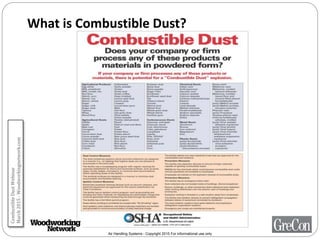

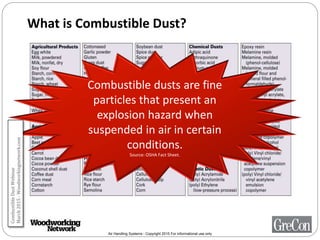

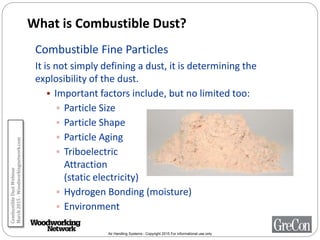

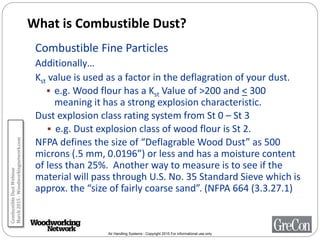

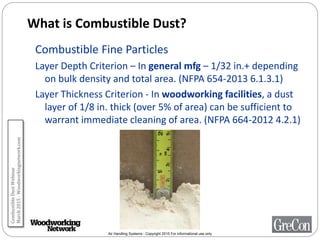

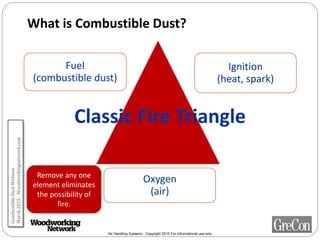

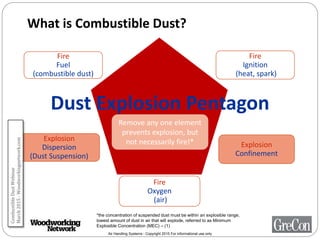

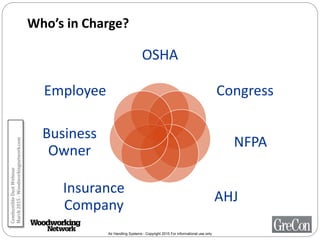

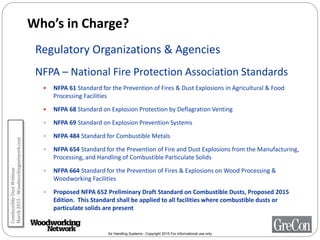

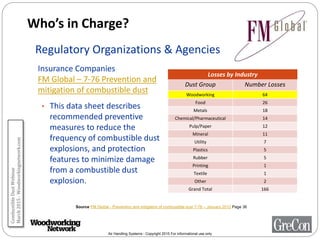

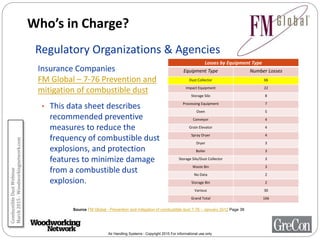

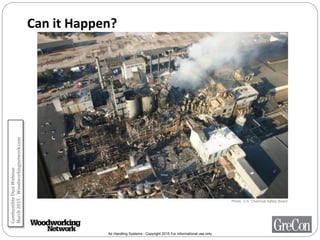

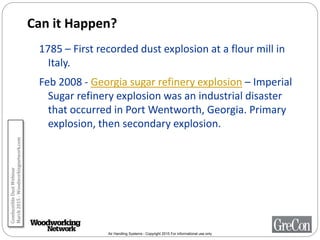

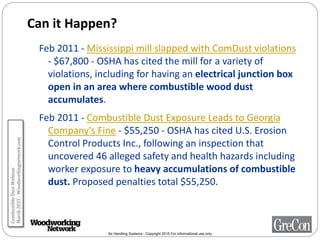

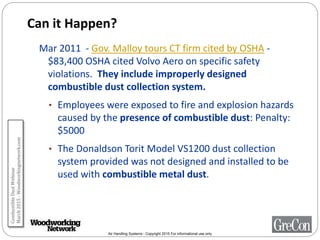

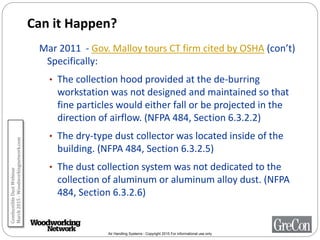

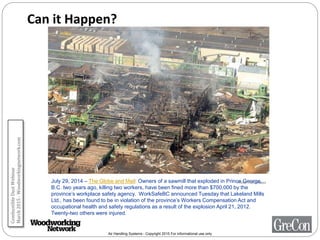

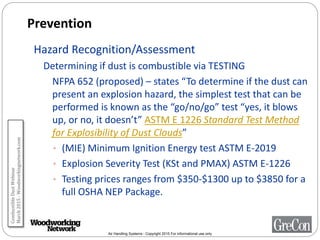

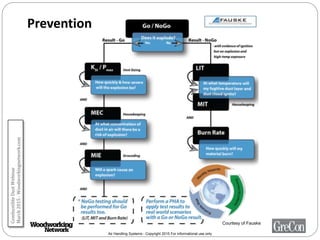

This document provides information from a webinar on combustible sawdust and how to protect workers and businesses. The webinar discusses what combustible dust is, examples of combustible dust explosions, who regulates combustible dust such as OSHA and NFPA, and that combustible dust explosions can happen in any facility that produces combustible dust. The webinar aims to educate attendees on preventing combustible dust explosions.