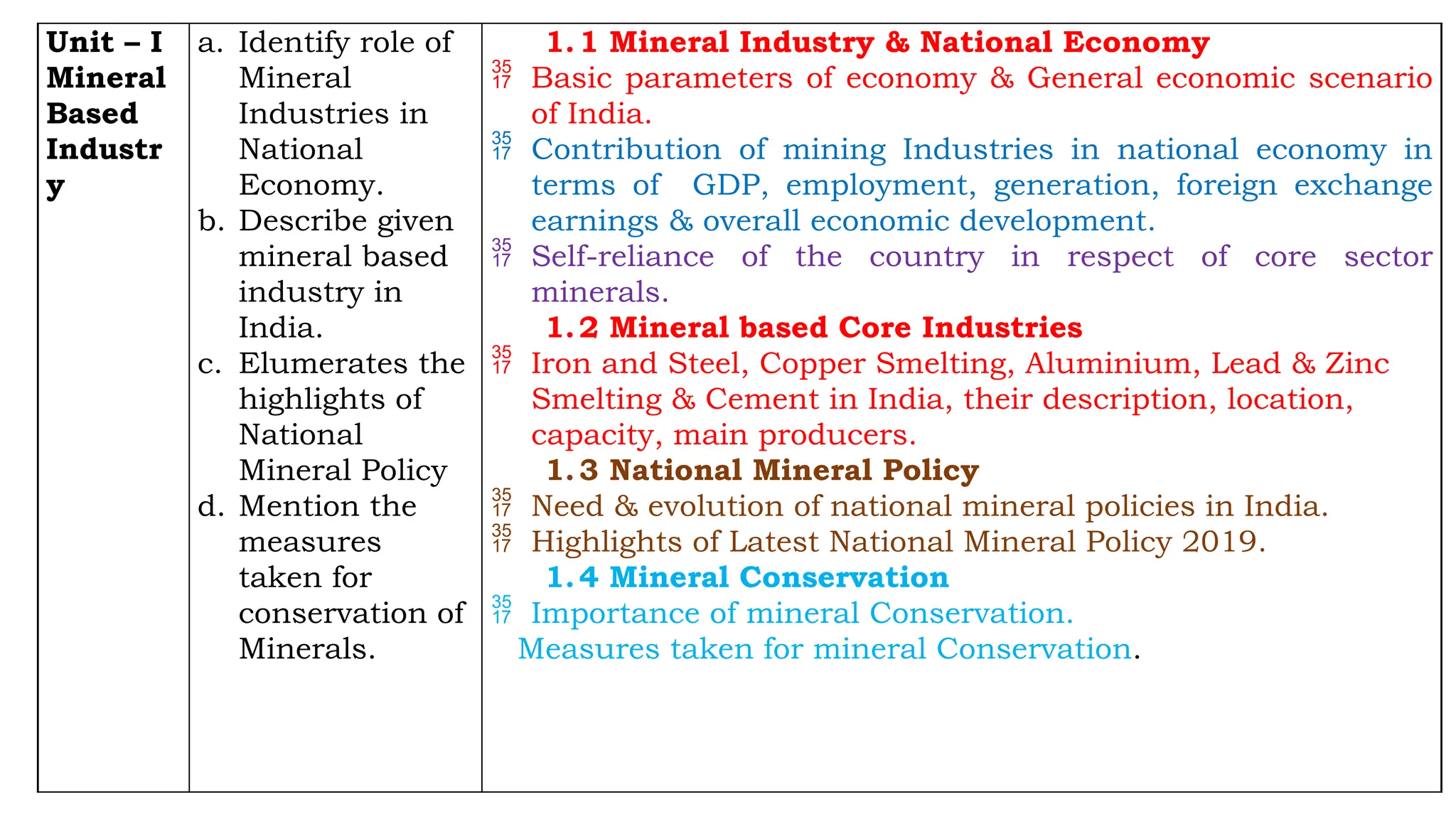

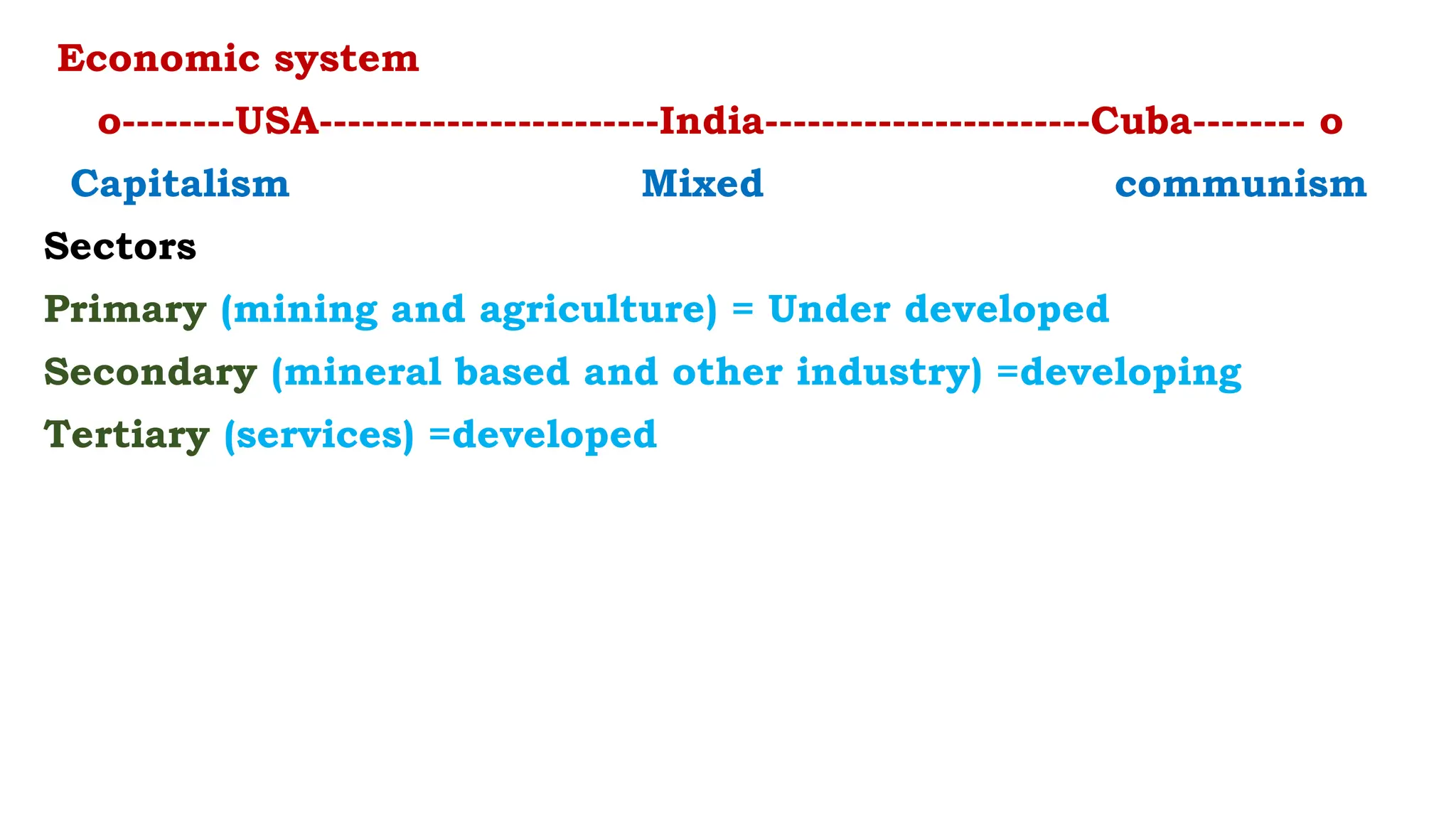

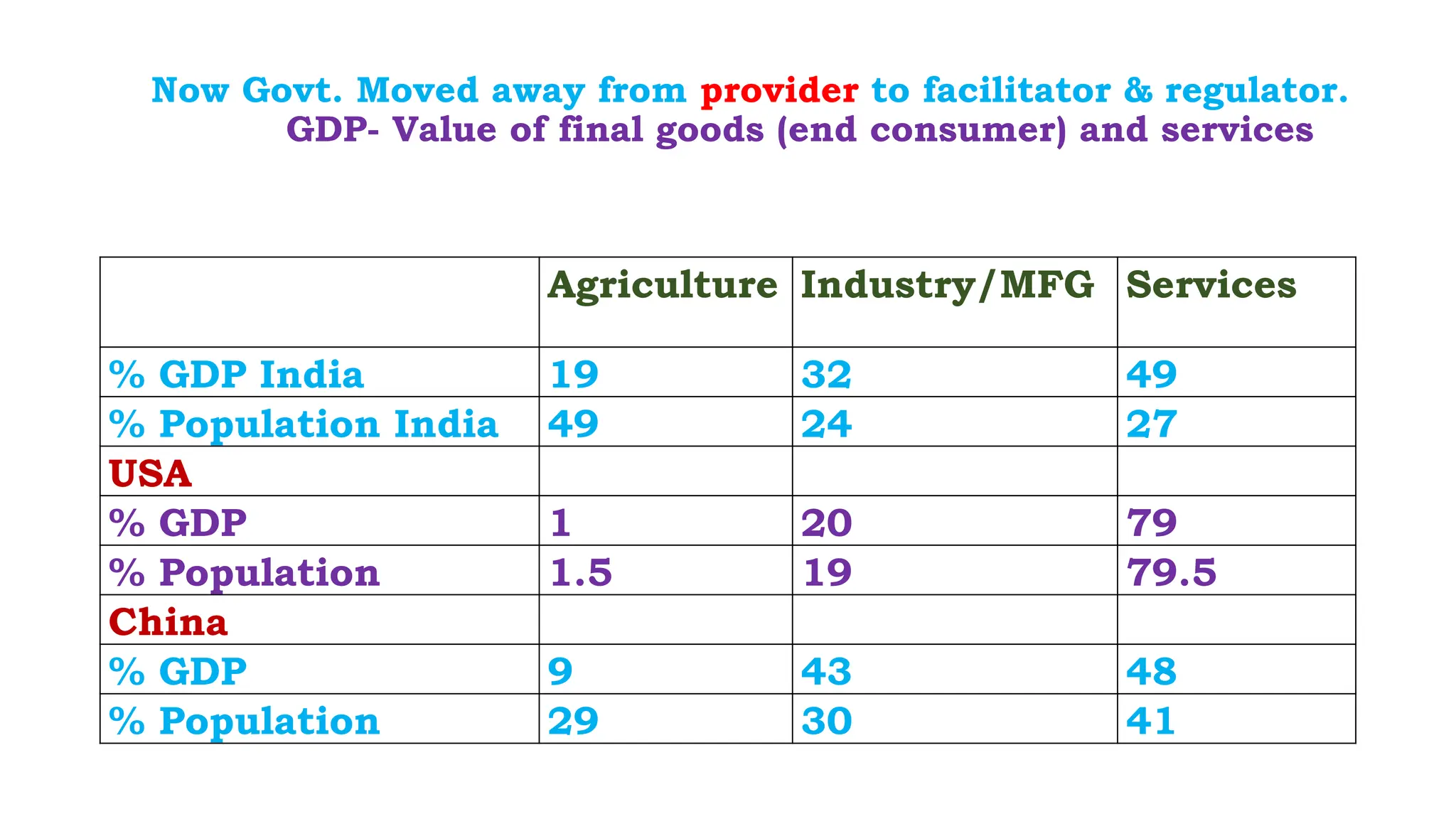

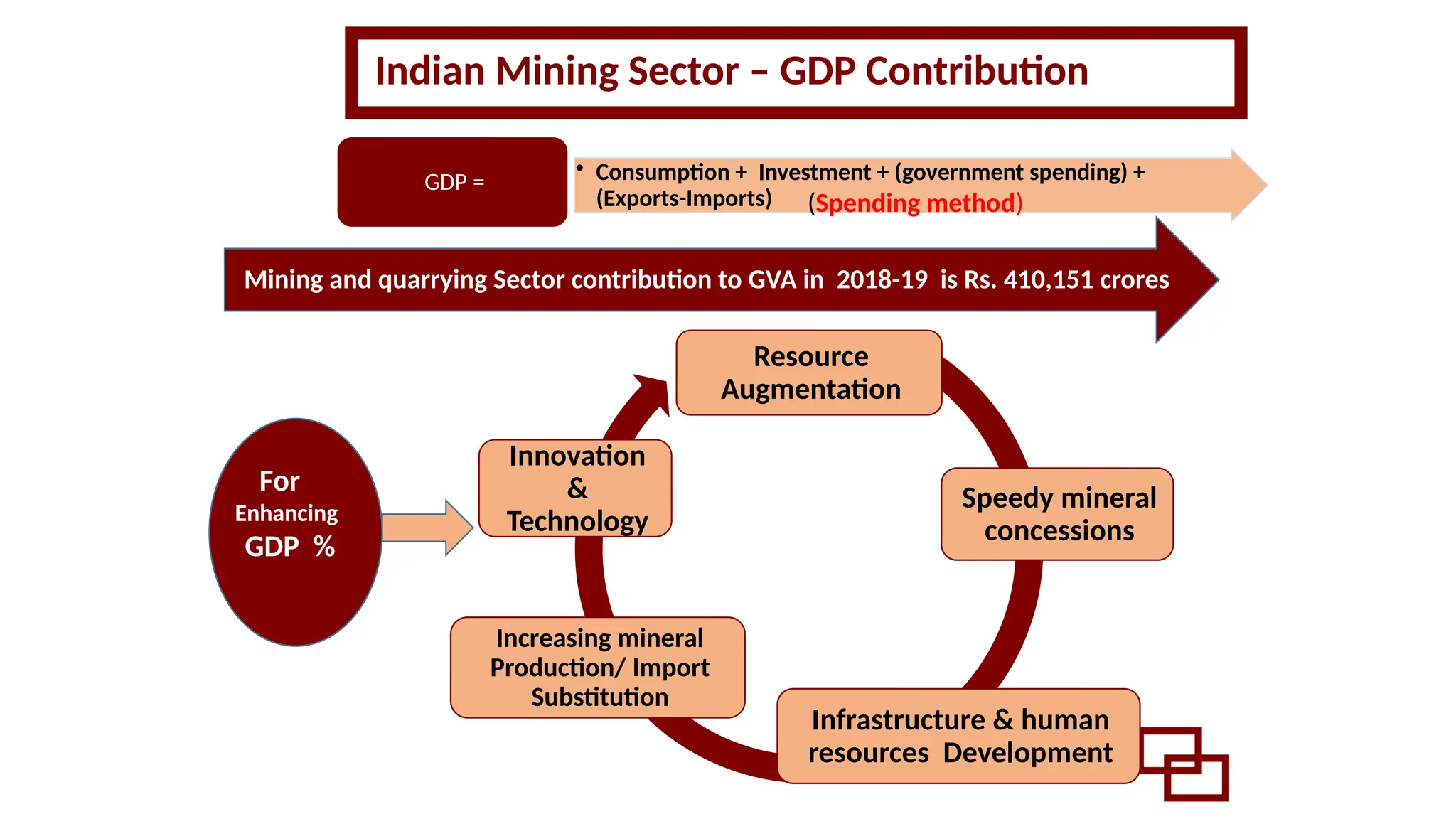

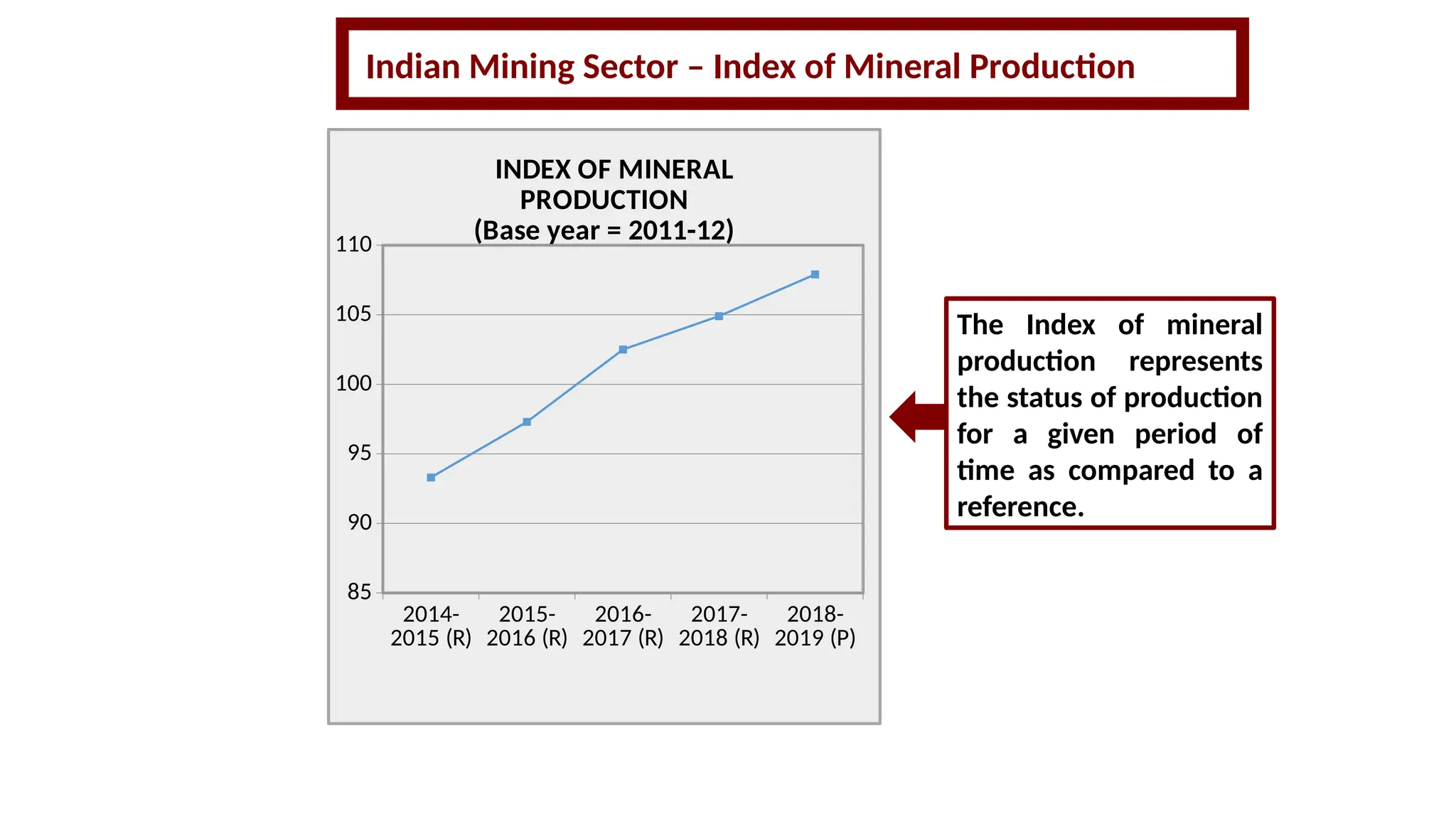

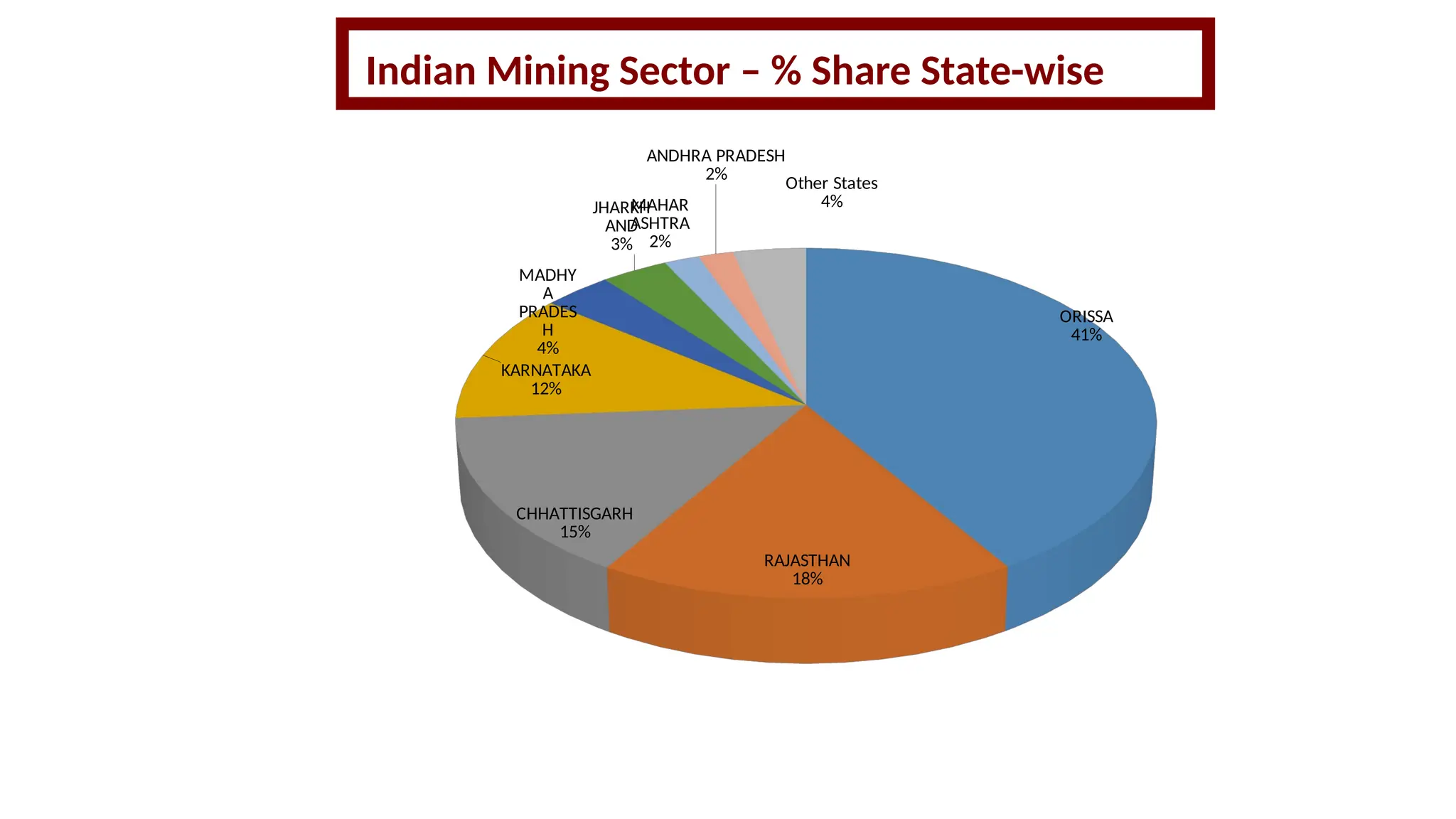

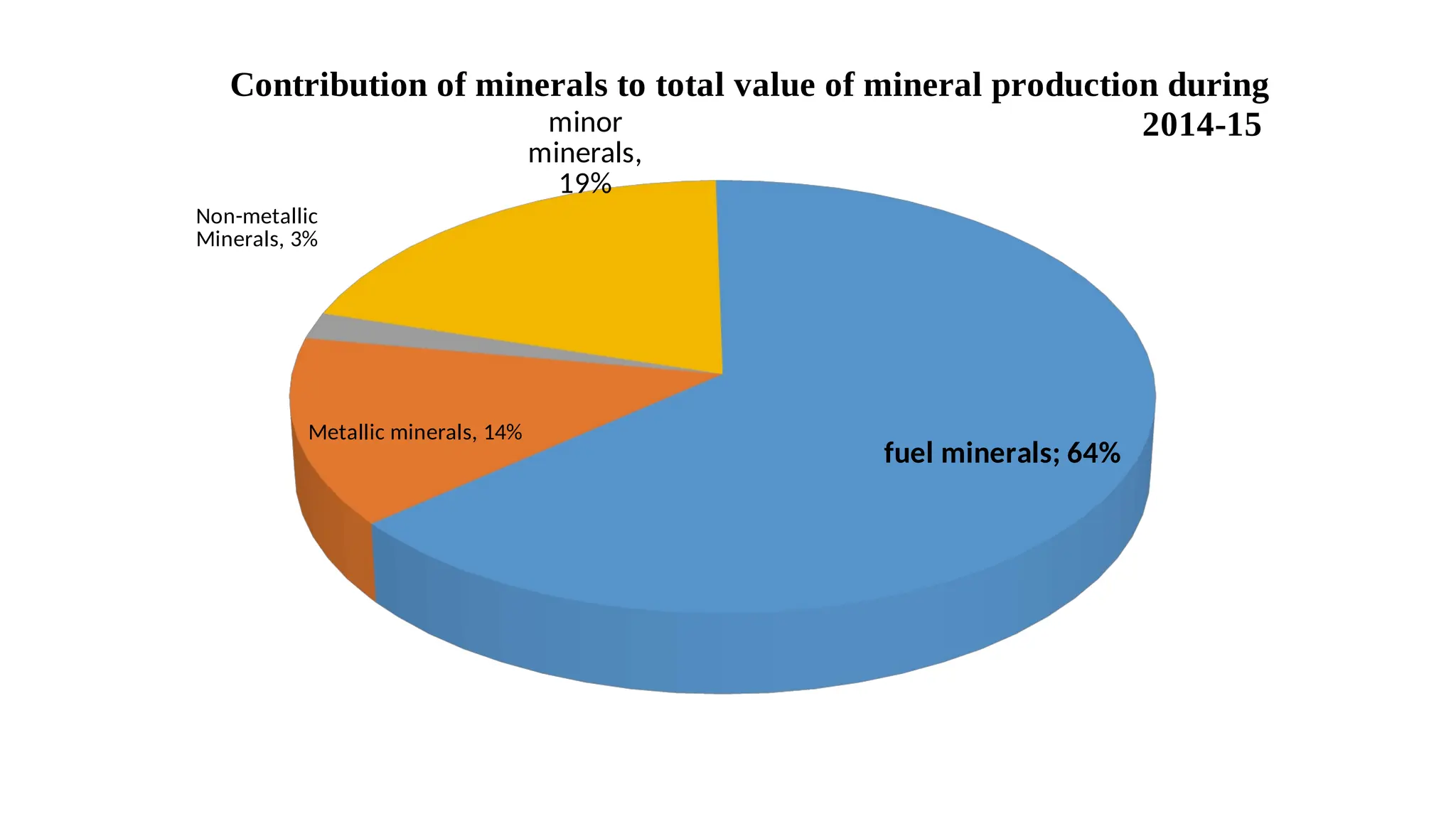

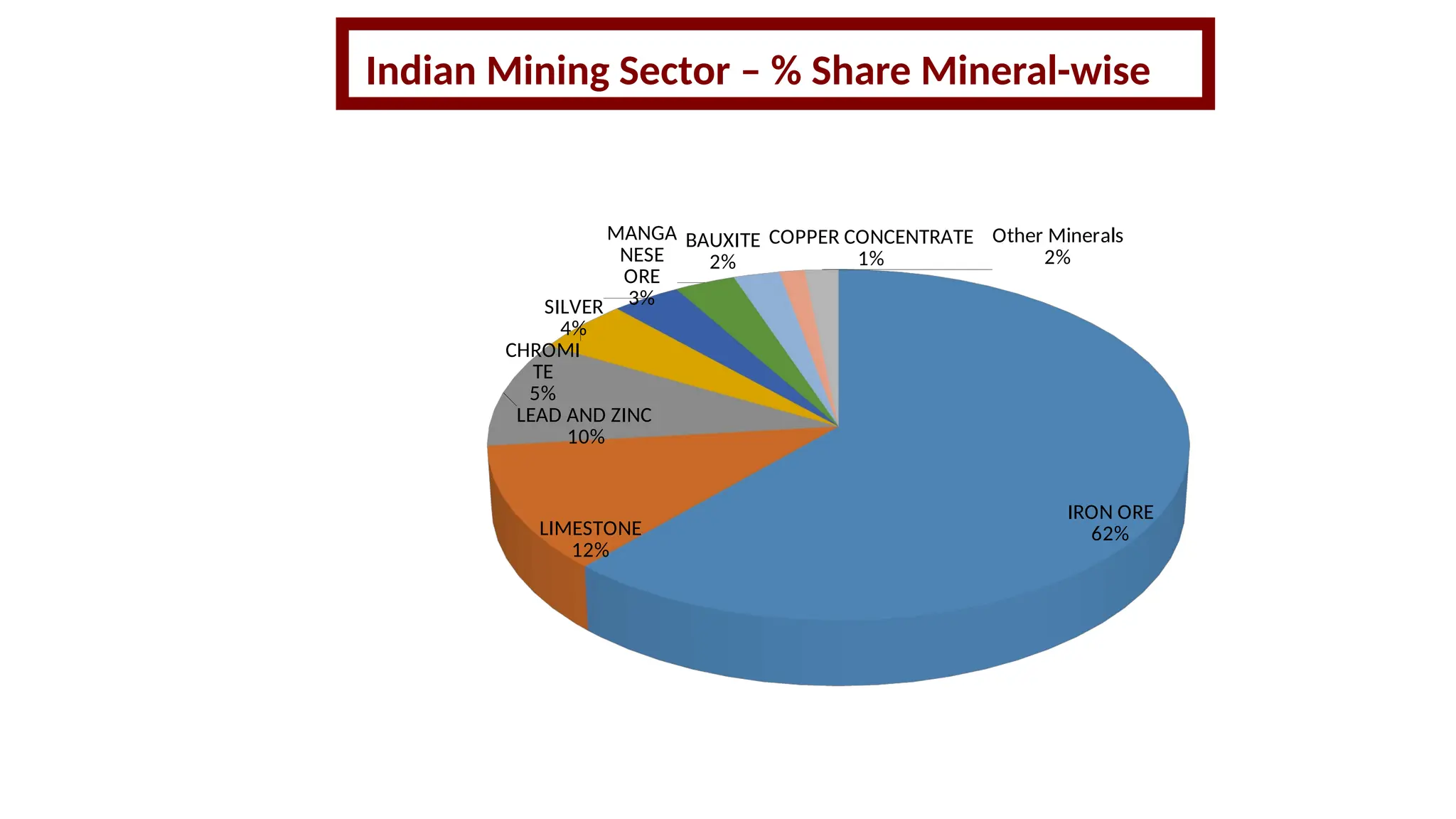

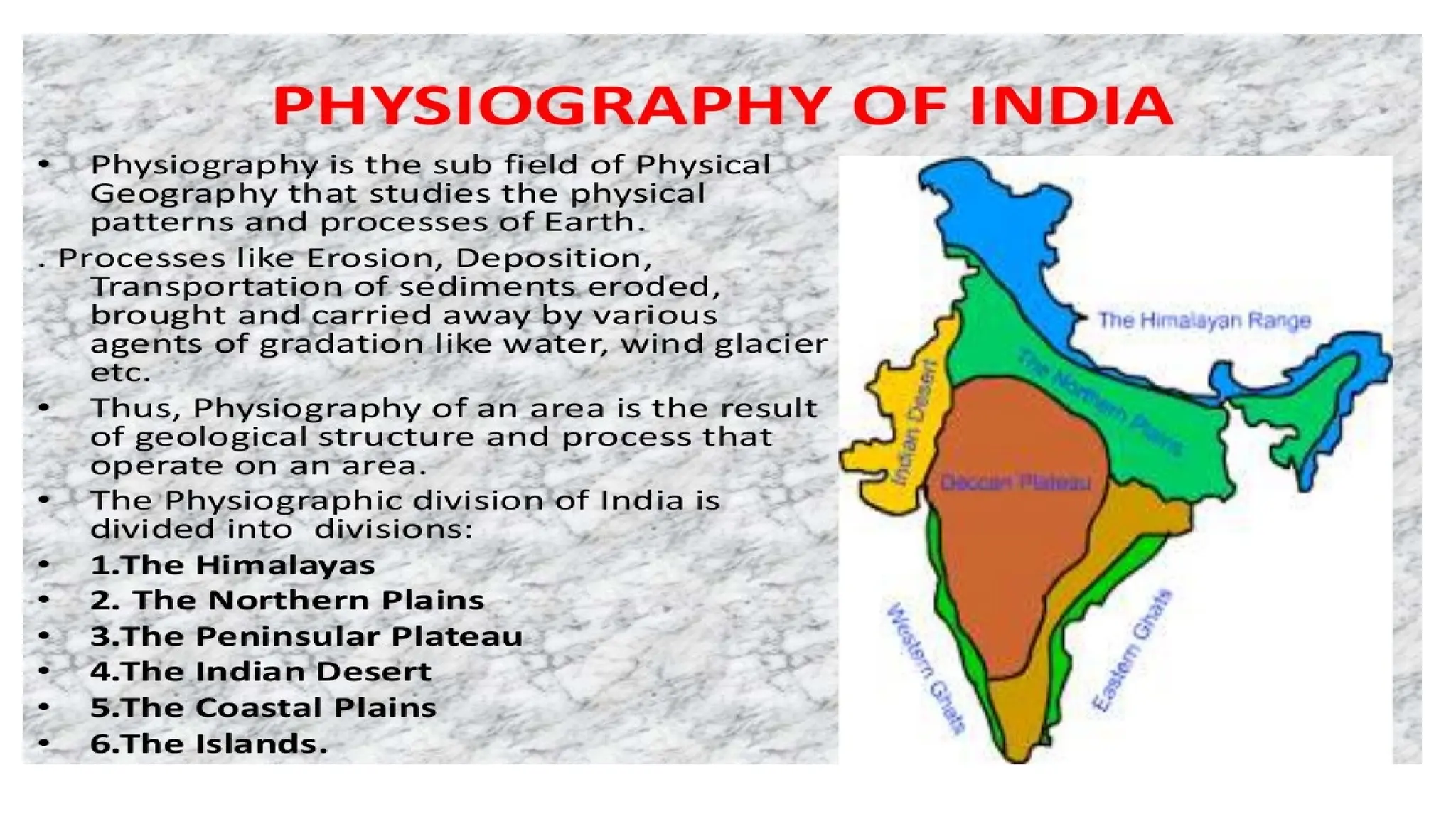

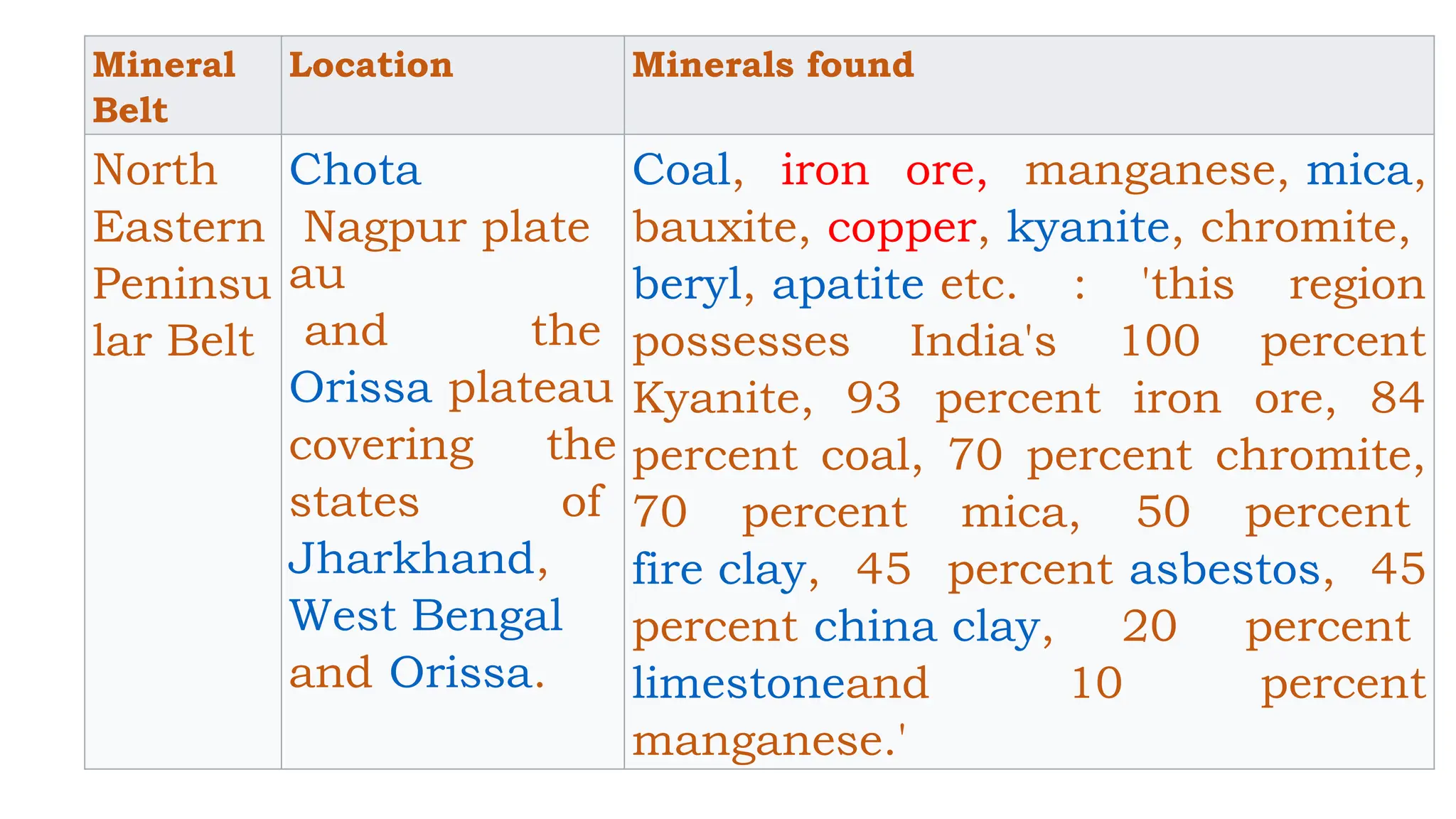

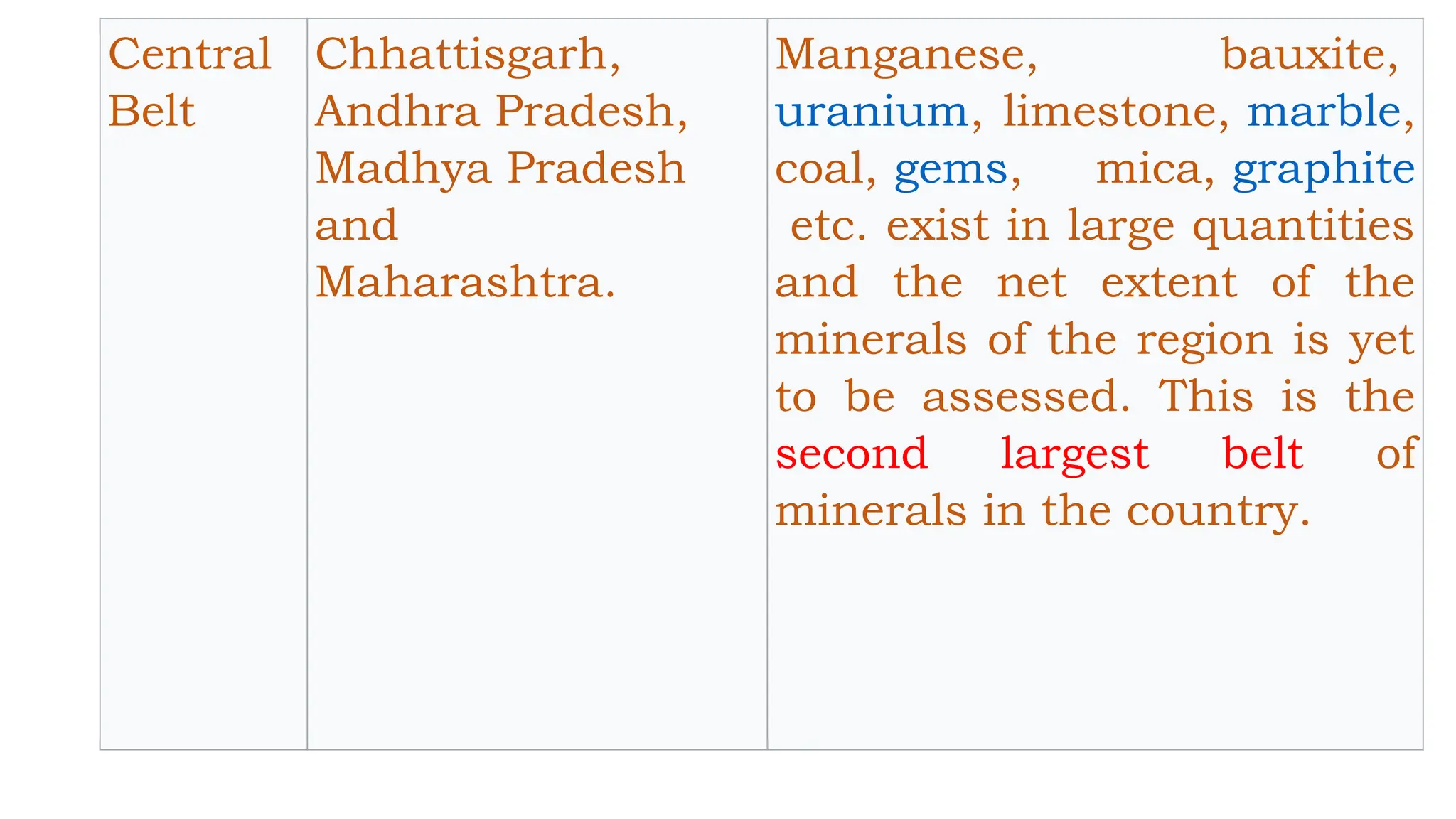

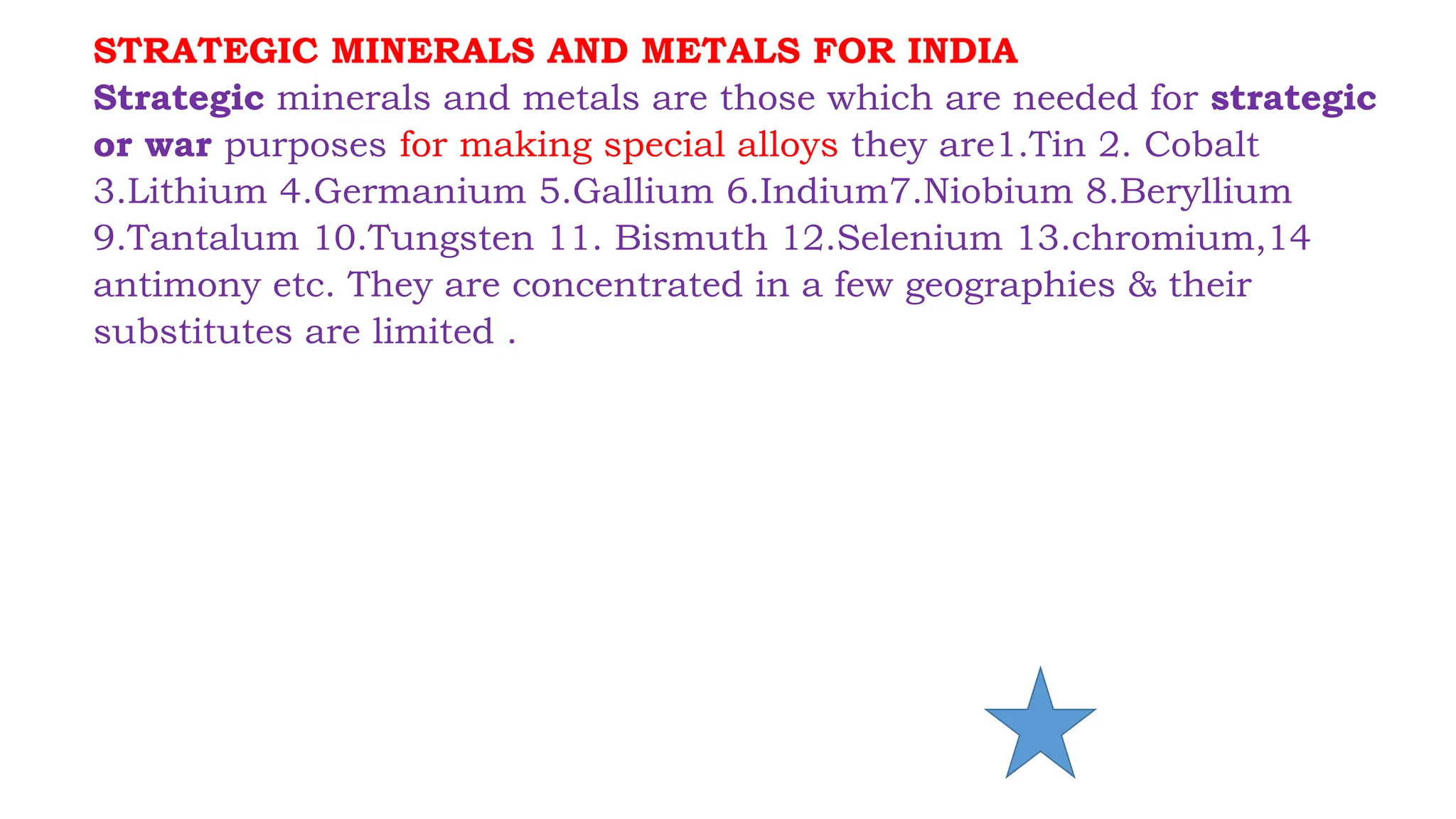

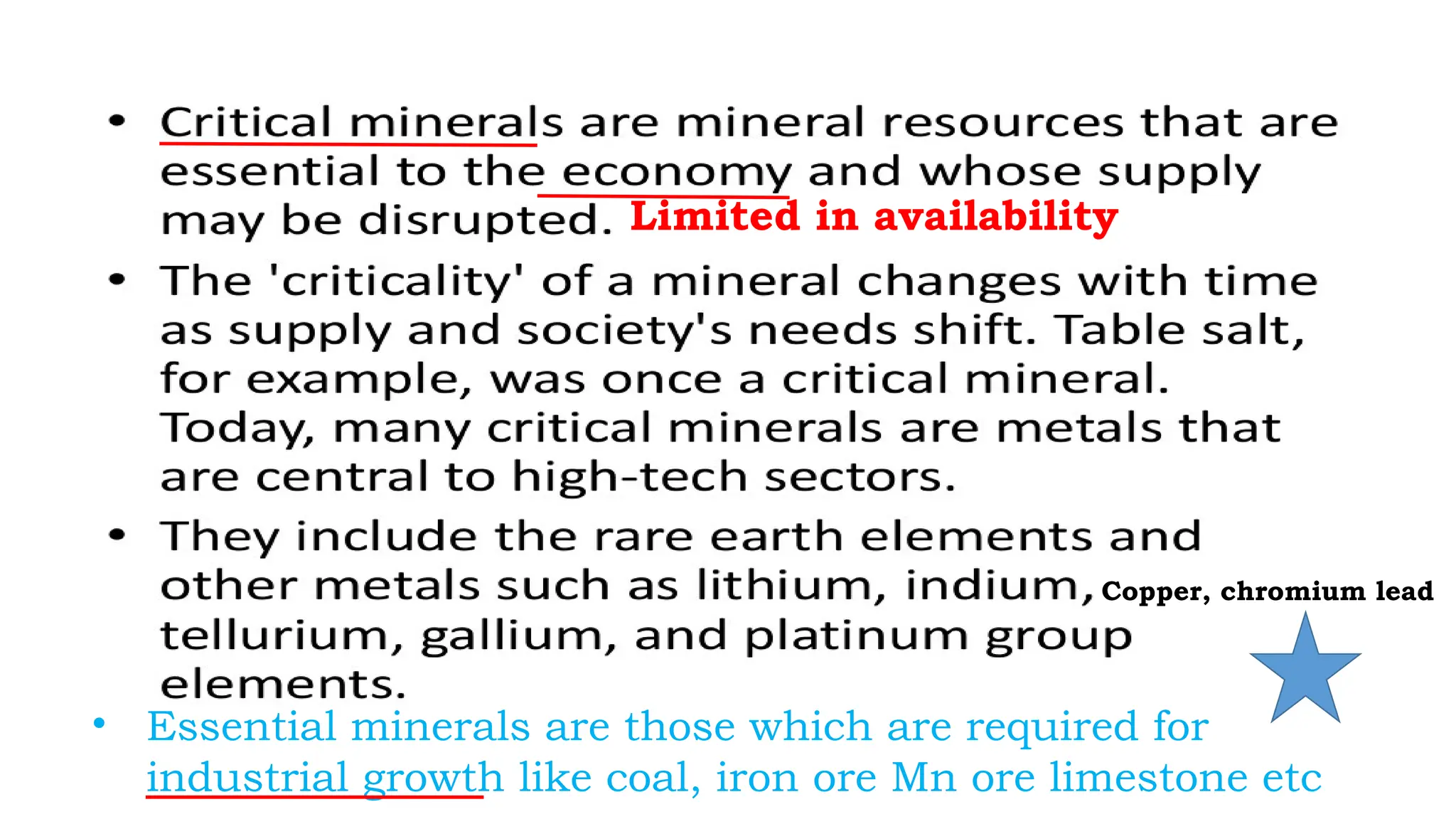

The document outlines the curriculum and course structure for a diploma in mining and mine surveying, focusing on mine economics and its role in the national economy. It discusses the contribution of the mining sector to India's GDP, employment, and economic development, alongside essential learning materials and legislative resources. The document also highlights India's economic transition and the current contributions of various minerals to national production and their geographical distribution.

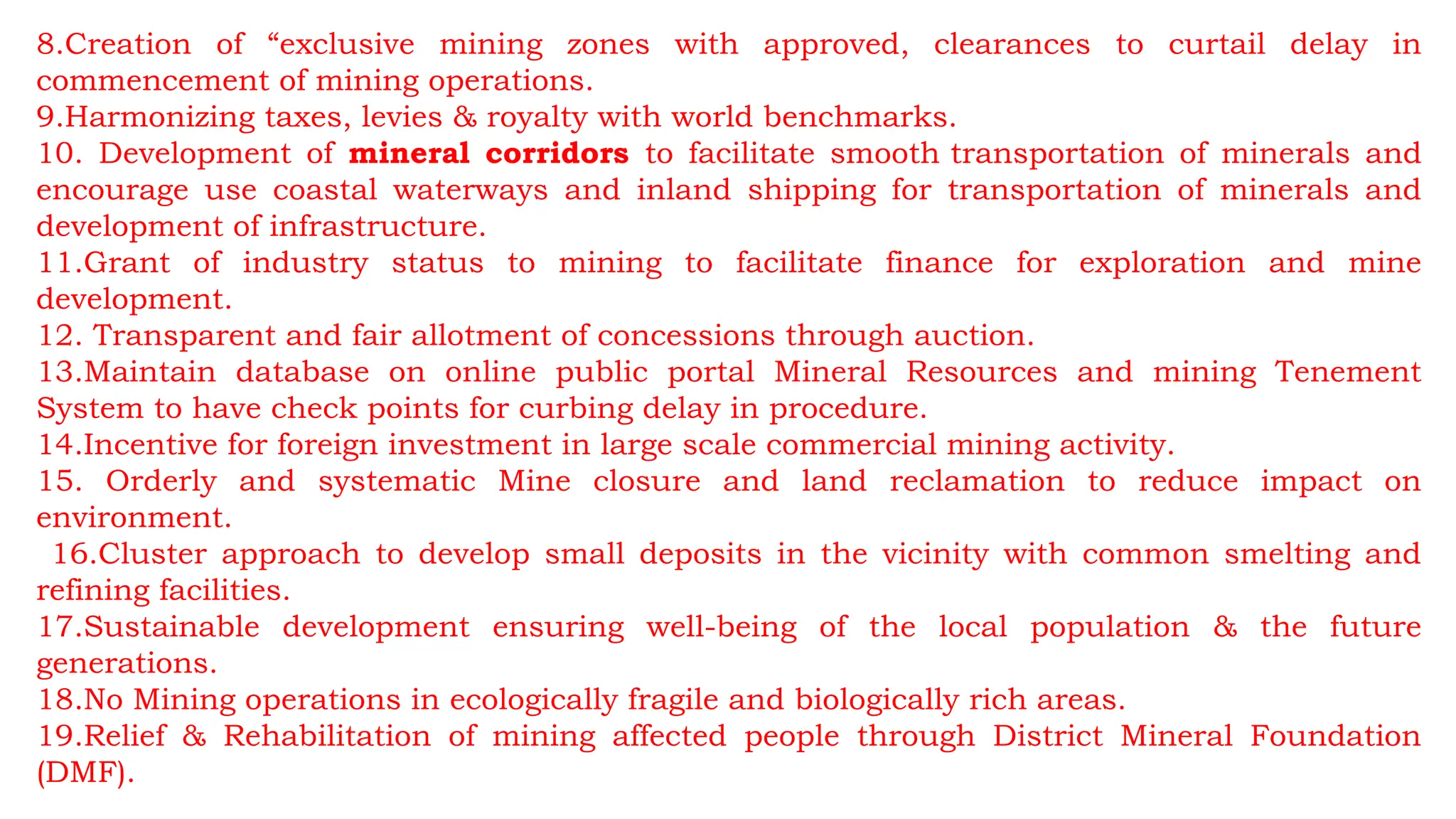

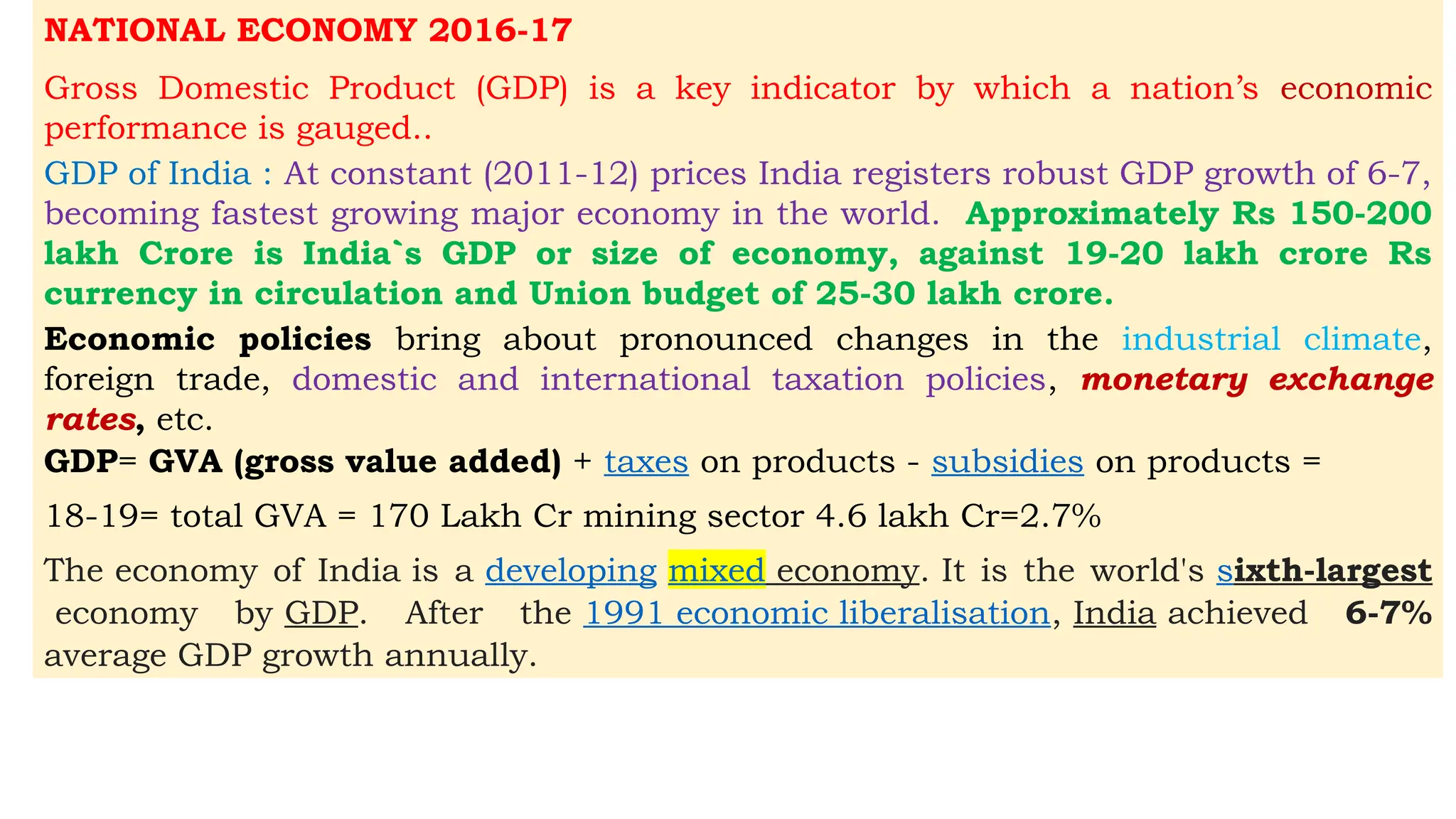

![Unit

Marks

as per

Curric

ulum

Max

Marks

[1.5 x

Clo.-

(2)]

Qu

e1

Que

-2

Que-

3

Que-

4

Que-5

Que-

6

Total

Marks

in a

paper

set

Remar

ks

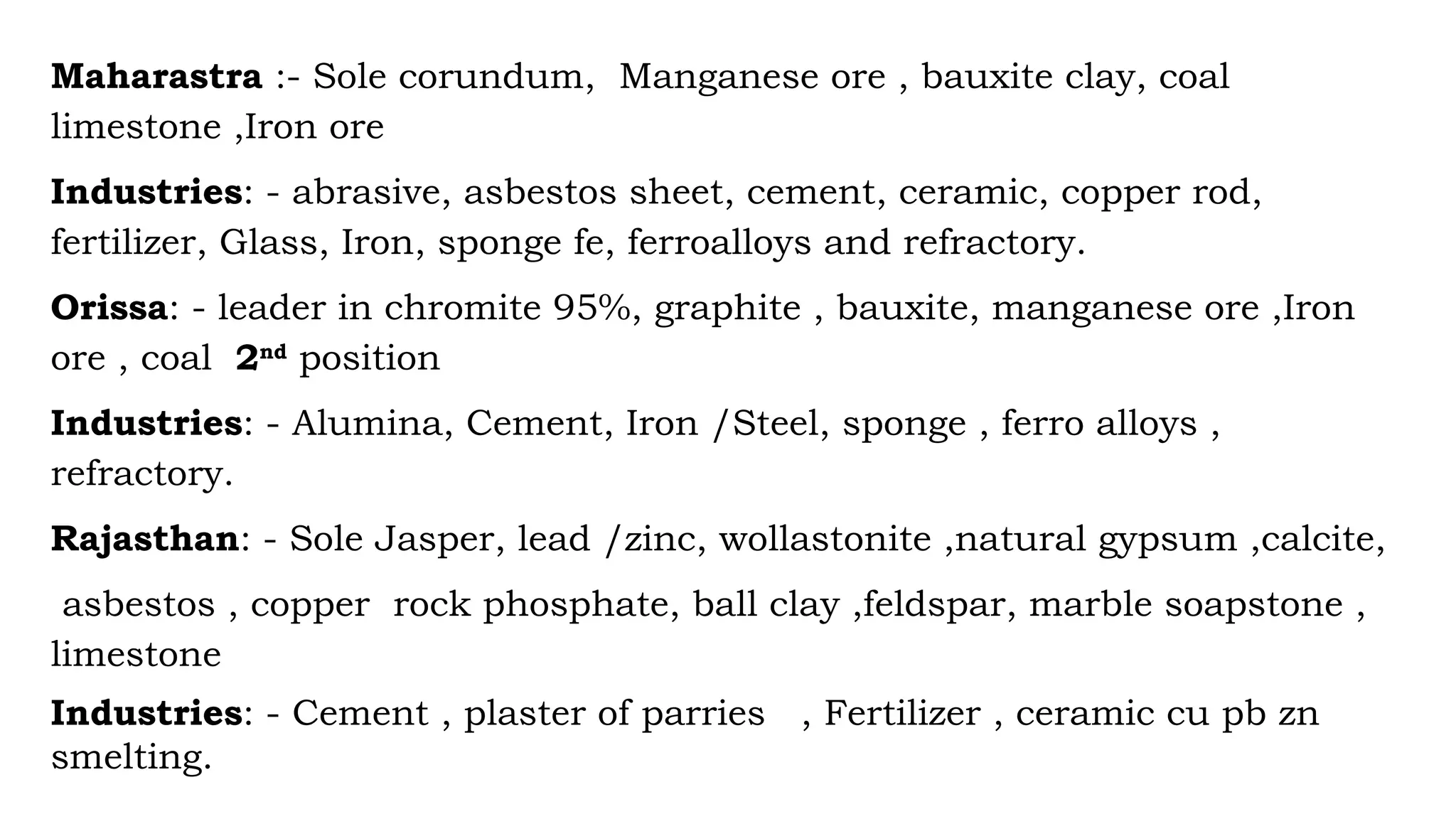

I 12 18 4 4 - 4 - 6 18

Q1 Define type of 2 marks

Q2 Explain type of 4 marks/6 marks](https://image.slidesharecdn.com/1-241010164801-0f9febd3/75/Mineral-resources-and-development-projects-2-2048.jpg)

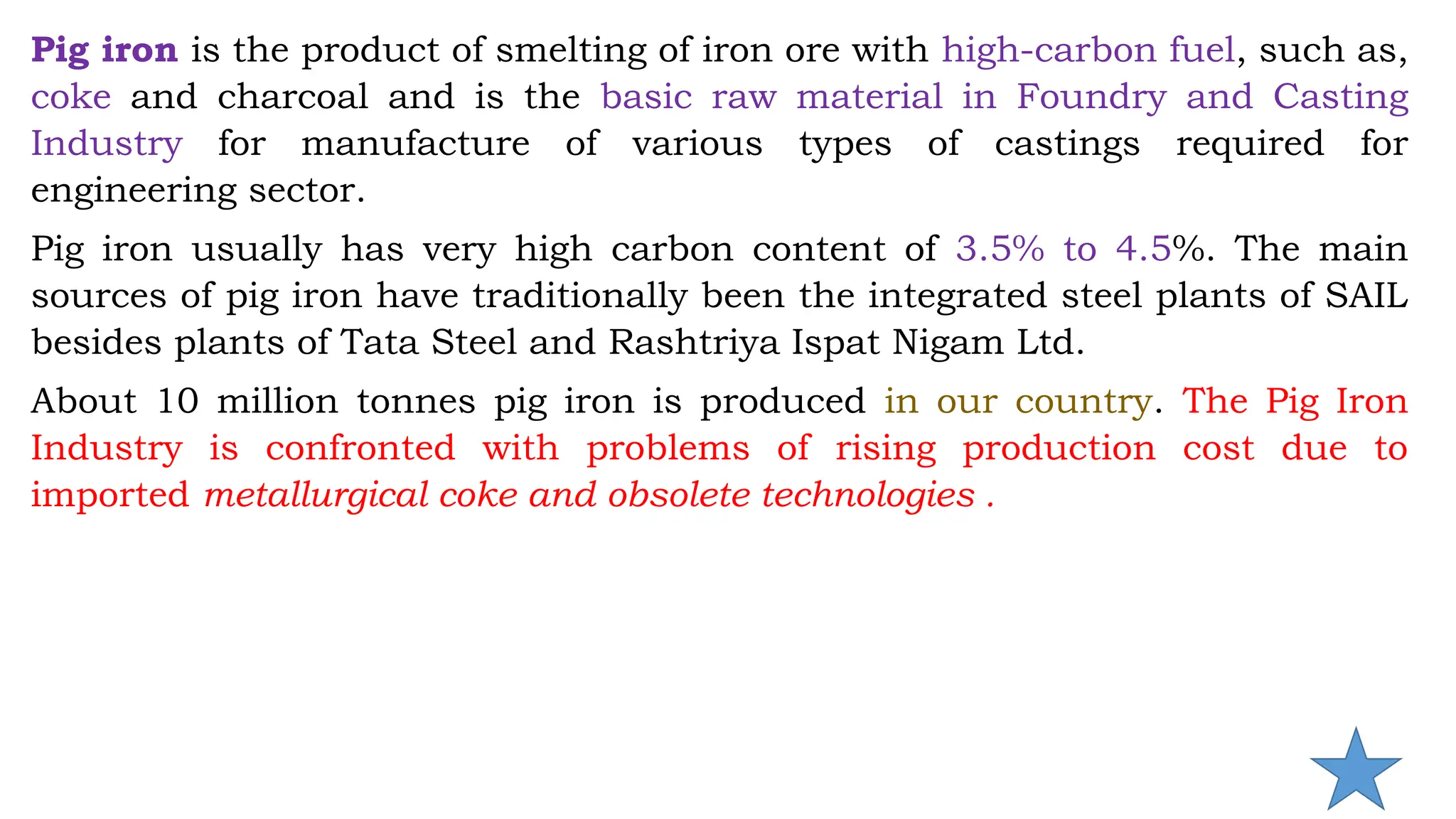

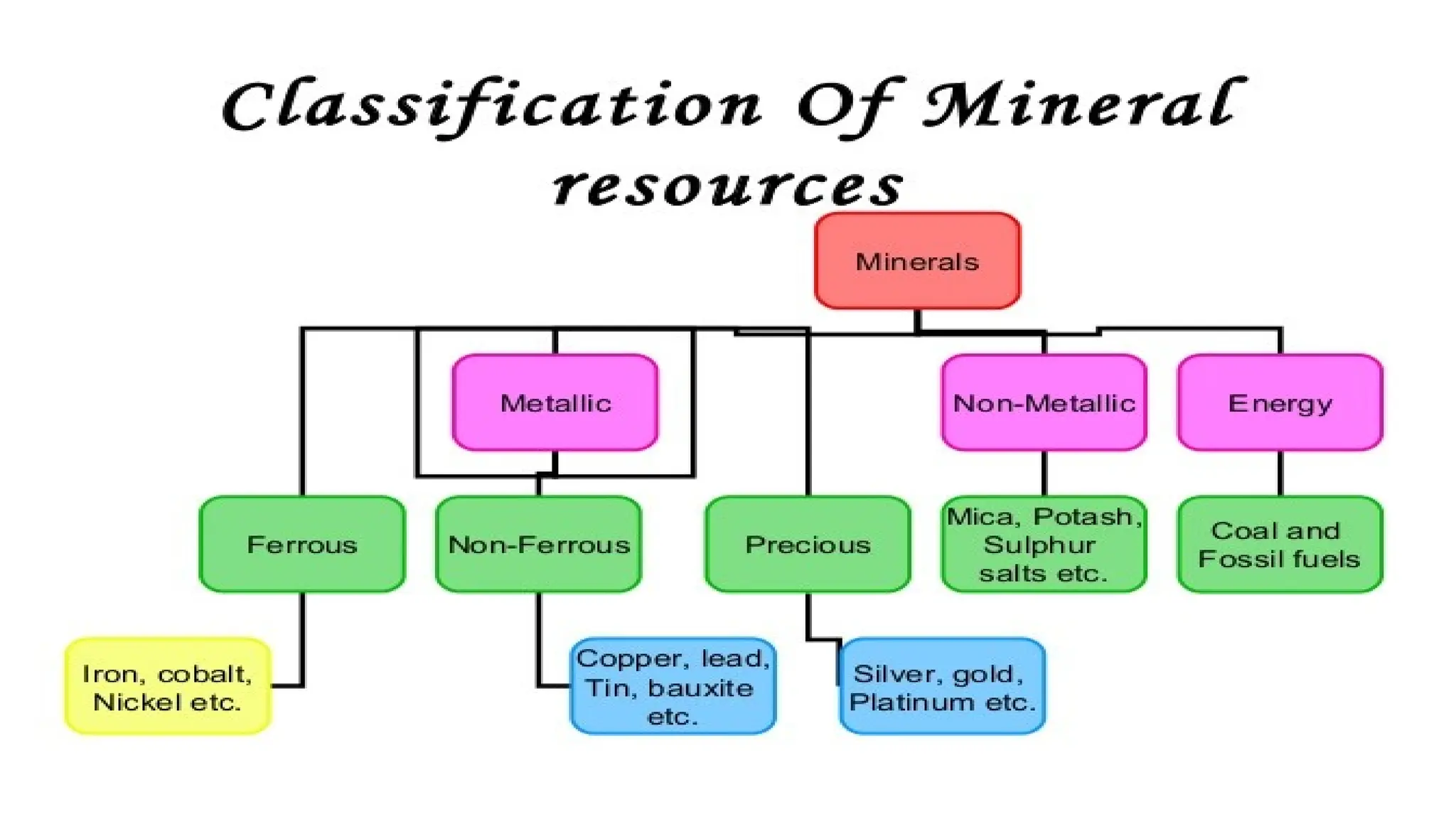

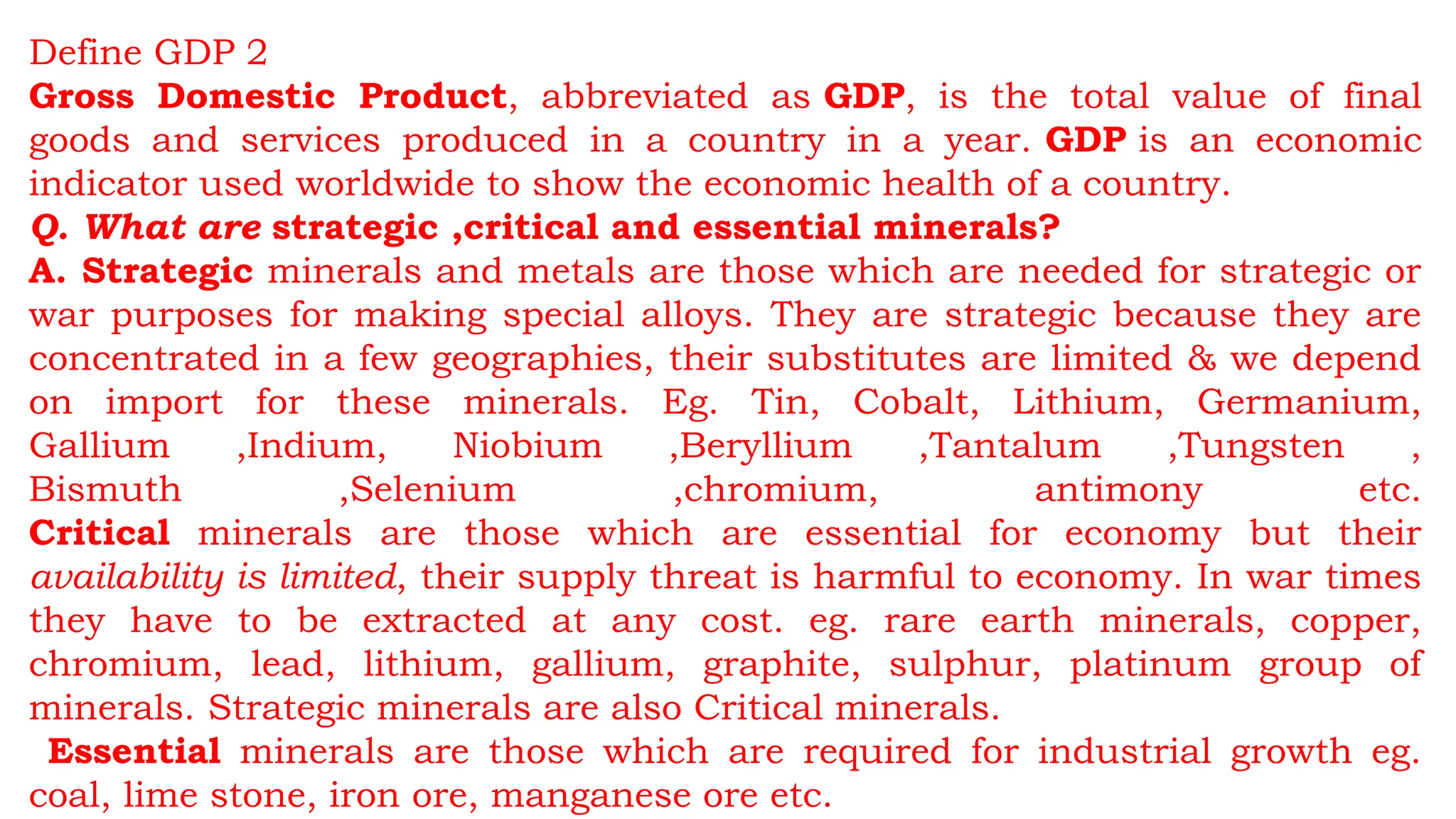

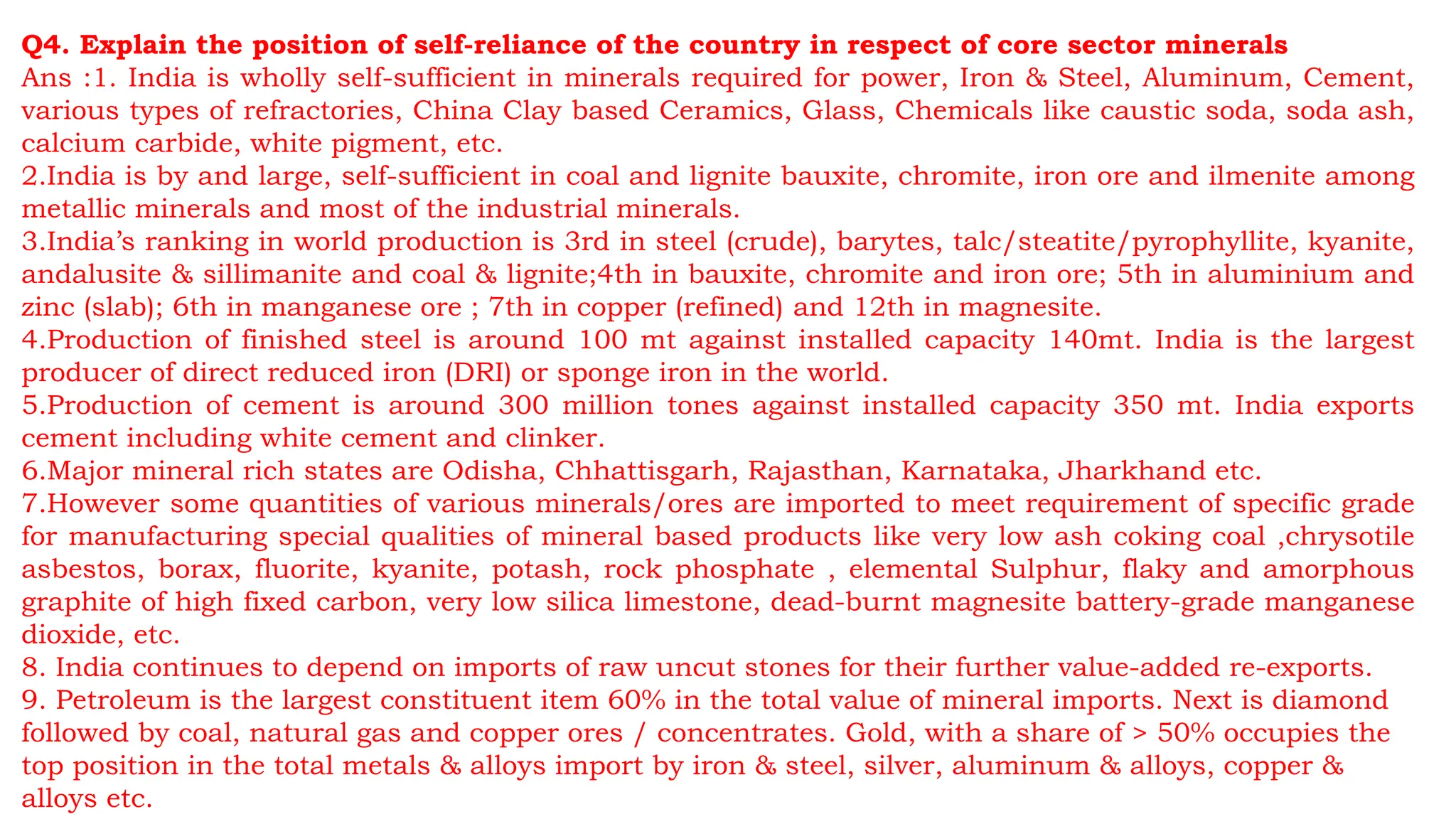

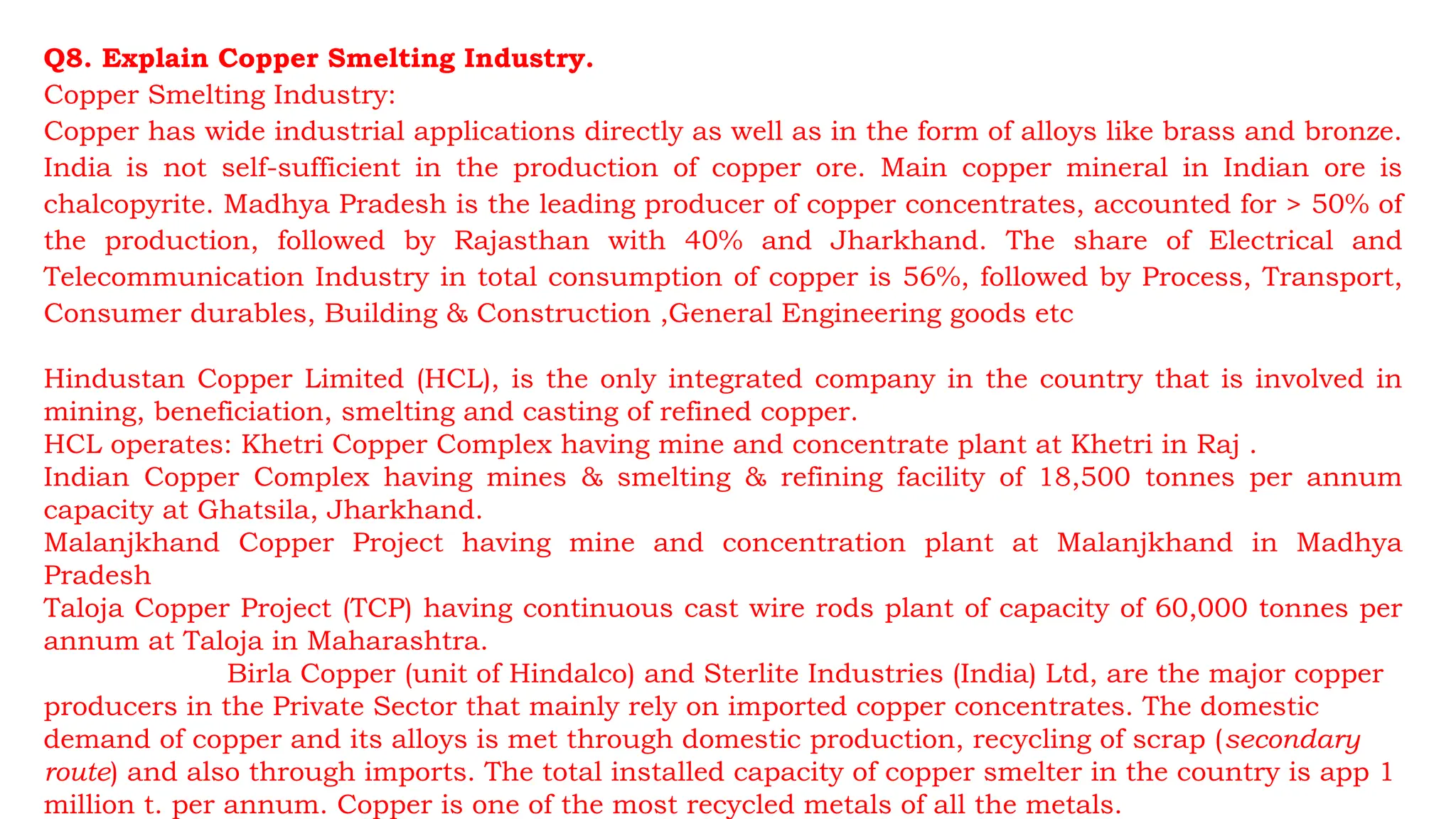

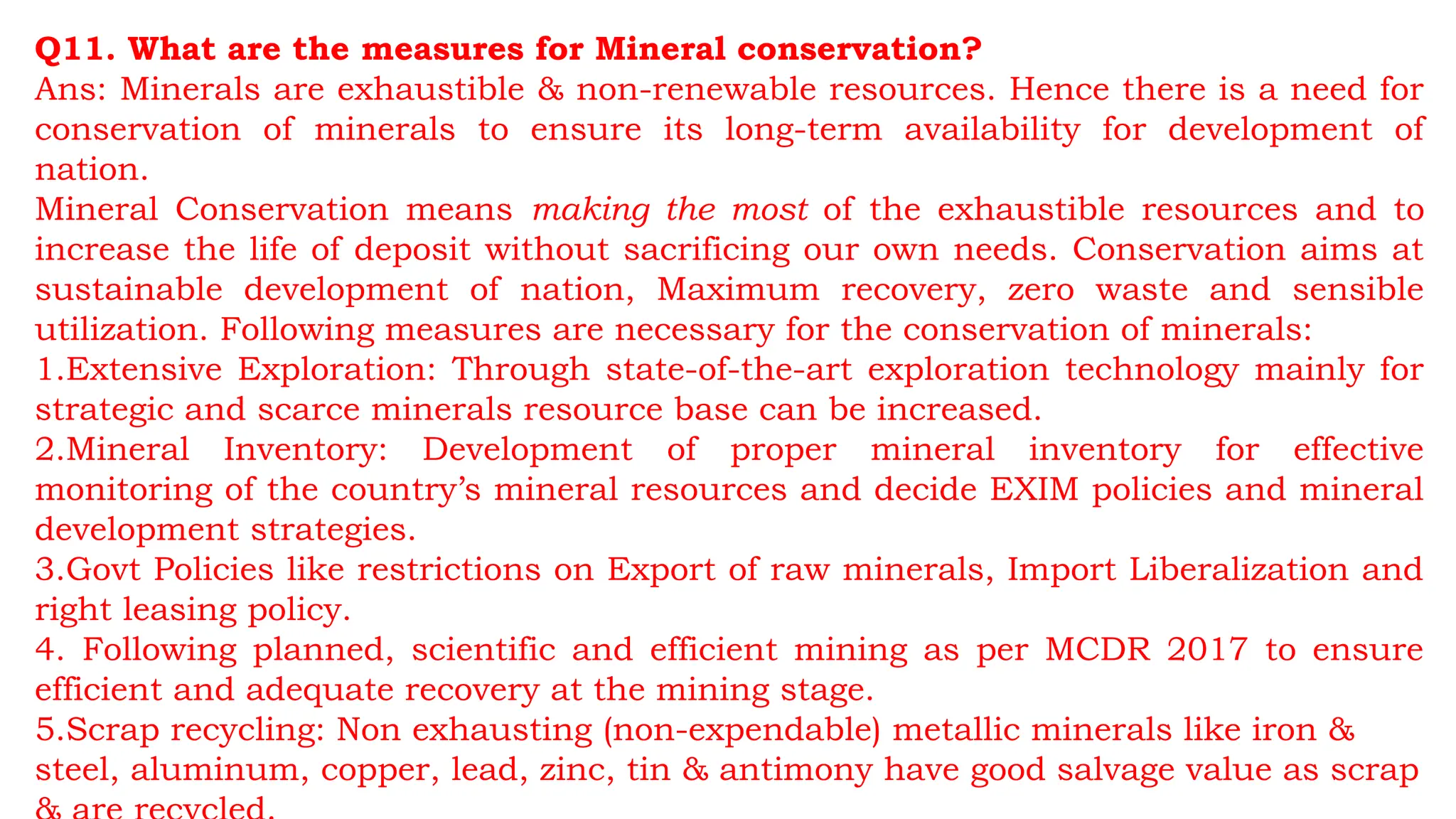

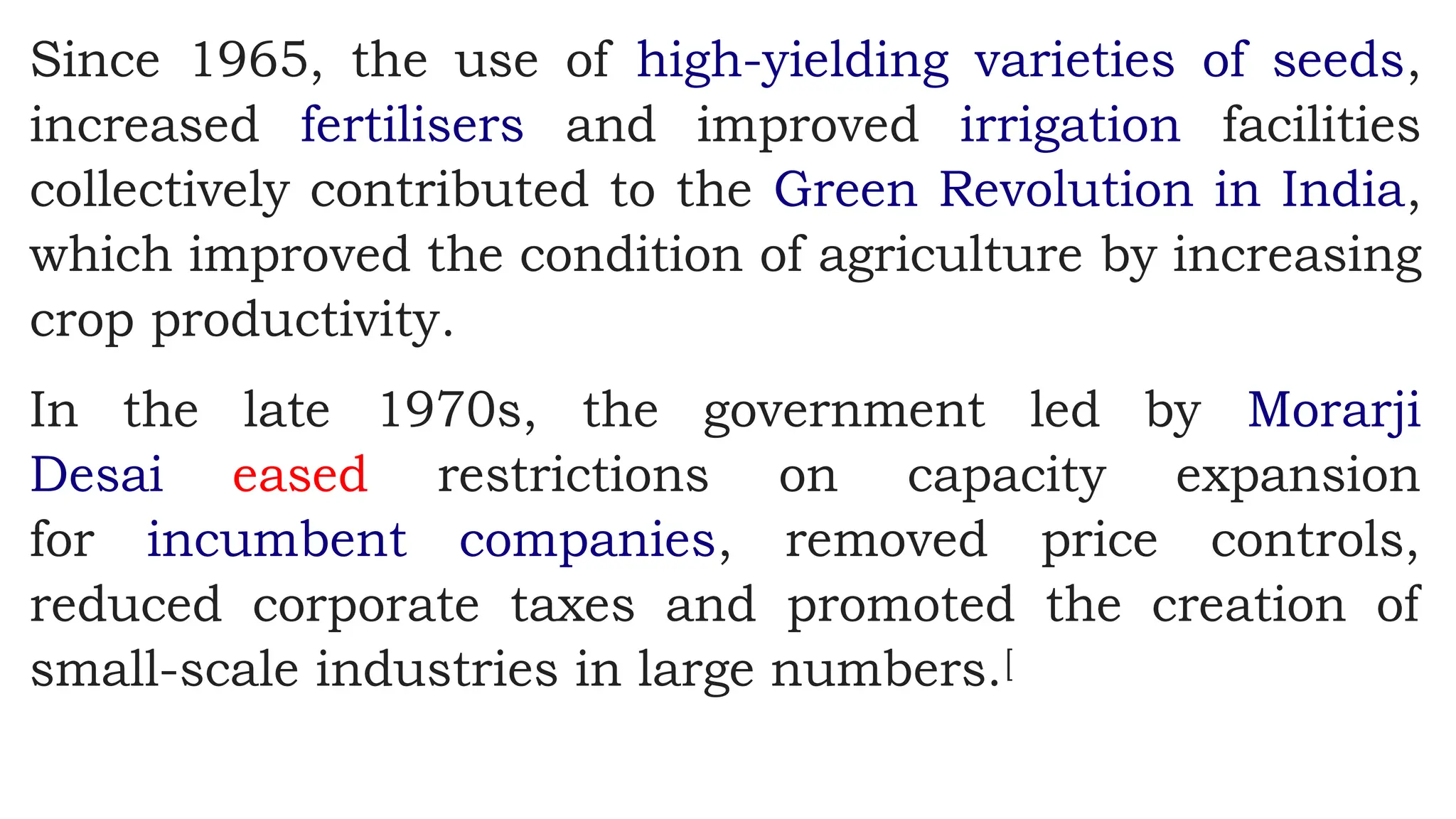

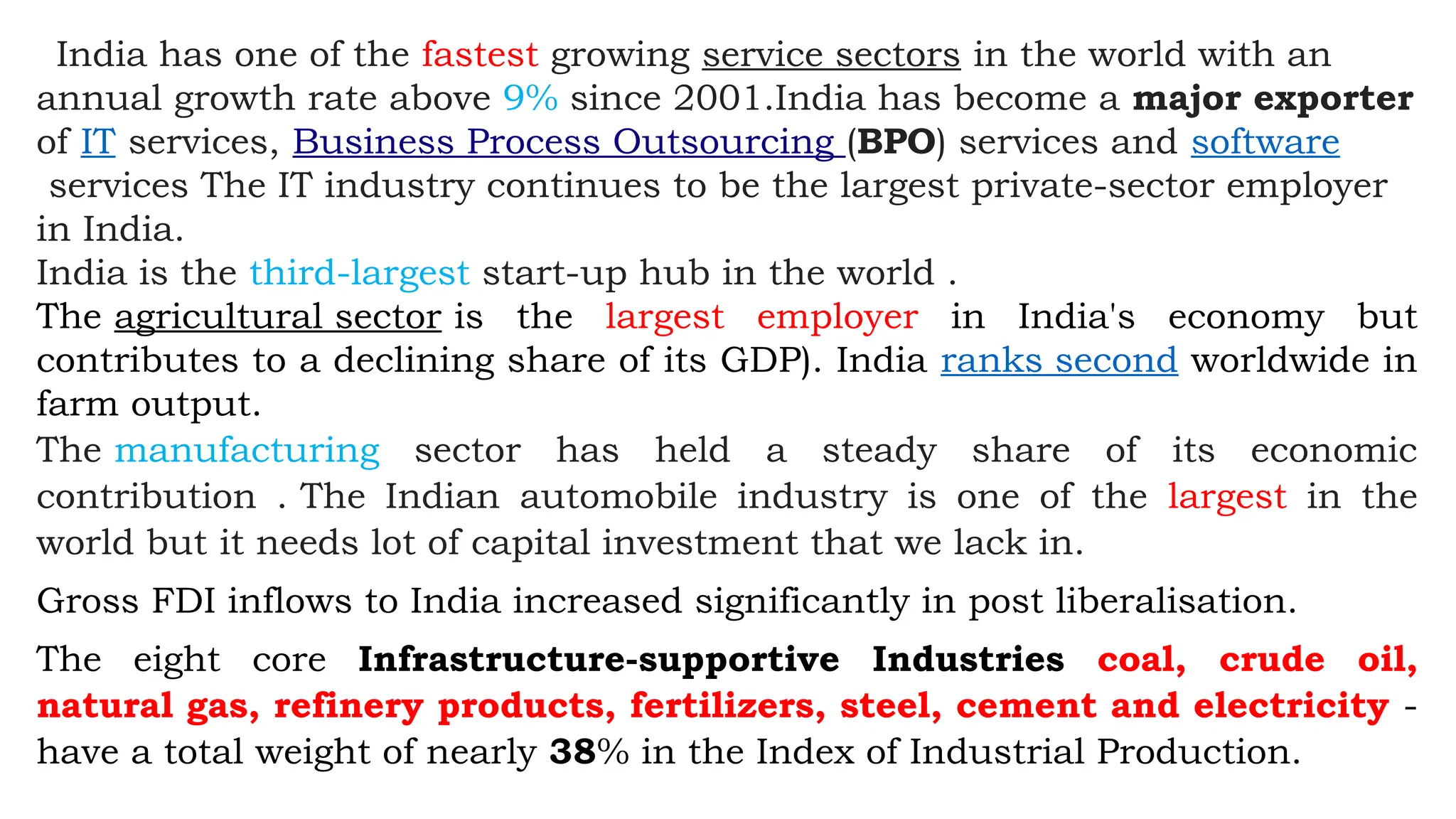

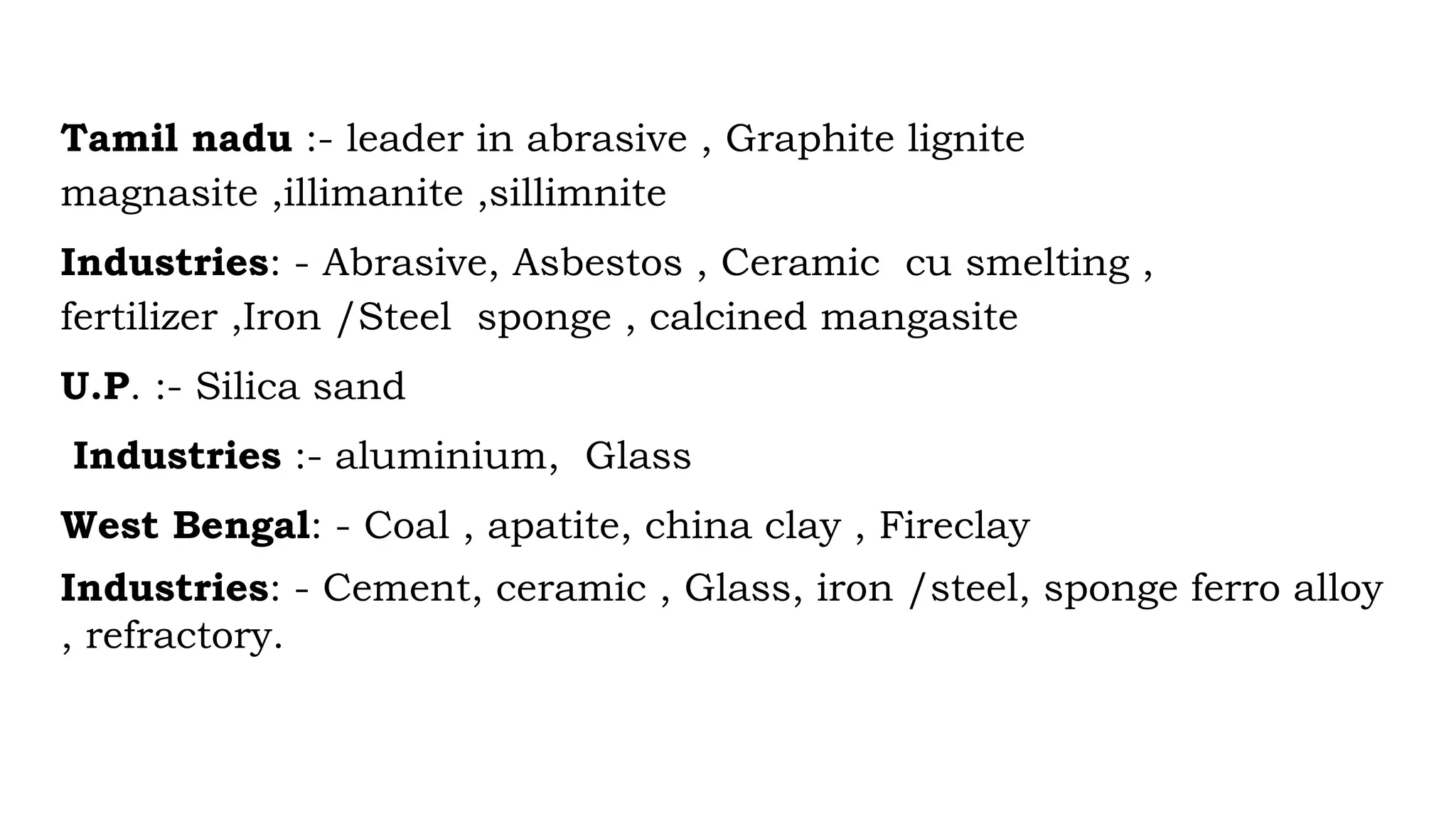

![Mineral Industries and National Economy

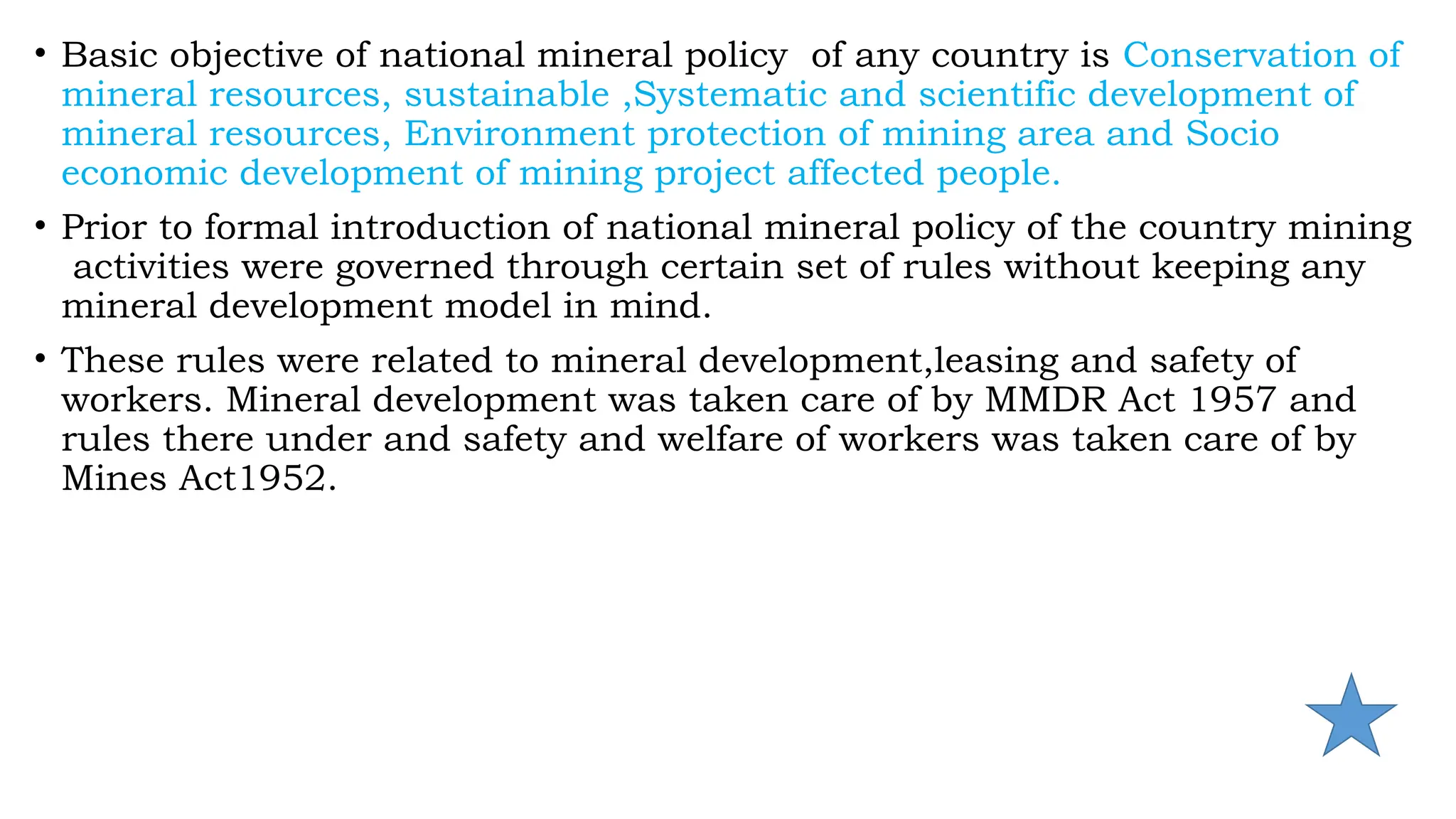

Def : MINERAL ECONOMICS = Study of how to manage production and use of scarce

mineral resources having alternative uses to meet demand at national level for growth

as well as welfare.

India has mining lease area (Excluding fuel, atomic and minor minerals) around 0.14

percent of total geographical area.

India produces as many as 90 important minerals which include 35 major minerals

[ie 4 fuel (coal, lignite, petroleum and NG)minerals, 5 atomic minerals(uranium,

thorium, tantalum, beryllium, zirconium, lithium, and rare earth minerals) 10

metallic (Bauxite, Chrome ore, Copper ore, Gold, Iron ore. Lead. Manganese ore,

Zinc etc) , 16 non-metallic/industrial minerals] and 55 minor minerals (including

building and other materials along with the recently notified 31 additional minerals)

(Apart from these there are few more major minerals of lesser occurrences thus total

about 45 major minerals).

10 metallic & 16 non-metallic minerals are also called as MCDR minerals.

Minor minerals are notified by central govt under sec 3e of MMDR Act 1957 they are

55 in nos. rest are major minerals.](https://image.slidesharecdn.com/1-241010164801-0f9febd3/75/Mineral-resources-and-development-projects-81-2048.jpg)