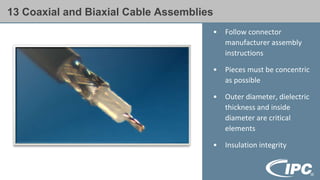

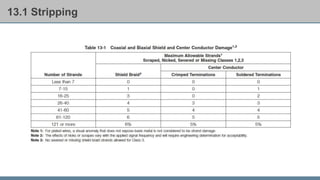

This document provides requirements and criteria for coaxial and biaxial cable assemblies. It discusses stripping techniques, center conductor termination methods including crimping and soldering, solder ferrule pins, coaxial connectors, shield termination, and center pins. Assembly instructions must be followed, components must be concentric, and dimensions like diameter and thickness are critical. Stripping and termination techniques vary depending on cable configuration. Minor defects that do not exceed limits are considered acceptable.