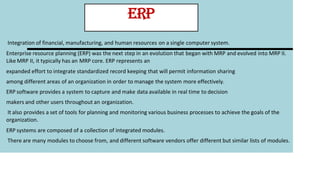

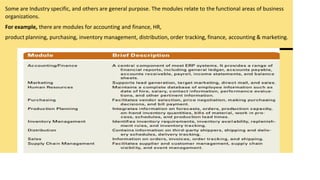

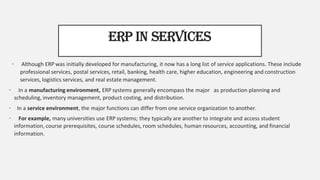

This document provides a comprehensive overview of Materials Requirements Planning (MRP) and Enterprise Resource Planning (ERP), detailing the processes, inputs, outputs, and benefits of MRP in manufacturing and service contexts. It emphasizes the importance of accurate inventory records, master schedules, and bills of materials for effective MRP operations. Additionally, it highlights the evolution of ERP from MRP, showcasing its application across various business domains and functions.

![Planned order receipt

• These represent to-be-ordered materials from a vendor or in-house shop to-be-received at the onset of the period, or

are similar to a scheduled receipt.

Planned order release

• These represent the planned amount to be ordered in the adjusted time period through the lead time offset such that

the materials can be received on time.

• Upon the actual release of orders, the planned order releases are removed from the form, and the receipts generated

by them are altered to scheduled receipts.

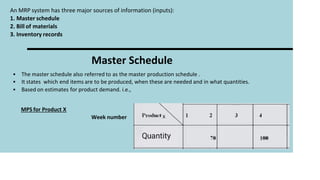

• The MPS determines gross or projected requirements for finished items to the MRP system, which do not consider

inventory on hand or on order.

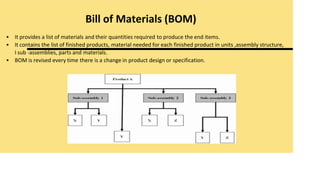

• The MRP computer program subsequently explodes the demands for finished items into requirements for part

components and materials by processing all major bills of materials on every single level.

• Thereafter, net requirements are measured by adjusting for current inventory and items ordered and recorded in the

inventory status file.

• Net requirements = Gross requirements – [On hand product quantity + Scheduled receipts]](https://image.slidesharecdn.com/mrperp-220828082609-761f408b/85/MRP-ERP-pdf-9-320.jpg)