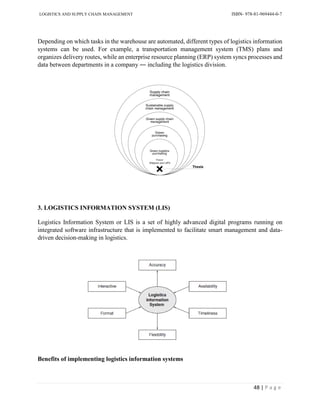

The document discusses the principles and significance of logistics and supply chain management, authored by R. Raja, and outlines various chapters that cover topics such as supply chain concepts, innovations, global perspectives, economic effects, and frameworks of logistics. It emphasizes the importance of efficient coordination, reduced costs, and improved customer satisfaction in supply chain operations. The content aims to raise public awareness and generate discussion about the evolution and impact of supply chains in contemporary business environments.