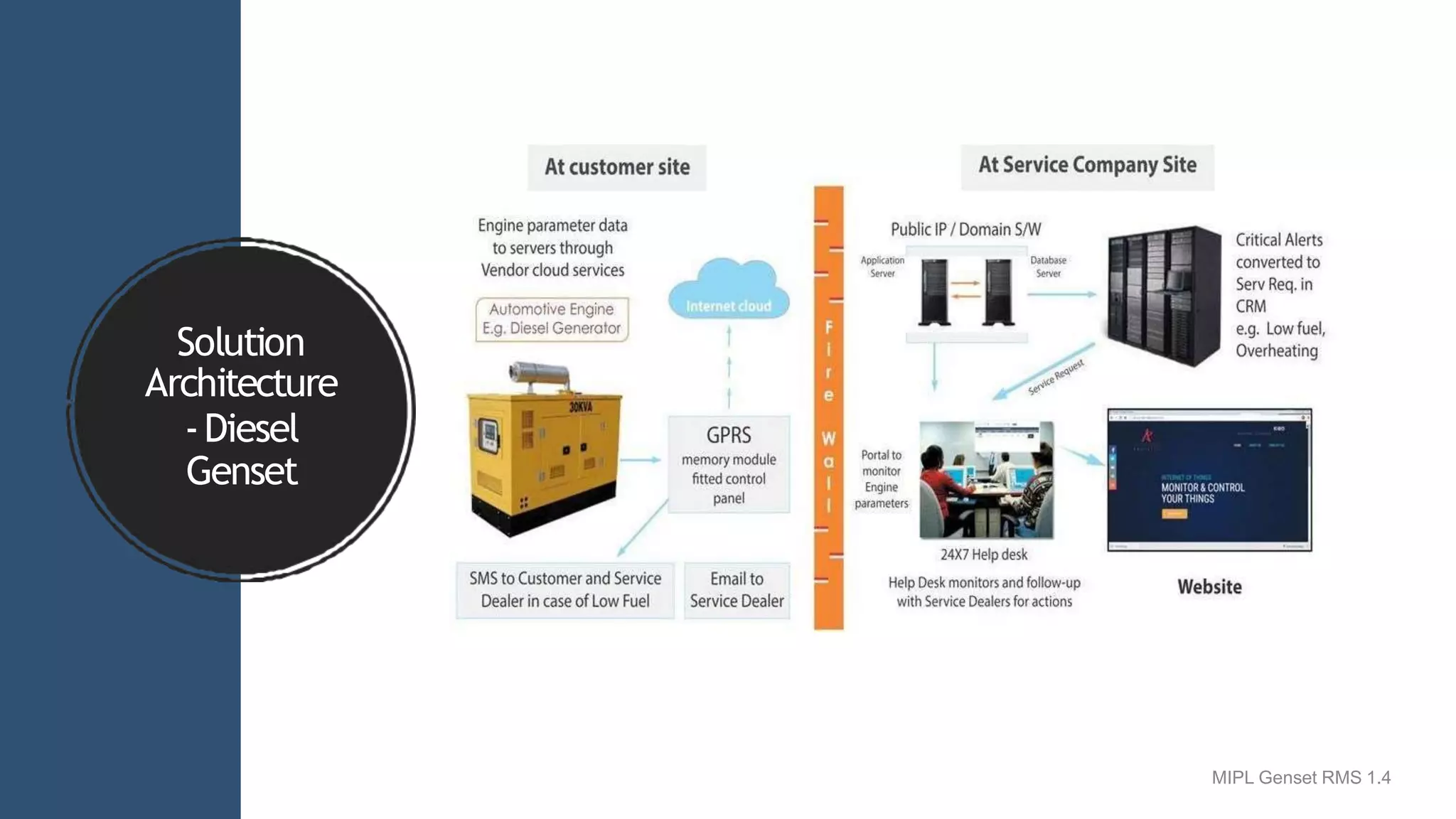

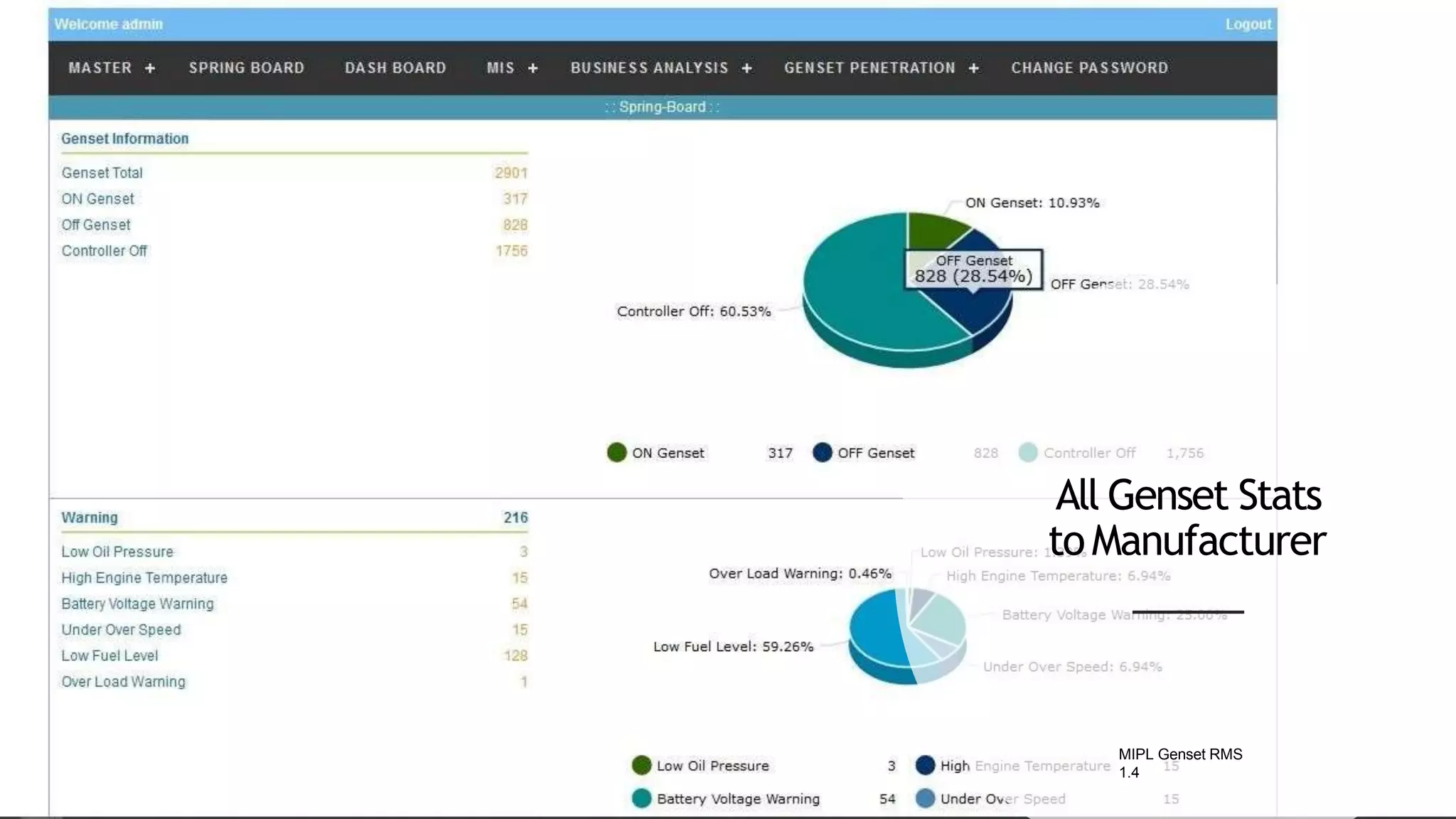

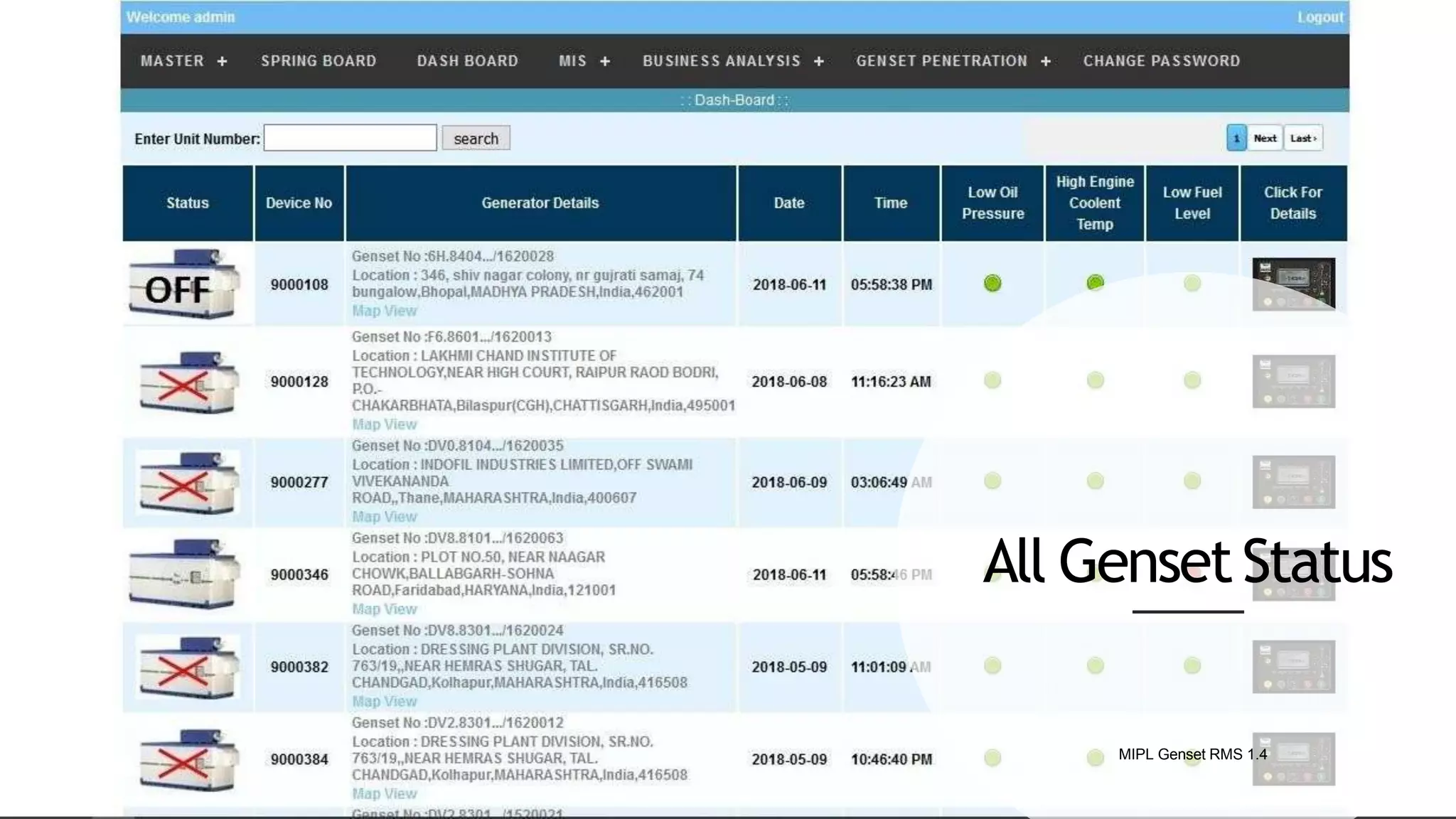

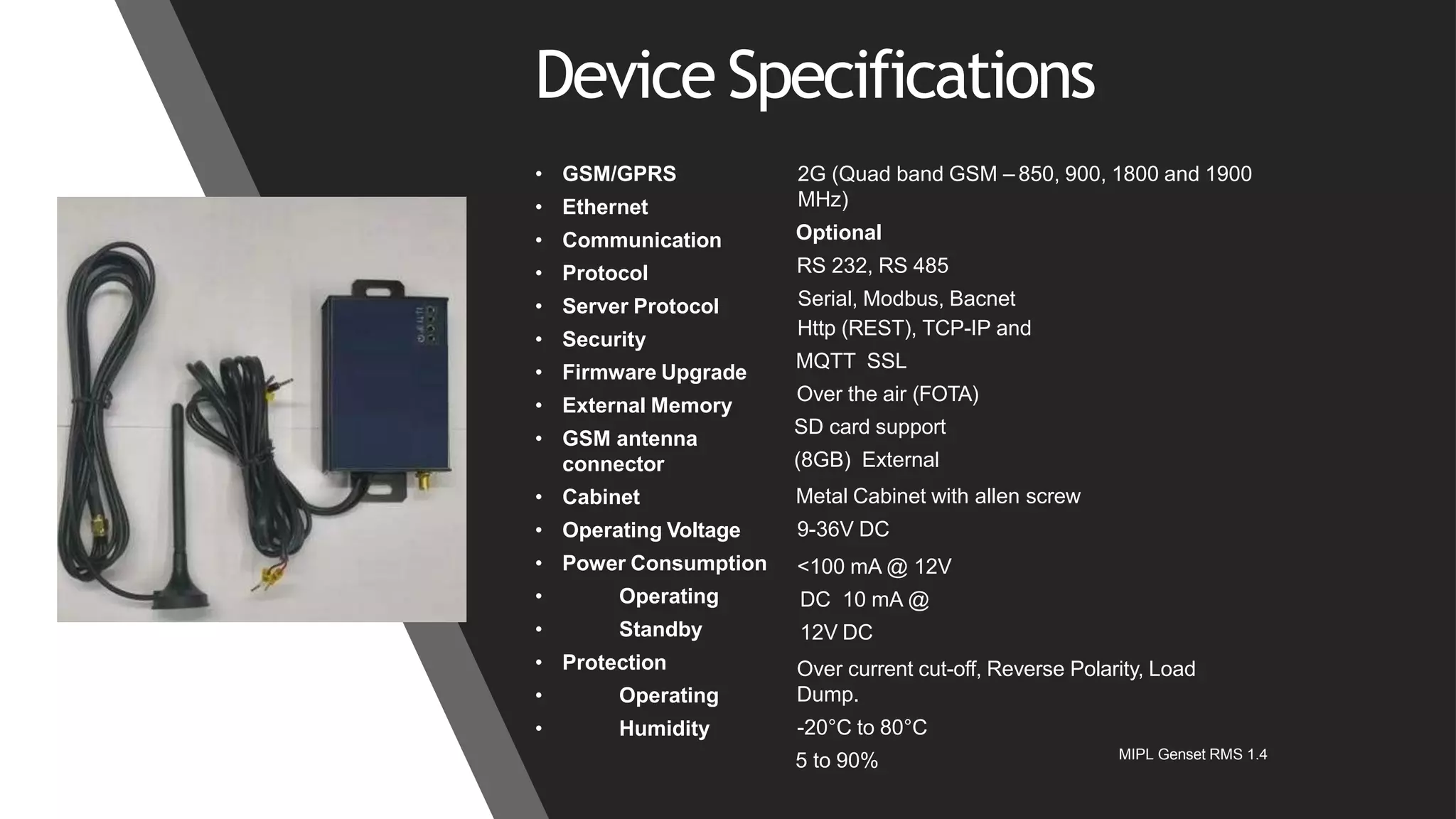

The document presents the MIPL Genset RMS 1.4, an IoT-enabled remote monitoring system for diesel generators developed by Maargha Infotech Pvt. Ltd., which offers real-time monitoring and diagnostic capabilities for improved operational efficiency and post-sales support. Key features include a virtual onsite service engineer available 24/7, automatic service requests, and comprehensive data logging for user expectations. The system is designed to provide manufacturers and dealers with critical insights into equipment functionality and maintenance needs across various geographical locations.