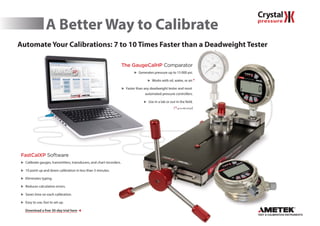

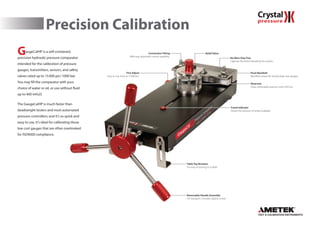

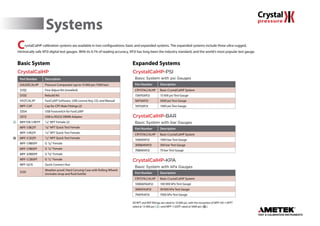

The document details the CrystalCalHP calibration system, which allows for calibration of pressure gauges and transmitters up to 15,000 psi with faster performance than traditional methods. It utilizes the FastCalXP software for quick 10-point calibrations that minimize errors and save time, making it ideal for both laboratory and field use. The system includes precision hydraulic pressure comparators and customizable configurations to meet various calibration needs.