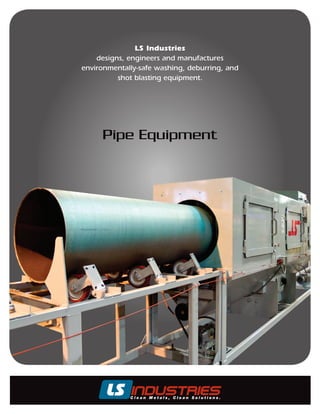

LS Industries designs, engineers, and manufactures environmentally-safe equipment for washing, deburring, and shot blasting metal parts and pipes. This includes complete pipe cleaning systems from small models to large custom designs. LS focuses on dependable construction and providing efficient cleaning and surface preparation for industrial and automotive applications.