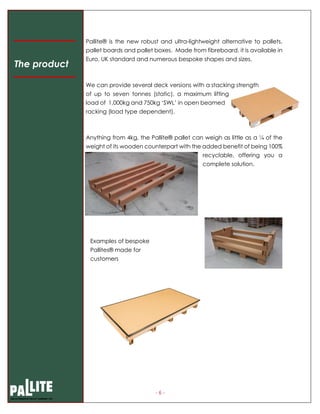

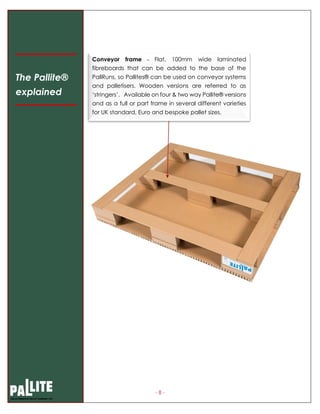

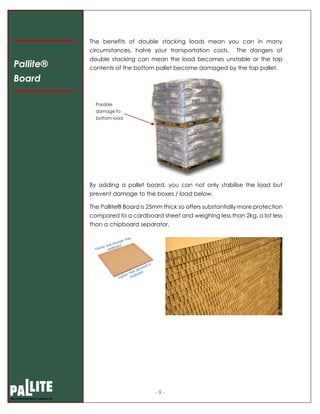

The document introduces Pallite®, a lightweight and recyclable alternative to wood pallets, pallet boards, and collapsible pallet boxes. It summarizes the key benefits of Pallite® including its lighter weight, lack of nails or splinters, recyclability, and strength. The document also provides details on Pallite®'s manufacturing process, testing standards, delivery options, and company background.