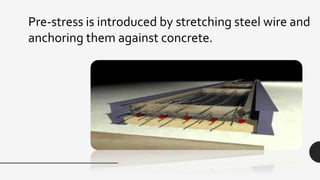

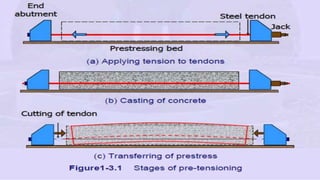

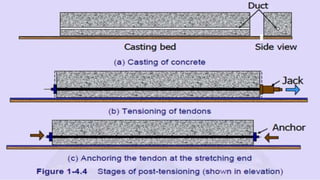

Prestressed concrete and fiber-reinforced concrete are methods to overcome concrete's weakness in tension. Prestressed concrete introduces tension into the concrete before hardening using steel wires stretched between anchors. This tension is then transferred to the concrete through bonding. Fiber-reinforced concrete uses fibers, such as steel, polypropylene or glass, to control cracking from shrinkage and drying. While fibers do not increase flexural strength, prestressed concrete allows for longer beam and floor spans than ordinary reinforced concrete.