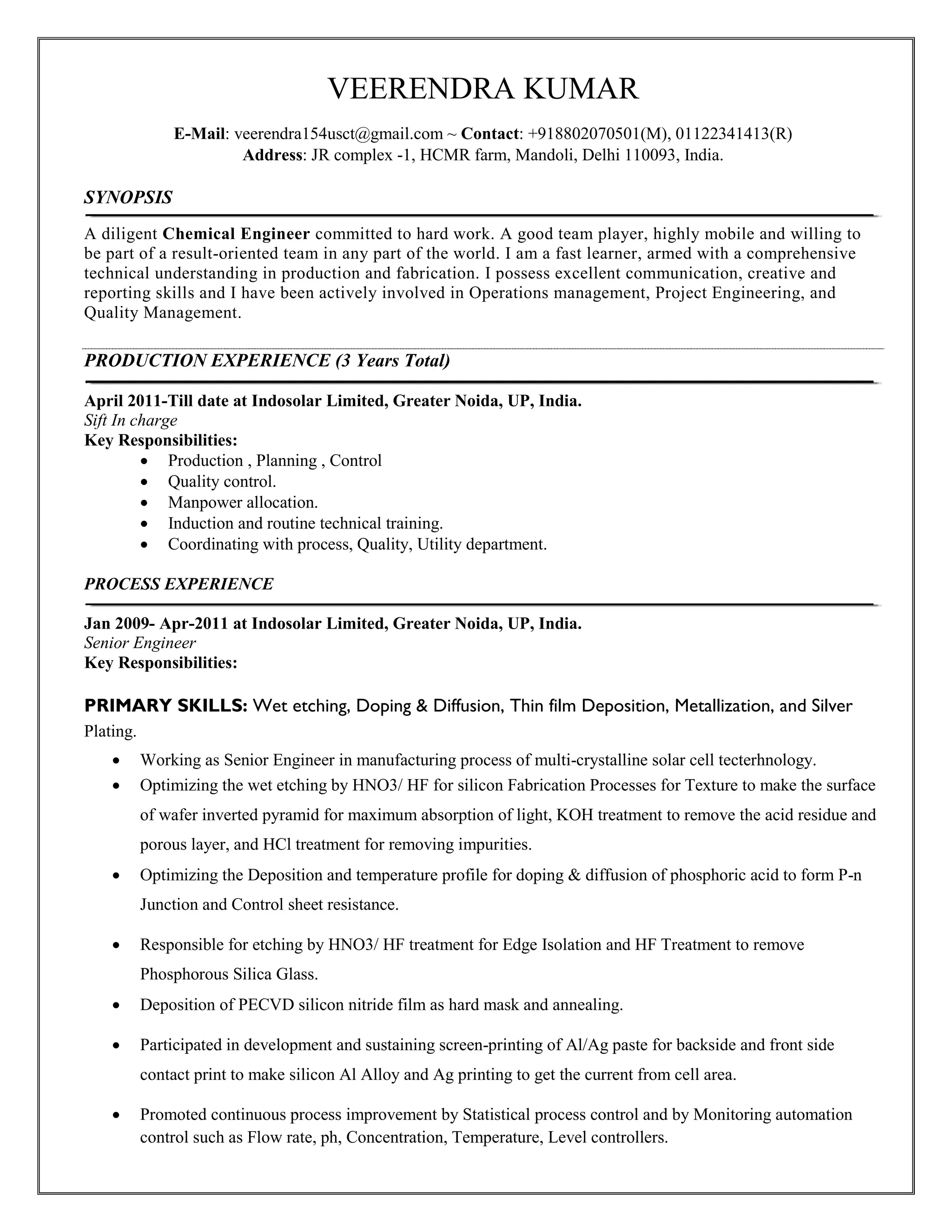

This document contains a summary of Veerendra Kumar's qualifications and experience. He has over 3 years of experience in production and process roles at Indosolar Limited, including as a Shift In Charge and Senior Engineer. He has skills in areas like wet etching, doping, diffusion, thin film deposition, and metallization related to manufacturing solar cells. He is pursuing an MBA in Operations and holds an M.E. in Polymer Technology and a B.Tech in Chemical Engineering.