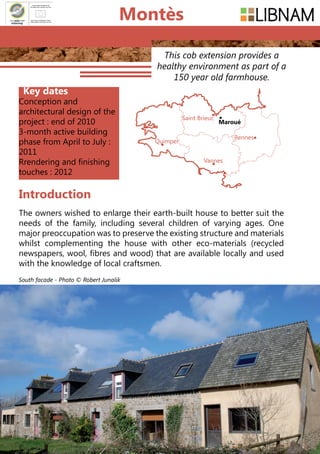

The owners wanted to expand their 150-year-old earth-built farmhouse to better suit their growing family. They added extensions on the east and west sides totaling an additional 115 square meters. Traditional and sustainable materials were used, including cob, wood, wool and recycled newspapers. The extensions provide three bedrooms, a living room and bathroom to give each family member their own living space while preserving the existing structure.