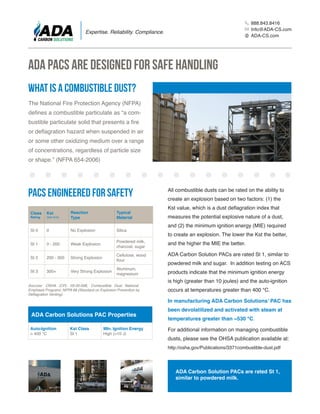

The document provides guidance on safely handling powdered activated carbon (PAC). It recommends avoiding spills and cleaning up any leaks or spills promptly. Develop procedures in advance for potential issues like smoldering or fluidization. Consult an ADA Carbon Solutions representative to help plan for safely managing and storing PAC to minimize risks. PAC has been safely handled for decades with education and planning.