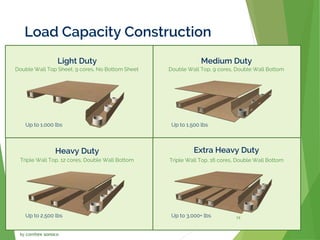

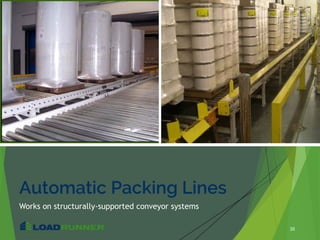

Conitex Sonoco is a global packaging solutions provider recognized for producing corrugated pallets tailored for the textile industry, enhancing the export of spun yarn with no recorded pallet failures since 2006. These pallets are lightweight, recyclable, customizable, and comply with ISPM-15 regulations, providing significant benefits like reduced shipping costs and environmental impact. The company's innovative design includes moisture-resistant technology and capabilities to support heavy loads, positioning it as a leader in sustainable packaging solutions.