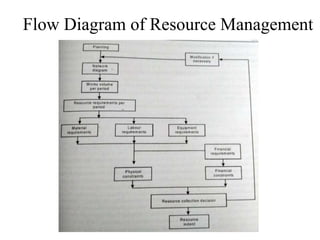

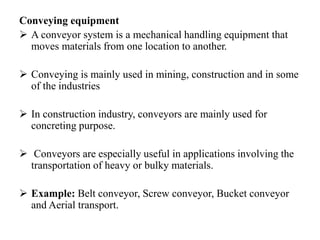

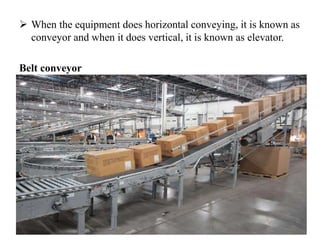

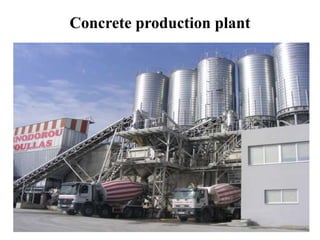

This document discusses resource management in construction projects. It explains that resource management involves planning resources to meet project objectives and client requirements. It discusses the types of resources that must be managed, including labor, materials, equipment, and finances. Effective resource management requires real-time visibility of resource needs, availability, locations, and the ability to reschedule accordingly. It also covers topics like labor classification and management, wage laws, and materials management objectives and functions.