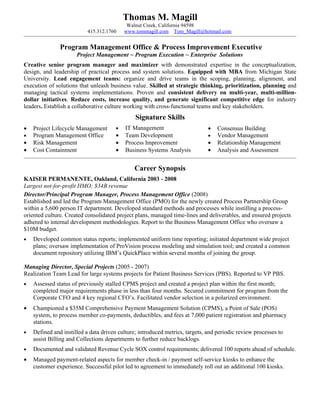

Thomas M. Magill is a senior program manager with over 25 years of experience leading large-scale process improvement and systems implementation projects across multiple industries. He has a proven track record of establishing program management offices, developing standard processes, and delivering multi-million dollar initiatives on time and under budget. His background includes positions at Kaiser Permanente, McKesson Corporation, and Baxter Healthcare where he drove initiatives to optimize operations, reduce costs, improve quality and generate competitive advantages for customers.