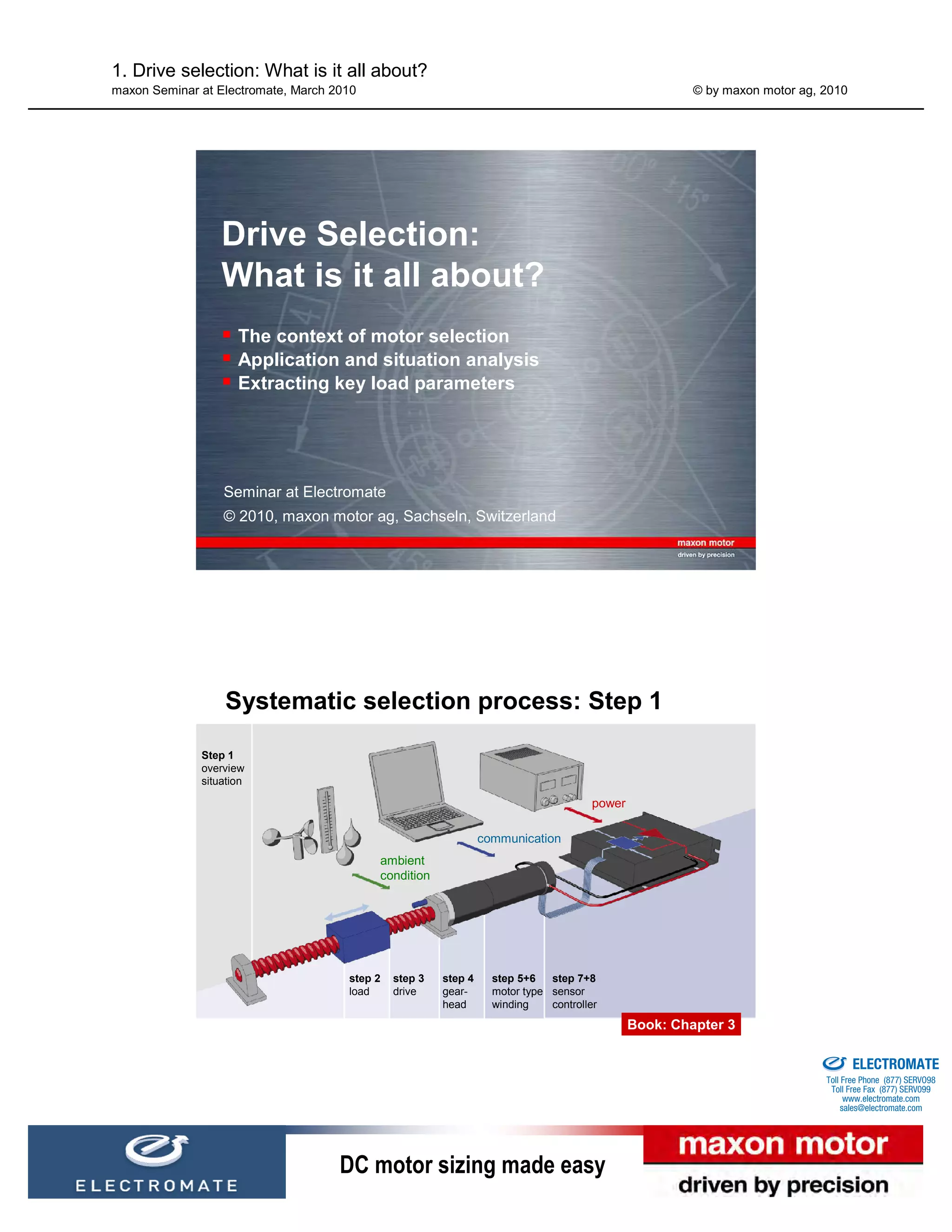

1. Drive selection involves analyzing the application, extracting key load parameters, and systematically selecting the appropriate drive components through multiple steps.

2. The first steps involve characterizing the load profile, including working points, motion profiles, and operating modes to determine the average and maximum loads.

3. Subsequent steps involve selecting appropriate mechanical drive elements like gearheads and spindles to transform speeds and torques, as well as determining resulting inertias and efficiencies.