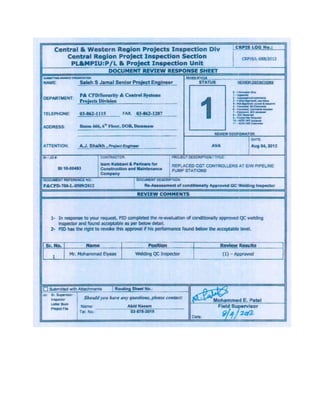

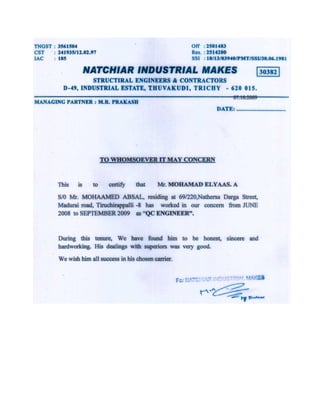

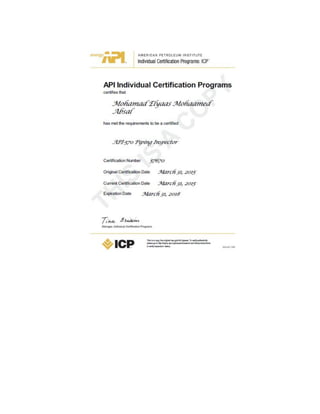

This document contains the resume of Mohamad Elyaas. It summarizes his contact information, educational background, professional certifications, skills, and work experience. For his current role, he works as a Mechanical Inspector based in Saudi Arabia, where he is responsible for quality assurance and inspection tasks such as reviewing documentation, inspecting materials, monitoring fabrication and testing, identifying non-conformities, and ensuring work is done according to standards and client specifications. Previously he has over 8 years of experience in quality control and inspection roles in India.