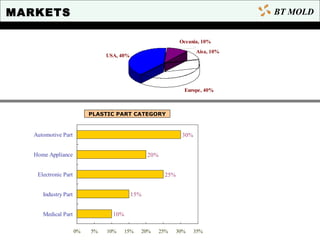

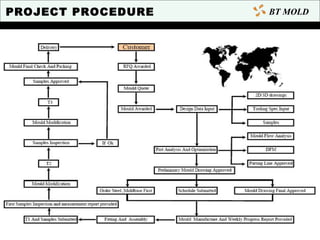

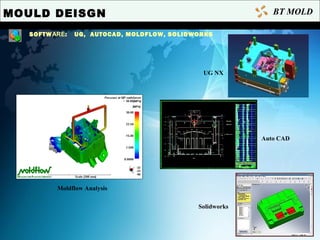

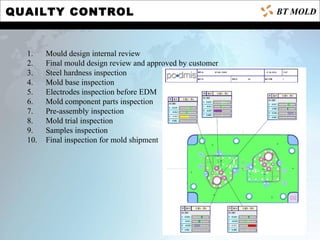

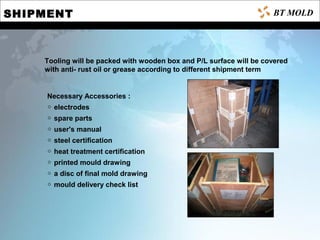

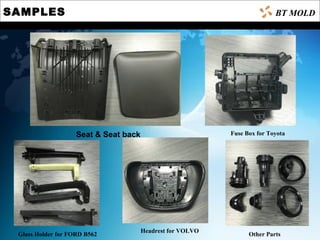

Shenzhen Yanan Precision Technology Co., Ltd. specializes in various mold projects, catering to industries including medical, electronics, automotive, and home appliances. The document outlines the company's manufacturing processes, quality control measures, equipment, and product samples, emphasizing their capabilities in mold design and trial production. Contact details for inquiries are also provided, highlighting the sales manager's information.