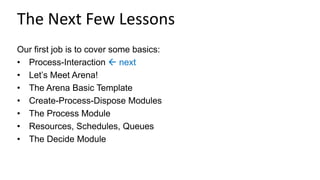

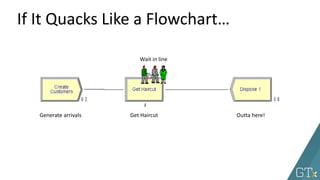

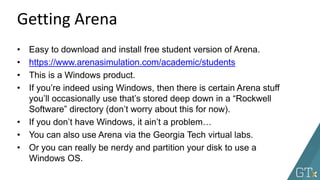

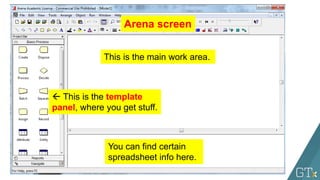

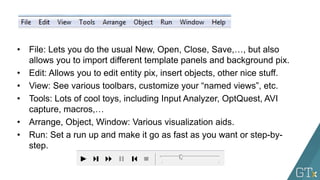

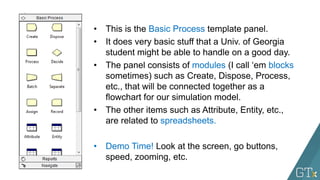

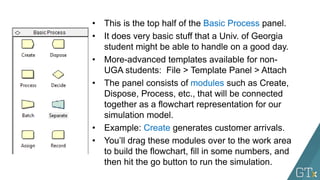

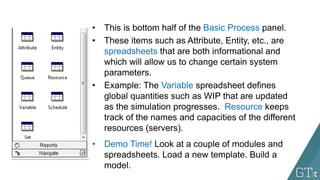

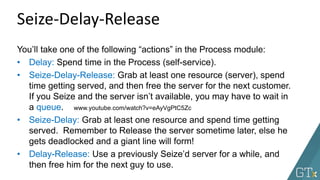

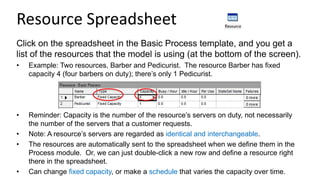

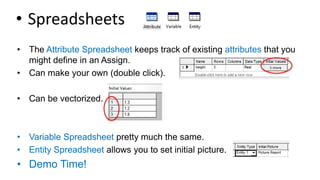

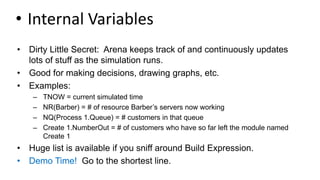

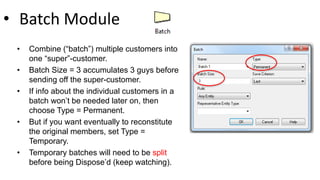

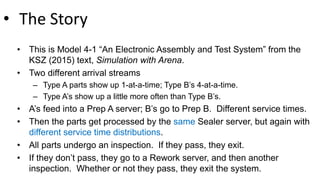

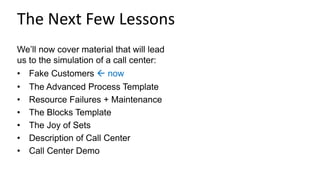

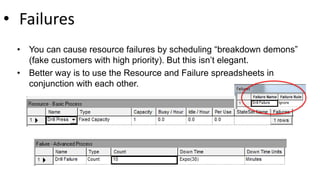

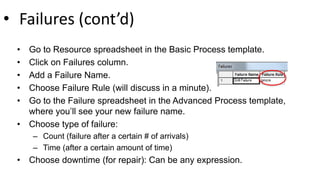

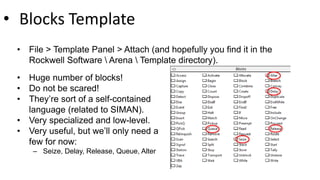

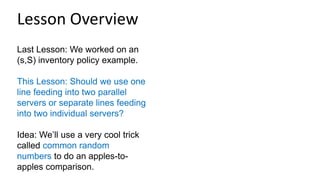

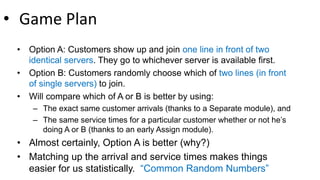

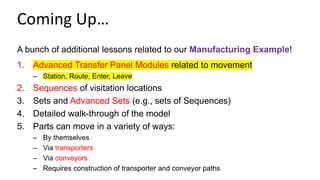

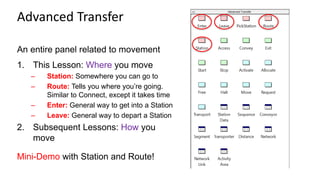

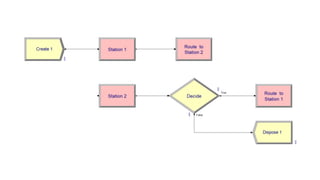

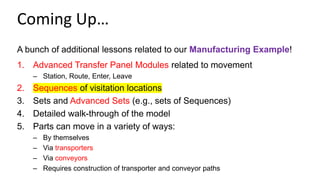

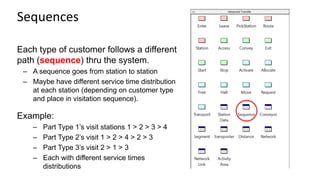

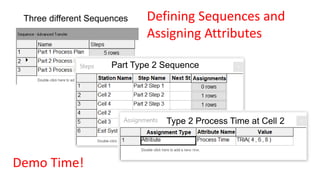

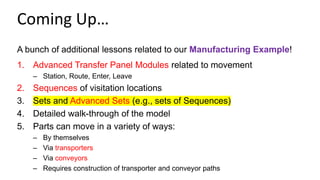

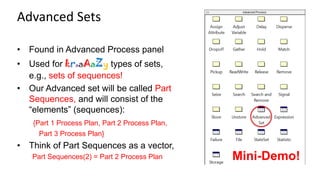

This document provides an overview of a module on the Arena computer simulation language. It discusses upcoming topics that will be covered, including an introduction to Arena, the basic process template, create-process-dispose modules, details on the process module, and resource, schedule, and queue spreadsheets. The goal is to learn the basics of Arena and build initial simulations using the basic process template and its modules.