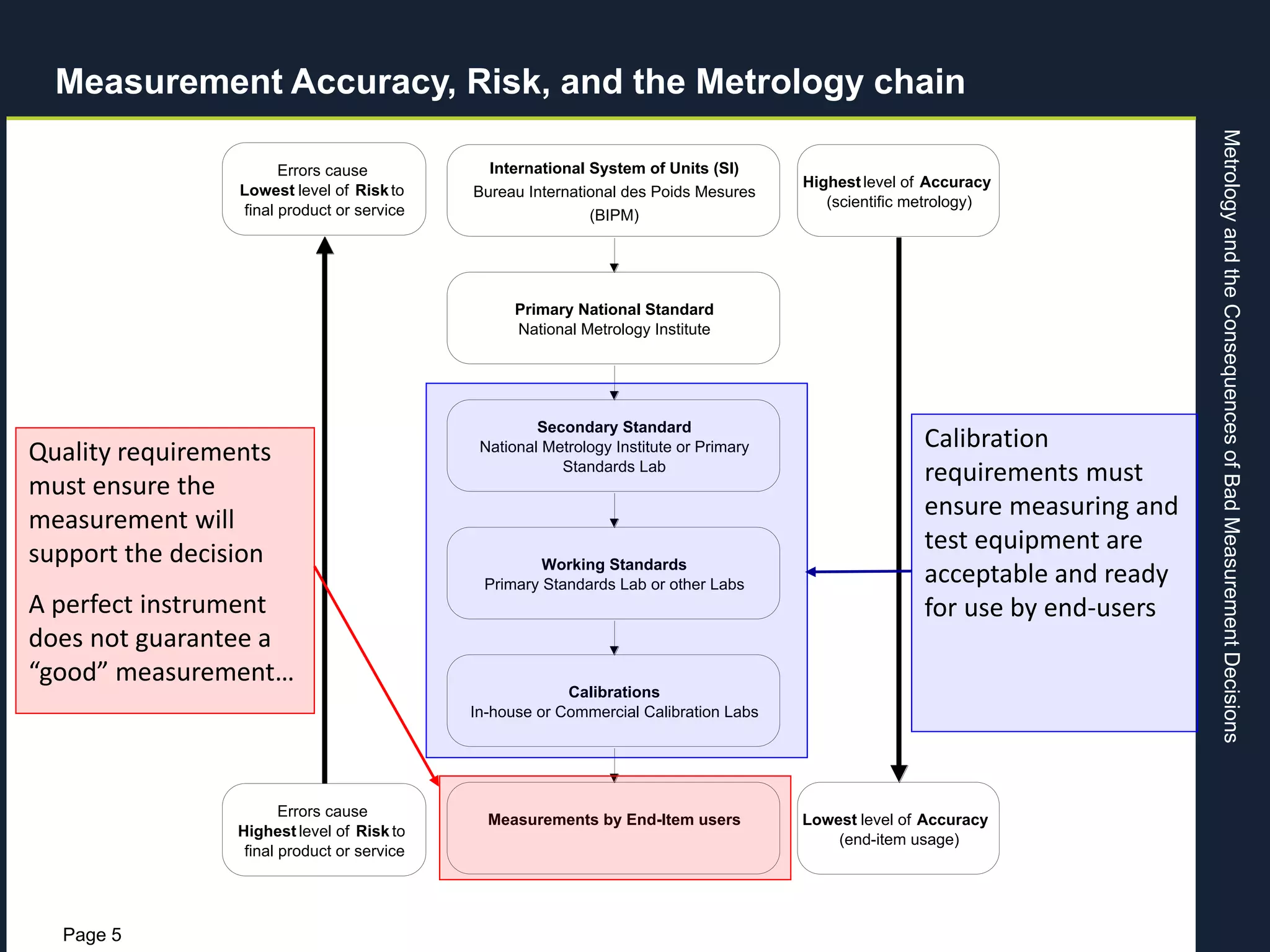

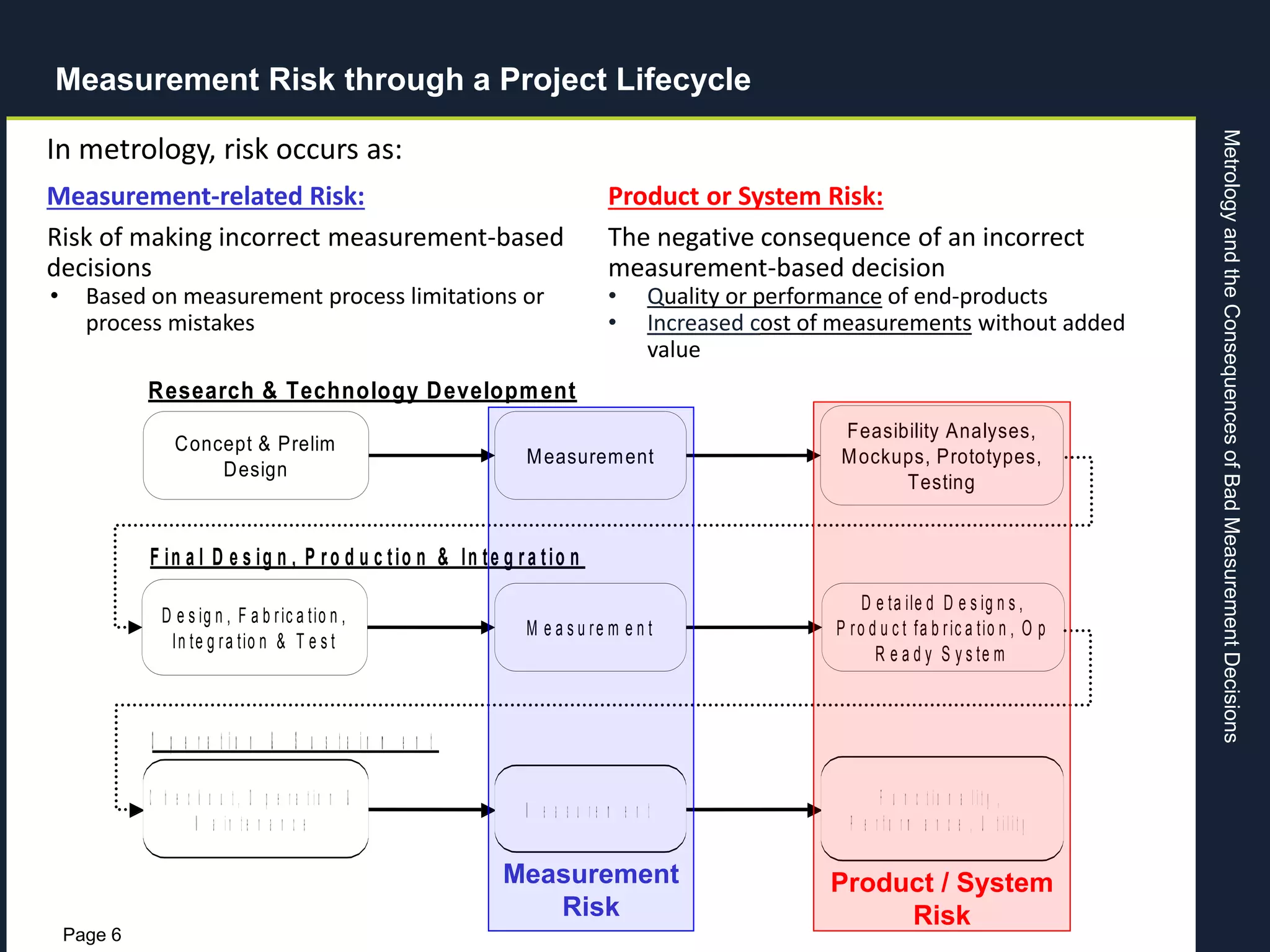

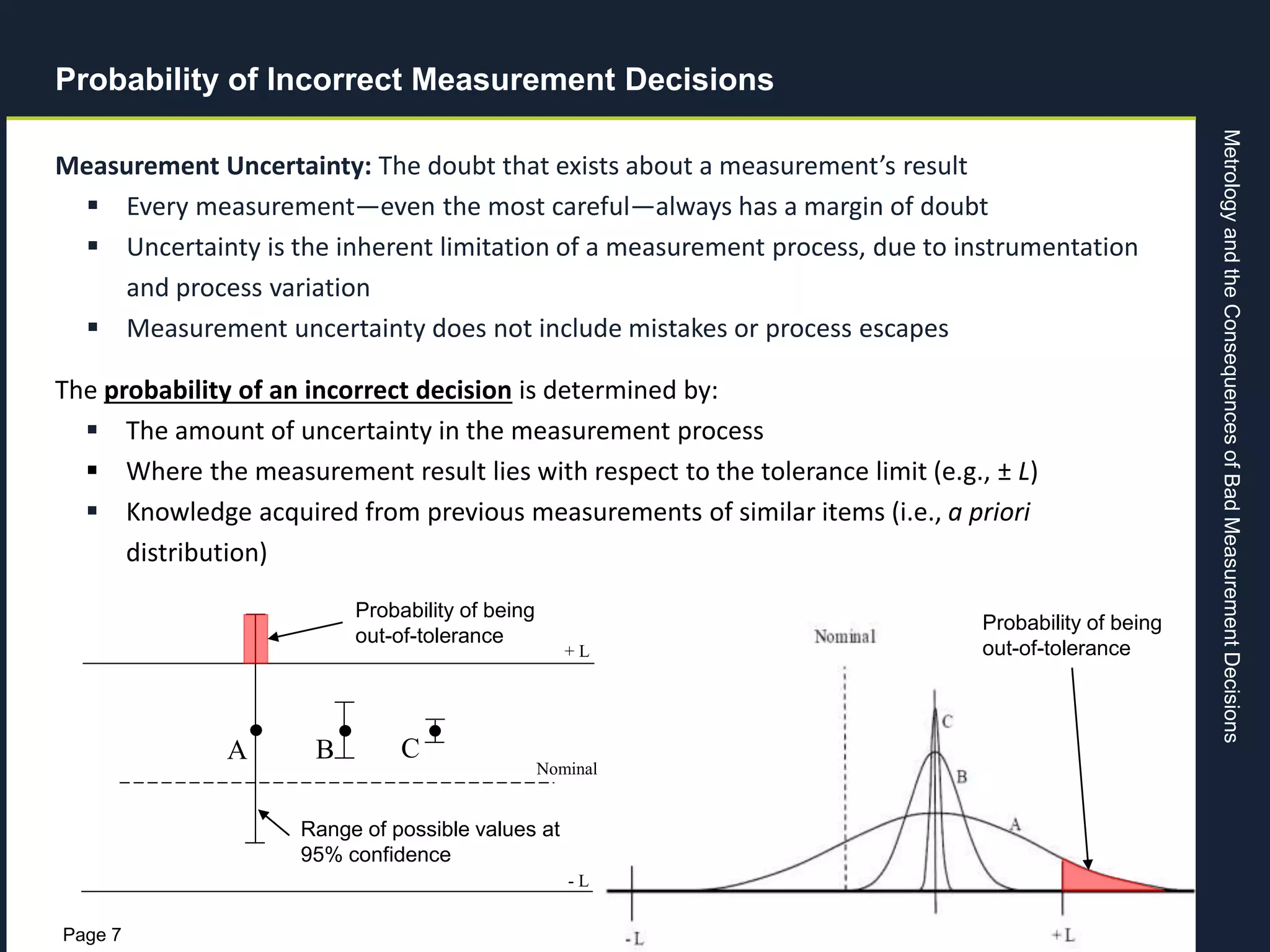

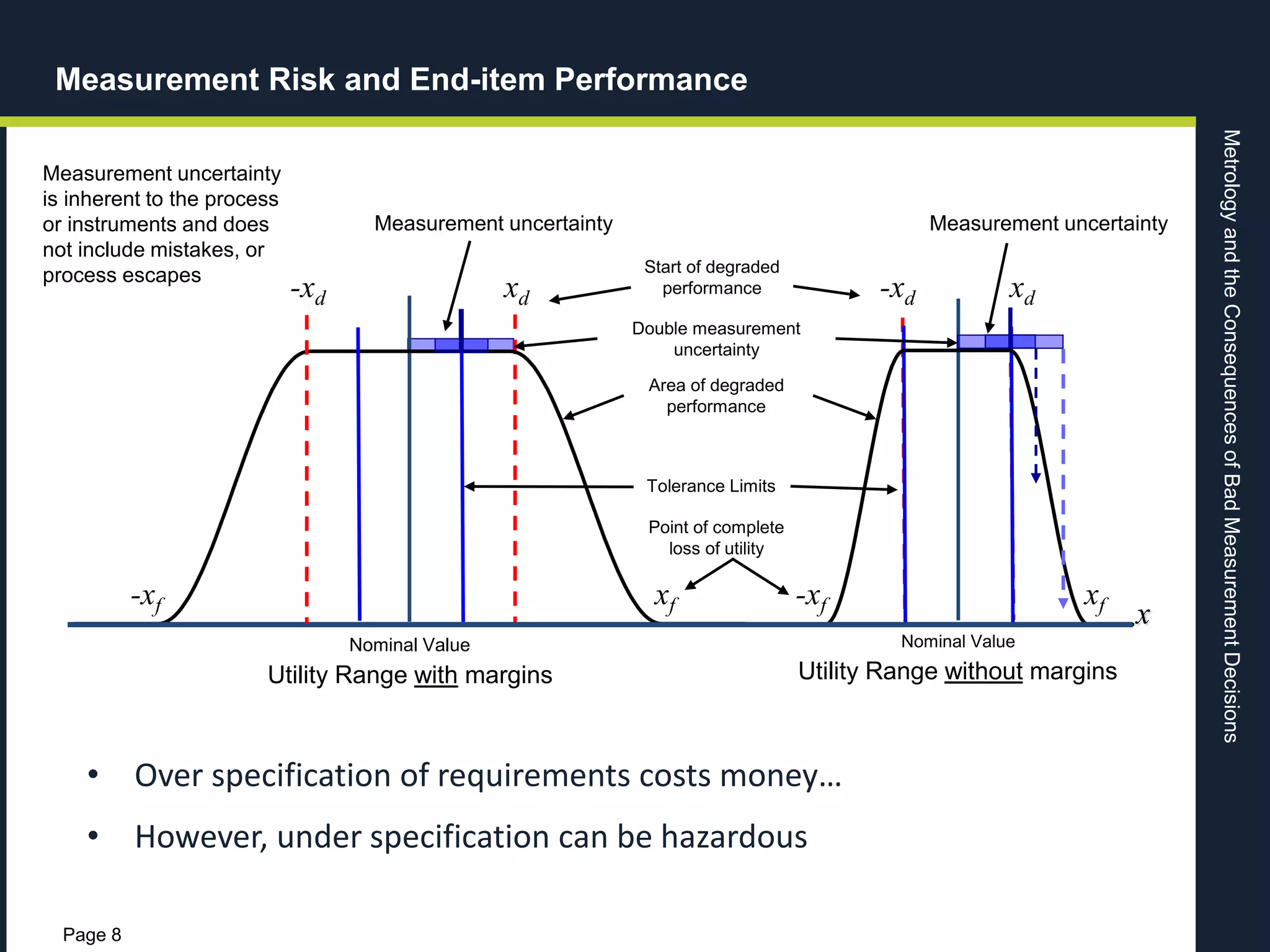

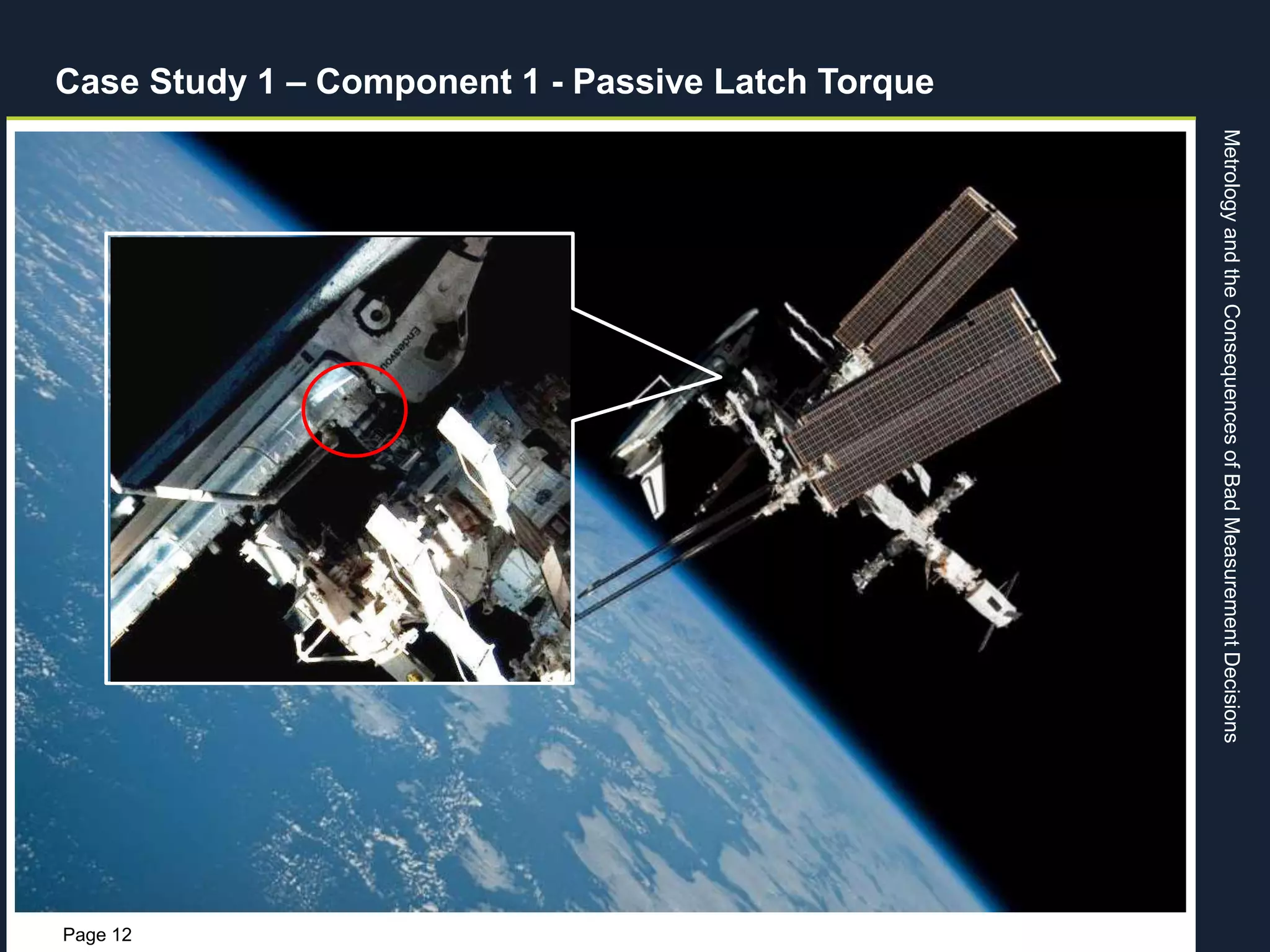

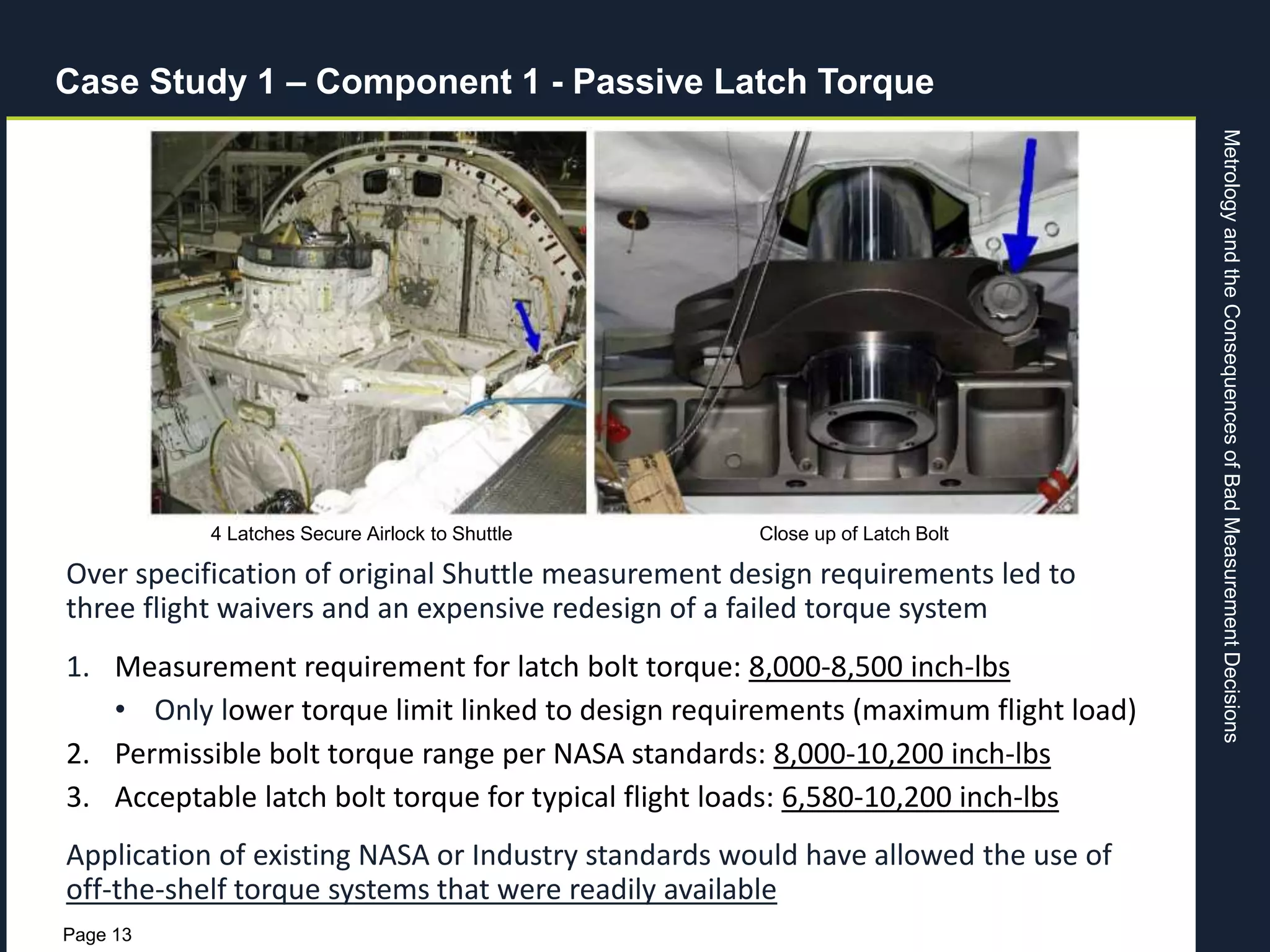

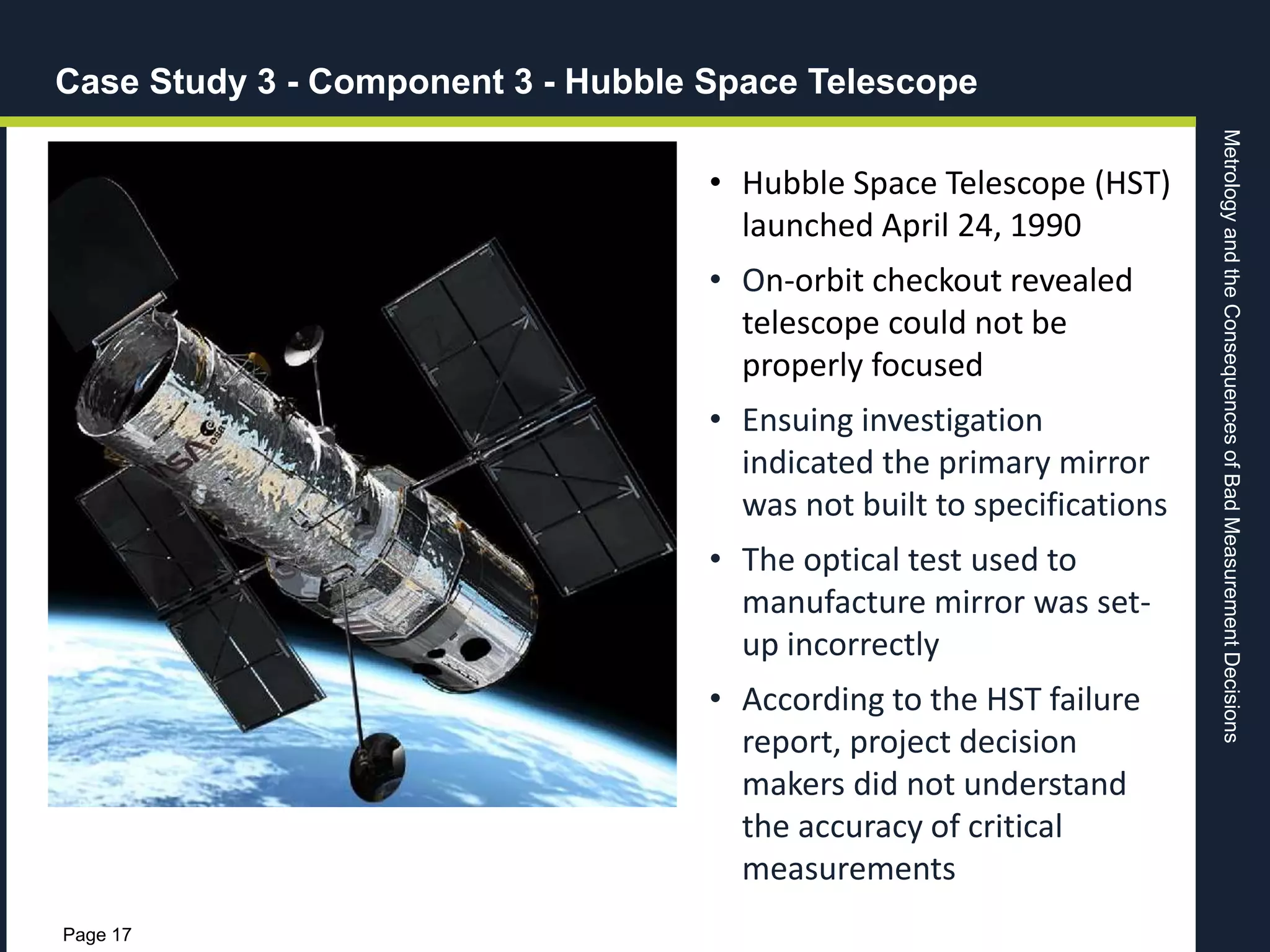

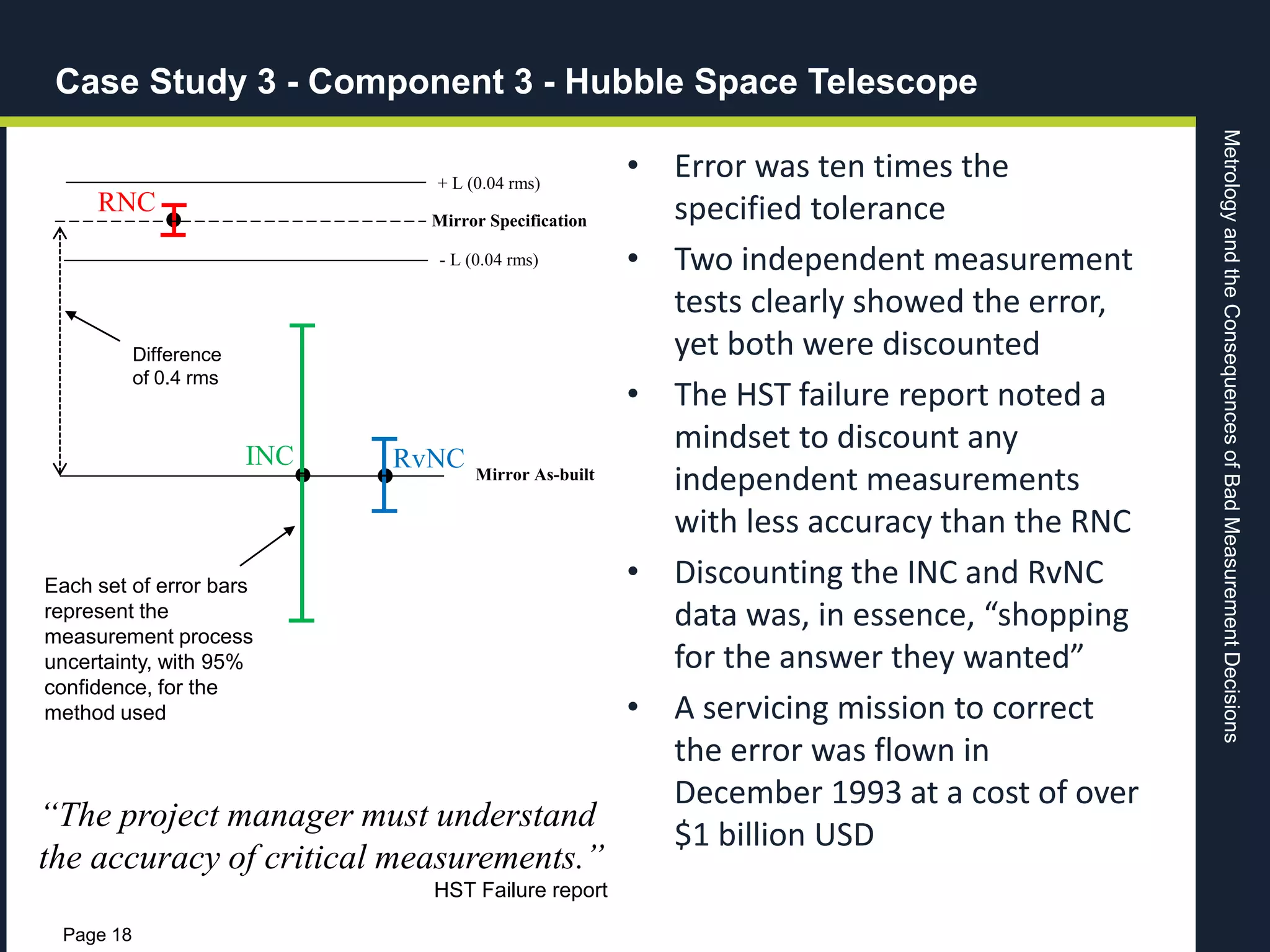

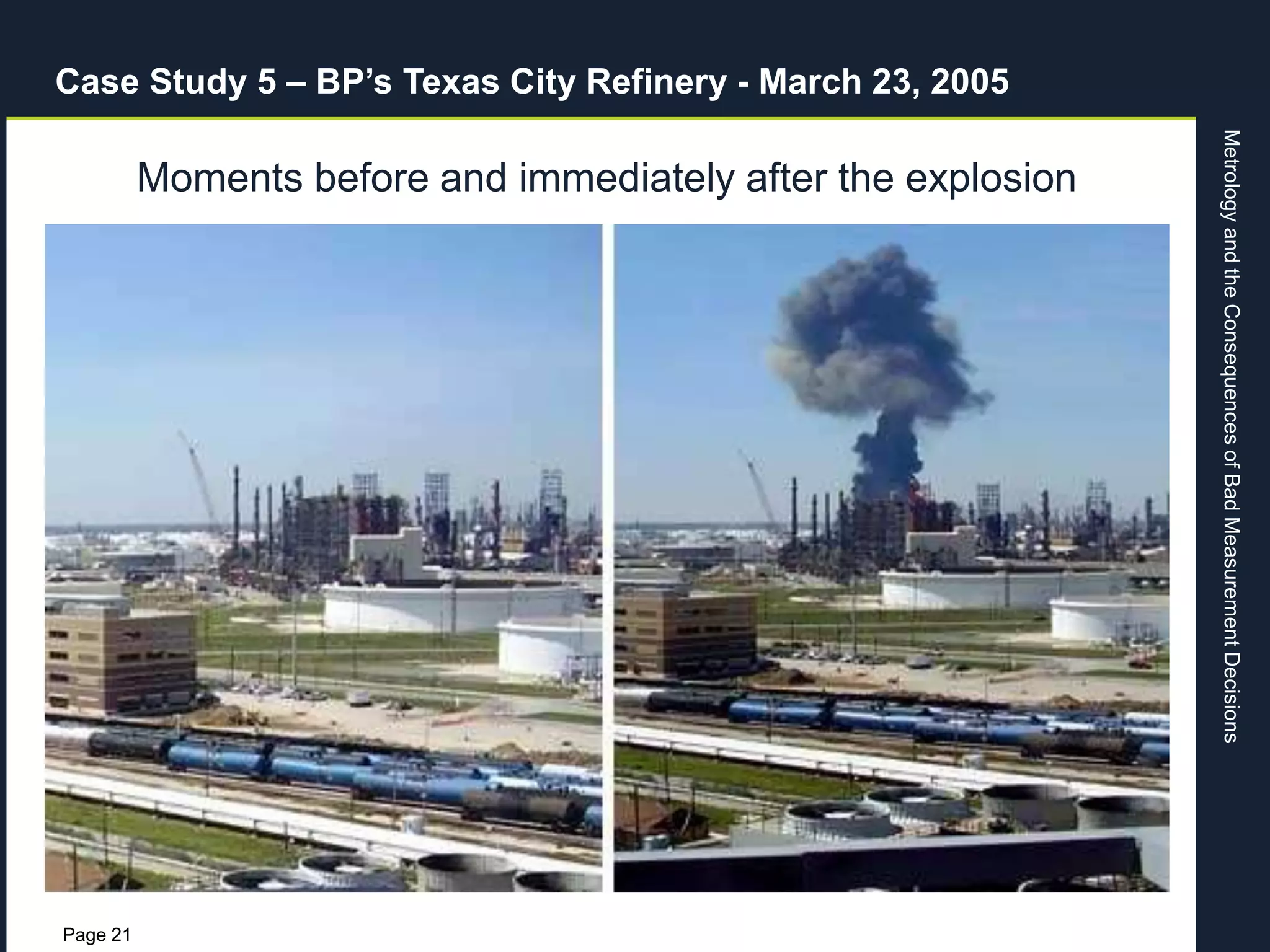

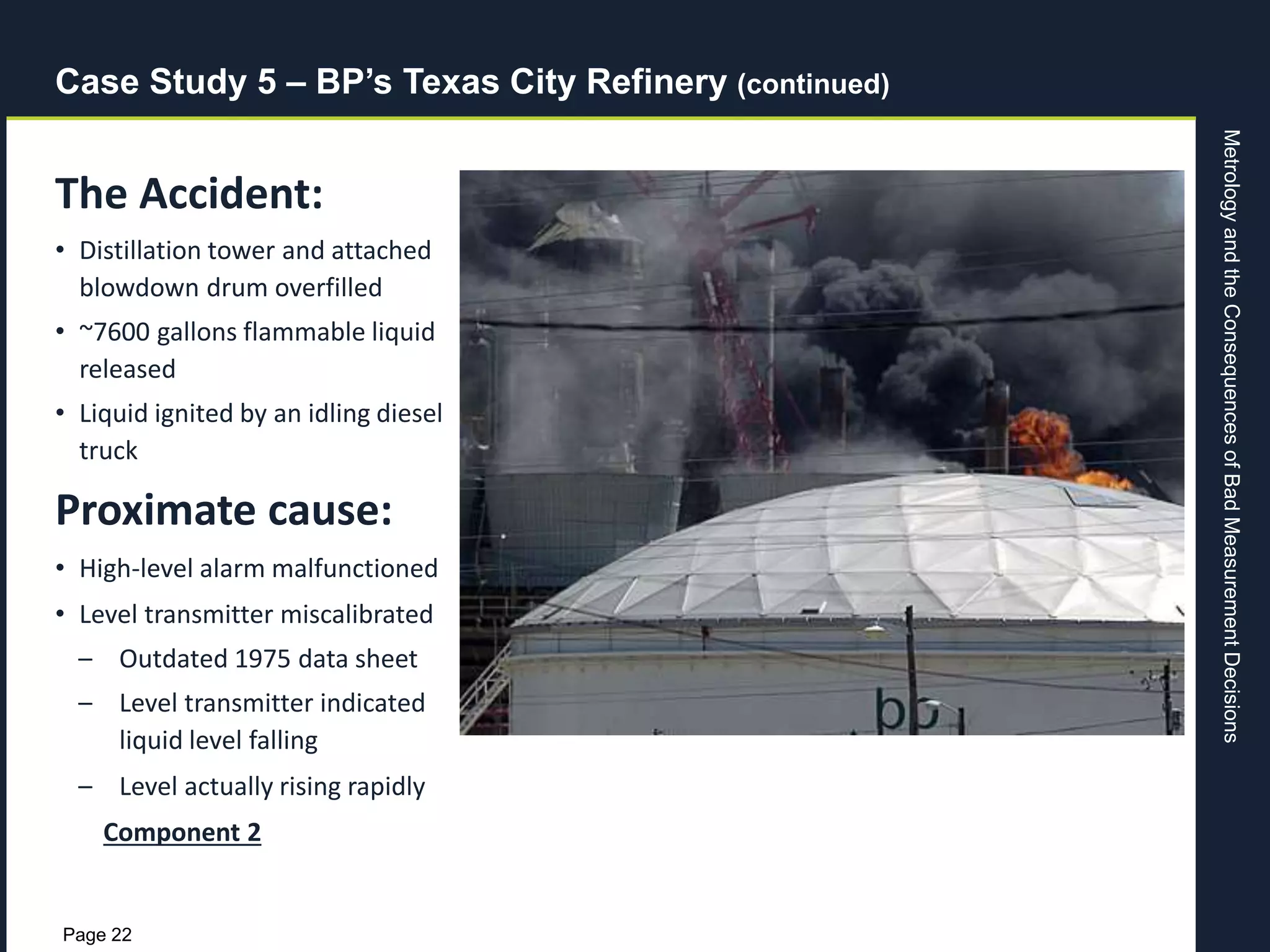

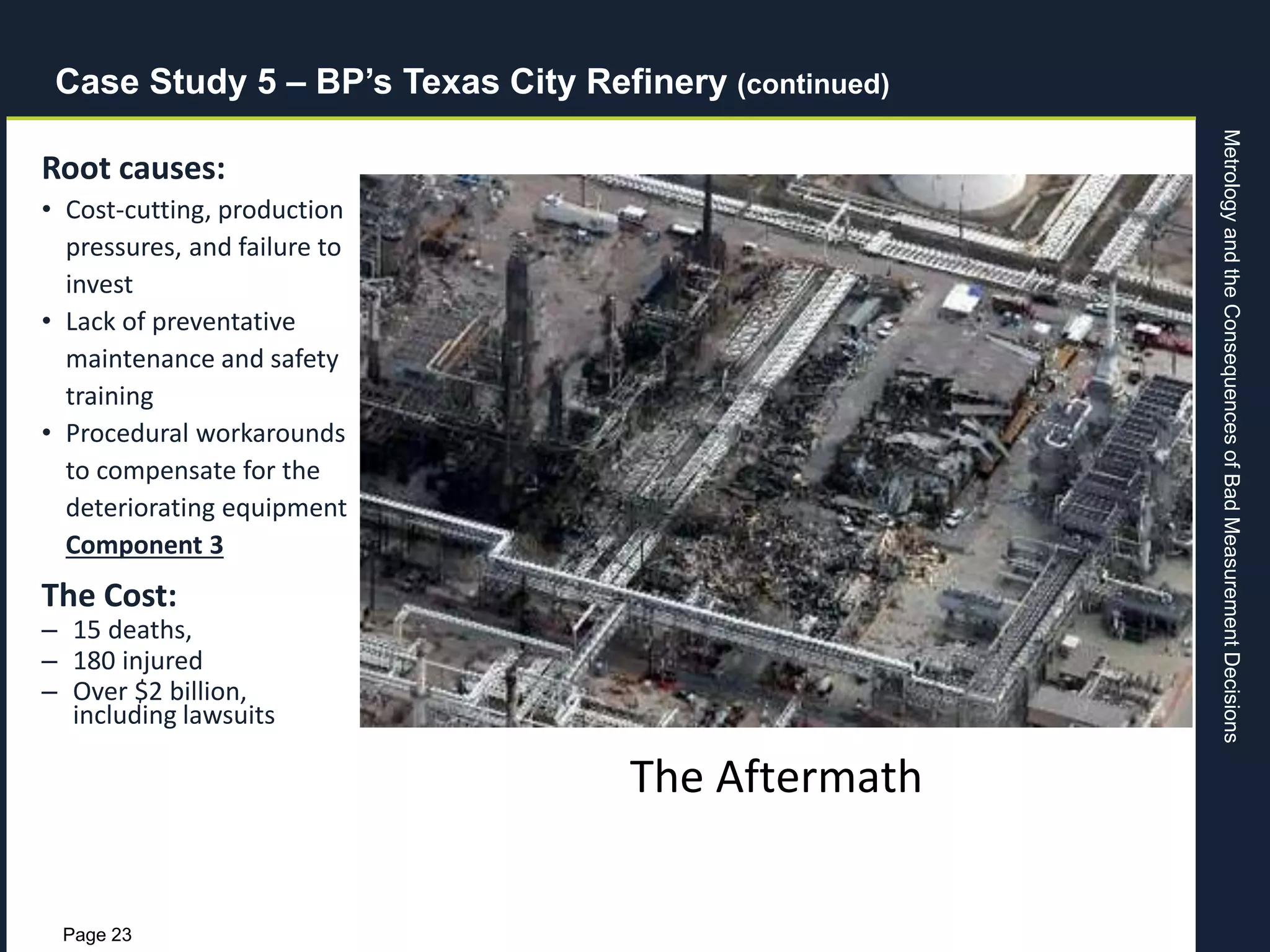

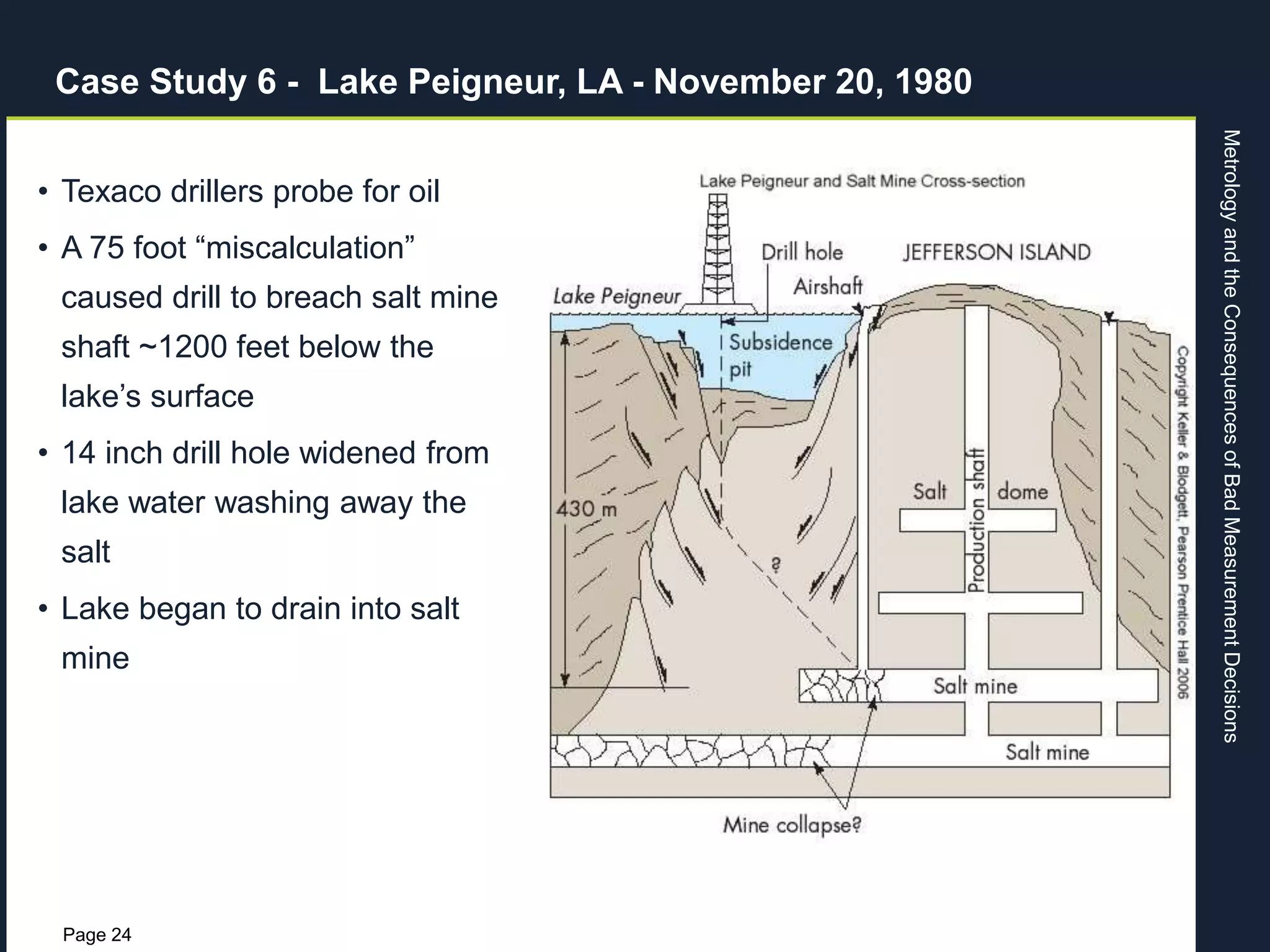

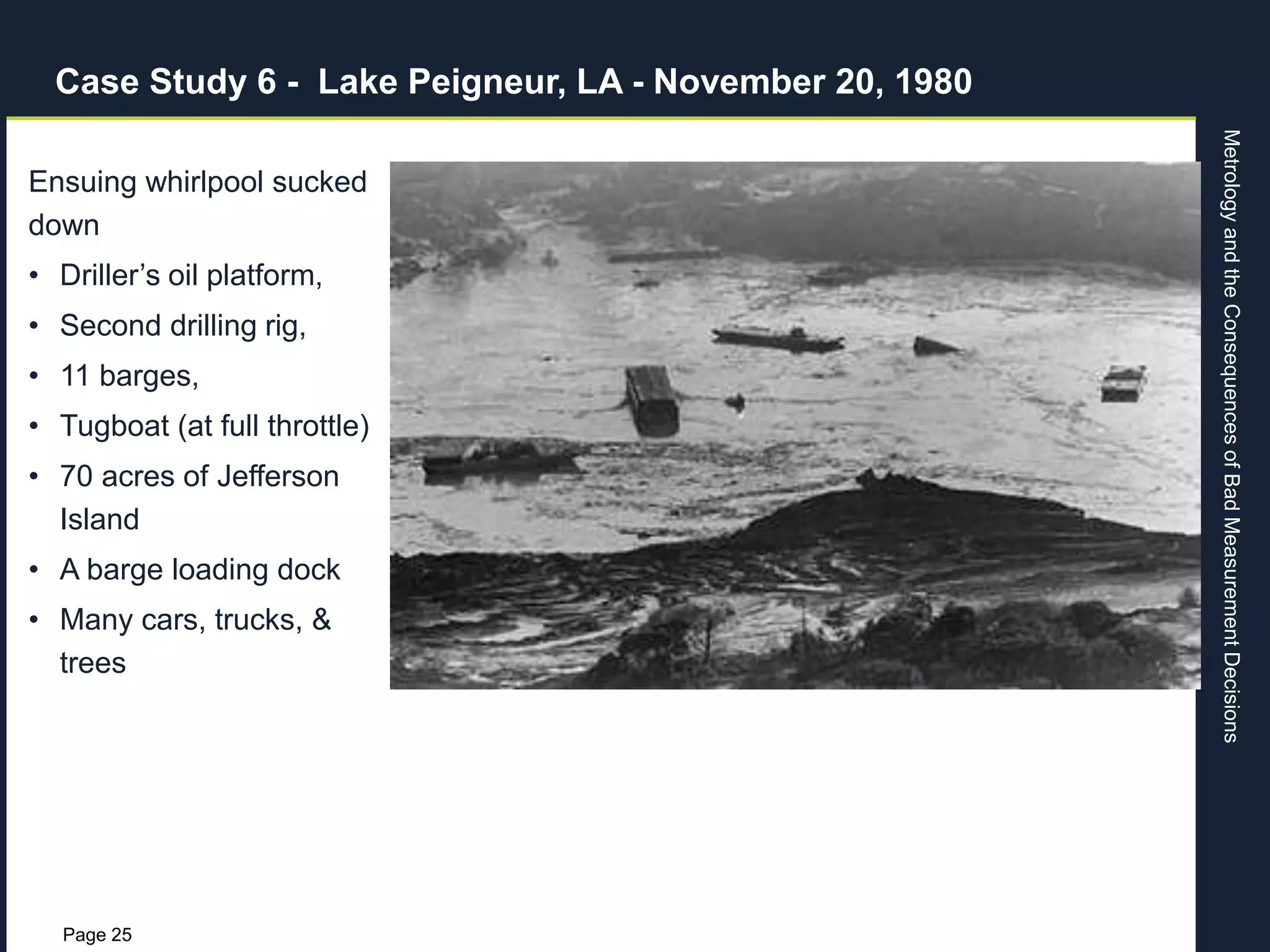

This document discusses the importance of metrology and the consequences of bad measurement decisions. It provides examples of failures that resulted from one or more inadequate elements: requirements that were not linked to performance, uncalibrated equipment, and improper measurement procedures. Consequences ranged from mission failures costing over $1 billion to loss of life. Ensuring measurements have good requirements, equipment, and processes is critical to making correct decisions and avoiding risk.