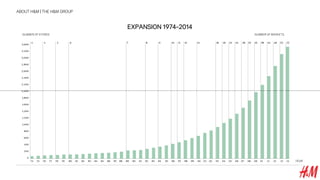

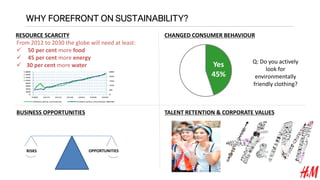

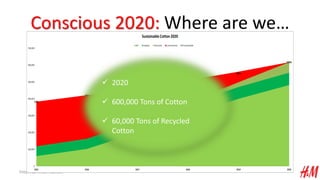

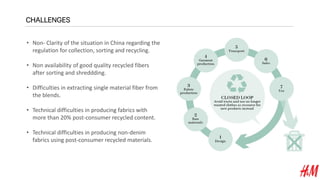

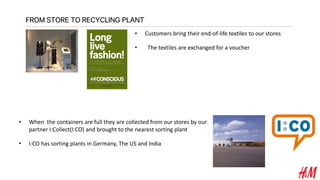

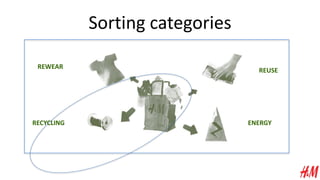

H&M operates in 61 countries with around 4,000 stores and focuses on sustainability by implementing initiatives such as a global garment collecting program that has collected over 16 million kg of textiles since 2013. The company aims to transition towards environmentally friendly practices, addressing challenges in recycling and sourcing, particularly in China where a large portion of their products are made. H&M's strategy includes a value chain approach that respects both current and future resource needs, highlighting their commitment to reducing waste and promoting a circular economy.