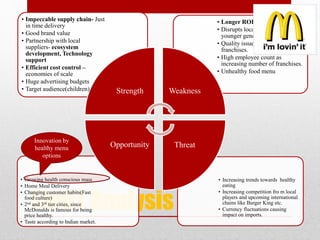

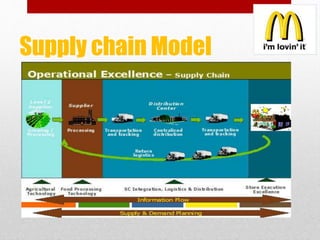

This document summarizes McDonald's supply chain model. McDonald's has achieved market success due to their strong and effective supply chain, which helps maintain affordable prices. Their supply chain involves a few key suppliers that provide large volumes, allowing costs to be cut. These suppliers implement advanced agricultural practices, food processing technologies, cold storage, and distribution to meet McDonald's stringent quality standards. McDonald's intensive supply chain model and market research encourages innovation, cost reduction, and the development of domestic agriculture and food production in partner countries.