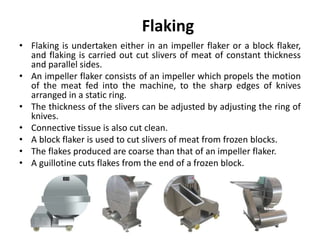

The document discusses modern meat processing techniques including comminution, curing, and mixing. It describes how comminution through mincing, milling, chopping, and flaking helps create uniform meat products and improves texture. Curing techniques like massaging, tumbling, and mixing impart mechanical energy to extract proteins and enhance tenderness. Various machines are used for each processing technique.