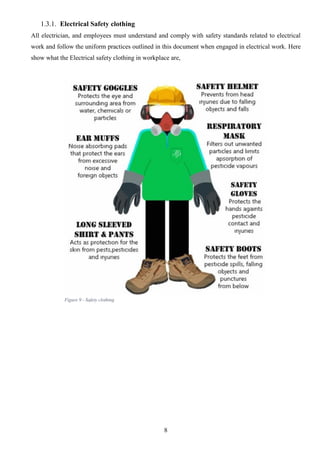

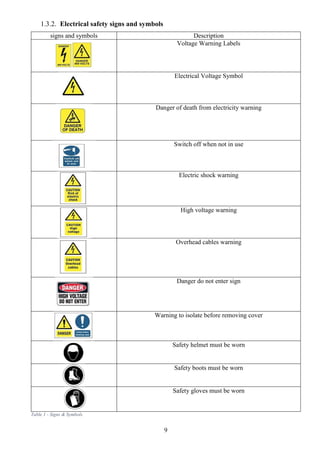

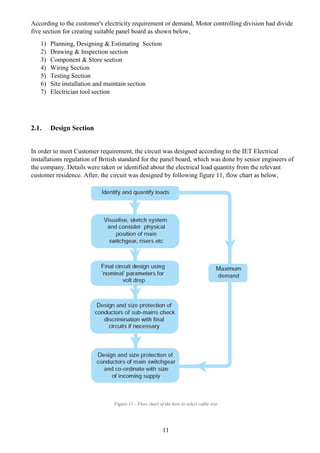

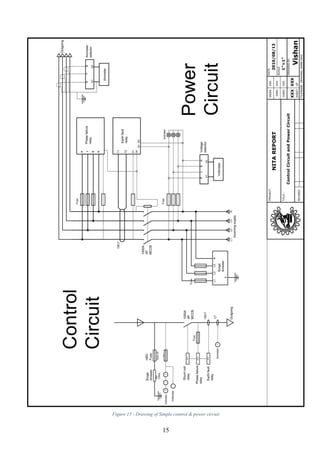

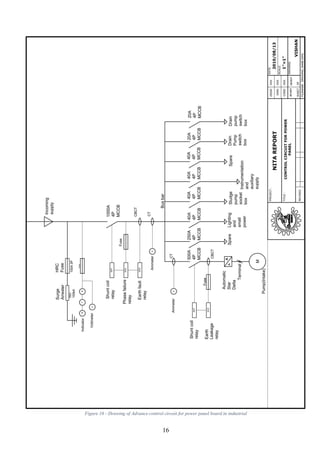

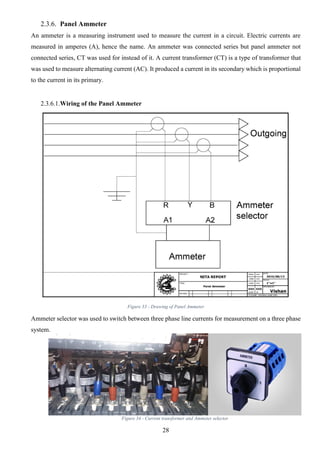

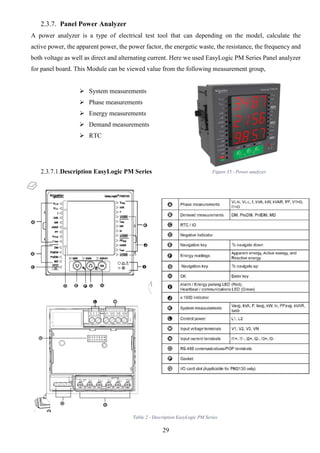

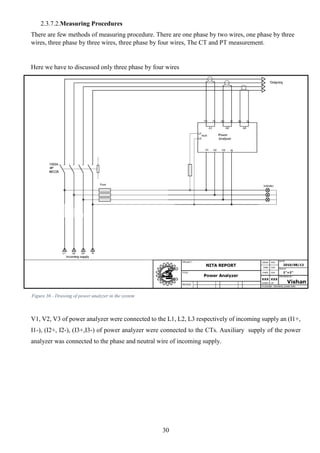

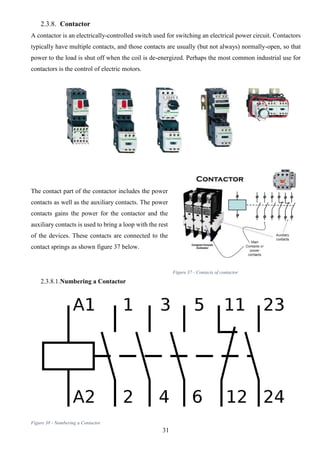

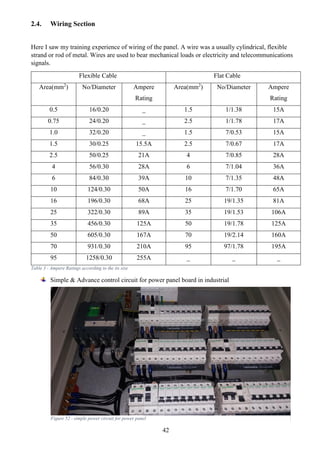

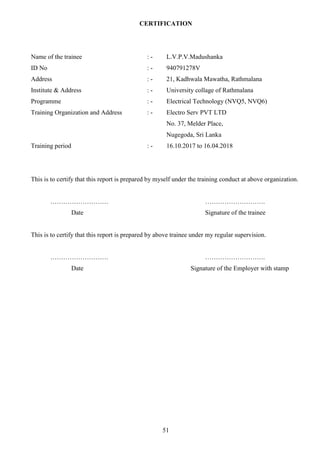

The document provides a report on an industrial training completed by L.V.P.V. Madushanka at Electro-Serv (PVT) LTD over a period of 6 months. It begins with an acknowledgment of those who supported the training. The first chapter introduces Electro-Serv and provides information on its vision, management style, safety practices, and organizational structure. The second chapter describes the trainee's experiences in different technical sections including design, inspection, components, wiring, and testing. The third chapter provides a conclusion on the industrial training program.