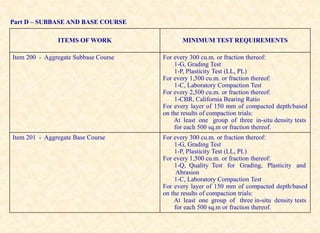

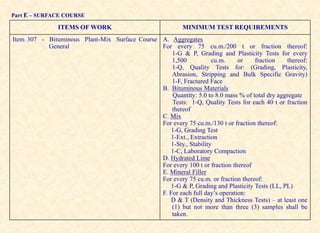

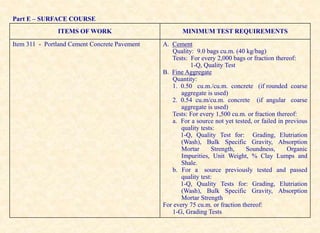

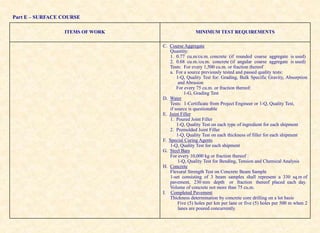

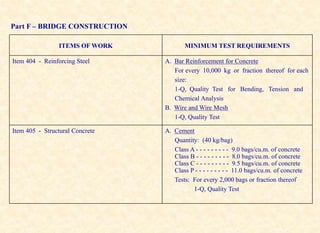

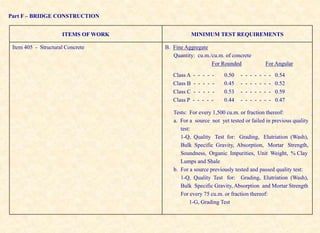

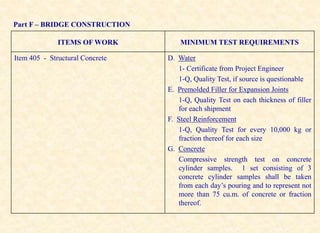

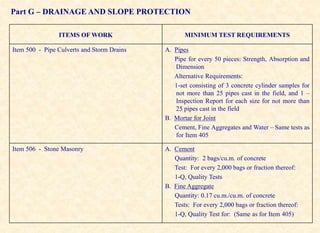

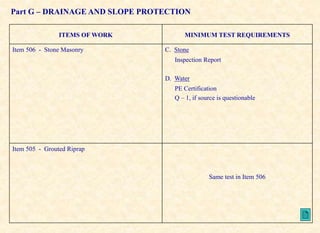

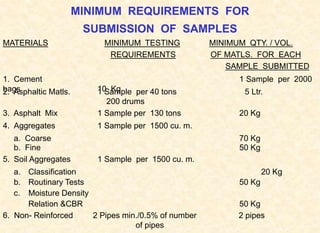

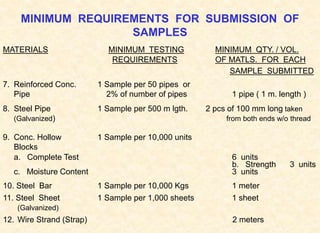

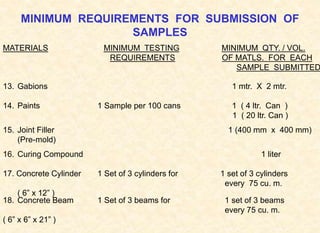

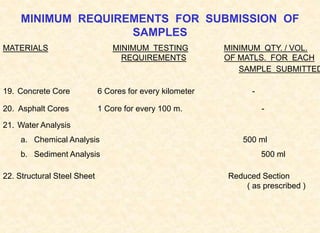

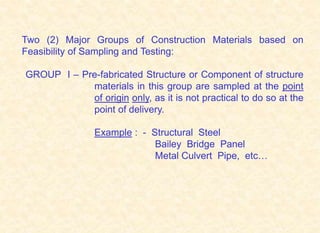

The document outlines the quality control programs and minimum testing requirements essential for ensuring the quality of construction materials and workmanship in project implementation. It defines quality, differentiates between quality control and quality assurance, and details procedures for material selection and testing requirements for various construction items. This comprehensive guide aims to guarantee high-quality work while optimizing costs and testing protocols throughout the construction process.