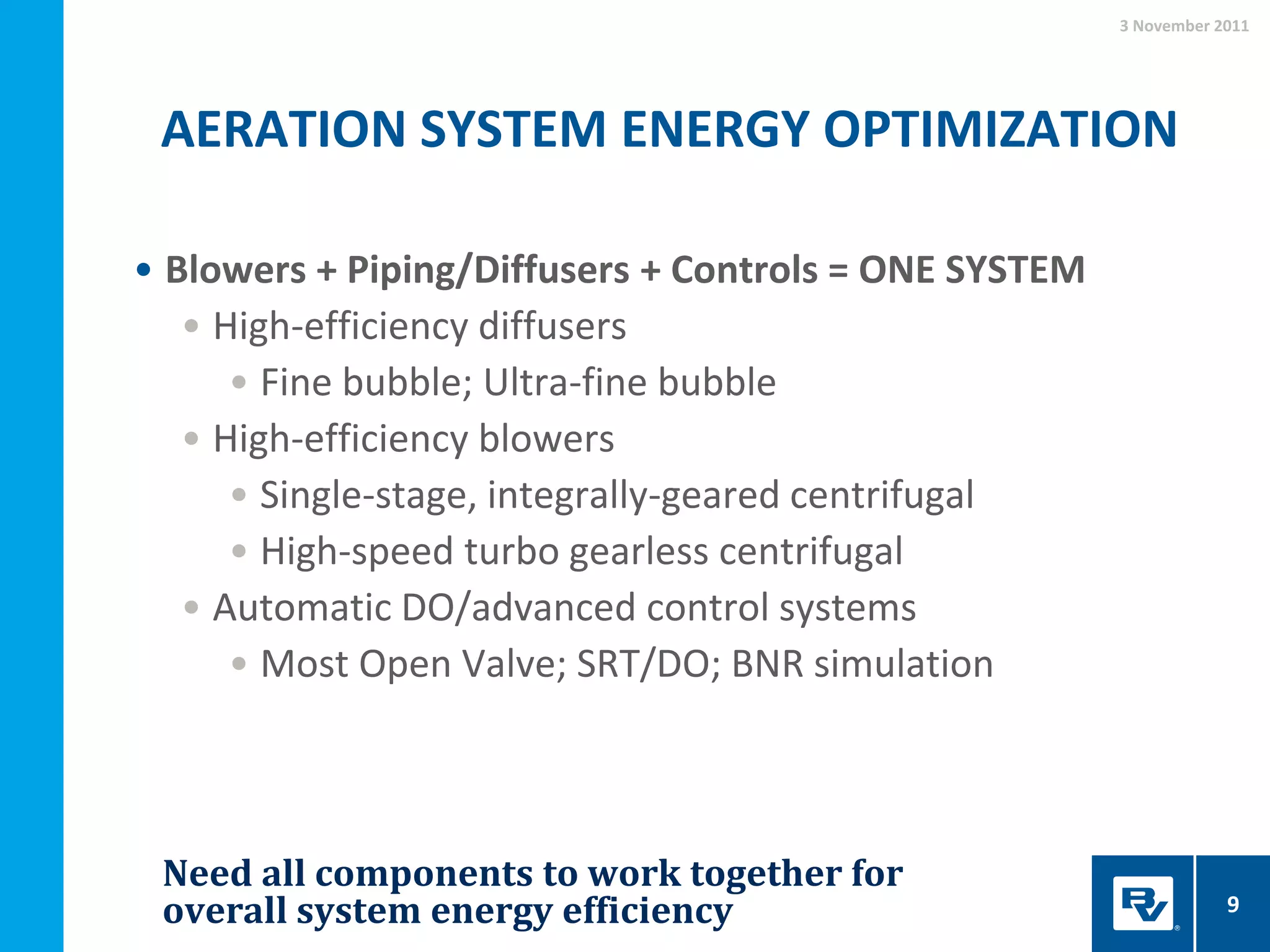

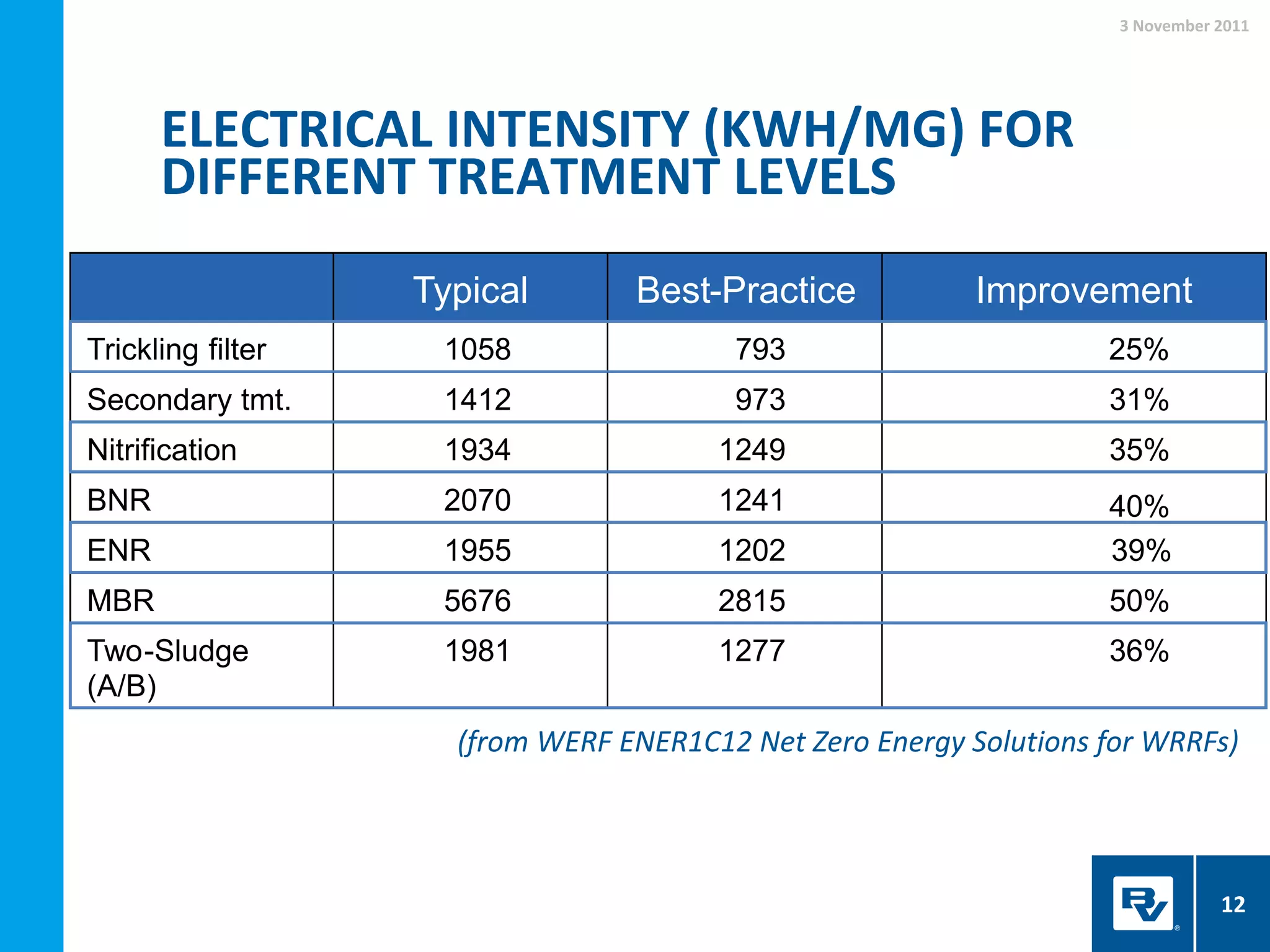

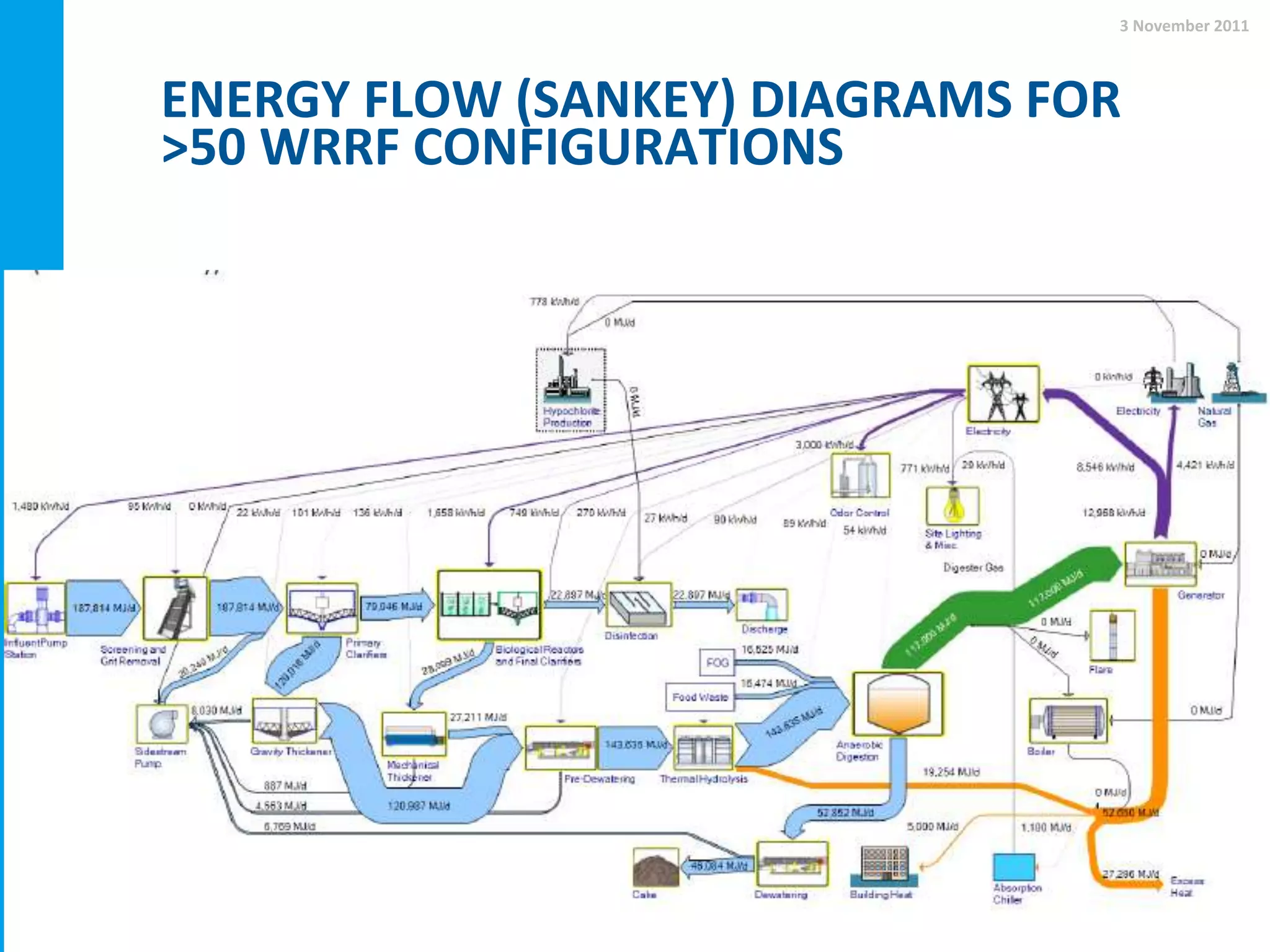

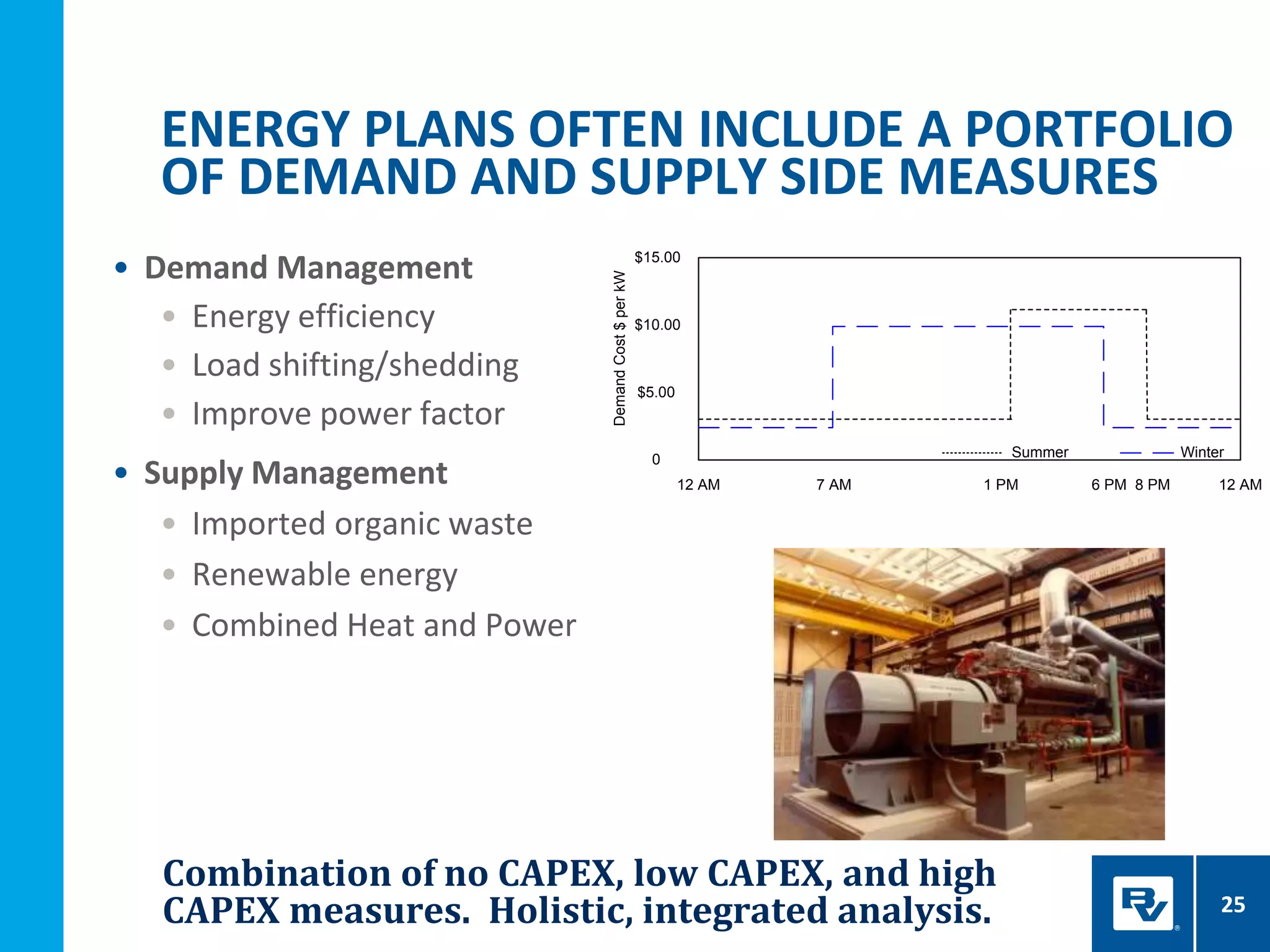

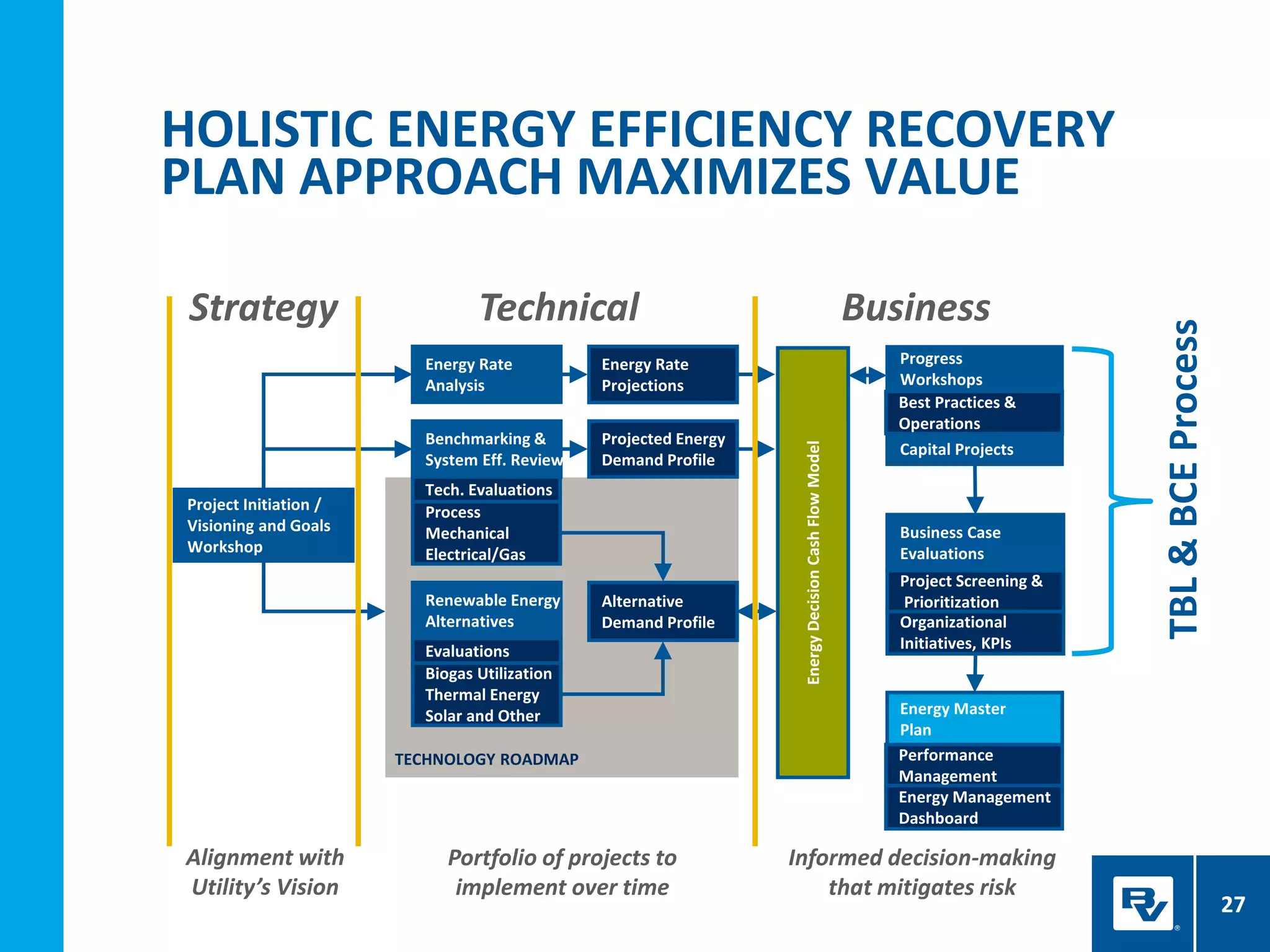

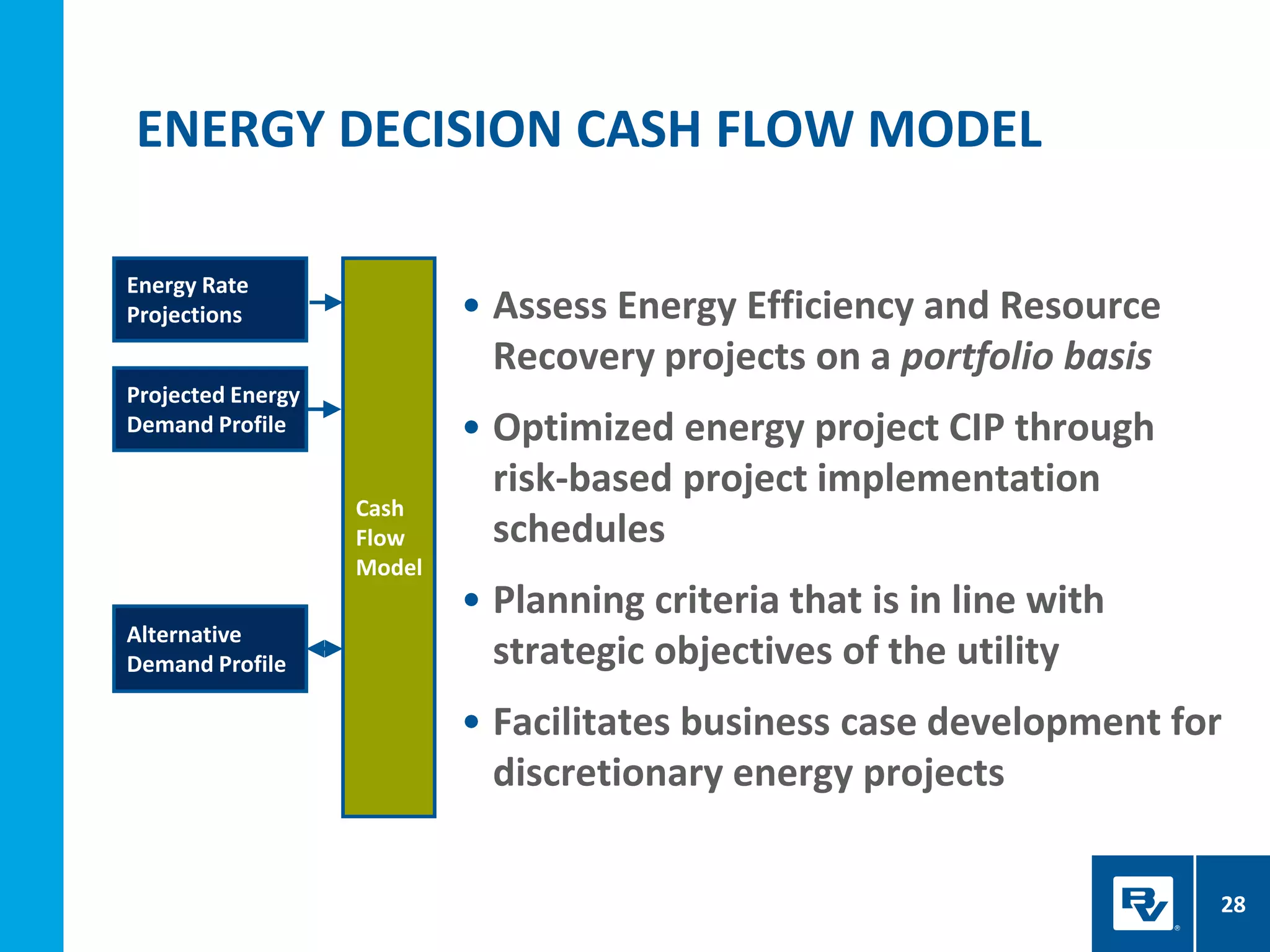

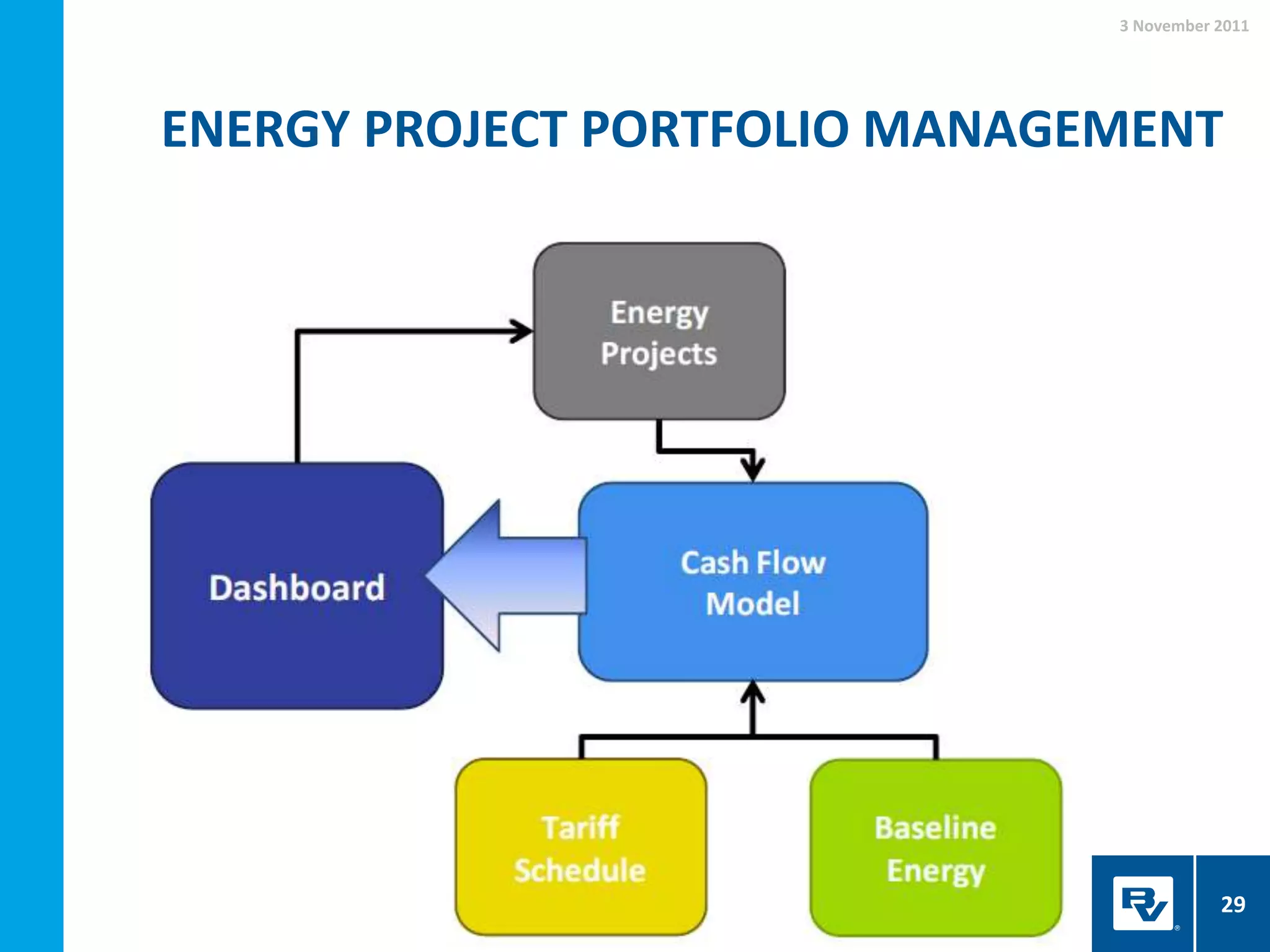

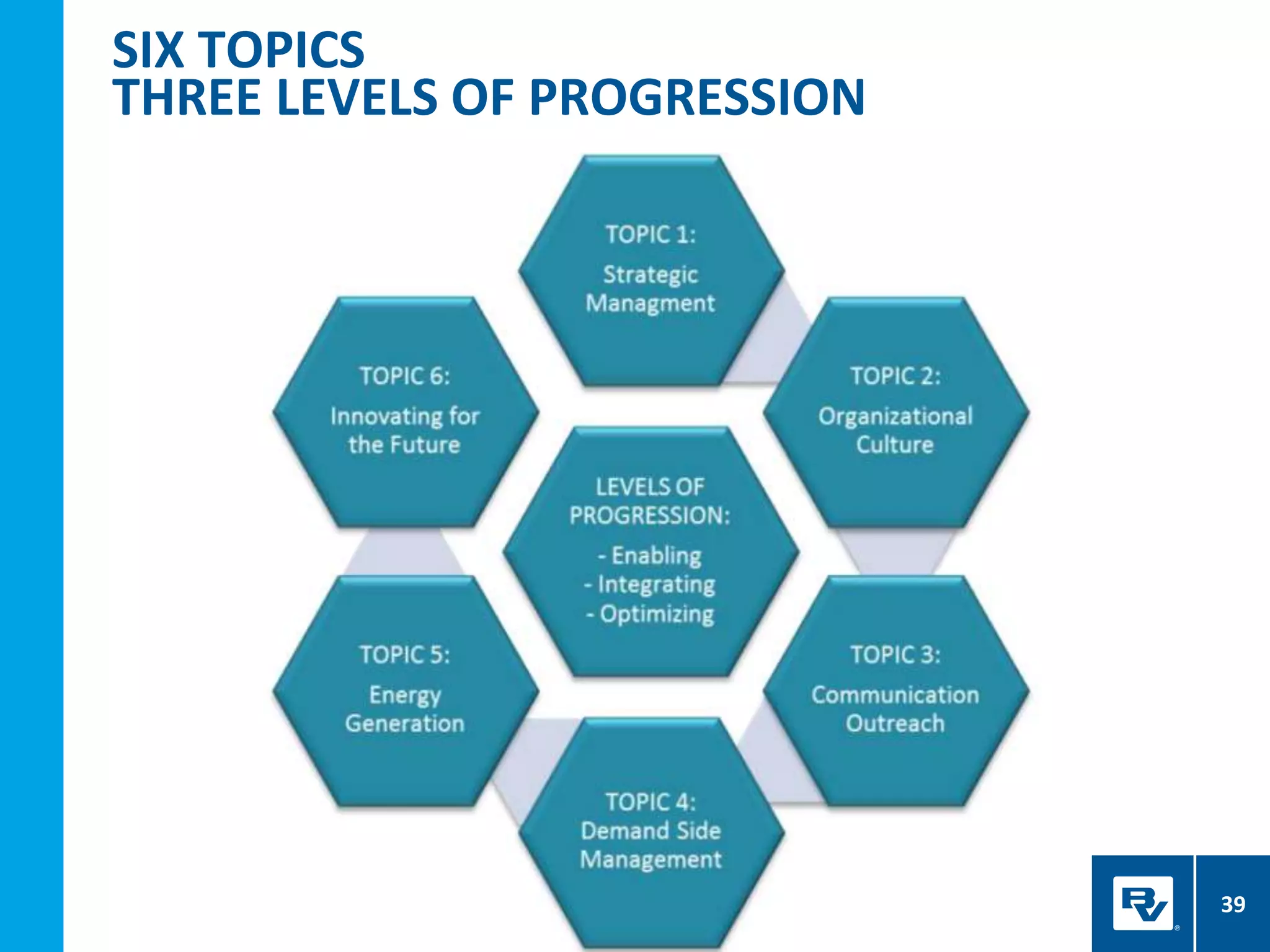

The document discusses the need for energy management in the water industry, outlining strategies such as resilience, efficiency, and resource recovery to achieve net zero energy use for water facilities. It highlights successful examples from various utilities and emphasizes the importance of integrated energy management approaches to maximize value and reduce costs. Various technological, organizational, and financial challenges are identified, alongside the importance of collaboration and innovative practices for future sustainability in the sector.