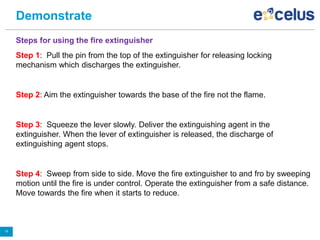

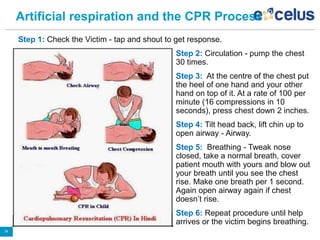

This document provides an overview of occupational health and safety topics including hazards, safe working practices, emergencies, first aid procedures, and documentation. It covers various types of hazards like physical, chemical, mechanical, electrical hazards. It describes safe working practices, use of personal protective equipment, safe material handling, classification of fires and use of fire extinguishers. The document demonstrates how to deal with emergency situations, provide first aid for bleeding, wounds, burns, choking, and perform CPR. It also shows how to move injured people correctly during an emergency.