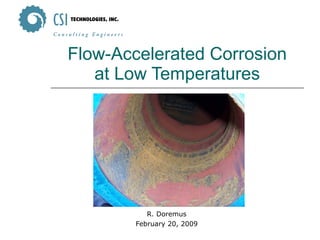

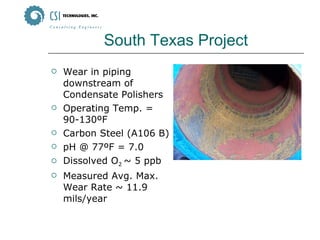

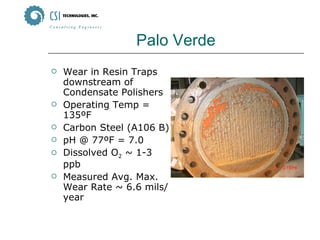

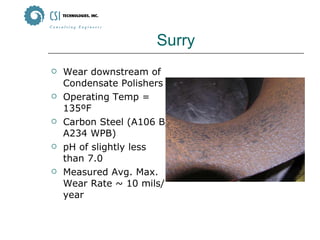

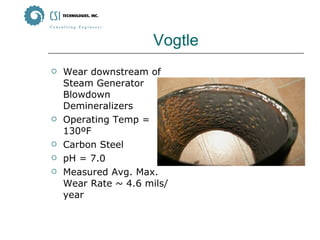

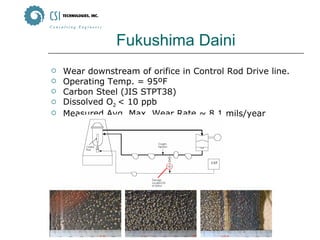

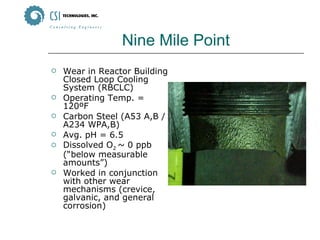

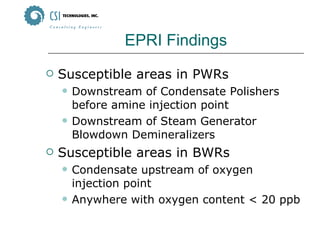

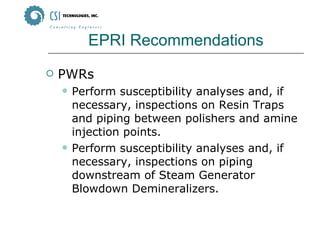

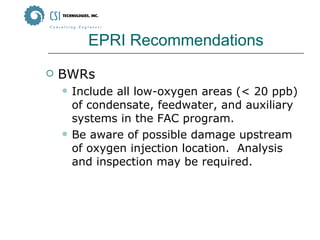

The document defines and discusses the phenomenon of low-temperature flow-accelerated corrosion (FAC), which can occur below 200°F. It summarizes operating experience with low-temperature FAC at several nuclear plants. The Electric Power Research Institute (EPRI) found susceptible areas in pressurized water reactors (PWRs) and boiling water reactors (BWRs) and made recommendations for inspections and analyses. The impact on corrosion susceptibility inspection projects is that piping downstream of condensate filters and demineralizers in PWRs, as well as low-oxygen areas in BWRs, should not be excluded from evaluations due to low temperatures.