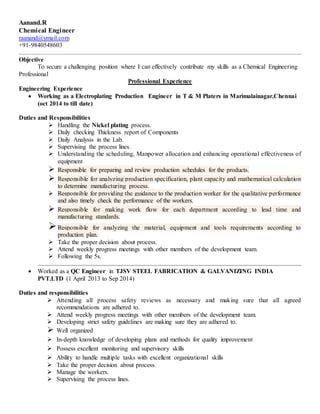

Aanand.R is seeking a challenging position as a Chemical Engineer. He has over 7 years of experience in engineering roles including as an Electroplating Production Engineer, QC Engineer, and Assistant Engineer. He has a B-Tech in Chemical Engineering and has worked on projects involving the manufacture of fatty alcohol and enrichment of heavy water.