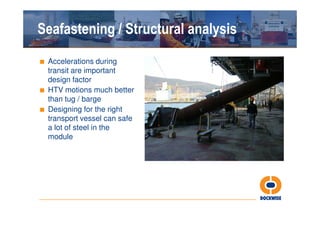

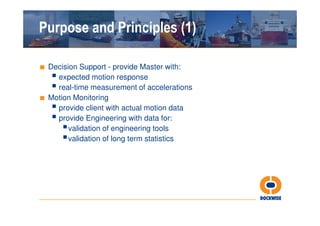

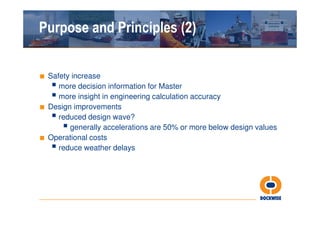

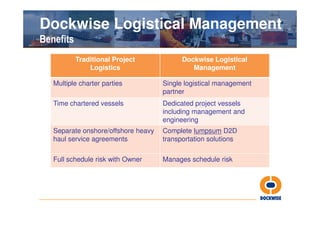

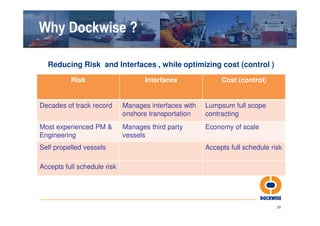

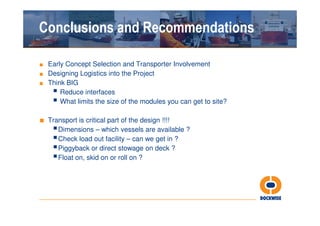

The document discusses modularization and heavy transport. It notes that modularization reduces risk and interfaces while optimizing costs. Dockwise specializes in transporting large modules by heavy transport vessels. These self-propelled vessels have advantages over tug and barge including larger carrying capacity, faster transit times, better cargo safety due to reduced motions, and allowing for smaller module steel sizes. Dockwise provides end-to-end logistical management and lumpsum solutions to transport modules from fabrication to installation sites. Early planning of transport is critical to project success.