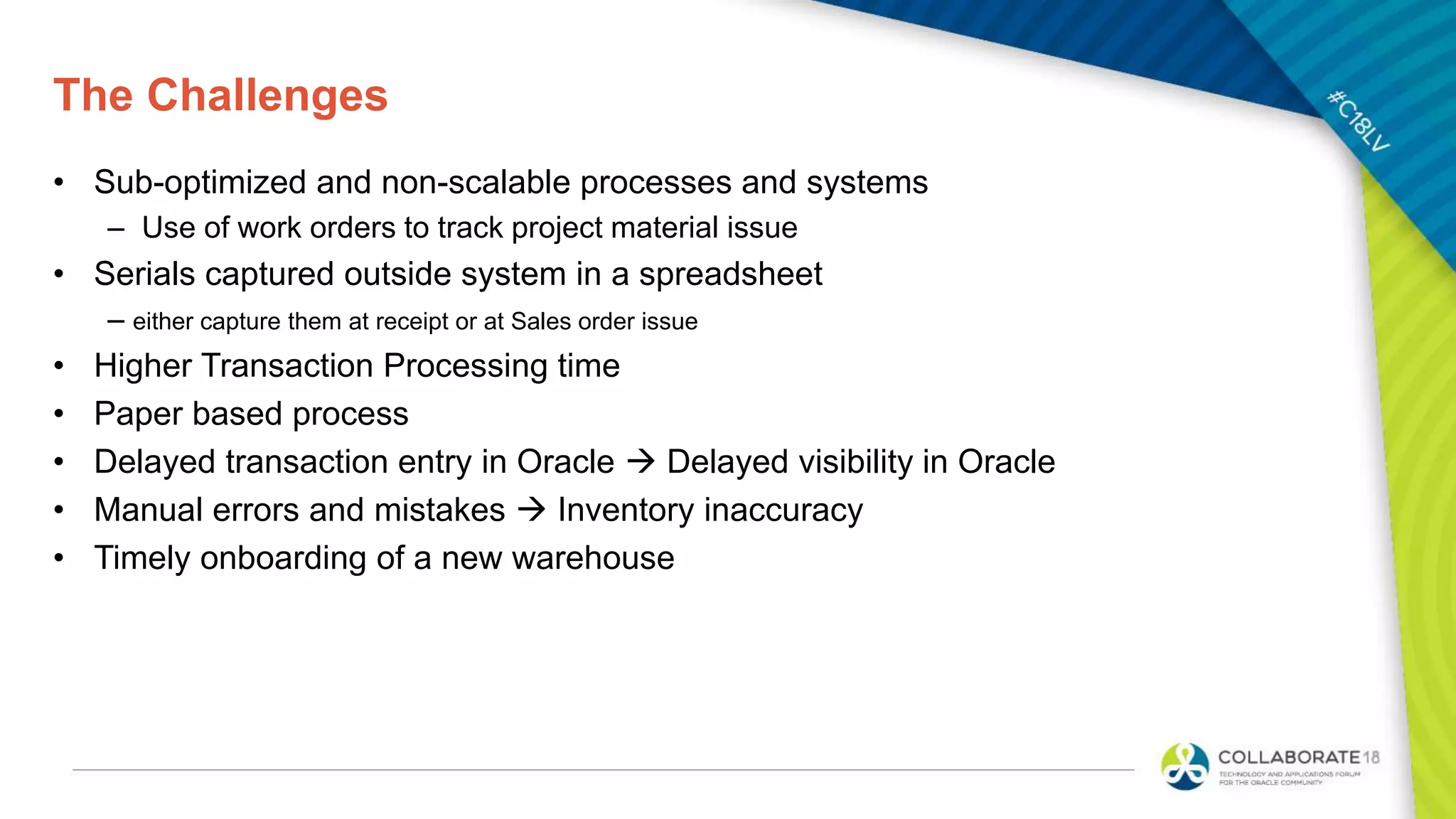

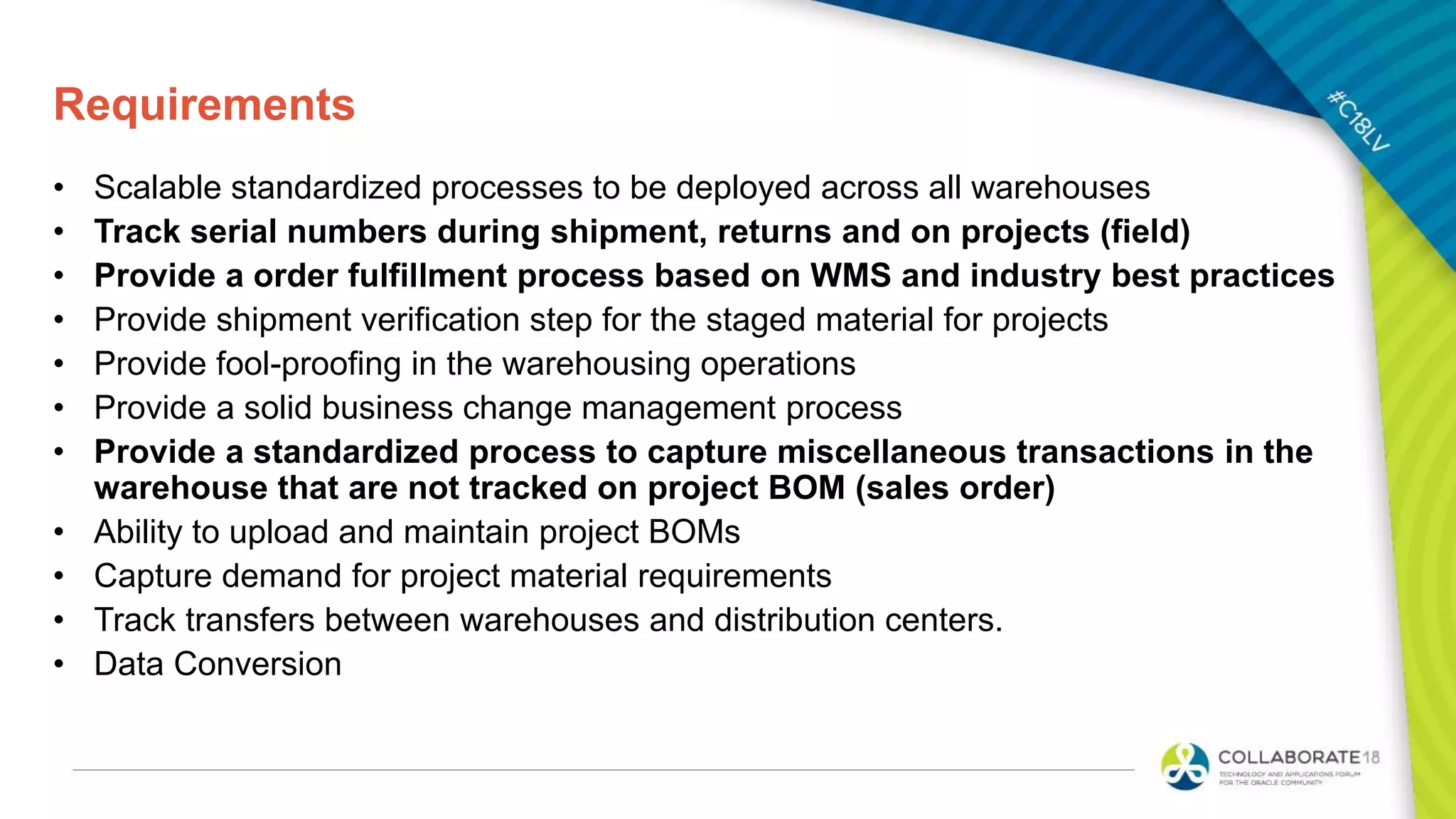

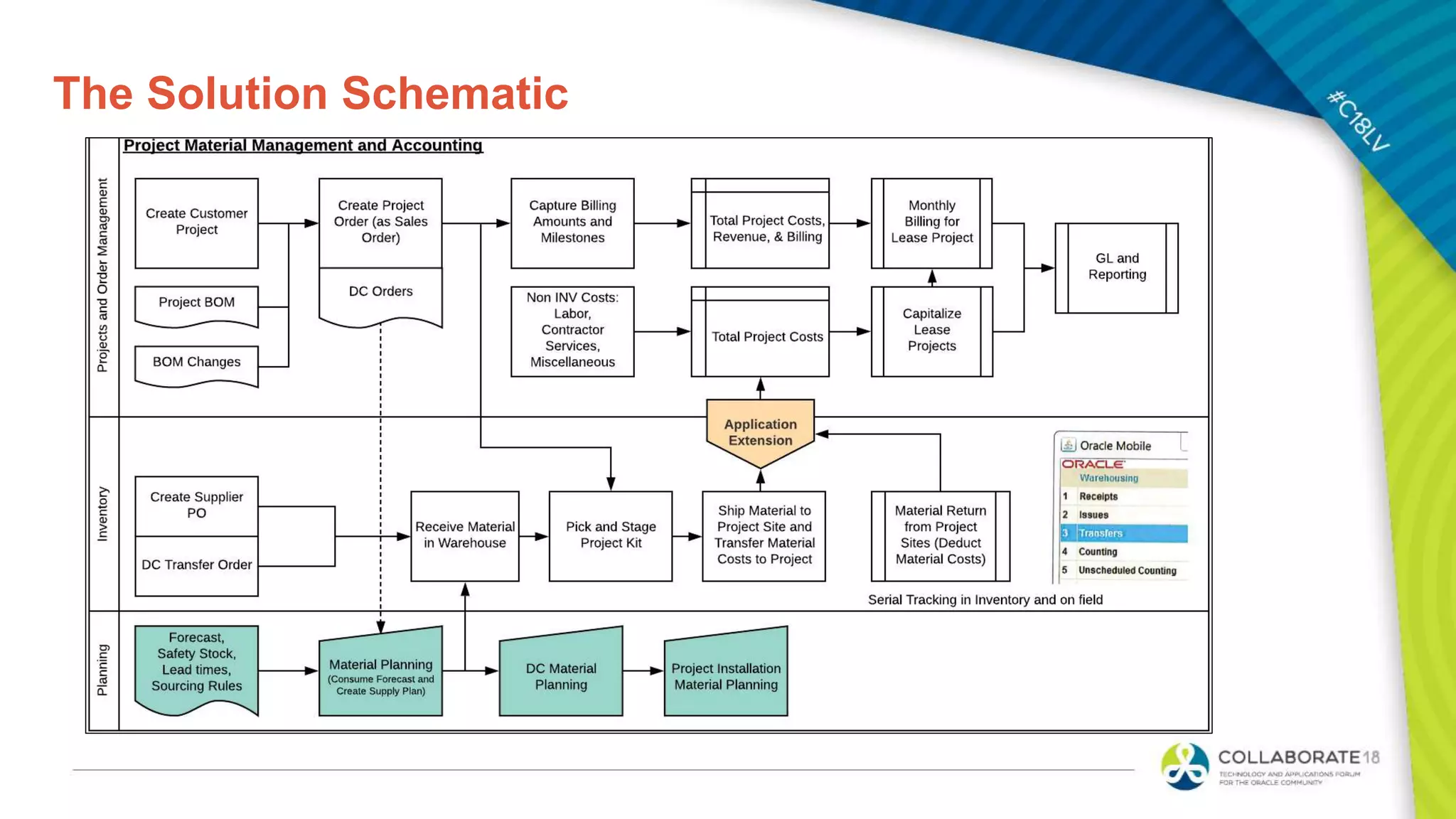

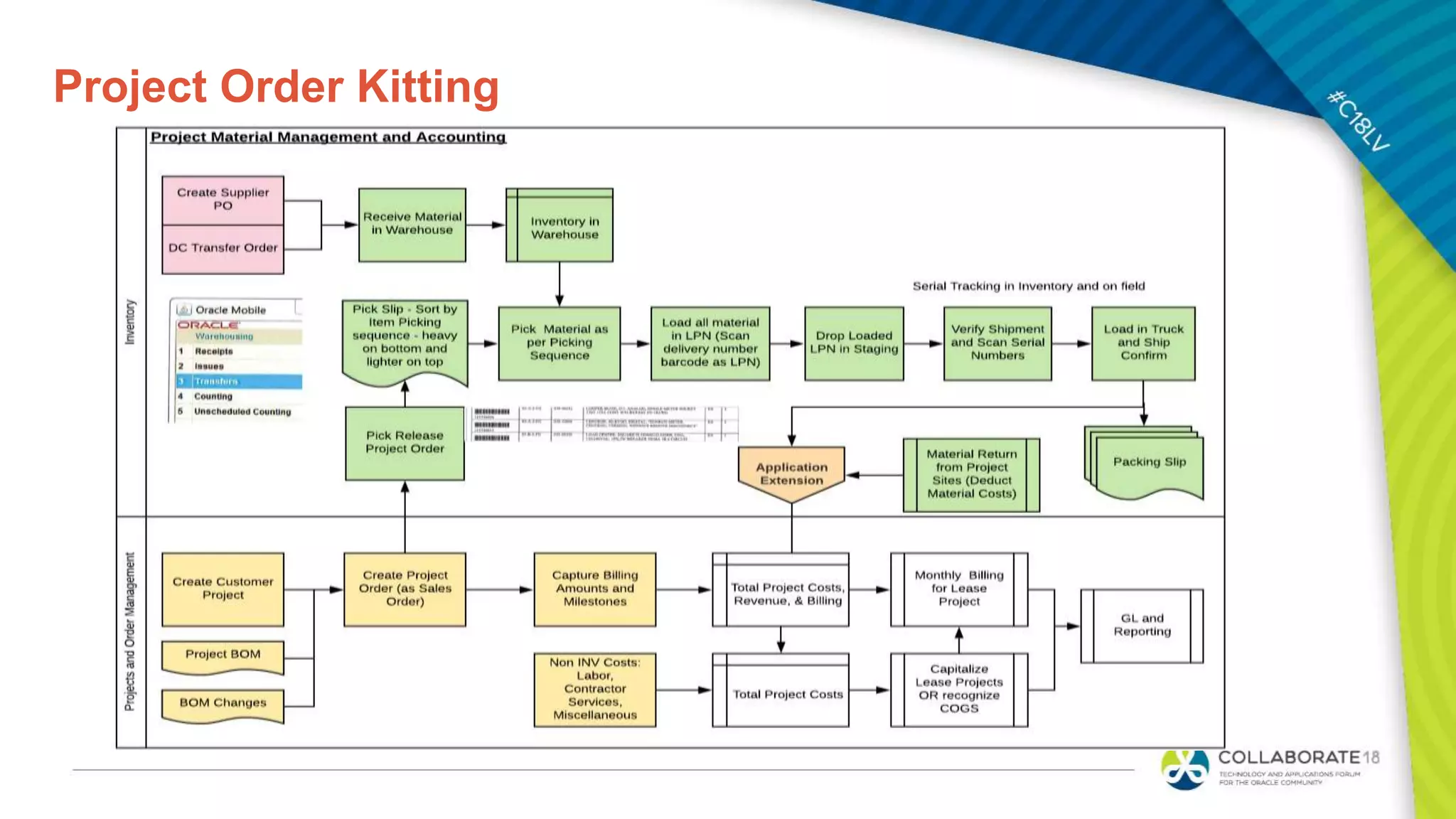

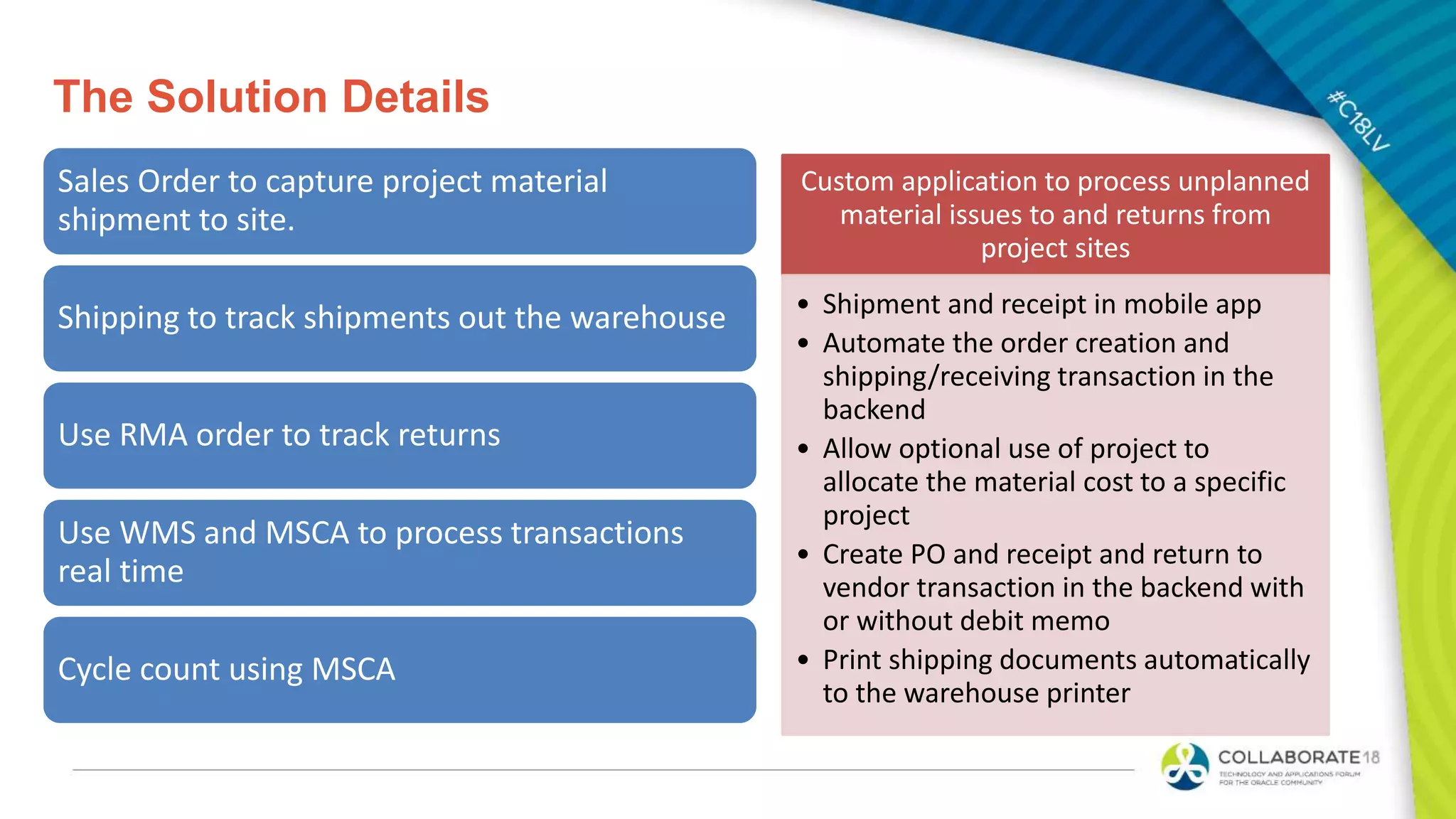

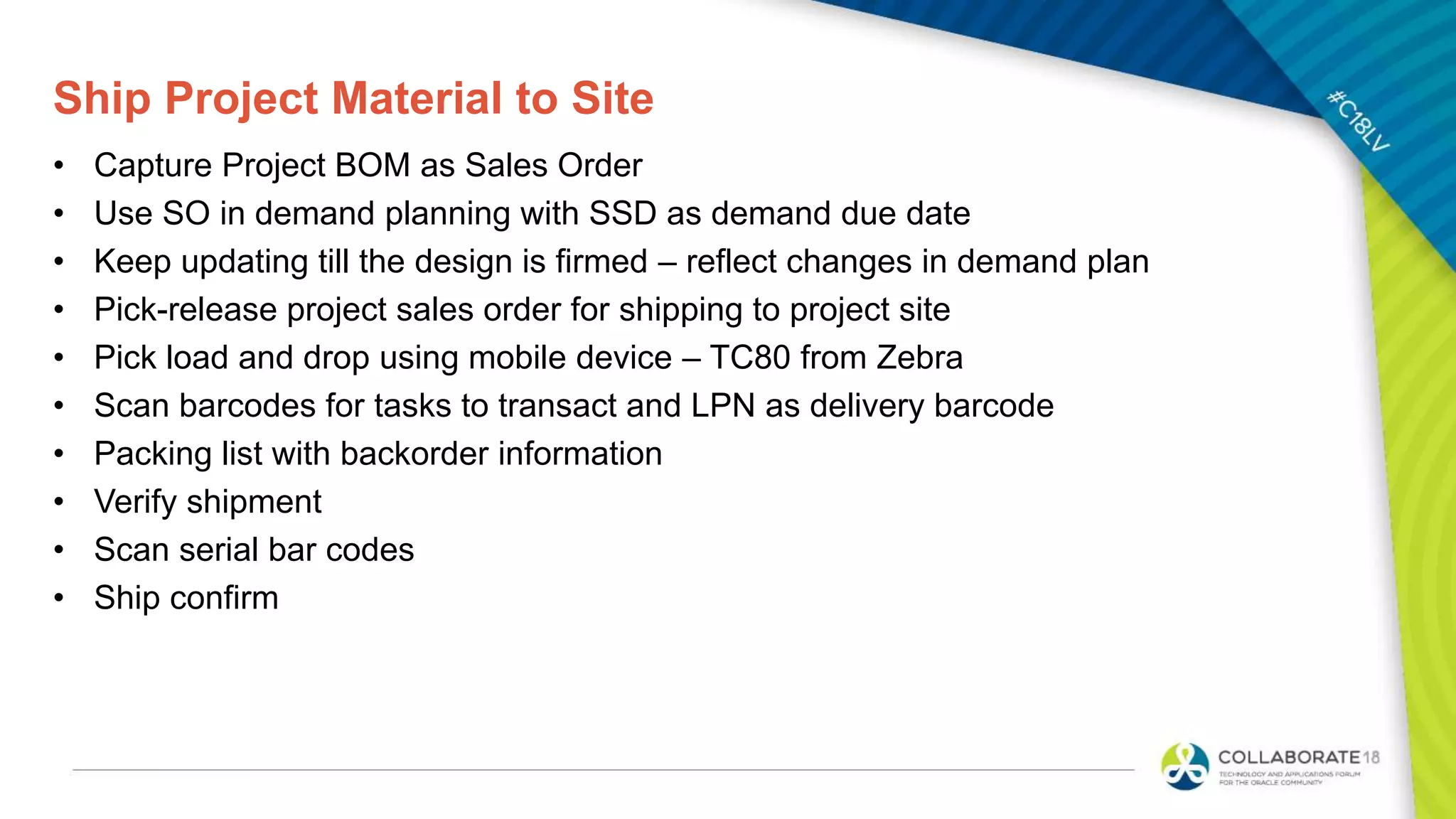

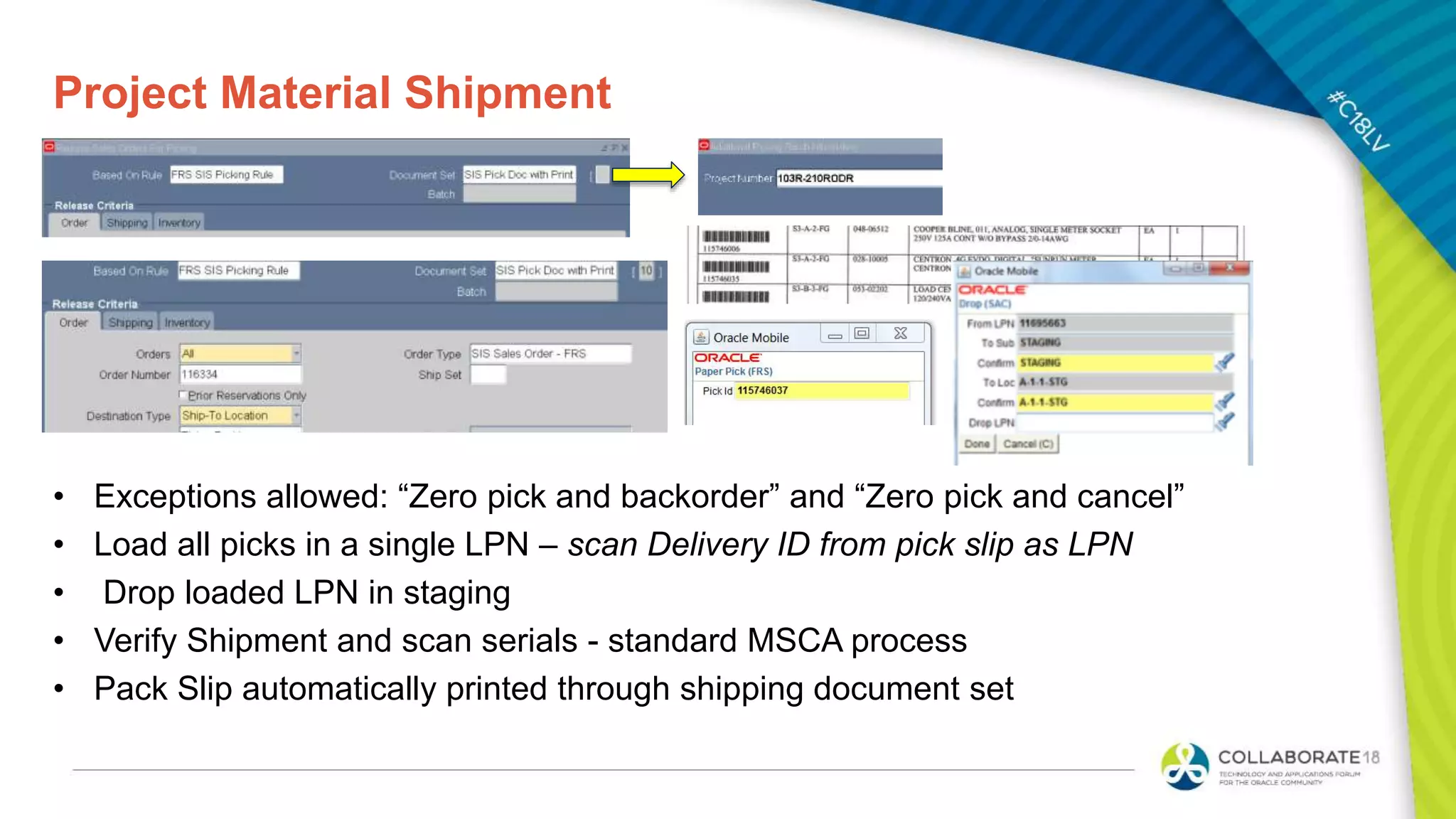

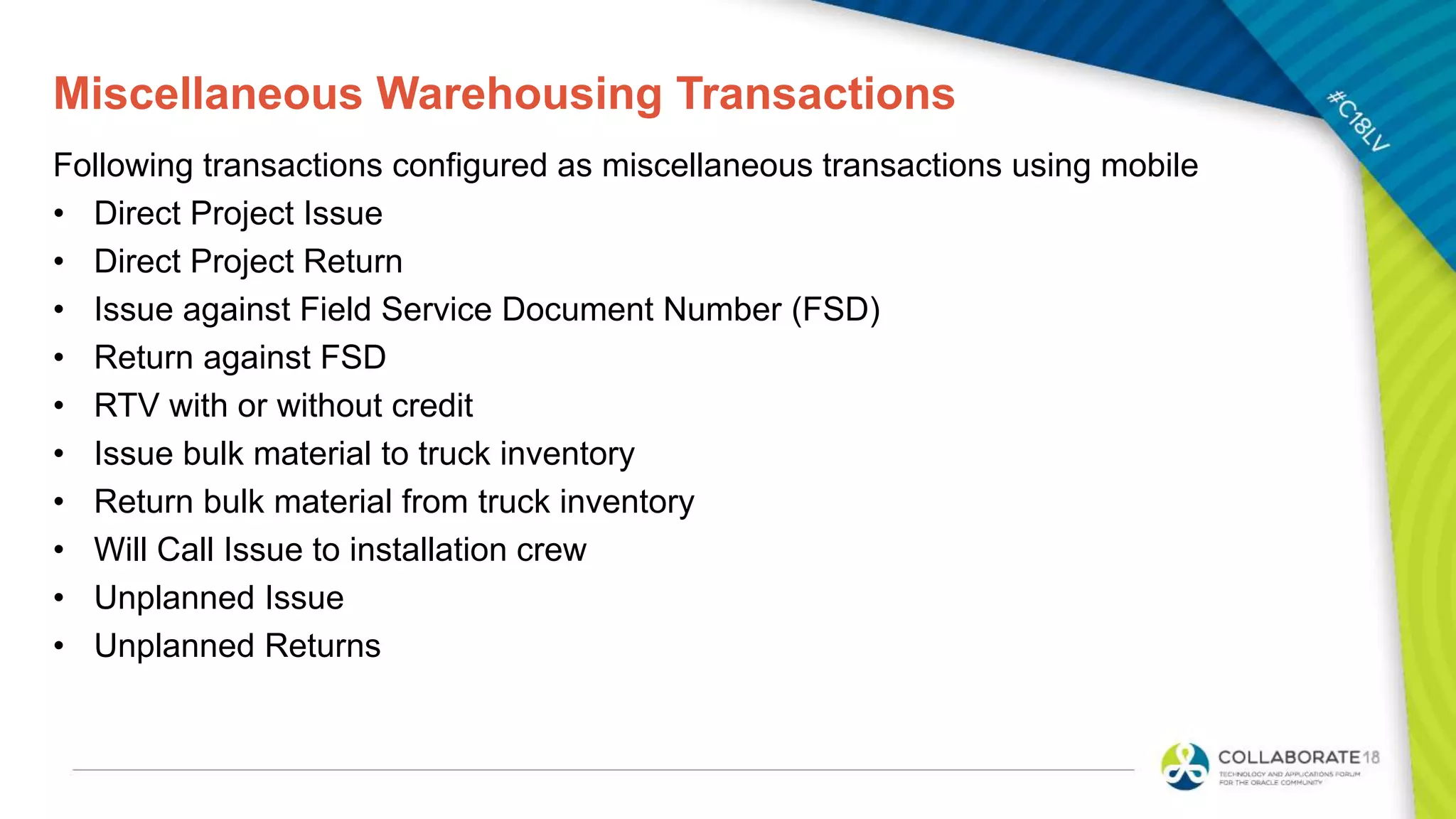

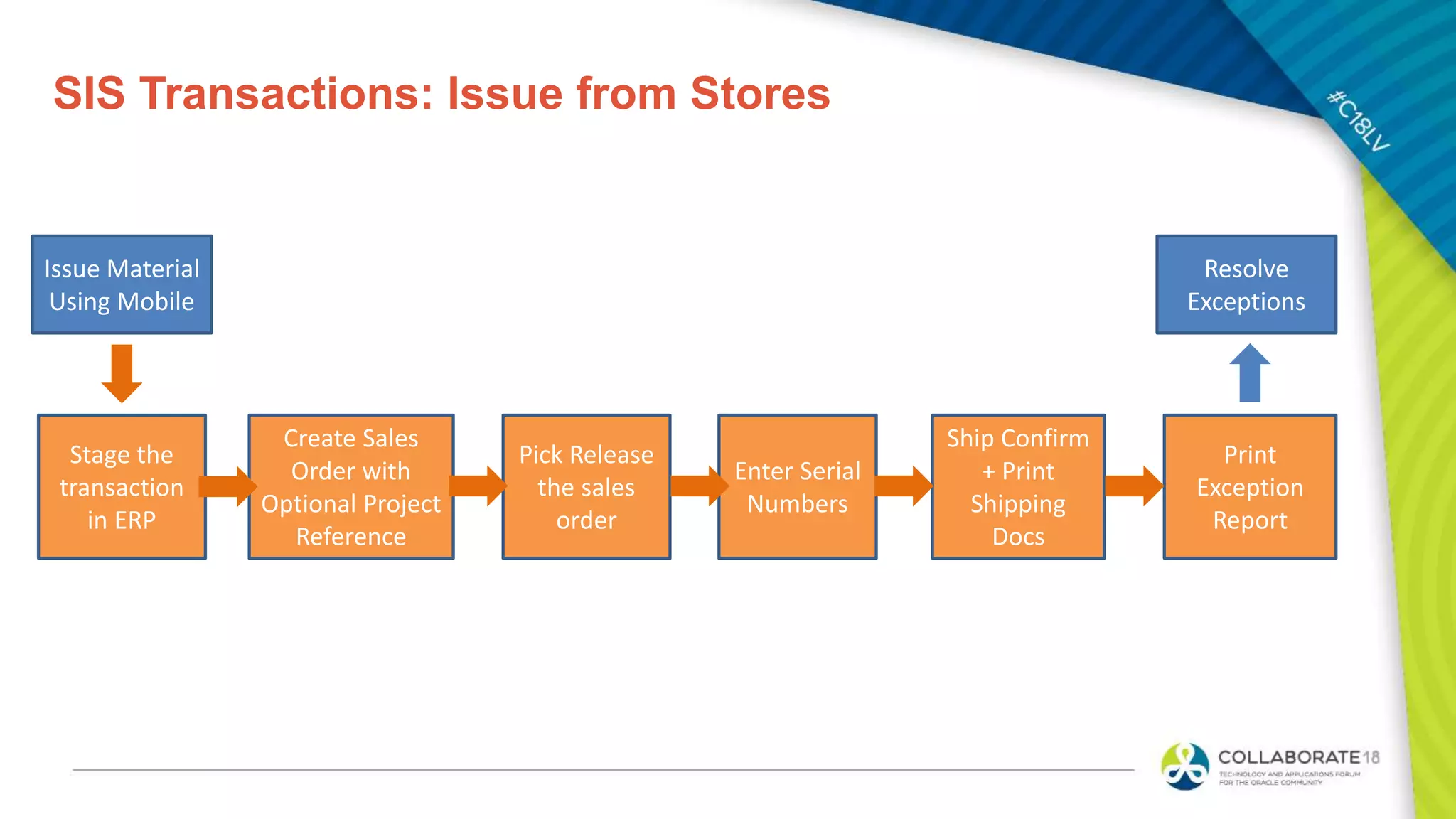

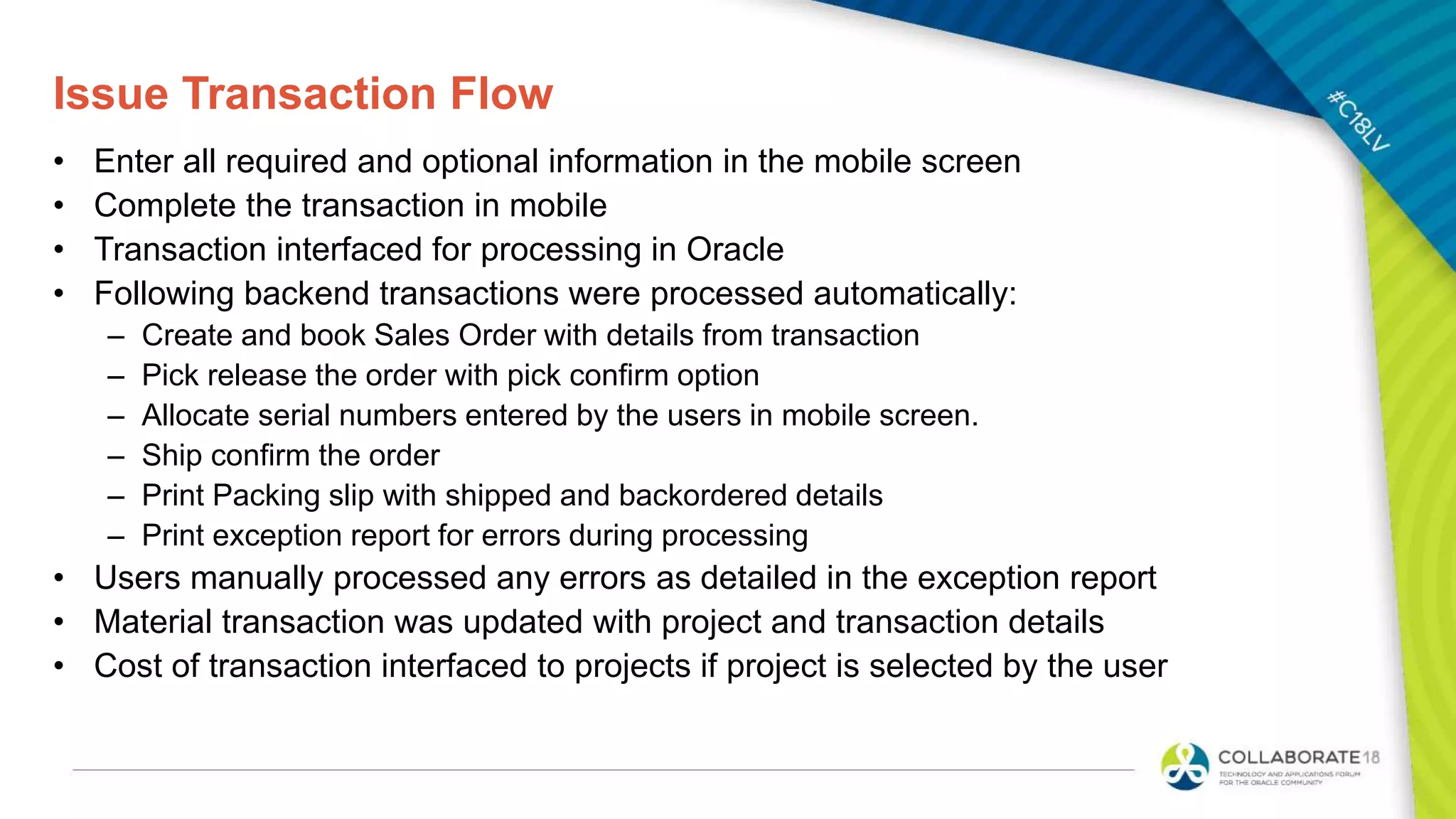

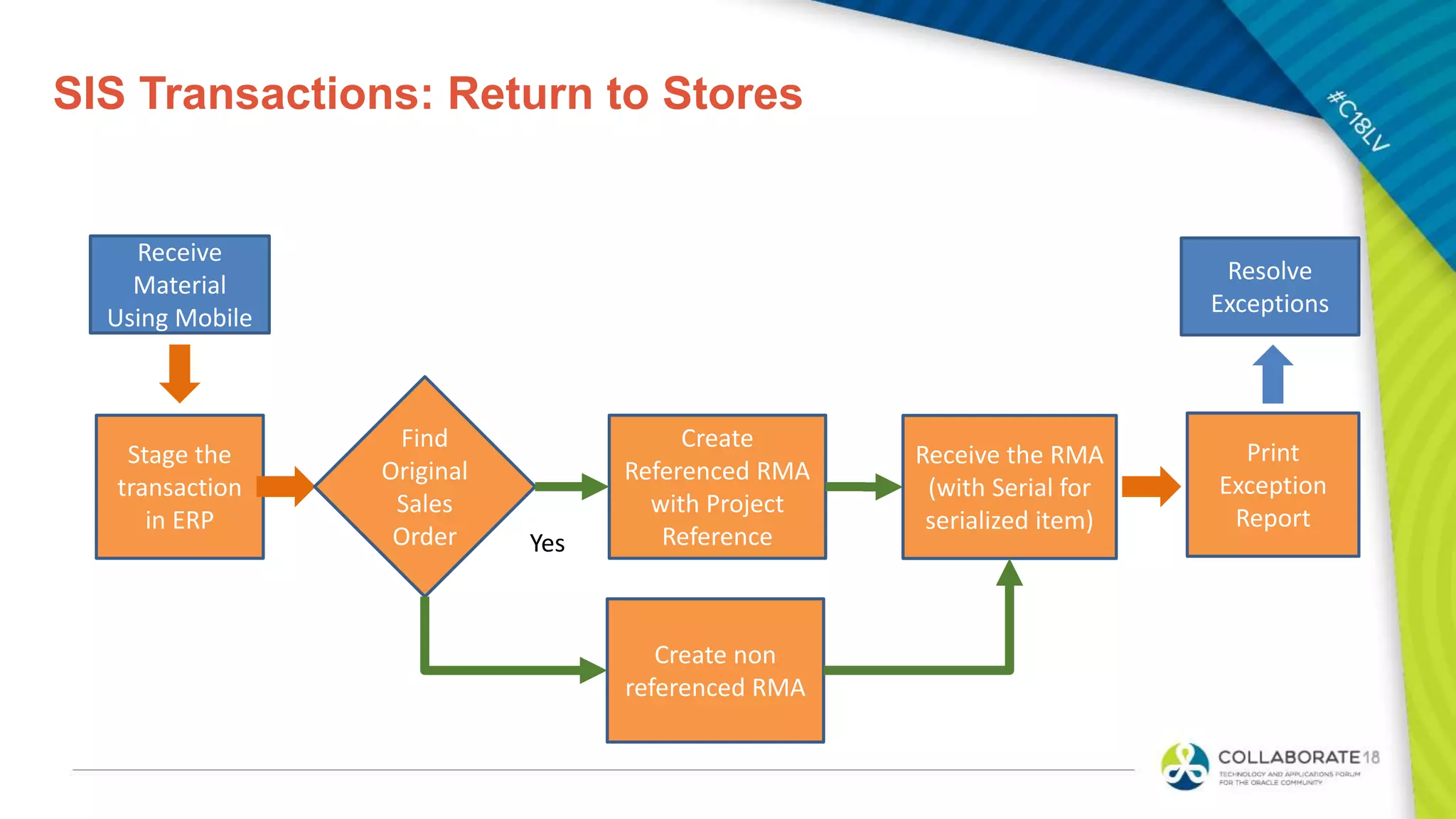

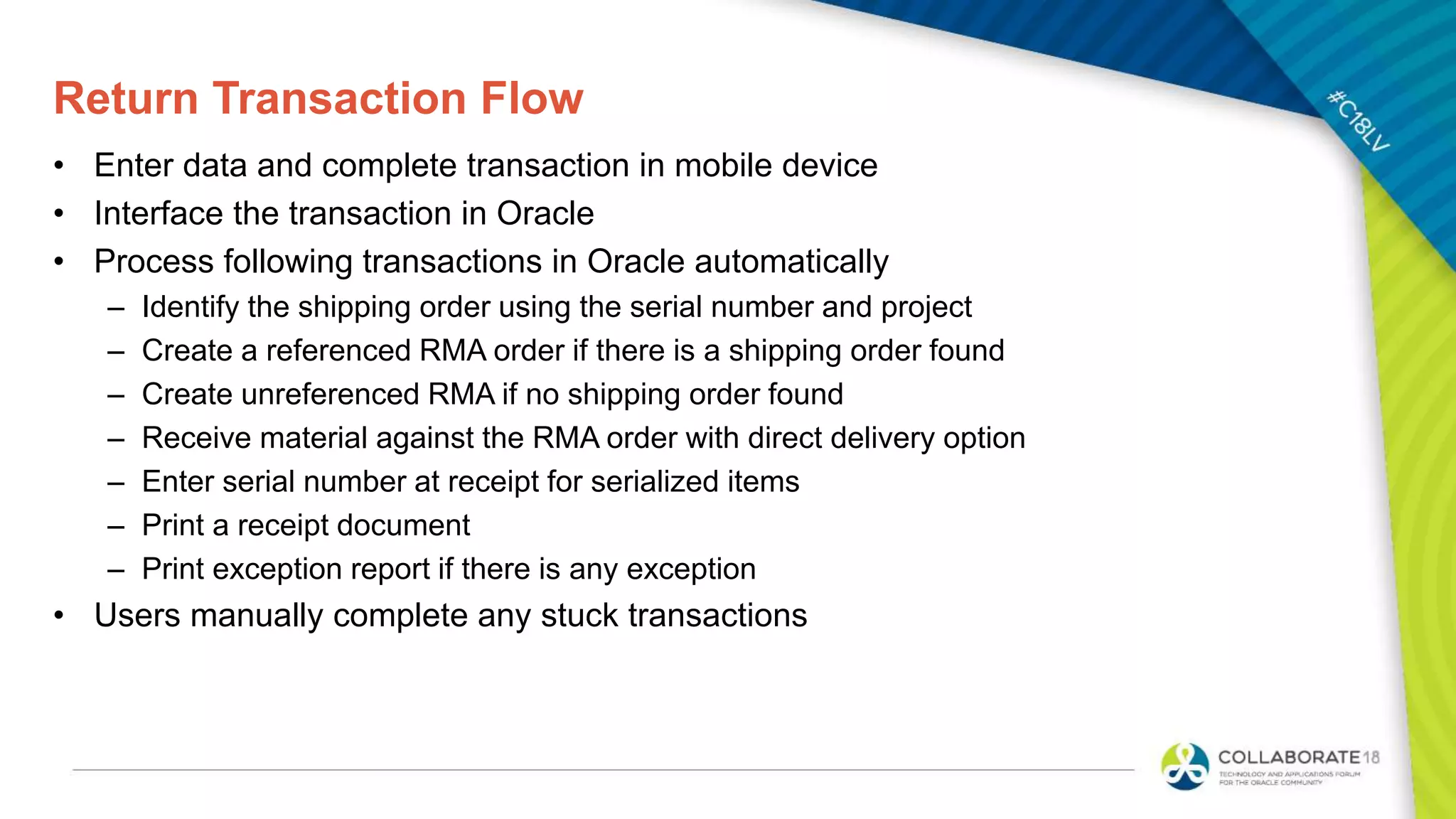

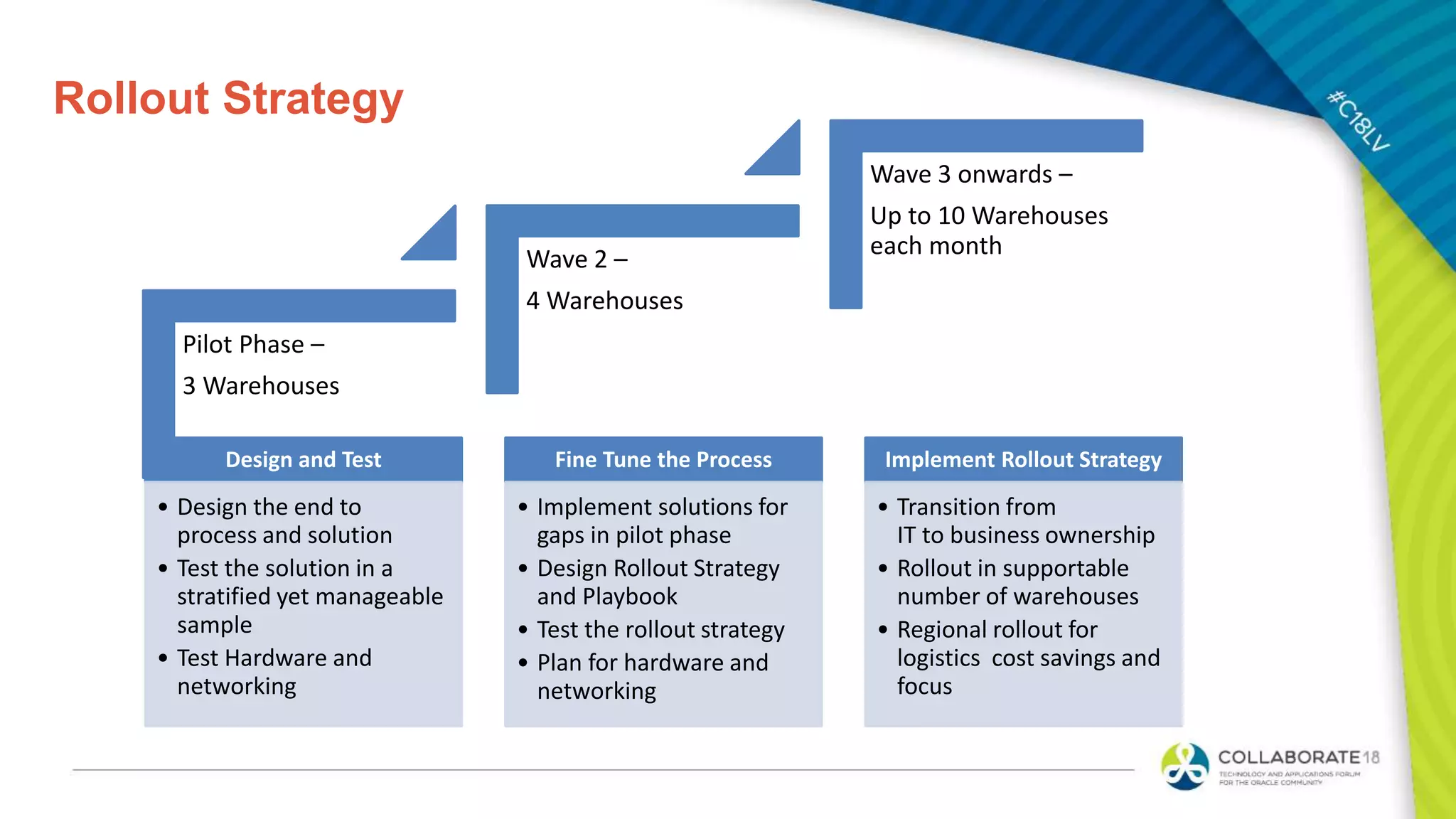

The document outlines a comprehensive plan for implementing a Warehouse Management System (WMS) across over 30 warehouses within 12 months, addressing various business challenges like sub-optimal processes and manual errors. It describes the solution approach, including mobile applications for transactions, automation of shipment processes, and efficient training strategies for new technology adoption. Key lessons learned highlight the importance of wireless infrastructure, training, and effective change management during the rollout phases.