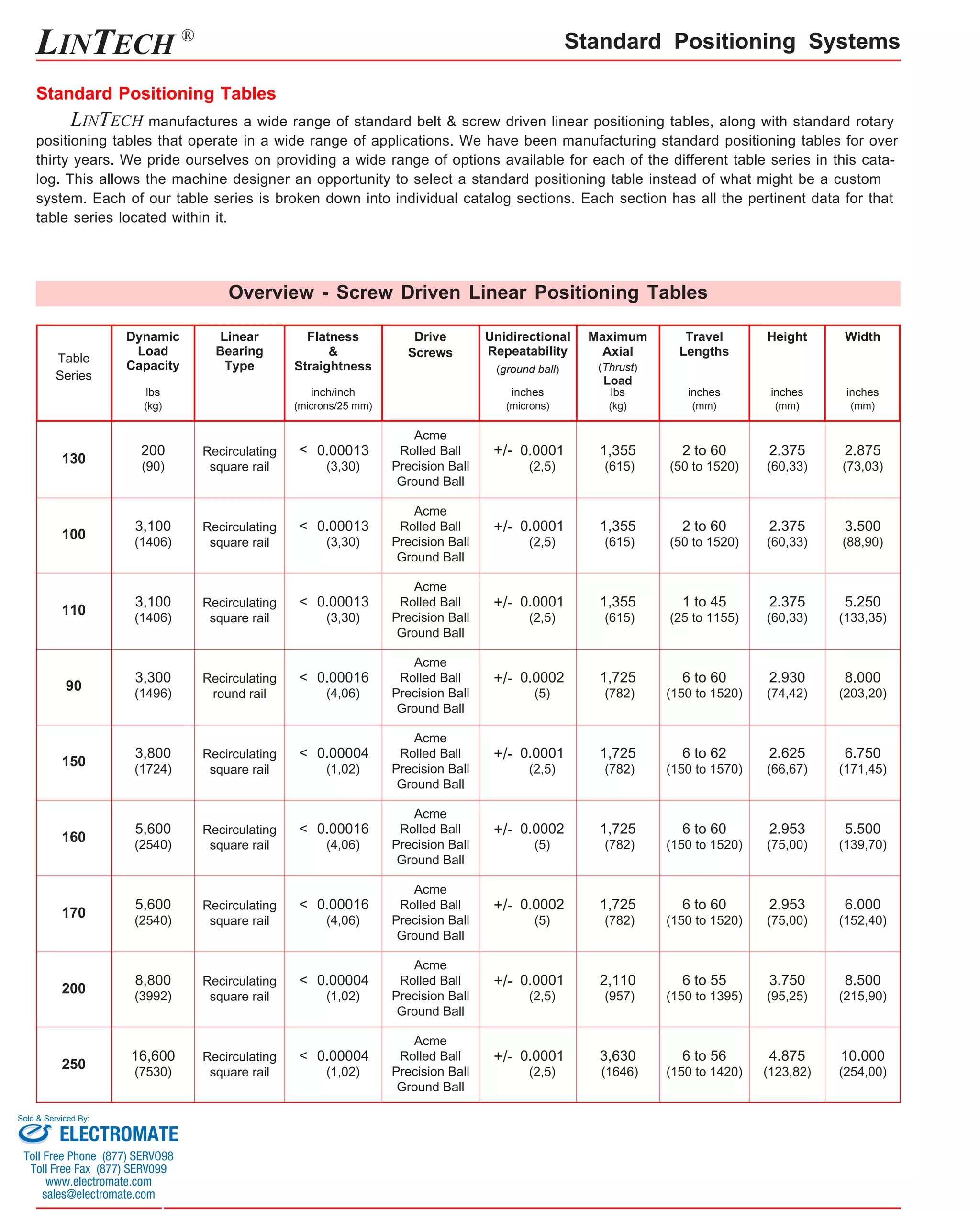

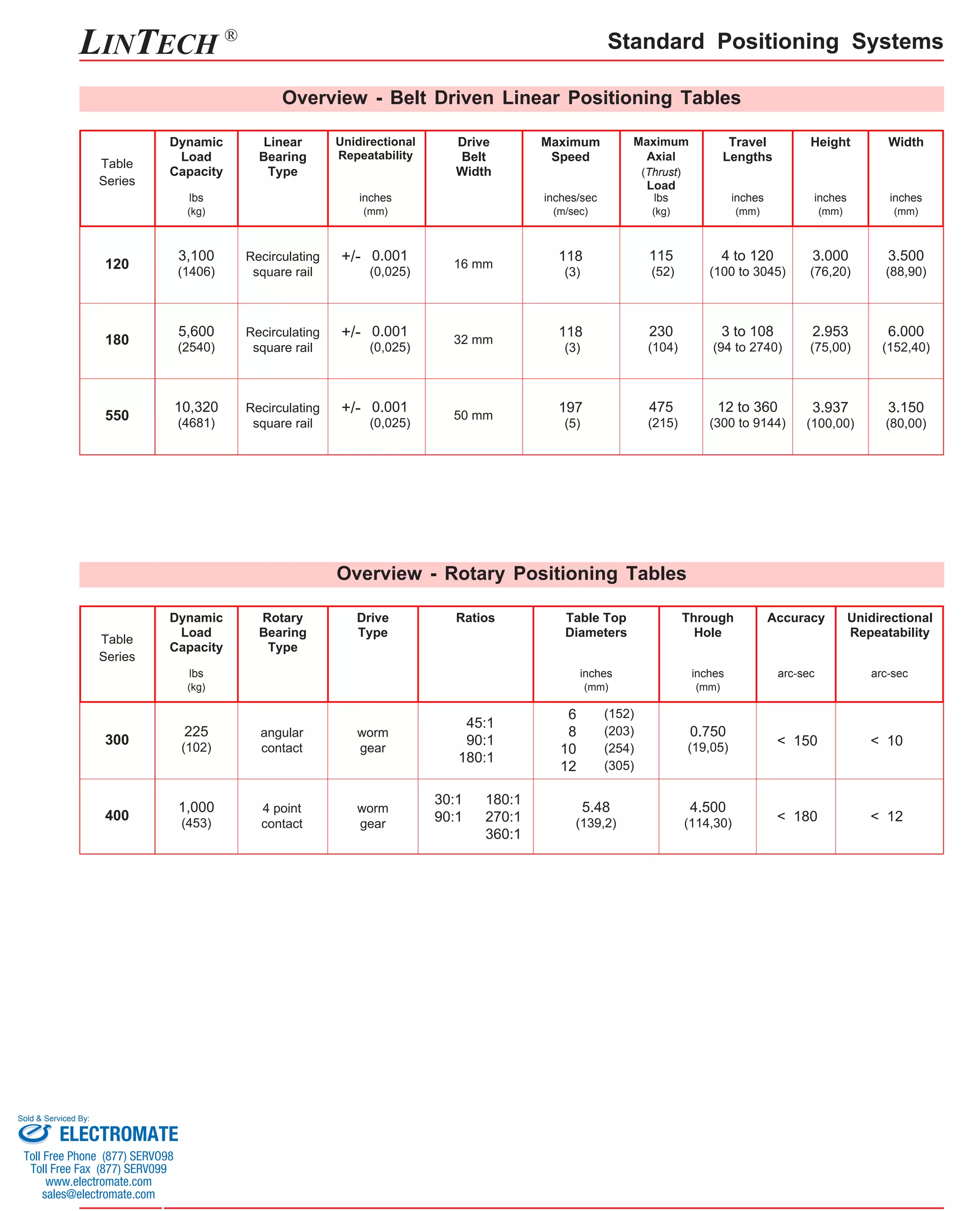

This document provides an overview and specifications for various standard and custom linear and rotary positioning systems manufactured by LINTECH. It includes specifications for several series of belt-driven and screw-driven linear positioning tables with different load capacities, travel lengths, speeds and accuracies. It also lists specifications for rotary positioning tables and provides considerations for selecting the appropriate type of positioning system for an application, such as whether accuracy, speed, load capacity or travel length is prioritized. The document indicates that LINTECH can also design and build custom positioning systems for applications where standard systems do not meet requirements.

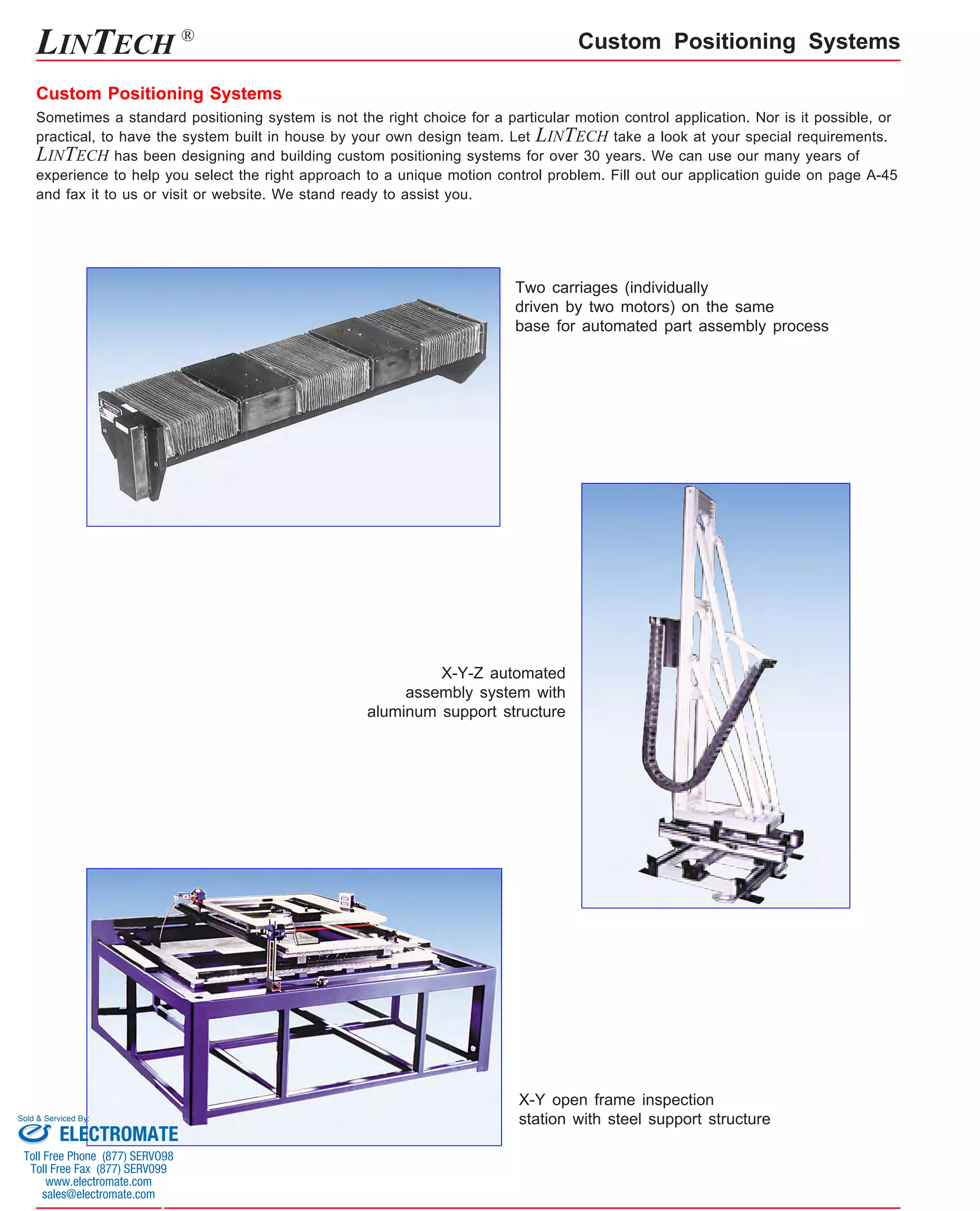

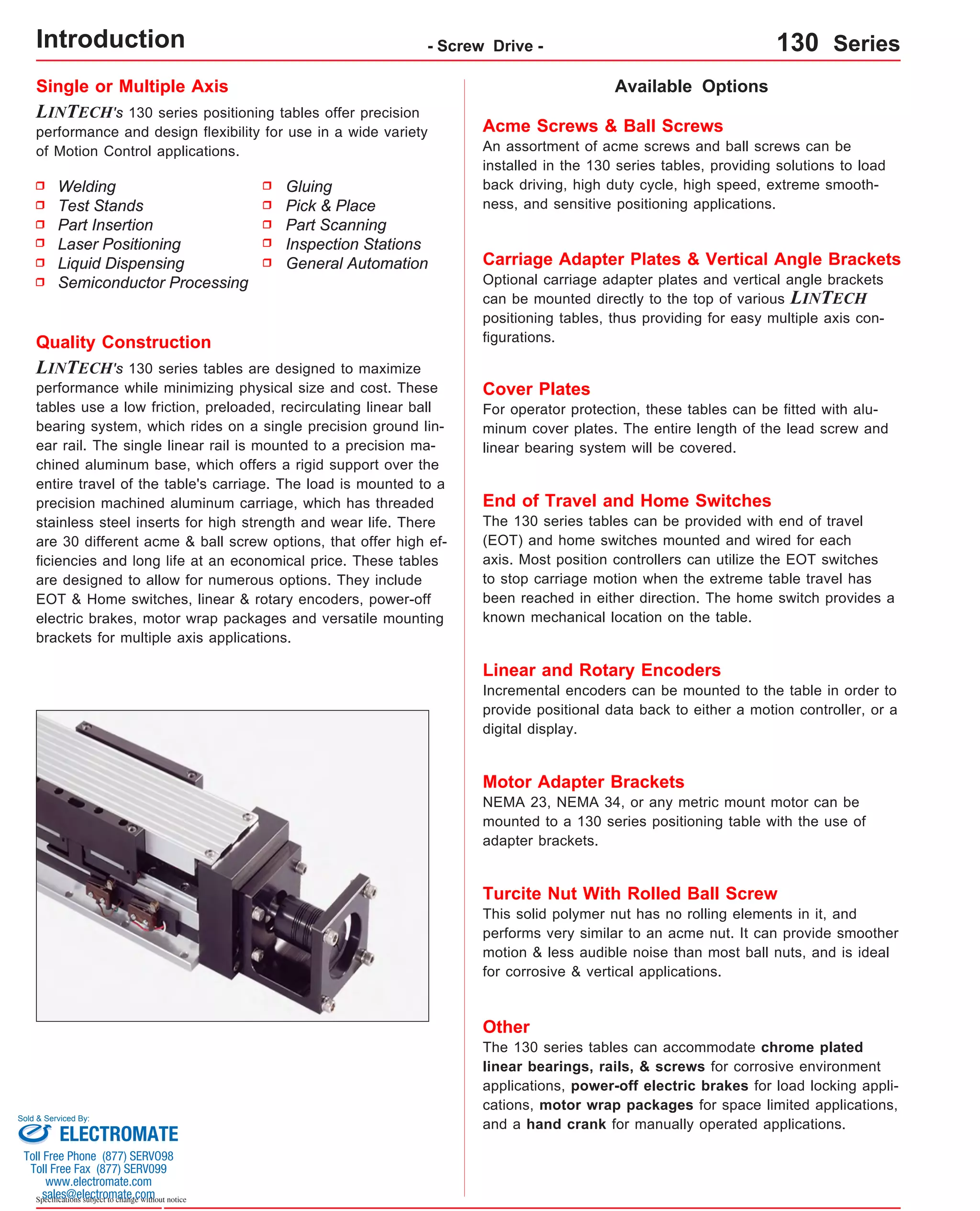

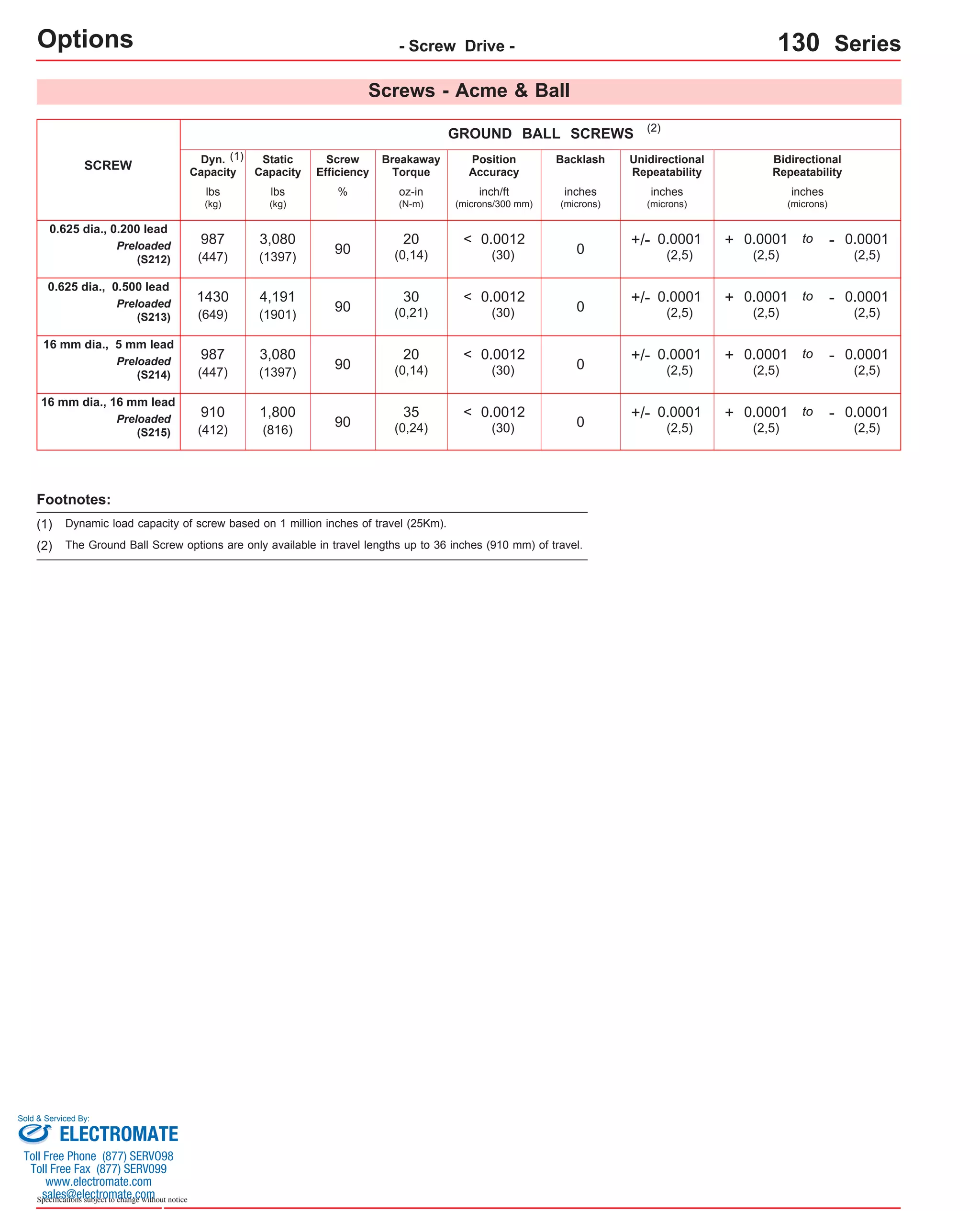

![Technical Reference - Screw Drive - 130-CP0 Series

- Without Cover Plates -

Mounting Dimensions

inches

(mm)

Dimensions & Specifications

Table Dimensions

inches

(mm)

Travel

Length

Screw

Length

inches

(mm)

9.25

(235)

Table

Weight

Model

Number lbs

(kg)

C

4.8

inches

(mm)

A

6.0

(152,4)

B

9.875

(250,8)

0.188

(4,8)

E M

13x402-CP0 3

8

(2,2)

11.875

(301,6)

1.188

(30,2) 8 11.25

13.875

(352,4)

0.313

(8,0) 12 13.25

15.875

(403,2)

1.313

(33,4) 12 15.25

19.875

(504,8)

1.438

(36,5) 16 19.25

23.875

(606,4)

1.563

(39,7) 20 23.25

27.875

(708,0)

1.688

(42,9) 24 27.25

31.875

(809,6)

1.813

(46,1) 28 31.25

37.875

(962,0)

1.063

(27,0) 36 37.25

43.875

(1114,4)

0.313

(8,0) 44 43.25

49.875

(1266,8)

1.438

(36,5) 48 49.25

55.875

(1419,2)

0.688

(17,5) 56 55.25

61.875

(1571,6)

1.813

(46,1) 60 61.25

67.875

(1724,0)

1.063

(27,0) 68 67.25

x = 1; Carriage has 1 bearing; Carriage weight = 1.1 lbs. (0,50 kg)

x = 2; Carriage has 2 bearings; Carriage weight = 1.2 lbs. (0,55 kg)

(1)

Footnotes:

(1) Weight shown is with a 0.625 inch (16 mm) diameter screw, a 1 bearing carriage [1.1 lbs (0,55 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a C100

style [0.09 lbs (0,04 kg)] coupling. When using a 0.500 inch diameter screw subtract 0.022 lbs per inch (0,00039 kg per mm) of screw length for a given model

number. When using a 2 bearing carriage add 0.1 lbs (0,05 kg) to each value.

Sold & Serviced By:

Specifications subject to change without notice

5.3

13x404-CP0 8.0

(203,2)

3 (286)

(2,4) 2

(50)

4

(100)

5.8

13x406-CP0 6

10.0

(150)

(254,0)

5 (337) (2,6) 6.3

13x408-CP0 8

12.0

(200)

(304,8)

5 (387) (2,9) 7.3

13x412-CP0 12

16.0

(300)

(406,4)

7 (489) (3,3) 8.3

13x416-CP0 16

20.0

(405)

(508,0)

9 (591) (3,8) 9.3

13x420-CP0 20

24.0

(505)

(609,6)

11 (692) (4,2) 10.3

13x424-CP0 24

28.0

(605)

(711.2)

13 (794) (4,7) 11.8

13x430-CP0 30

34.0

(760)

(863,6)

17 (946) (5,4) 13.3

13x436-CP0 36

40.0

(910)

(1016,0)

21 (1099) (6,0) 14.8

13x442-CP0 42

46.0

(1060)

(1168,4)

23 (1251) (6,7) 16.3

13x448-CP0 48

52.0

(1215)

(1320,8)

27 (1403) (7,4) 17.8

13x454-CP0 54

58.0

(1370)

(1473,2)

29 (1556) (8,1) 19.3

13x460-CP0 60

64.0

(1520)

(1625,6)

33 (1708) (8,8) version: 01/2014

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-61-2048.jpg)

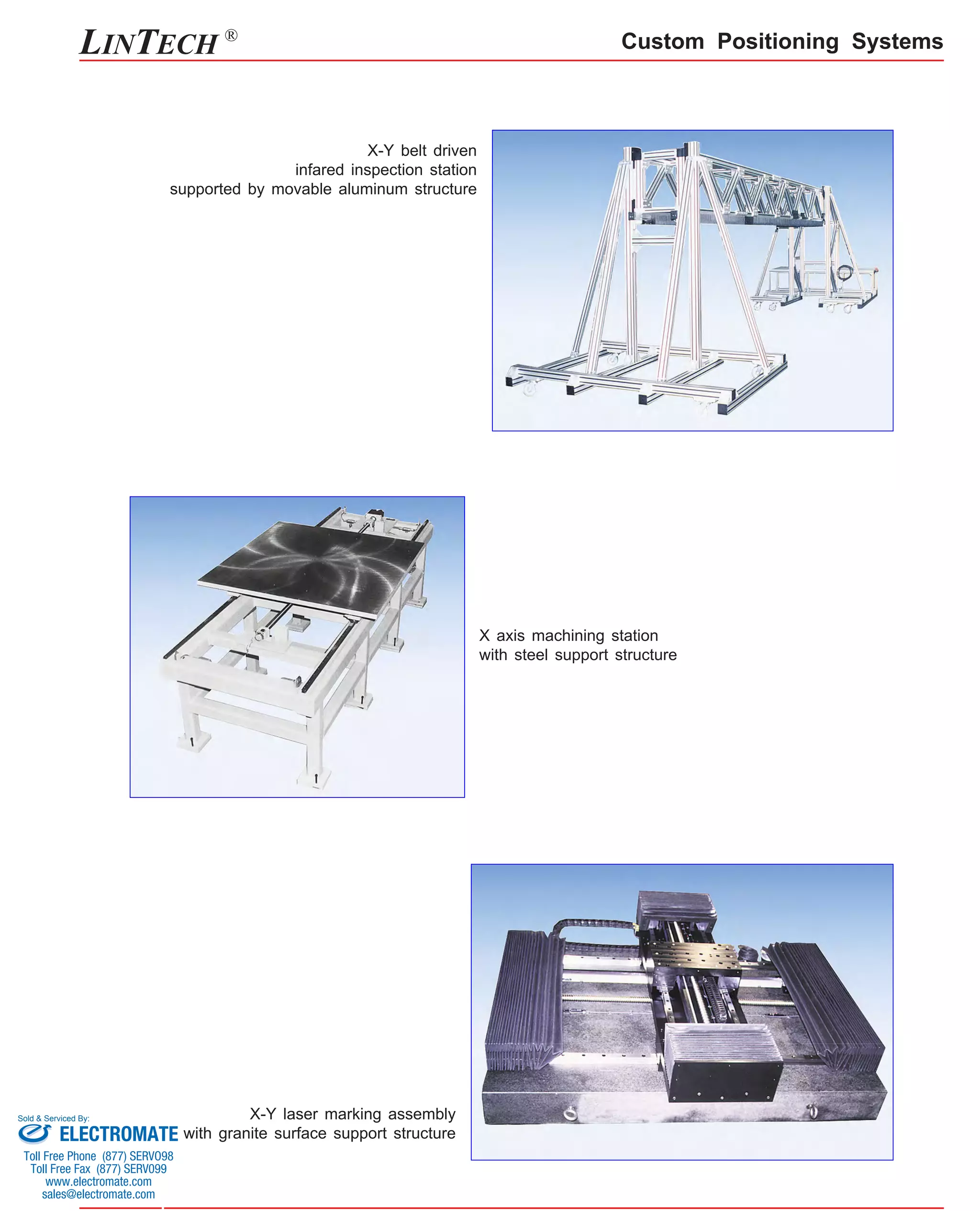

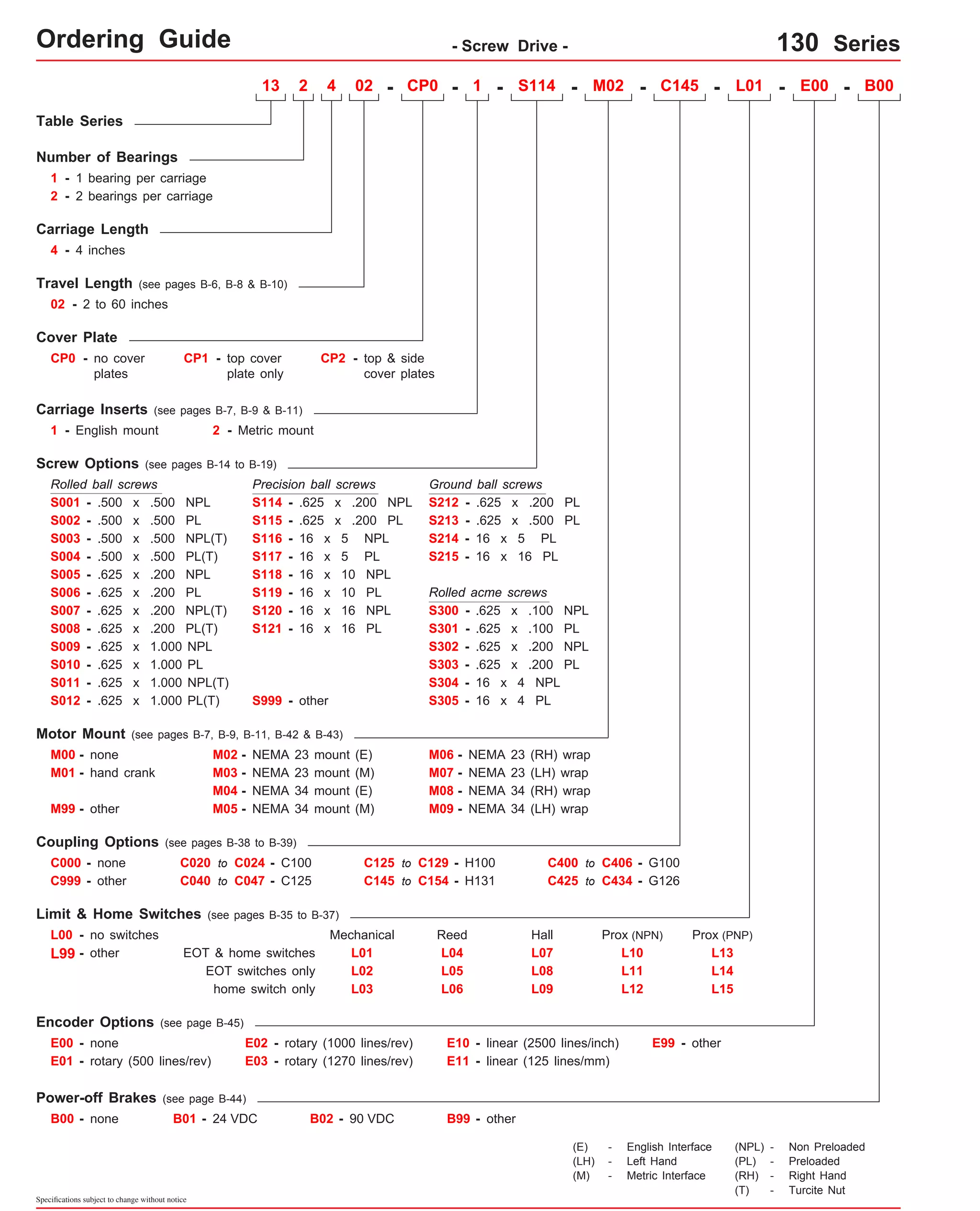

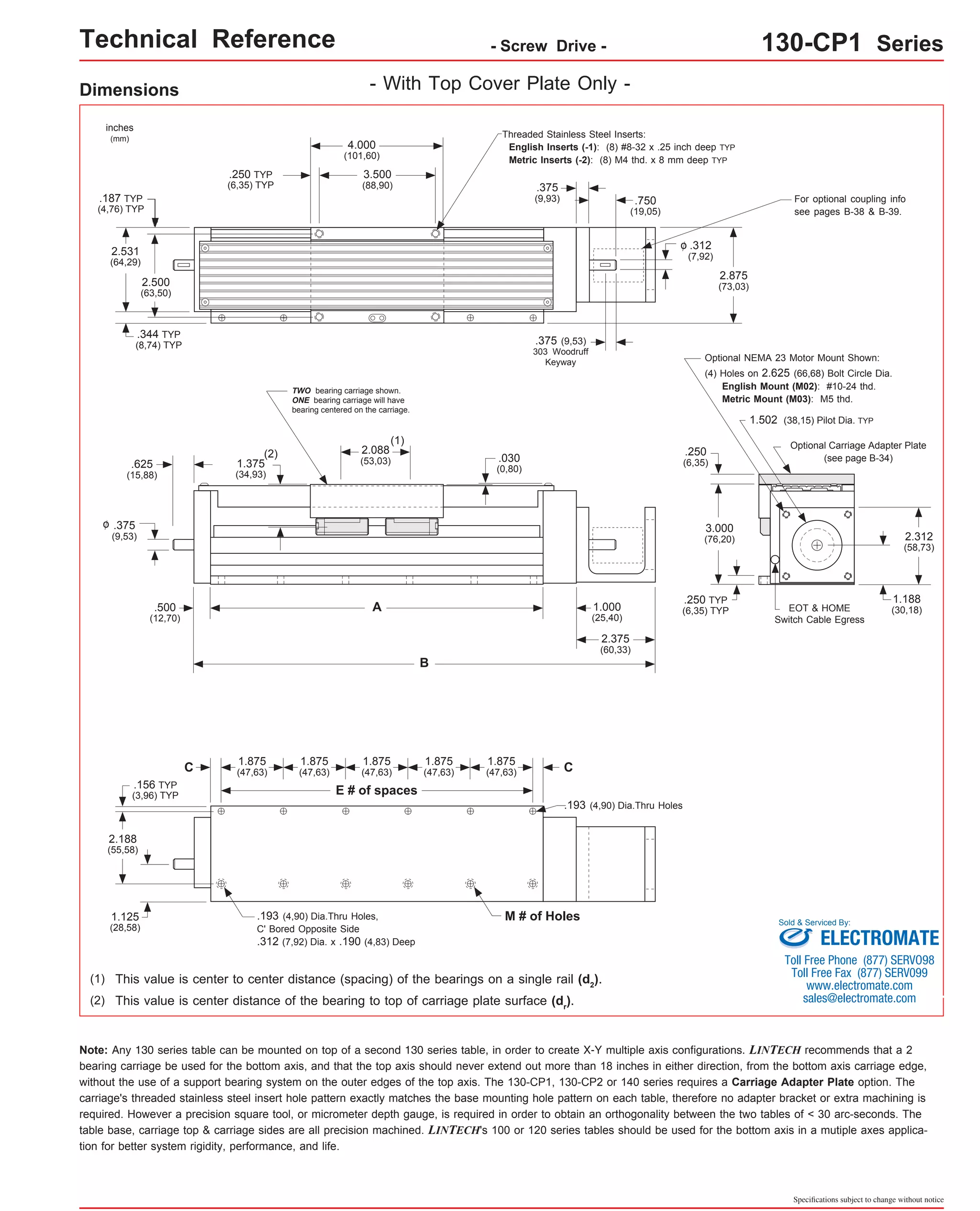

![Technical Reference - Screw Drive - 130-CP1 Series

Dimensions & Specifications

Travel

Length

Table Dimensions

Model

Number lbs

(kg)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

5.5

inches

(mm)

A

6.0

(152,4)

B

9.875

(250,8)

0.188

(4,8)

E M

13x402-CP1 8

(2,5)

Screw

Length

inches

(mm)

9.25

(235)

Table

Weight

13x404-CP1 (2,8) 8.0

13x406-CP1 (3,1) 10.0

13x408-CP1 (3,4) 12.0

13x412-CP1 (4,0) 16.0

13x416-CP1 (4,5) 20.0

13x420-CP1 (5,1) 24.0

13x424-CP1 (5,7) 28.0

13x430-CP1 (6,6) 34.0

13x436-CP1 (7,5) 40.0

13x442-CP1 (8,4) 46.0

13x448-CP1 (9,3) 52.0

13x454-CP1 (10,1) 58.0

13x460-CP1 (11,0) 64.0

x = 1; Carriage has 1 bearing; Carriage weight = 1.4 lbs. (0,64 kg)

x = 2; Carriage has 2 bearings; Carriage weight = 1.5 lbs. (0,68 kg)

(1)

3

6.2

(203,2)

11.875

(301,6)

1.188

3 8 11.25

(30,2) (286)

2

(50)

4

(100)

6.8

(254,0)

13.875

(352,4)

0.313

(8,0) 12 13.25

5 (337) 6

(150)

7.4

(304,8)

15.875

(403,2)

1.313

(33,4) 12 15.25

5 (387) 8

(200)

8.8

(406,4)

19.875

(504,8)

1.438

(36,5) 16 19.25

7 (489) 12

(300)

10.0

(508,0)

23.875

(606,4)

1.563

(39,7) 20 23.25

9 (591) 16

(405)

11.3

(609,6)

27.875

(708,0)

1.688

(42,9) 24 27.25

11 (692) 20

(505)

12.6

(711.2)

31.875

(809,6)

1.813

(46,1) 28 31.25

13 (794) 24

(605)

14.6

(863,6)

37.875

(962,0)

1.063

(27,0) 36 37.25

17 (946) 30

(760)

16.5

(1016,0)

43.875

(1114,4)

0.313

(8,0) 44 43.25

21 (1099) 36

(910)

18.4

(1168,4)

49.875

(1266,8)

1.438

(36,5) 48 49.25

23 (1251) 42

(1060)

20.4

(1320,8)

55.875

(1419,2)

0.688

(17,5) 56 55.25

27 (1403) 48

(1215)

22.3

(1473,2)

61.875

(1571,6)

1.813

(46,1) 60 61.25

29 (1556) 54

(1370)

24.3

(1625,6)

67.875

(1724,0)

1.063

(27,0) 68 67.25

33 (1708) 60

(1520)

Sold & Serviced By:

Specifications subject to change without notice

- With Top Cover Plate Only -

Footnotes:

(1) Weight shown is with a 0.625 inch (16 mm) diameter screw, a 1 bearing carriage [1.1 lbs (0,55 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a

C100 style [0.09 lbs (0,04 kg)] coupling. When using a 0.500 inch diameter screw subtract 0.022 lbs per inch (0,00039 kg per mm) of screw length for a

given model number. When using a 2 bearing carriage add 0.1 lbs (0,05 kg) to each value.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-63-2048.jpg)

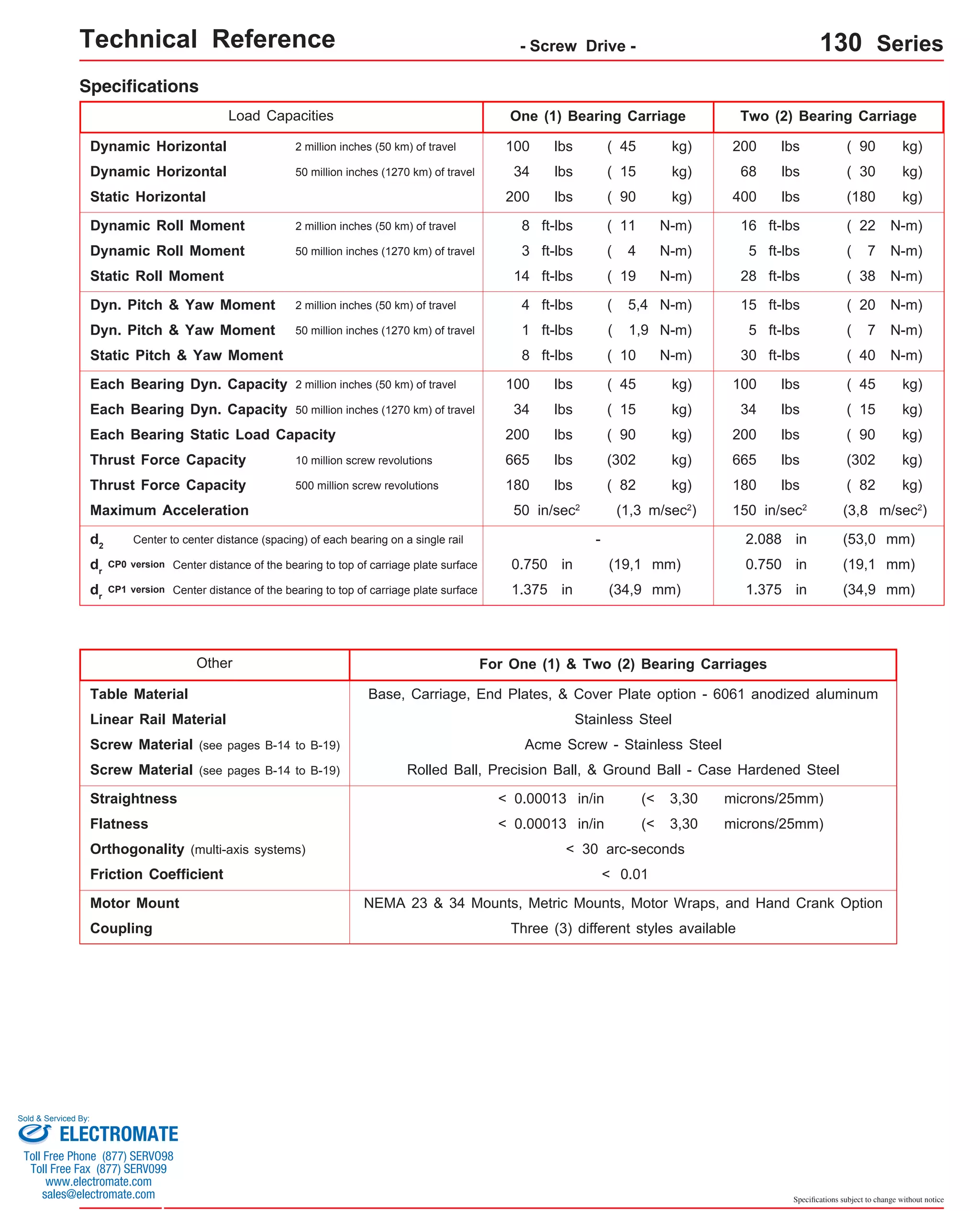

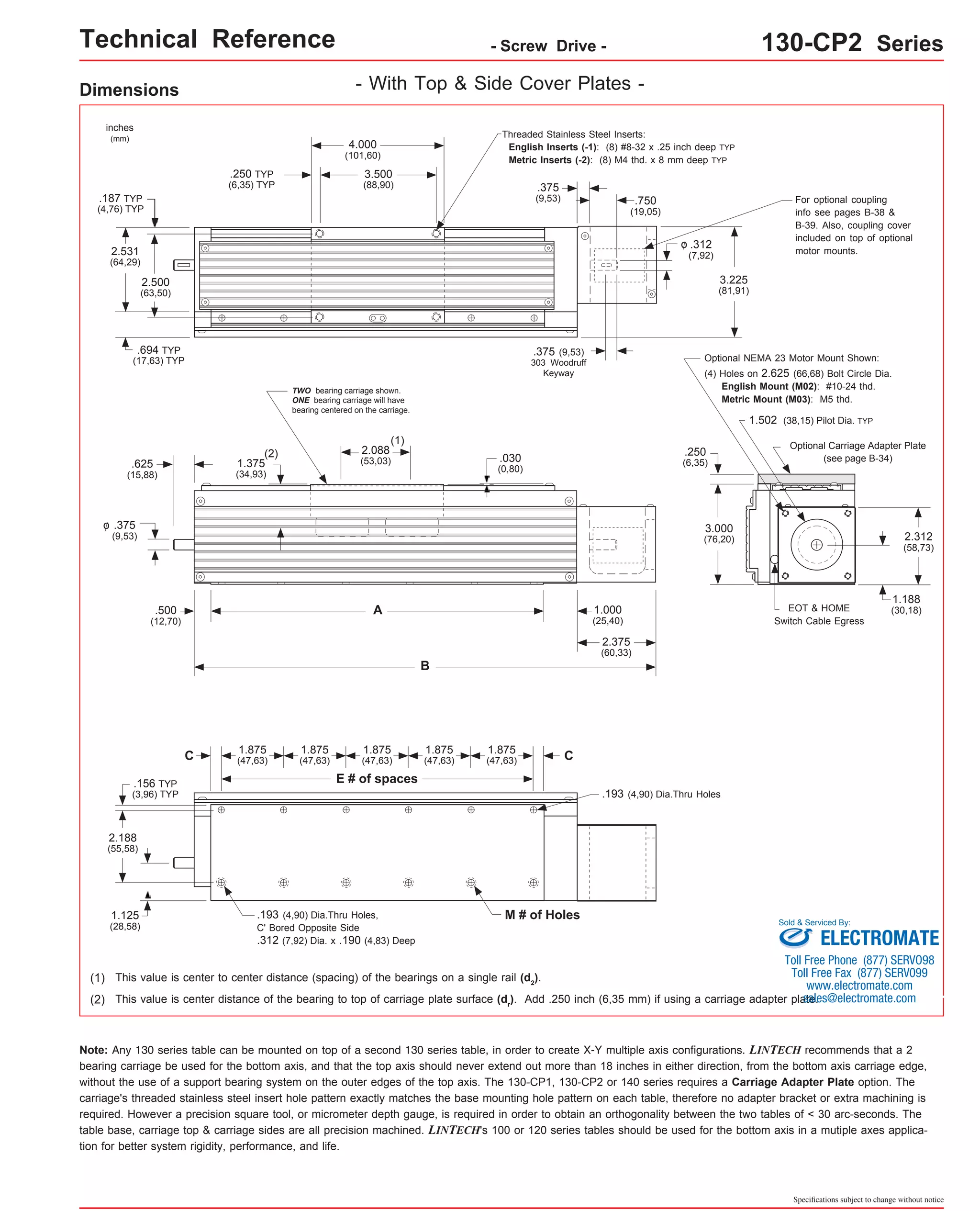

![Technical Reference - Screw Drive - 130-CP2 Series

Dimensions & Specifications

Travel

Length

Table Dimensions

Model

Number lbs

(kg)

5.7

(2,58)

6.4

(2,90)

7.0

(3,17)

7.6

(3,45)

9.1

(4,13)

10.4

(4,72)

11.7

(5,31)

13.1

(5,94)

15.1

(6,85)

17.1

(7,76)

19.1

(8,66)

21.2

(9,62)

23.2

(10,52)

25.3

(11,47)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

13x402-CP2

inches

(mm)

A

6.0

(152,4)

B

9.875

(250,8)

0.188

(4,8)

E M

8

Screw

Length

inches

(mm)

9.25

(235)

Table

Weight

x = 1; Carriage has 1 bearing; Carriage weight = 1.4 lbs. (0,64 kg)

x = 2; Carriage has 2 bearings; Carriage weight = 1.5 lbs. (0,68 kg)

(1)

3

13x404-CP2 8.0

(203,2)

11.875

(301,6)

1.188

3 8 11.25

(30,2) (286)

2

(50)

4

(100)

13x406-CP2 10.0

(254,0)

13.875

(352,4)

0.313

(8,0) 12 13.25

5 (337) 6

(150)

13x408-CP2 12.0

(304,8)

15.875

(403,2)

1.313

(33,4) 12 15.25

5 (387) 8

(200)

13x412-CP2 16.0

(406,4)

19.875

(504,8)

1.438

(36,5) 16 19.25

7 (489) 12

(300)

13x416-CP2 20.0

(508,0)

23.875

(606,4)

1.563

(39,7) 20 23.25

9 (591) 16

(405)

13x420-CP2 24.0

(609,6)

27.875

(708,0)

1.688

(42,9) 24 27.25

11 (692) 20

(505)

13x424-CP2 28.0

(711.2)

31.875

(809,6)

1.813

(46,1) 28 31.25

13 (794) 24

(605)

13x430-CP2 34.0

(863,6)

37.875

(962,0)

1.063

(27,0) 36 37.25

17 (946) 30

(760)

13x436-CP2 40.0

(1016,0)

43.875

(1114,4)

0.313

(8,0) 44 43.25

21 (1099) 36

(910)

13x442-CP2 46.0

(1168,4)

49.875

(1266,8)

1.438

(36,5) 48 49.25

23 (1251) 42

(1060)

13x448-CP2 52.0

(1320,8)

55.875

(1419,2)

0.688

(17,5) 56 55.25

27 (1403) 48

(1215)

13x454-CP2 58.0

(1473,2)

61.875

(1571,6)

1.813

(46,1) 60 61.25

29 (1556) 54

(1370)

13x460-CP2 64.0

(1625,6)

67.875

(1724,0)

1.063

(27,0) 68 67.25

33 (1708) 60

(1520)

Sold & Serviced By:

Specifications subject to change without notice

- With Top & Side Cover Plates -

Footnotes:

(1) Weight shown is with a 0.625 inch (16 mm) diameter screw, a 1 bearing carriage [1.1 lbs (0,55 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a

C100 style [0.09 lbs (0,04 kg)] coupling. When using a 0.500 inch diameter screw subtract 0.022 lbs per inch (0,00039 kg per mm) of screw length for a

given model number. When using a 2 bearing carriage add 0.1 lbs (0,05 kg) to each value.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-65-2048.jpg)

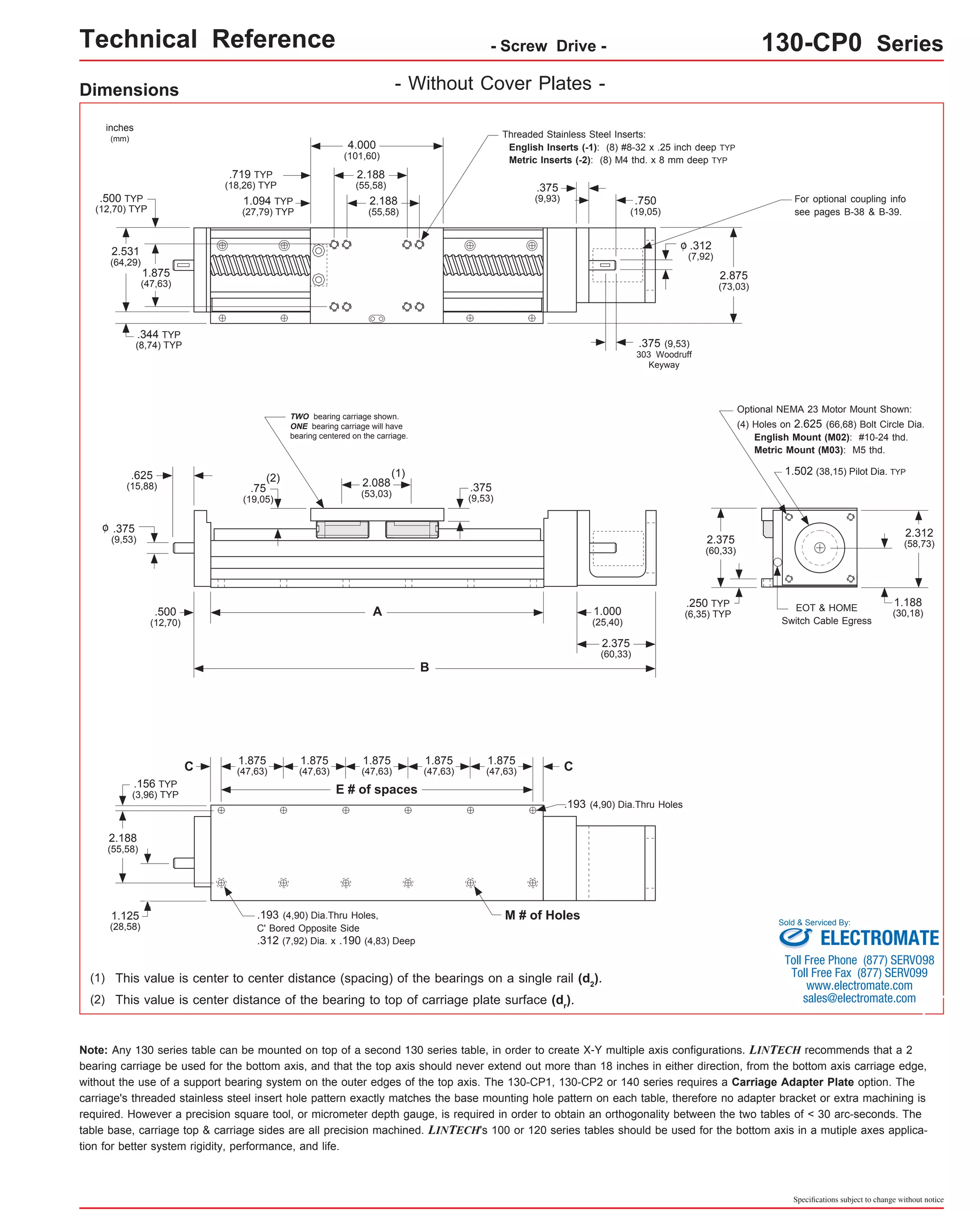

![Technical Reference - Belt Drive - 140-CP0 Series

Mounting Dimensions

inches

(mm)

Table Dimensions

inches

(mm)

Travel

Length

Table

Weight

Model

Number lbs

14x4004-CP0

14x4006-CP0

Footnotes:

(1)

- Without Cover Plates -

Belt

Weight

ounces

(gm)

1.3

(36,8)

B C

E M

inches

(mm)

A

4

8.0

14.0

1.188

(100)

(203,2)

(355,6)

(30,2) 3 8 6

10.0

16.0

0.313

(150)

(254,0)

(406,4)

(8,0) 5 12 8

12.0

18.0

1.313

(200)

(304,8)

(457,2)

(33,4) 5 12 12

16.0

22.0

1.438

(300)

(406,4)

(558,8)

(36,5) 7 16 16

20.0

26.0

1.563

(405)

(508,0)

(660,4)

(39,7) 9 20 20

24.0

30.0

1.688

(505)

(609,6)

(762,0)

(42,9) 11 24 24

28.0

34.0

1.813

(605)

(711.2)

(863,6)

(46,1) 13 28 30

34.0

40.0

1.063

(760)

(863,6)

(1016,0)

(27,0) 17 36 36

40.0

46.0

0.313

(910)

(1016,0)

(1168,4)

(8,0) 21 44 42

46.0

52.0

1.438

(1060)

(1168,4)

(1320,8)

(36,5) 23 48 48

52.0

58.0

0.688

(1215)

(1320,8)

(1473,2)

(17,5) 27 56 54

58.0

64.0

1.813

(1370)

(1473,2)

(1625,6)

(46,1) 29 60 60

64.0

70.0

1.063

(1520)

(1625,6)

(1778,0)

(27,0) 33 68 76.0

(1930,4)

82.0

(2082,8)

72

(1820)

88.0

(2235,2)

94.0

(2387,6)

84

(2130)

100.0

(2540,0)

106.0

(2692,4)

96

(2435)

112.0

(2844,8)

118.0

(2997,2)

108

(2740)

124.0

(3149,6)

130.0

(3302,0)

120

(3045)

39 80

45 92

51 104

57 116

63 128

0.500

(12,7)

0.875

(22,2)

0.313

(8,0)

0.688

(17,5)

1.063

(27,0)

x = 1; Carriage has 1 bearing; Carriage weight = 1.4 lbs. (0,64 kg)

x = 2; Carriage has 2 bearings; Carriage weight = 1.5 lbs. (0,68 kg)

Specifications subject to change without notice

1.5

(42,5)

14x4008-CP0

1.7

(48,2)

Dimensions & Specifications

14x4012-CP0

2.1

(59,5)

14x4016-CP0

2.5

(70,9)

14x4020-CP0

2.9

(82,2)

14x4024-CP0

3.3

(93,6)

14x4030-CP0

3.9

(110,6)

14x4036-CP0

4.5

(127,6)

14x4042-CP0

5.1

(144,6)

14x4084-CP0

9.3

(263,7)

14x4096-CP0

10.5

(297,7)

14x4108-CP0

11.7

(331,7)

14x4120-CP0 12.9

(365,7)

14x4048-CP0

5.7

(161,6)

14x4054-CP0

6.3

(178,6)

14x4060-CP0

6.9

(195,6)

14x4072-CP0

8.1

(229,6)

(kg)

4.8

(2,2)

(1)

5.3

(2,4)

5.8

(2,6)

6.3

(2,9)

7.3

(3,3)

8.3

(3,8)

9.3

(4,2)

10.3

(4,7)

11.8

(5,4)

13.3

(6,0)

14.8

(6,7)

16.3

(7,4)

17.8

(8,1)

20.8

(9,4)

23.8

(10,8)

26.8

(12,2)

29.8

(13,5)

32.8

(14,9)

Sold & Serviced By:

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Weight shown is with a 1 bearing carriage [1.4 lbs (0,64 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a H100 style [0.08 lbs (0,04 kg)] coupling.

When using a 2 bearing carriage add 0.1 lbs (0,04 kg) to each value.

ELECTROMATE

version: 01/2014](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-79-2048.jpg)

![Technical Reference - Belt Drive - 140-CP1 Series

Dimensions & Specifications

Travel

Length

Table Dimensions

Model

Number lbs

1.188

(30,2) 3 8 4

(100)

14x4006-CP1 1.5

1.438

(36,5) 23 48 42

(1060)

0.688

(17,5) 27 56 48

(1215)

1.813

(46,1) 29 60 54

(1370)

1.063

(27,0) 33 68 60

(1520)

Sold & Serviced By:

Specifications subject to change without notice

- With Top Cover Plate Only -

14x4004-CP1

Belt

Weight

ounces

(gm)

1.3

(36,8)

0.313

(8,0) 5 12 6

(150)

1.313

(33,4) 5 12 8

(200)

1.438

(36,5) 7 16 12

(300)

1.563

(39,7) 9 20 16

(405)

1.688

(42,9) 11 24 20

(505)

1.813

(46,1) 13 28 24

(605)

1.063

(27,0) 17 36 30

(760)

0.313

(8,0) 21 44 36

(910)

x = 1; Carriage has 1 bearing; Carriage weight = 1.4 lbs. (0,64 kg)

x = 2; Carriage has 2 bearings; Carriage weight = 1.5 lbs. (0,68 kg)

(42,5)

14x4008-CP1 1.7

(48,2)

14x4012-CP1 2.1

(59,5)

14x4016-CP1 2.5

(70,9)

14x4020-CP1 2.9

(82,2)

14x4024-CP1 3.3

(93,6)

14x4030-CP1 3.9

(110,6)

14x4036-CP1 4.5

(127,6)

14x4042-CP1 5.1

(144,6)

14x4048-CP1 5.7

(161,6)

14x4054-CP1 6.3

(178,6)

14x4060-CP1 6.9

(195,6)

(kg)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

4.8

(2,2)

inches

(mm)

A

B E M

Table

Weight

(1)

5.3

(2,4)

8.0

(203,2)

14.0

(355,6)

5.8

(2,6)

10.0

(254,0)

16.0

(406,4)

6.3

(2,9)

12.0

(304,8)

18.0

(457,2)

7.3

(3,3)

16.0

(406,4)

22.0

(558,8)

8.3

(3,8)

20.0

(508,0)

26.0

(660,4)

9.3

(4,2)

24.0

(609,6)

30.0

(762,0)

10.3

(4,7)

28.0

(711.2)

34.0

(863,6)

11.8

(5,4)

34.0

(863,6)

40.0

(1016,0)

13.3

(6,0)

40.0

(1016,0)

46.0

(1168,4)

14.8

(6,7)

46.0

(1168,4)

52.0

(1320,8)

16.3

(7,4)

52.0

(1320,8)

58.0

(1473,2)

17.8

(8,1)

58.0

(1473,2)

64.0

(1625,6)

64.0

(1625,6)

70.0

(1778,0)

Footnotes:

(1) Weight shown is with a 1 bearing carriage [1.4 lbs (0,64 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a H100 style [0.08 lbs (0,04 kg)] coupling.

When using a 2 bearing carriage add 0.1 lbs (0,04 kg) to each value.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-81-2048.jpg)

![Technical Reference - Belt Drive - 140-CP2 Series

Dimensions & Specifications - With Top Cover Plate Only -

Travel

Length

Table Dimensions

Model

Number lbs

14x4004-CP2

1.188

(30,2) 3 8 4

(100)

14x4006-CP2 1.5

1.438

(36,5) 23 48 42

(1060)

0.688

(17,5) 27 56 48

(1215)

1.813

(46,1) 29 60 54

(1370)

1.063

(27,0) 33 68 60

(1520)

Sold & Serviced By:

Specifications subject to change without notice

Belt

Weight

ounces

(gm)

1.3

(36,8)

0.313

(8,0) 5 12 6

(150)

1.313

(33,4) 5 12 8

(200)

1.438

(36,5) 7 16 12

(300)

1.563

(39,7) 9 20 16

(405)

1.688

(42,9) 11 24 20

(505)

1.813

(46,1) 13 28 24

(605)

1.063

(27,0) 17 36 30

(760)

0.313

(8,0) 21 44 36

(910)

x = 1; Carriage has 1 bearing; Carriage weight = 1.4 lbs. (0,64 kg)

x = 2; Carriage has 2 bearings; Carriage weight = 1.5 lbs. (0,68 kg)

(42,5)

14x4008-CP2 1.7

(48,2)

14x4012-CP2 2.1

(59,5)

14x4016-CP2 2.5

(70,9)

14x4020-CP2 2.9

(82,2)

14x4024-CP2 3.3

(93,6)

14x4030-CP2 3.9

(110,6)

14x4036-CP2 4.5

(127,6)

14x4042-CP2 5.1

(144,6)

14x4048-CP2 5.7

(161,6)

14x4054-CP2 6.3

(178,6)

14x4060-CP2 6.9

(195,6)

(kg)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

5.0

(2,3)

inches

(mm)

A

B E M

Table

Weight

(1)

5.5

(2,5)

8.0

(203,2)

14.0

(355,6)

6.0

(2,7)

10.0

(254,0)

16.0

(406,4)

6.6

(3,0)

12.0

(304,8)

18.0

(457,2)

7.7

(3,5)

16.0

(406,4)

22.0

(558,8)

8.7

(3,9)

20.0

(508,0)

26.0

(660,4)

9.8

(4,5)

24.0

(609,6)

30.0

(762,0)

10.9

(5,0)

28.0

(711.2)

34.0

(863,6)

12.5

(5,7)

34.0

(863,6)

40.0

(1016,0)

14.0

(6,4)

40.0

(1016,0)

46.0

(1168,4)

15.6

(7,1)

46.0

(1168,4)

52.0

(1320,8)

17.2

(7,8)

52.0

(1320,8)

58.0

(1473,2)

18.8

(8,5)

58.0

(1473,2)

64.0

(1625,6)

64.0

(1625,6)

70.0

(1778,0)

Footnotes:

(1) Weight shown is with a 1 bearing carriage [1.4 lbs (0,64 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a H100 style [0.08 lbs (0,04 kg)] coupling.

When using a 2 bearing carriage add 0.1 lbs (0,04 kg) to each value.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-83-2048.jpg)

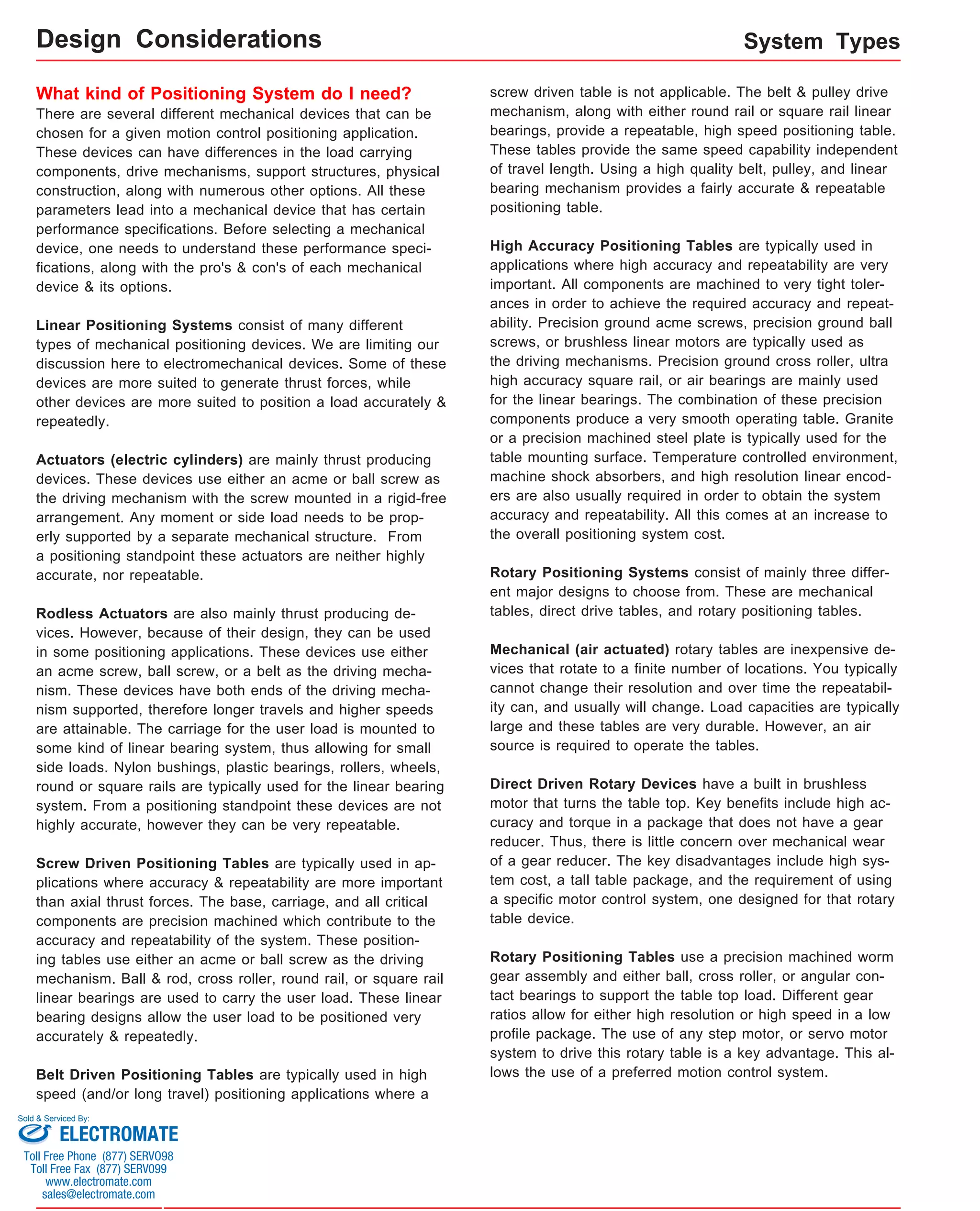

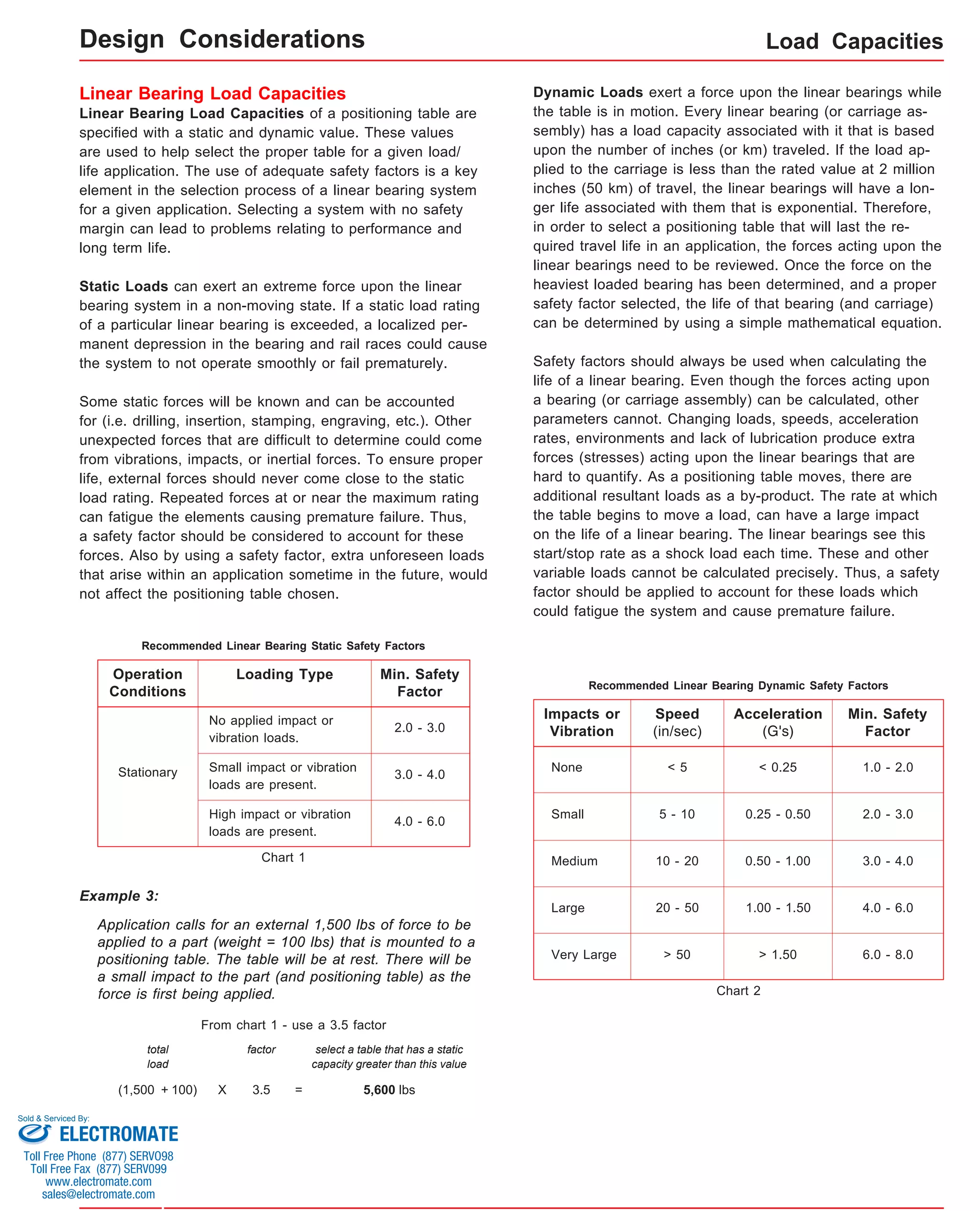

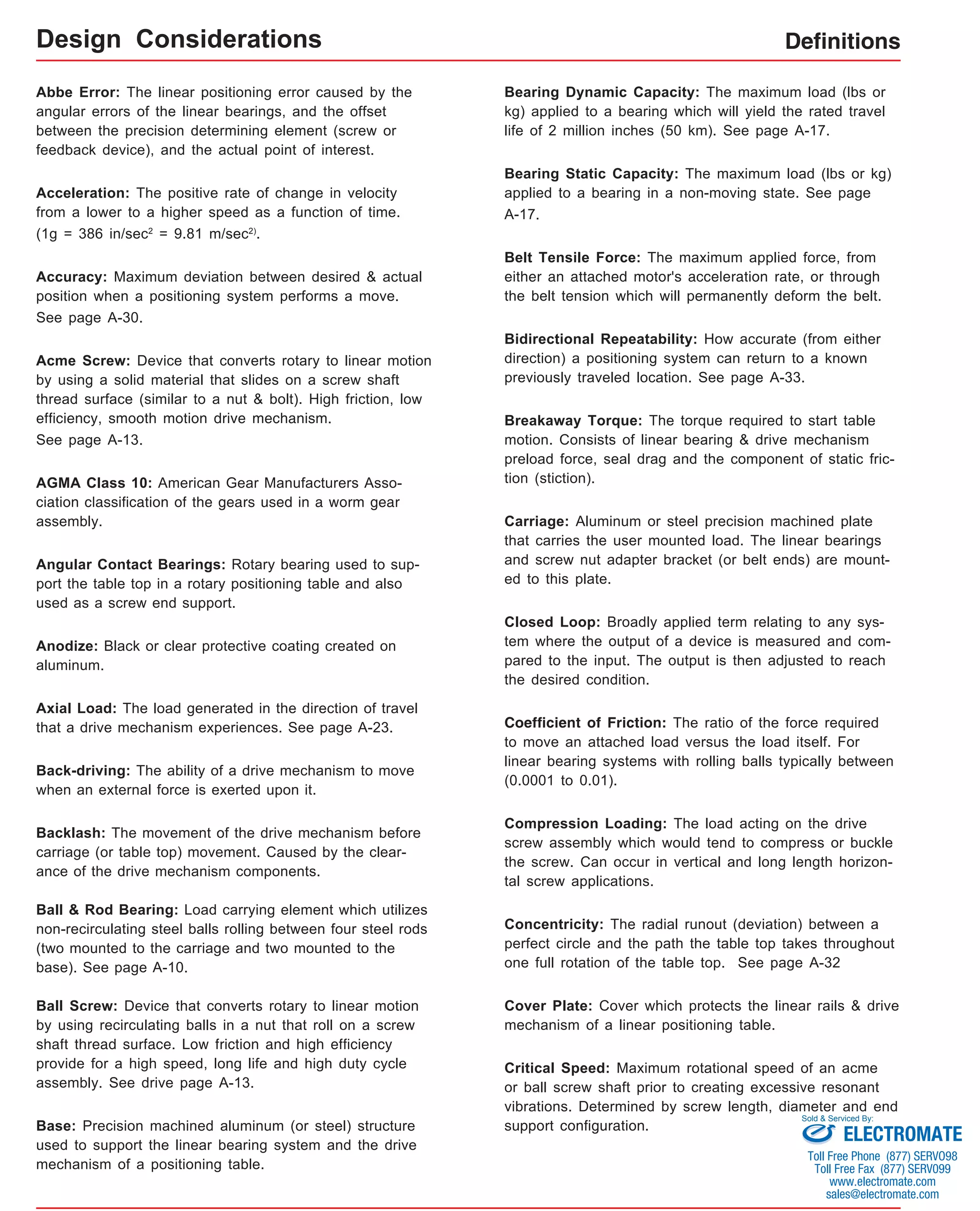

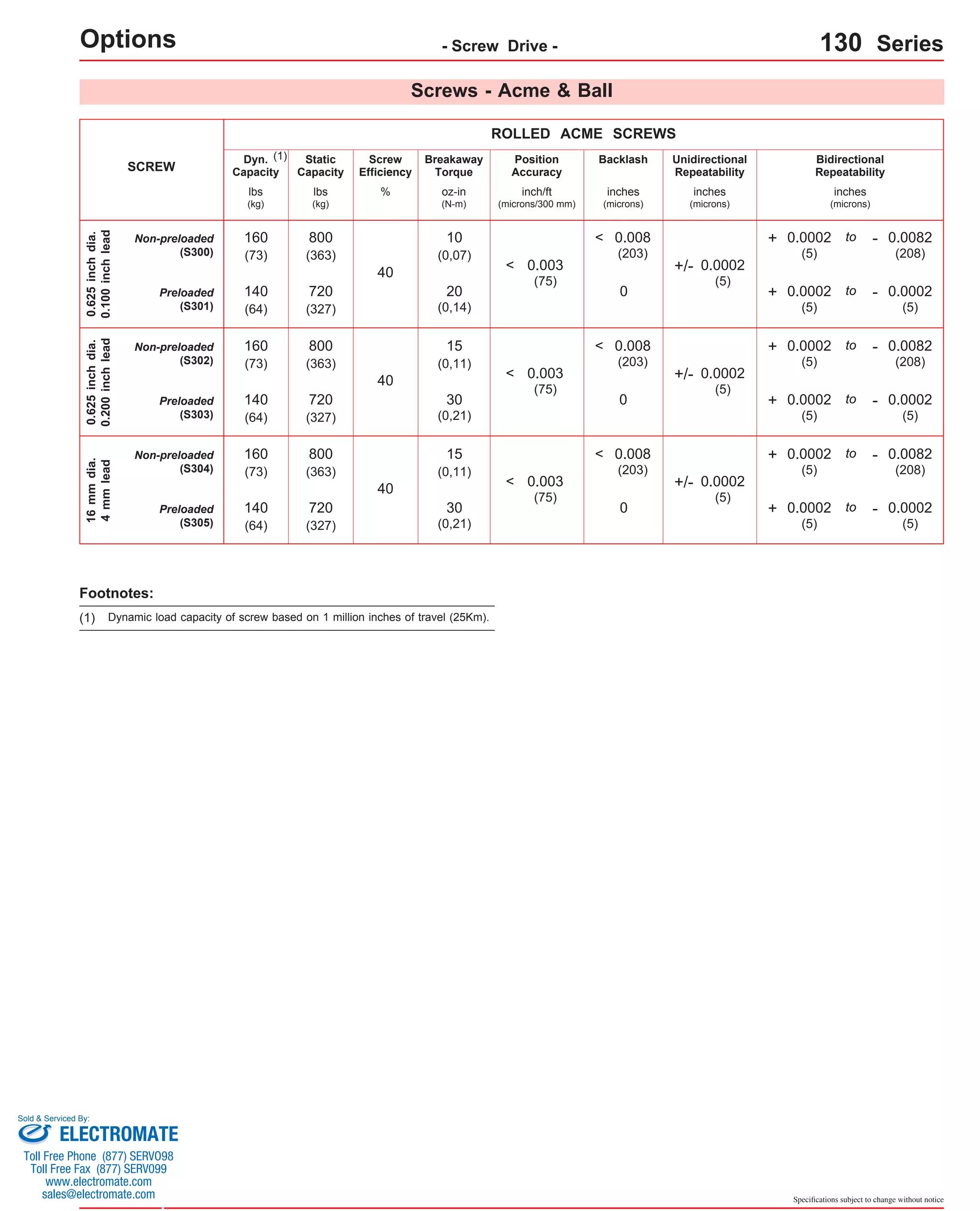

![Technical Reference - Belt Drive - 140 Series

2.809

(71,35)

Master/Slave 140 Series Configuration

For some X-Y belt drive applications, the

master/slave configuration shown to the right

may be required. This system provides two

bottom (X) axes spread apart a set distance,

yet driven by one motor. The spreading of the

two bottom axes minimizes the deflection on

the Y axis, reduces the moment loading on the

X axes carriages, increases the system rigidity,

and prevents twisting of the Y axis as it acceler-ates

to a set speed. LINTECH can provide the

shaft supports, the cross shaft, the couplings,

and the 140 series belt drive table without a

motor mount bracket. The shaft supports are

required as the couplings DO NOT provide ad-equate

support of the shaft by themselves. Also,

the shaft supports prevent the cross shaft from

"whipping" at long lengths and high speeds.

The chart below lists the maximum carriage

speed available with a given distance between

shaft supports. A minimum of two shaft supports

is always required. More than two can be used

to increase the speed of a longer spread sys-tem.

The equations below show the relationship

between the # of shaft supports, the spread be-tween

the two bottom axes (B), and the distance

between individual shaft supports (A).

Max. Ref.

A

C191 coupling C191 coupling

(see chart)

Shaft Supports (44192)

B

Shaft Supports (44192)

C' Bore for 1/4-20 (M6)

socket head cap screw

Steel Cross Shaft: 0.500 inch (12,7 mm) diameter;

0.055 lbs/in (0,00098 kg/mm);

Rockwell 60-65C

A = distance between shaft supports

B = distance between 2 bottom axes

Maximum

Distance Between

Shaft Supports

(inches) (RPM)

30

36

48

<=

<=

<=

(in/sec)

54

60

66

<=

<=

<=

72

84

96

<=

<=

<=

108

<=

<= 120

118

89

50

39

32

26

22

16

12

10

8

2000

1500

840

660

535

440

370

270

208

164

133

A

Maximum

Shaft

Speed

Equivalent

Carriage

Speed

2 Shaft Supports:

3 Shaft Supports:

4 Shaft Supports:

A = [B - 7.50 in (190,5 mm)]

A = [B - 8.53 in (216,7 mm)] / 2

A = [B - 9.56 in (242,8 mm)] / 3

Note: The user is required to supply the mounting surface

for the above configurations. LINTECH normally only sup-plies

all the positioning hardware. A common base plate can

be provided by LINTECH upon request.

Sold & Serviced By:

Specifications subject to change without notice

(mm)

762

914

1219

1372

1524

1676

1829

2134

2438

2743

3048

(mm/sec)

3000

2250

1260

990

802

660

555

405

312

246

200

inches

(mm) 1.000

(25,4)

1.000 Max. Ref.

(25,4)

2.000

(50,8)

1.030

(26,16)

1.375

(34,93)

2.530

(64,26)

2.530

(75,57)

B - 2.25

(B - 57,15)

(required shaft length)

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-86-2048.jpg)

![Technical Reference - Screw Drive - 100-CP0 Series

(1)

Travel

Length

Table Dimensions

Model

Number lbs

inches

(mm)

1.250

(31,7) 8 13.25

(337) 6 1

(150)

0.250

(6,3) 12 15.25

(387) 8 3

(200)

0.250

(6,3) 16 19.25

(489) 12 5

(300)

1.250

(31,7) 16 23.25

(591) 16 5

(405)

0.750

(19,0) 20 27.25

(692) 20 7

(505)

0.250

(6,3) 24 31.25

(794) 24 9

(605)

0.750

(19,0) 28 37.25

(946) 30 11

(760)

1.250

(31,7) 32 43.25

(1099) 36 13

(910)

1.750

(44,4) 36 49.25

(1251) 42 15

(1060)

0.750

(19,0) 52 67.25

(1708) 60 23

(1520)

Sold & Serviced By:

Specifications subject to change without notice

(kg)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

A

10x402-CP0

6.0

5.1

(152,4)

(2,3) B

9.875

(250,8)

0.500

(12,7)

E M

8

Screw

Length

inches

(mm)

9.25

(235)

Table

Weight

55.875

(1419,2)

2.250

(57,1) 40 55.25

x = 2; Carriage has 2 bearings; Carriage weight = 1.2 lbs. (0,54 kg)

x = 4; Carriage has 4 bearings; Carriage weight = 1.4 lbs. (0,63 kg)

(1)

1

10x404-CP0 8.0

11.875

0.250

1

8 11.25

5.9

(203,2)

(301,6)

(6,3) (286) (2,7) 2

(50)

4

(100)

10x406-CP0 10.0

13.875

6.7

(254,0)

(352,4)

(3,0) Dimensions & Specifications

10x408-CP0 12.0

15.875

7.5

(304,8)

(403,2)

(3,4) 10x412-CP0 16.0

19.875

9.1

(406,4)

(504,8)

(4,1) 10x416-CP0 20.0

23.875

10.7

(508,0)

(606,4)

(4,8) 10x420-CP0 24.0

27.875

12.3

(609,6)

(708,0)

(5,6) 10x424-CP0 28.0

31.875

13.9

(711.2)

(809,6)

(6,3) 10x430-CP0 34.0

37.875

16.3

(863,6)

(962,0)

(7,4) 10x436-CP0 40.0

43.875

18.7

(1016,0)

(1114,4)

(8,5) 10x442-CP0 46.0

49.875

21.1

(1168,4)

(1266,8)

(9,6) 23.5

10x448-CP0 48

52.0

(1215)

(1320,8)

17 (1403) (10,6) 10x454-CP0 54 58.0

61.875

0.250

21

48 61.25

25.9

(1370)

(1473,2)

(1571,6)

(6,3)

(1556)

(11,4) 10x460-CP0 64.0

67.875

28.3

(1625,6)

(1724,0)

(12,8) - Without Cover Plates -

D

1.250

(31,7)

2.500

(63,5)

2.500

(63,5)

2.000

(50,8)

1.500

(38,1)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

Footnotes:

Weight shown is with a 0.625 inch (16 mm) diameter screw, a 2 bearing carriage [1.2 lbs (0,54 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a

C100 style [0.09 lbs (0,04 kg)] coupling. When using a 0.500 inch diameter screw subtract 0.022 lbs per inch (0,00039 kg per mm) of screw length for a

given model number. When using a 4 bearing carriage add 0.2 lbs (0,09 kg) to each value.

version: 01/2014

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-107-2048.jpg)

![Technical Reference - Screw Drive - 100-CP1 Series

Travel

Length

Table Dimensions

Model

Number lbs

inches

(mm)

1.250

(31,7) 8 13.25

(337) 6 1

(150)

0.250

(6,3) 12 15.25

(387) 8 3

(200)

0.250

(6,3) 16 19.25

(489) 12 5

(300)

1.250

(31,7) 16 23.25

(591) 16 5

(405)

0.750

(19,0) 20 27.25

(692) 20 7

(505)

0.250

(6,3) 24 31.25

(794) 24 9

(605)

0.750

(19,0) 28 37.25

(946) 30 11

(760)

1.250

(31,7) 32 43.25

(1099) 36 13

(910)

1.750

(44,4) 36 49.25

(1251) 42 15

(1060)

2.250

(57,1) 40 55.25

(1403) 48 17

(1215)

0.250

(6,3) 48 61.25

(1556) 54 21

(1370)

0.750

(19,0) 52 67.25

(1708) 60 23

(1520)

Footnotes:

Sold & Serviced By:

Specifications subject to change without notice

(kg)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

A

10x402-CP1

6.0

6.1

(152,4)

(2,8) B

9.875

(250,8)

0.500

(12,7)

E M

8

Screw

Length

inches

(mm)

9.25

(235)

Table

Weight

x = 2; Carriage has 2 bearings; Carriage weight = 1.5 lbs. (0,68 kg)

x = 4; Carriage has 4 bearings; Carriage weight = 1.7 lbs. (0,77 kg)

(1)

1

10x404-CP1 8.0

11.875

0.250

1

8 11.25

7.0

(203,2)

(301,6)

(6,3) (286) (3,2) 2

(50)

4

(100)

10x406-CP1 10.0

13.875

7.9

(254,0)

(352,4)

(3,6) Dimensions & Specifications

10x408-CP1 12.0

15.875

8.8

(304,8)

(403,2)

(4,0) 10x412-CP1 16.0

19.875

10.6

(406,4)

(504,8)

(4,8) 10x416-CP1 20.0

23.875

12.3

(508,0)

(606,4)

(5,6) 10x420-CP1 24.0

27.875

14.0

(609,6)

(708,0)

(6,3) 10x424-CP1 28.0

31.875

15.9

(711.2)

(809,6)

(7,2) 10x430-CP1 34.0

37.875

18.6

(863,6)

(962,0)

(8,4) 10x436-CP1 40.0

43.875

21.3

(1016,0)

(1114,4)

(9,7) 10x442-CP1 46.0

49.875

24.0

(1168,4)

(1266,8)

(10,9) 10x448-CP1 52.0

55.875

26.7

(1320,8)

(1419,2)

(12,1) 10x454-CP1 58.0

61.875

29.4

(1473,2)

(1571,6)

(13,3) 10x460-CP1 64.0

67.875

32.1

(1625,6)

(1724,0)

(14,6) - With Top Cover Plate Only -

D

1.250

(31,7)

2.500

(63,5)

2.500

(63,5)

2.000

(50,8)

1.500

(38,1)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

(1)

Weight shown is with a 0.625 inch (16 mm) diameter screw, a 2 bearing carriage [1.5 lbs (0,68 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a

C100 style [0.09 lbs (0,04 kg)] coupling. When using a 0.500 inch diameter screw subtract 0.022 lbs per inch (0,00039 kg per mm) of screw length for a

given model number. When using a 4 bearing carriage add 0.2 lbs (0,09 kg) to each value.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-109-2048.jpg)

![Technical Reference - Screw Drive - 100-CP2 Series

Travel

Length

Table Dimensions

Model

Number lbs

inches

(mm)

1.250

(31,7) 8 13.25

(337) 6 1

(150)

0.250

(6,3) 12 15.25

(387) 8 3

(200)

0.250

(6,3) 16 19.25

(489) 12 5

(300)

1.250

(31,7) 16 23.25

(591) 16 5

(405)

0.750

(19,0) 20 27.25

(692) 20 7

(505)

0.250

(6,3) 24 31.25

(794) 24 9

(605)

0.750

(19,0) 28 37.25

(946) 30 11

(760)

1.250

(31,7) 32 43.25

(1099) 36 13

(910)

1.750

(44,4) 36 49.25

(1251) 42 15

(1060)

2.250

(57,1) 40 55.25

(1403) 48 17

(1215)

0.250

(6,3) 48 61.25

(1556) 54 21

(1370)

0.750

(19,0) 52 67.25

(1708) 60 23

(1520)

Footnotes:

Sold & Serviced By:

Specifications subject to change without notice

(kg)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

A

10x402-CP2

6.0

6.4

(152,4)

(2,9) B

9.875

(250,8)

0.500

(12,7)

E M

8

Screw

Length

inches

(mm)

9.25

(235)

Table

Weight

x = 2; Carriage has 2 bearings; Carriage weight = 1.5 lbs. (0,68 kg)

x = 4; Carriage has 4 bearings; Carriage weight = 1.7 lbs. (0,77 kg)

(1)

1

10x404-CP2 8.0

11.875

0.250

1

8 11.25

7.3

(203,2)

(301,6)

(6,3) (286) (3,3) 2

(50)

4

(100)

10x406-CP2 10.0

13.875

8.3

(254,0)

(352,4)

(3,8) Dimensions & Specifications

10x408-CP2 12.0

15.875

9.2

(304,8)

(403,2)

(4,2) 10x412-CP2 16.0

19.875

11.1

(406,4)

(504,8)

(5,0) 10x416-CP2 20.0

23.875

13.0

(508,0)

(606,4)

(5,9) 10x420-CP2 24.0

27.875

14.8

(609,6)

(708,0)

(6,7) 10x424-CP2 28.0

31.875

16.8

(711.2)

(809,6)

(7,6) 10x430-CP2 34.0

37.875

19.6

(863,6)

(962,0)

(8,9) 10x436-CP2 40.0

43.875

22.5

(1016,0)

(1114,4)

(10,2) 10x442-CP2 46.0

49.875

25.4

(1168,4)

(1266,8)

(11,5) 10x448-CP2 52.0

55.875

28.2

(1320,8)

(1419,2)

(12,8) 10x454-CP2 58.0

61.875

31.1

(1473,2)

(1571,6)

(14,1) 10x460-CP2 64.0

67.875

34.0

(1625,6)

(1724,0)

(15,4) - With Top & Side Cover Plates -

D

1.250

(31,7)

2.500

(63,5)

2.500

(63,5)

2.000

(50,8)

1.500

(38,1)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

(1)

Weight shown is with a 0.625 inch (16 mm) diameter screw, a 2 bearing carriage [1.5 lbs (0,68 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a

C100 style [0.09 lbs (0,04 kg)] coupling. When using a 0.500 inch diameter screw subtract 0.022 lbs per inch (0,00039 kg per mm) of screw length for a

given model number. When using a 4 bearing carriage add 0.2 lbs (0,09 kg) to each value.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-111-2048.jpg)

![Technical Reference - Screw Drive - 110-WC1 Series

Travel

Length

Table Dimensions

Model

Number lbs

inches

(mm)

1.250

(31,7) 8 13.25

(337) 4.000 1

(100)

0.250

(6,3) 12 15.25

(387) 5.500 3

(139)

0.250

(6,3) 16 19.25

(489) 8.500 5

(215)

1.250

(31,7) 16 23.25

(591) 11.500 5

(292)

0.750

(19,0) 20 27.25

(692) 14.375 7

(365)

0.250

(6,3) 24 31.25

(794) 17.375 9

(441)

0.750

(19,0) 28 37.25

(946) 22.000 11

(558)

1.250

(31,7) 32 43.25

(1099) 28.000 13

(711)

1.750

(44,4) 36 49.25

(1251) 31.750 15

(806)

2.250

(57,1) 40 55.25

(1403) 36.375 17

(923)

0.250

(6,3) 48 61.25

(1556) 40.750 21

(1035)

0.750

(19,0) 52 67.25

(1708) 45.500 23

(1155)

Footnotes:

Sold & Serviced By:

Specifications subject to change without notice

(kg)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

A

11x401-WC1

6.250

6.3

(158,7)

(2,9) B

9.875

(250,8)

0.500

(12,7)

E M

8

Screw

Length

inches

(mm)

9.25

(235)

Table

Weight

x = 2; Carriage has 2 bearings; Carriage weight = 1.8 lbs. (0,82 kg)

x = 4; Carriage has 4 bearings; Carriage weight = 2.0 lbs. (0,91 kg)

(1)

1

11x402-WC1 8.250

11.875

0.250

1

8 11.25

7.3

(203,2)

(301,6)

(6,3) (286) (3,3) 1.000

(25)

2.500

(63)

11x404-WC1 10.250

13.875

8.2

(260,3)

(352,4)

(3,7) Dimensions & Specifications

11x405-WC1 12.250

15.875

9.2

(311,1)

(403,2)

(4,2) 11x408-WC1 16.250

19.875

11.1

(412,7)

(504,8)

(5,0) 11x411-WC1 20.250

23.875

13.0

(514,3)

(606,4)

(5,9) 11x414-WC1 24.250

27.875

14.9

(615,9)

(708,0)

(6,8) 11x417-WC1 28.250

31.875

16.9

(717,5)

(809,6)

(7,7) 11x422-WC1 34.250

37.875

19.8

(869,9)

(962,0)

(9,0) 11x428-WC1 40.250

43.875

22.6

(1022,3)

(1114,4)

(10,2) 11x431-WC1 46.250

49.875

25.5

(1174,7)

(1266,8)

(11,6) 11x436-WC1 52.250

55.875

28.4

(1327,1)

(1419,2)

(12,9) 11x440-WC1 58.250

61.875

31.3

(1479,5)

(1571,6)

(14,2) 11x445-WC1 64.250

67.875

34.1

(1631,9)

(1724,0)

(15,5) - With Waycovers -

D

1.250

(31,7)

2.500

(63,5)

2.500

(63,5)

2.000

(50,8)

1.500

(38,1)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

(1)

Weight shown is with a 0.625 inch (16 mm) diameter screw, a 2 bearing carriage [1.8 lbs (0,82 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a

C100 style [0.09 lbs (0,04 kg)] coupling. When using a 0.500 inch diameter screw subtract 0.022 lbs per inch (0,00039 kg per mm) of screw length for a

given model number. When using a 4 bearing carriage add 0.2 lbs (0,09 kg) to each value.

version: 01/2014

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-115-2048.jpg)

![Technical Reference - Belt Drive - 120-CP0 Series

Dimensions & Specifications

Travel

Length

Table Dimensions

- Without Cover Plates -

Model

Number lbs

Footnotes:

(1)

(kg)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

8.4

inches

(mm)

A

8.0

(203,2)

B

14.000

(355,6)

0.250

(6,3)

E M

12x4004-CP0 8

(3,8)

Belt

Weight

ounces

(gm)

1.3

(36,8)

Table

Weight

18.000

(457,2)

0.250

(6,3) 12 1.7

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

94.000

(2387,6) 72

106.000

(2692,4) 80

118.000

(2997,2) 88

x = 2; Carriage has 2 bearings; Carriage weight = 1.6 lbs. (0,73 kg)

x = 4; Carriage has 4 bearings; Carriage weight = 1.8 lbs. (0,82 kg)

(1)

1

Specifications subject to change without notice

9.1

12x4006-CP0 (4,1) 10.0

(254,0)

16.000

(406,4)

1.250

(31,7) 8 1.5

1 (42,5)

4

(100)

6

(150)

9.8

12x4008-CP0 8

12.0

(200)

(304,8)

3 (48,2) (4,4) 11.1

12x4012-CP0 (5,0) 16.0

(406,4)

22.000

(558,8)

0.250

(6,3) 16 2.1

5 (59,5) 12

(300)

12.4

12x4016-CP0 (5,6) 20.0

(508,0)

26.000

(660,4)

1.250

(31,7) 16 2.5

5 (70,9) 16

(405)

13.7

12x4020-CP0 (6,2) 24.0

(609,6)

30.000

(762,0)

0.750

(19,0) 20 2.9

7 (82,2) 20

(505)

15.1

12x4024-CP0 (6,8) 28.0

(711,2)

34.000

(863,6)

0.250

(6,3) 24 3.3

9 (93,6) 24

(605)

17.1

12x4030-CP0 (7,8) 34.0

(863,6)

40.000

(1016,0)

0.750

(19,0) 28 3.9

11 (110,6) 30

(760)

19.1

12x4036-CP0 (8,7) 40.0

(1016,0)

46.000

(1168,4)

1.250

(31,7) 32 4.5

13 (127,6) 36

(910)

21.1

12x4042-CP0 (9,6) 46.0

(1168,4)

52.000

(1320,8)

1.750

(44,4) 36 5.1

15 (144,6) 42

(1060)

35.1

12x4084-CP0 84

88.0

9.3

(2130)

(2235,2)

33 (263,7)

(15,9) 39.1

12x4096-CP0 96

100.0

10.5

(2435)

(2540,0)

37 (297,7)

(17,7) 43.1

12x4108-CP0 108

112.0

11.7

(2740)

(2844,8)

41 (331,7)

(19,6) 47.1

12x4120-CP0 (21,4) 124.0

(3149,6)

130.000

(3302,0) 100 12.9

47 (365,7) 120

(3045)

D

2.500

(63,5)

2.500

(63,5)

2.000

(50,8)

1.500

(38,1)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

23.1

12x4048-CP0 (10,4) 52.0

(1320,8)

58.000

(1473,2)

2.250

(57,1) 40

5.7

17 (161,6) 48

(1215)

25.1

12x4054-CP0 (11,4) 58.0

(1473,2)

64.000

(1625,6)

0.250

(6,3) 48

6.3

21 (178,6) 54

(1370)

12x4060-CP0 64.0

(1625,6)

70.000

(1778,0)

0.750

(19,0) 52

6.9

23 (195,6) 60

(1520)

31.1

12x4072-CP0 (14,1) 76.0

(1930,4)

82.000

(2082,8)

1.750

(44,4) 60

8.1

27 (229,6) 72

(1820)

27.1

(12,3)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

0.250

(6,3)

1.250

(31,7)

2.250

(57,1)

0.750

(19,0)

Weight shown is with a 2 bearing carriage [1.6 lbs (0,73 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a H100 style [0.08 lbs (0,04 kg)] coupling.

When using a 4 bearing carriage add 0.2 lbs (0,09 kg) to each value.

version: 01/2014](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-129-2048.jpg)

![Technical Reference - Belt Drive - 120-CP1 Series

Dimensions & Specifications

Travel

Length

Table Dimensions

- With Top Cover Plate Only -

Model

Number lbs

inches

(mm)

A

8.0

(203,2)

B

14.000

(355,6)

0.250

(6,3)

E M

18.000

(457,2)

D

2.500

(63,5)

2.500

(63,5)

2.000

(50,8)

1.500

(38,1)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

0.250

(6,3) 12 1.7

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

2.500

(63,5)

Footnotes:

(1) For travels greater than 72 inches (1820 mm) a cover plate (-CP1) cannot be used due to the sag of the cover plate.

(2)

(kg)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

8.4

12x4004-CP1 8

(3,8)

Belt

Weight

ounces

(gm)

1.3

(36,8)

Table

Weight

x = 2; Carriage has 2 bearings; Carriage weight = 1.6 lbs. (0,73 kg)

x = 4; Carriage has 4 bearings; Carriage weight = 1.8 lbs. (0,82 kg)

(2)

1

Sold & Serviced By:

Specifications subject to change without notice

9.1

12x4006-CP1 (4,1) 10.0

(254,0)

16.000

(406,4)

1.250

(31,7) 8 1.5

1 (42,5)

4

(100)

6

(150)

9.8

12x4008-CP1 8

12.0

(200)

(304,8)

3 (48,2) (4,4) 11.1

12x4012-CP1 (5,0) 16.0

(406,4)

22.000

(558,8)

0.250

(6,3) 16 2.1

5 (59,5) 12

(300)

12.4

12x4016-CP1 (5,6) 20.0

(508,0)

26.000

(660,4)

1.250

(31,7) 16 2.5

5 (70,9) 16

(405)

13.7

12x4020-CP1 (6,2) 24.0

(609,6)

30.000

(762,0)

0.750

(19,0) 20 2.9

7 (82,2) 20

(505)

15.1

12x4024-CP1 (6,8) 28.0

(711,2)

34.000

(863,6)

0.250

(6,3) 24 3.3

9 (93,6) 24

(605)

17.1

12x4030-CP1 (7,8) 34.0

(863,6)

40.000

(1016,0)

0.750

(19,0) 28 3.9

11 (110,6) 30

(760)

19.1

12x4036-CP1 (8,7) 40.0

(1016,0)

46.000

(1168,4)

1.250

(31,7) 32 4.5

13 (127,6) 36

(910)

21.1

12x4042-CP1 (9,6) 46.0

(1168,4)

52.000

(1320,8)

1.750

(44,4) 36 5.1

15 (144,6) 42

(1060)

23.1

12x4048-CP1 (10,4) 52.0

(1320,8)

58.000

(1473,2)

2.250

(57,1) 40

5.7

17 (161,6) 48

(1215)

25.1

12x4054-CP1 (11,4) 58.0

(1473,2)

64.000

(1625,6)

0.250

(6,3) 48

6.3

21 (178,6) 54

(1370)

12x4060-CP1 64.0

(1625,6)

70.000

(1778,0)

0.750

(19,0) 52

6.9

23 (195,6) 60

(1520)

31.1

12x4072-CP1 (14,1) 76.0

(1930,4)

82.000

(2082,8)

1.750

(44,4) 60

8.1

27 (229,6) 72

(1820)

27.1

(12,3)

(1)

Weight shown is with a 2 bearing carriage [1.6 lbs (0,73 kg)], a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a H100 style [0.08 lbs (0,04 kg)] coupling.

When using a 4 bearing carriage add 0.2 lbs (0,09 kg) to each value.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-131-2048.jpg)

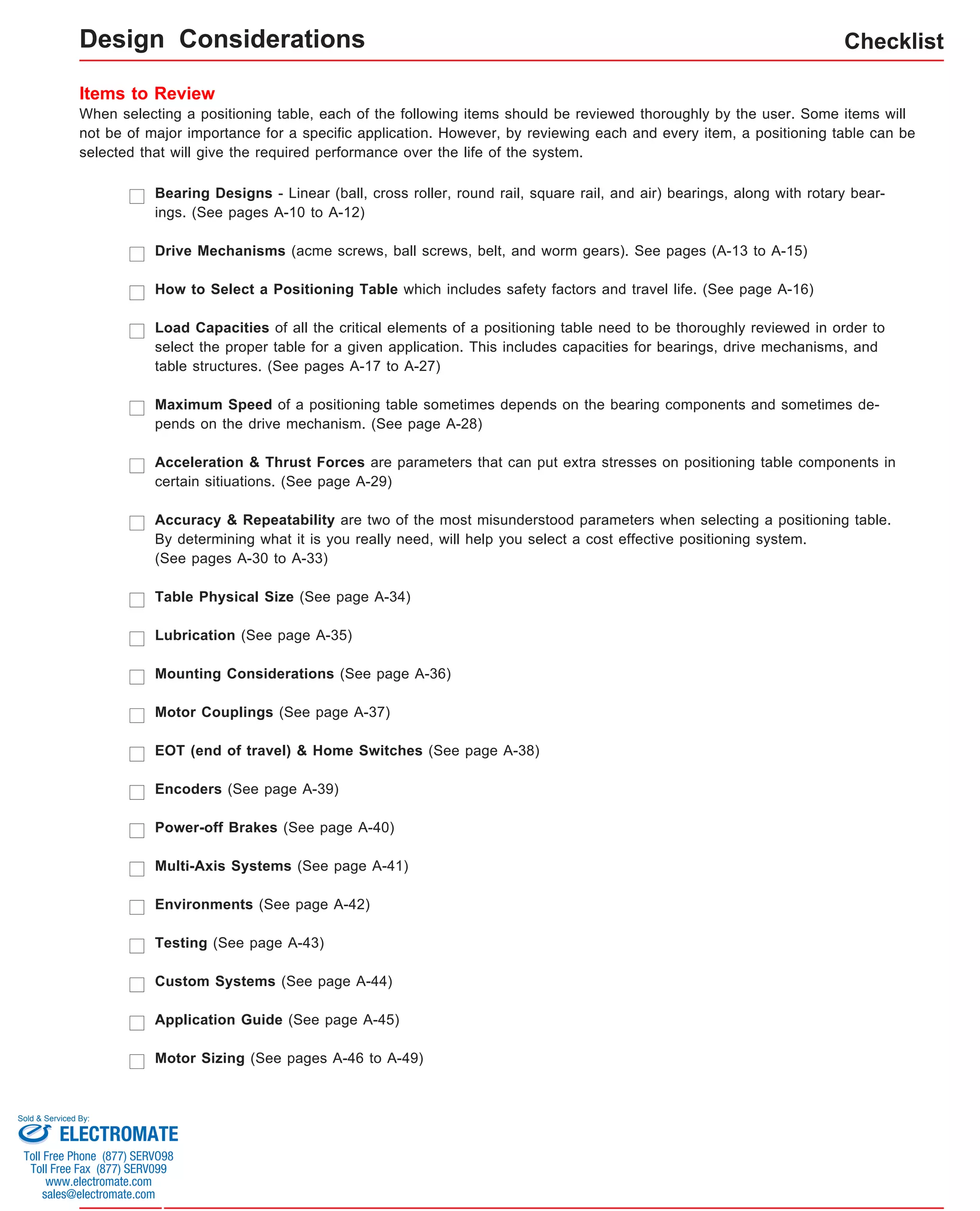

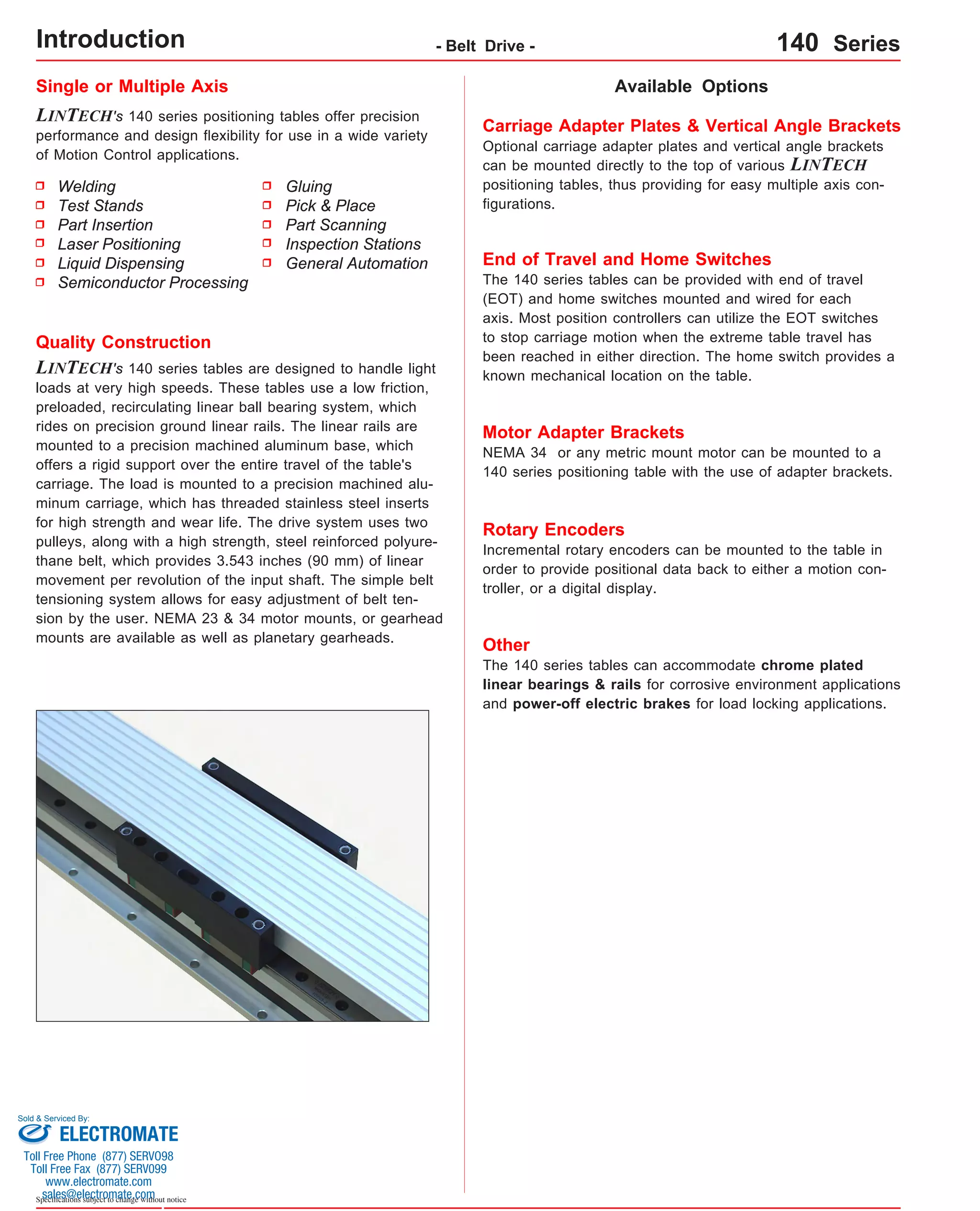

![Technical Reference - Belt Drive - 120 Series

Master/Slave 120 Series Configuration

For some X-Y belt drive applications, the

master/slave configuration shown to the right

may be required. This system provides two bot-tom

(X) axes spread apart a set distance, yet

driven by one motor. The spreading of the two

bottom axes minimizes the deflection on the Y

axis, reduces the moment loading on the X axes

carriages, increases the system rigidity, and

prevents twisting of the Y axis as it accelerates

to a set speed. LINTECH can provide the shaft

supports, the cross shaft, the couplings, and

the 120 series belt drive table without a motor

mount bracket. The shaft supports are required

as the couplings DO NOT provide adequate

support of the shaft by themselves. Also, the

shaft supports prevent the cross shaft from

"whipping" at long lengths and high speeds.

The chart below lists the maximum carriage

speed available with a given distance between

shaft supports. A minimum of two shaft supports

is always required. More than two can be used

to increase the speed of a longer spread sys-tem.

The equations below show the relationship

between the # of shaft supports, the spread be-tween

the two bottom axes (B), and the distance

between individual shaft supports (A).

A

(see chart)

Shaft Supports (44192)

B - 2.25

(B - 57,15)

(required shaft length)

Max. Ref.

C191 coupling C191 coupling

B

Shaft Supports (44192)

1.030

(26,16)

C' Bore for 1/4-20 (M6)

socket head cap screw

Steel Cross Shaft: 0.500 inch (12,7 mm) diameter;

0.055 lbs/in (0,00098 kg/mm);

Rockwell 60-65C

Example #1: Above configuration with Y axis and 2 extended carriage adapter

plates.

Example #2: Above configuration with Y axis, 2 extended carriage adapter

plates, and 2 horizontal angle brackets.

A = distance between shaft supports

B = distance between 2 bottom axes

Maximum

Distance Between

Shaft Supports

(inches) (RPM)

30

36

48

<=

<=

<=

(in/sec)

54

60

66

<=

<=

<=

72

84

96

<=

<=

<=

108

<=

<= 120

118

89

50

39

32

26

22

16

12

10

8

2000

1500

840

660

535

440

370

270

208

164

133

A

Maximum

Shaft

Speed

Equivalent

Carriage

Speed

2 Shaft Supports:

3 Shaft Supports:

4 Shaft Supports:

A = [B - 7.50 in (190,5 mm)]

A = [B - 8.53 in (216,7 mm)] / 2

A = [B - 9.56 in (242,8 mm)] / 3

Note: The user is required to supply the mounting surface

for the above configurations. LINTECH normally only sup-plies

all the positioning hardware. A common base plate can

be provided by LINTECH upon request.

Specifications subject to change without notice

(mm)

762

914

1219

1372

1524

1676

1829

2134

2438

2743

3048

(mm/sec)

3000

2250

1260

990

802

660

555

405

312

246

200

inches

(mm) 1.000

(25,4)

1.000 Max. Ref.

(25,4)

2.000

(50,8)

1.375

(34,93)

2.530

(64,26)

2.530

(75,57)

2.465

(62,61)](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-134-2048.jpg)

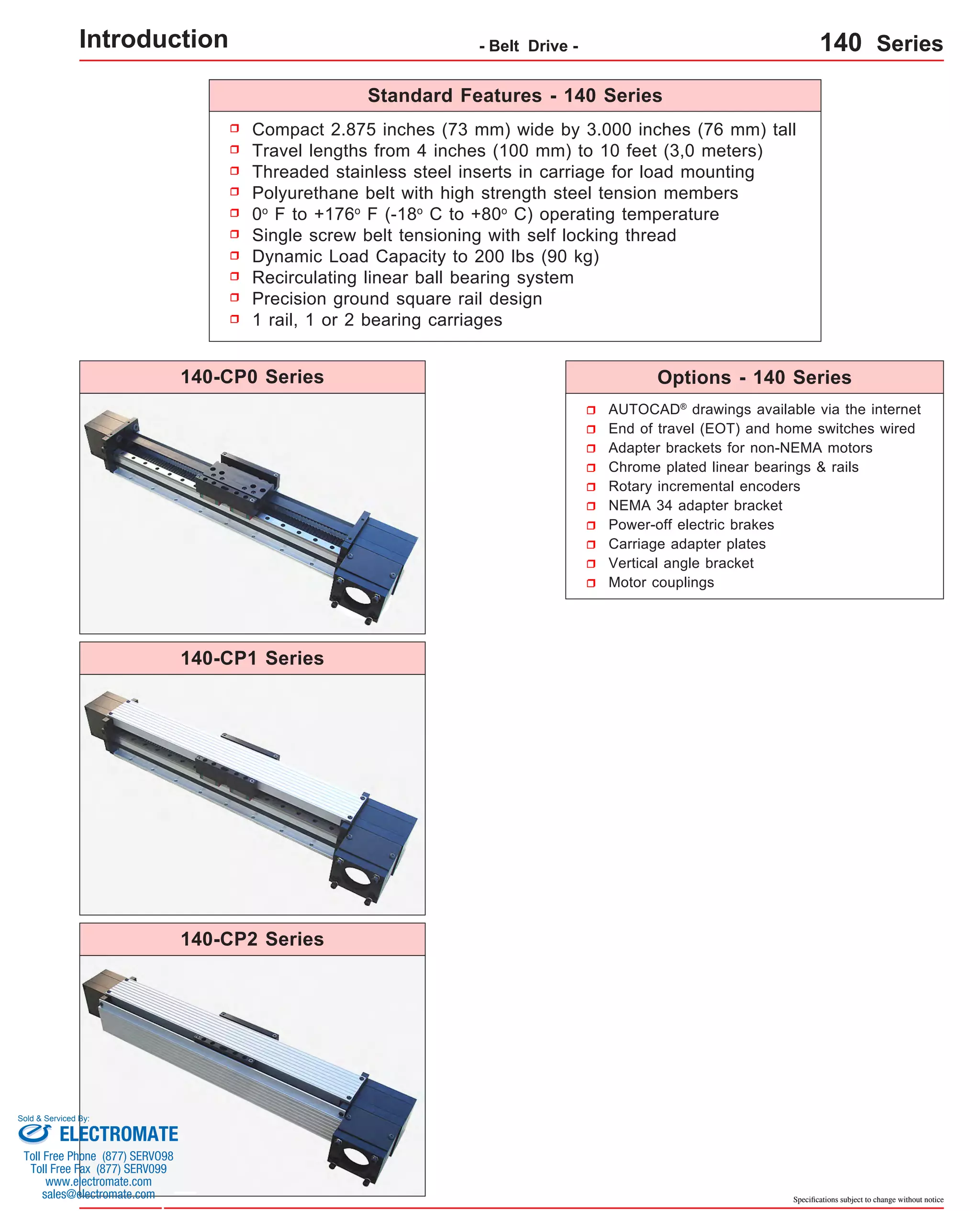

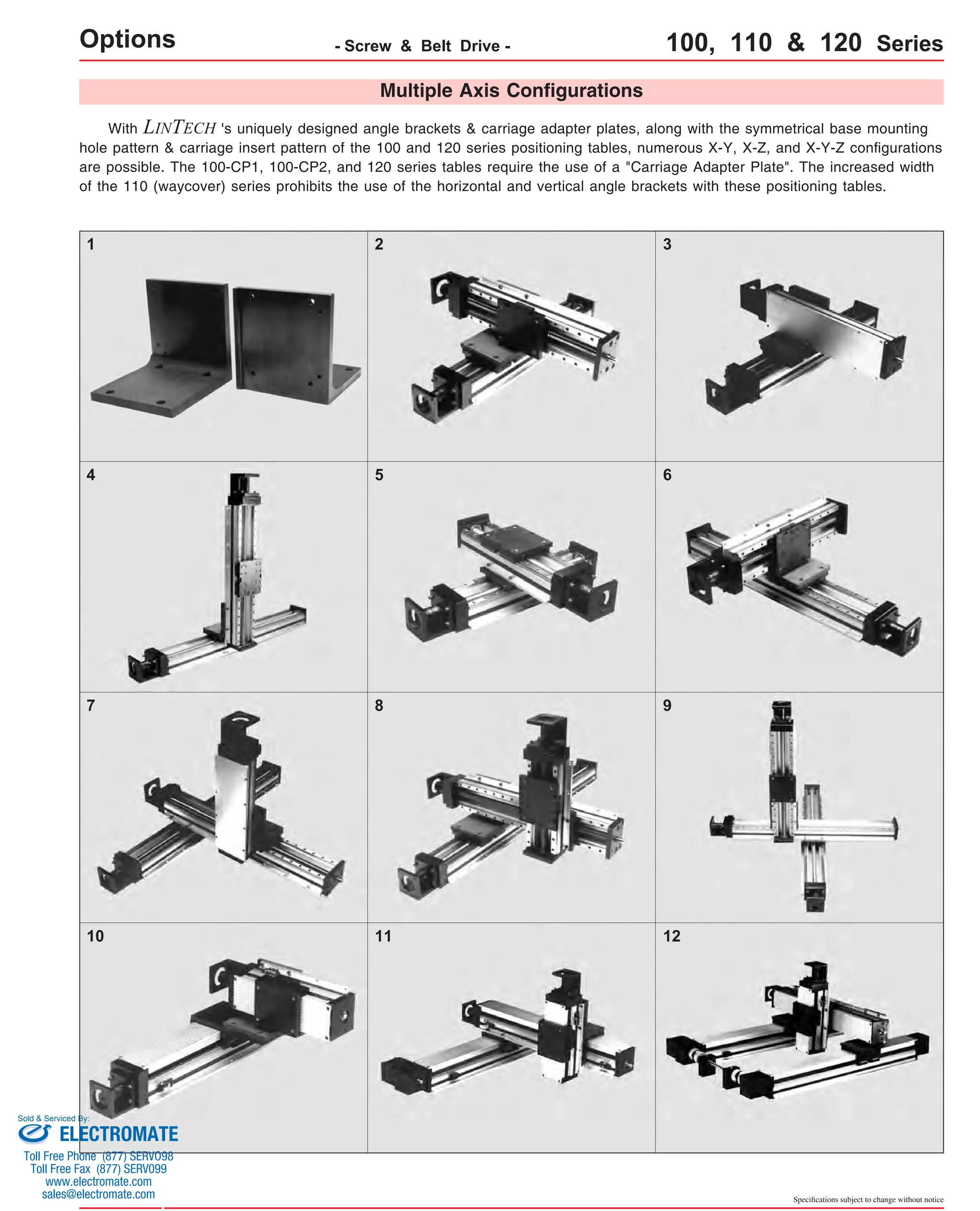

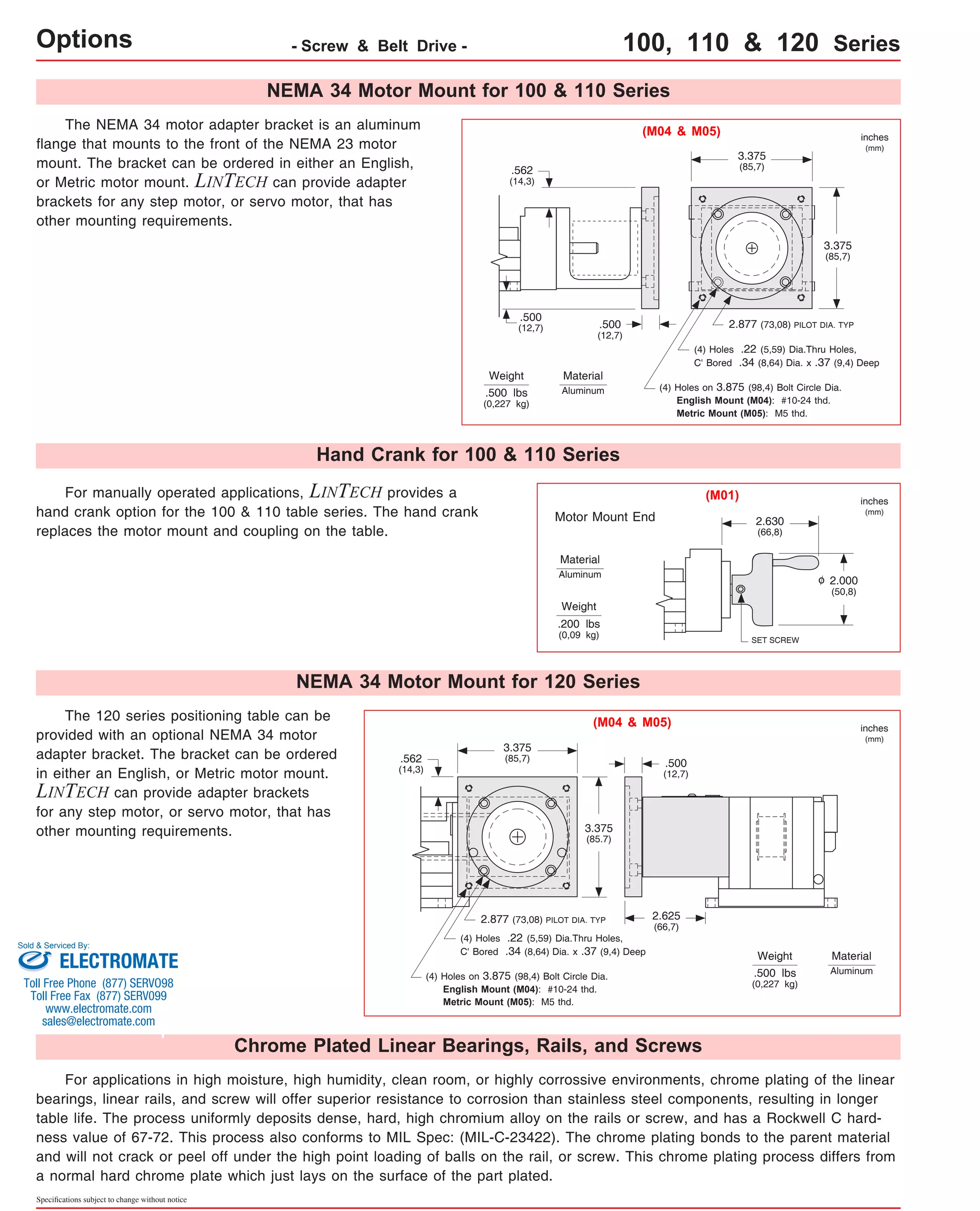

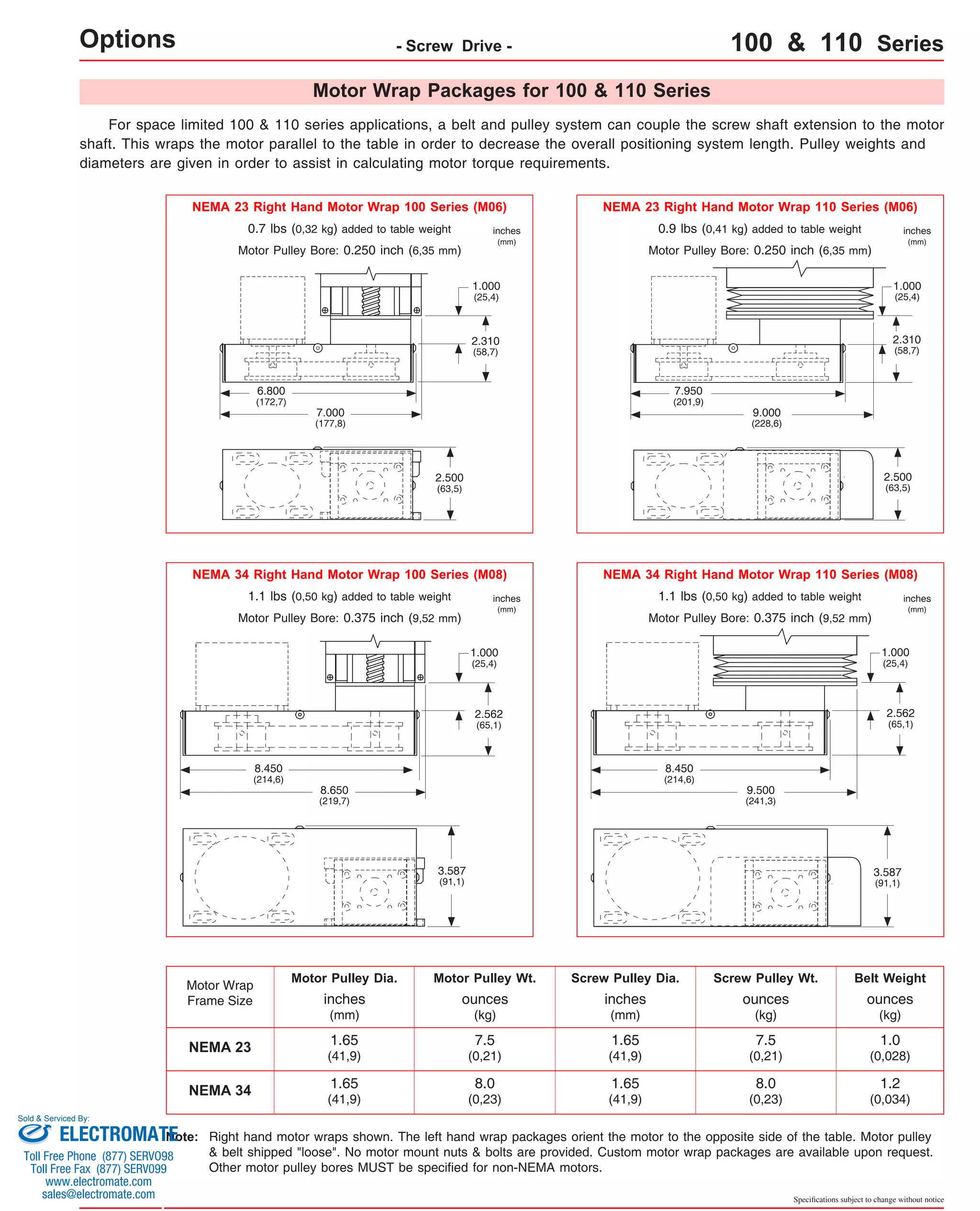

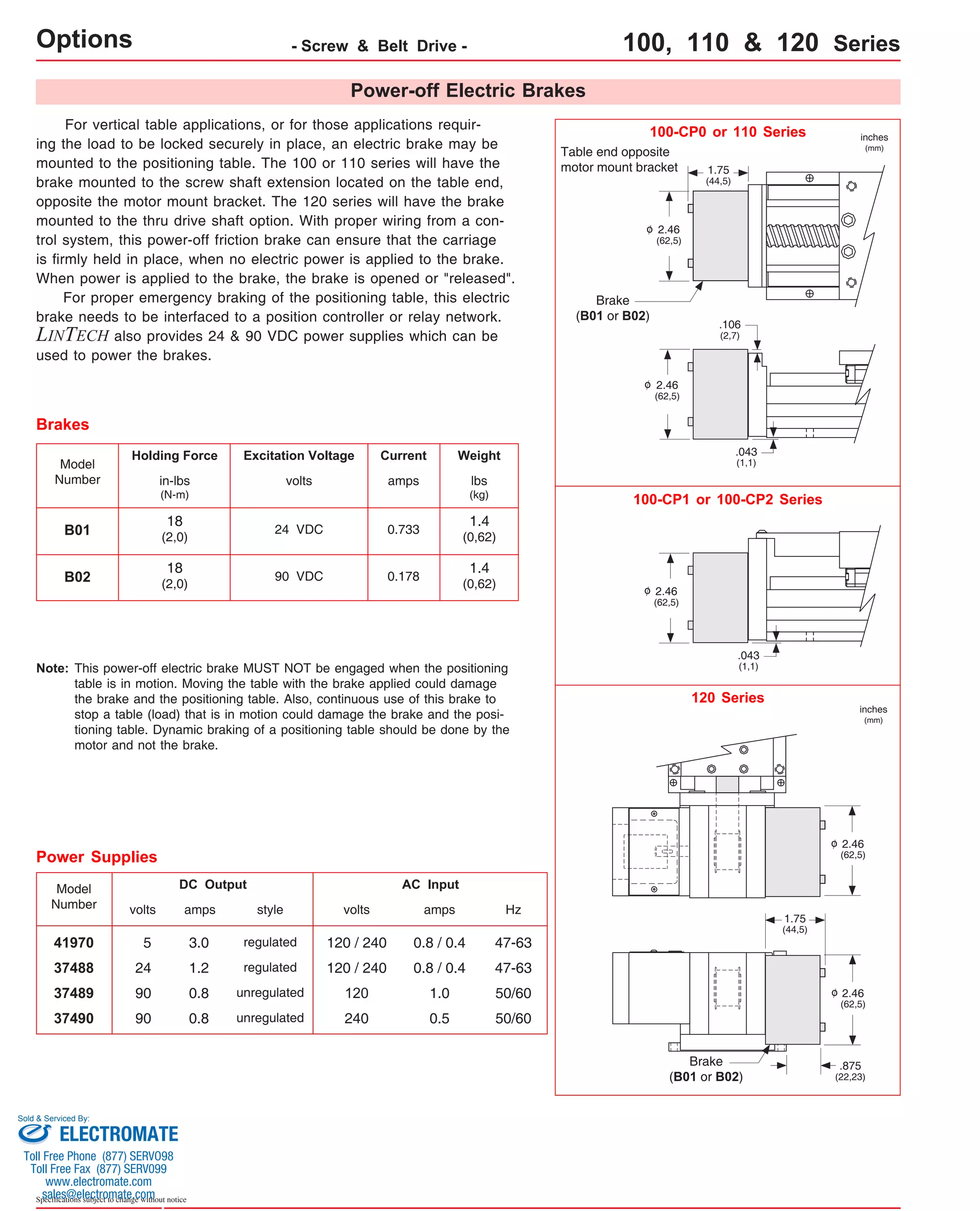

![Options - Screw & Belt Drive - 100, 110 & 120 Series

Carriage Adapter Plates

Optional carriage adapter plates assist in the creation of simple X-Y, X-Z, and X-Y-Z multiple axis systems. The regular car-riage

adapter plate can be used by either the 100-CP1, 100-CP2, or 120 series tables, while the extended adapter plate can be

used with the 100, 110, or 120 series tables. The extended carriage adapter plate can be used in applications to increase the Y

axis travel without having to use a longer travel table. A precision square tool, or micrometer depth gauge, is required in order

to obtain an orthogonality between the two tables of < 30 arc-seconds.

Threaded Stainless Steel Inserts:

English Mount (part # 43551): (4) #8-32 x .25 inch deep TYP

Metric Mount (part # 202297): (4) M4 thd. x 6,35 mm deep TYP

.193 (4,90) Dia.Thru Holes,

C' Bored .312 (7,92) Dia. x .190 (4,83) Deep

3.875

(98,43)

3.188

(80,98)

.344

(8,74)

3.500

(88,90)

.188

(4,78)

2.500

(63,50)

3.125

(79,38)

3.500

(88,90)

.500

(12,70)

.188

(4,78)

Weight

.50 lbs

(0,23 kg)

inches

(mm)

Thick

.375

(9,53)

Regular Carriage Adapter Plate

Threaded Stainless Steel Inserts:

English Mount (part # 44384): (4) #8-32 x .375 inch deep TYP

Metric Mount (part # 202298): (4) M4 thd. x 9,53 mm deep TYP

.193 (4,90) Dia.Thru Holes,

C' Bored .312 (7,92) Dia. x .190 (4,83) Deep

Weight

1.1 lbs

(0,50 kg)

inches

(mm)

Thick

.375

(9,53)

Extended Carriage Adapter Plate

3.875

(98,43)

.188

(4,78)

.500

(12,70)

3.188

(80,98)

.188

(4,78)

3.500

(88,90)

3.125

(79,38)

2.500

(63,50)

.344

(8,74)

3.500

(88,90)

4.000

(101,60)

7.000

(177,80)

2.500

(63,50)

3.188

(80,98)

3.500

(88,90)

.344

(8,72)

.188

(4,76)

Material

Aluminum

Material

Aluminum

* Subtract an additional 0.875 inches (22,22 mm) from the above values if a 110 series table is used as the bottom axis.

* If a 110 series table is used as the top axis, the Y travel distance is the same as the 110 series table travel due to the waycovers.

Sold & Serviced By:

Specifications subject to change without notice

Y

Notes:

(1) Above Y travel distance (need to refer to Base Mounting Dimensions on pages C-6, C-8, C-10, C-14 & C-28):

For D dimension = 2.50 inches (63,5 mm): Y = [table travel length] - [C dimension] + [0.50 inches (12,7 mm)]

For D dimension < 2.50 inches (63,5 mm): Y = [table travel length] - [C dimension] - [D dimension] + [0.50 inches (12,7 mm)]

The extended carriage adapter plate works with all top axis tables that use the optional NEMA 23 motor mount. Care should be taken if the optional NEMA

34 motor mount, or any other motor mount is used on the top axis table. The motor mount could extend below the table base, thus interfering with the

extended carriage adapter plate.

*

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-145-2048.jpg)

![Technical Reference - Screw Drive - 90-WC0 Series

Dimensions & Specifications - Without Waycovers -

Travel

Length

Table Dimensions

Screw

Length

Model

Number lbs

inches

(mm)

6

(150)

12

(300)

E

B

15.75

(400,0)

19.25

(488,9)

21.75

(552,4)

inches

(mm)

14.94

(379,4)

20.94

(531,9)

26.94

(684,3)

32.94

(836,7)

38.94

(989,1)

44.94

(1141,5)

56.94

(1446,3)

68.94

(1751,1)

C

10.00

(254,0)

16.00

(406,4)

22.00

(558,8)

28.00

(711,2)

34.00

(863,6)

40.00

(1016,0)

52.00

(1320,8)

64.00

(1625,6)

16.00

(406,4)

22.00

(558,8)

28.00

(711,2)

34.00

(863,6)

40.00

(1016,0)

46.00

(1168,4)

58.00

(1473,2)

70.00

(1778,0)

6.00

(152,4)

4.00

(101,6)

90612-WC0 8 (7,6)

18

(455)

25.25

(641,3)

27.75

(704,8)

See Detail 1

90618-WC0 10 (9,1)

24

(605)

31.25

(793,7)

33.75

(857,2)

See Detail 2

90624-WC0 14 (14,1)

30

(760)

37.25

(946,1)

39.75

(1009,6)

See Detail 3

90630-WC0 16 (16,3)

36

(910)

43.25

(1098,5)

45.75

(1162,0)

See Detail 4

90636-WC0 18 (18,6)

48

(1215)

55.25

(1403,3)

57.75

(1466,8)

See Detail 5

90648-WC0 24 (23,1)

60

(1520)

67.25

(1708,1)

69.75

(1771,6)

See Detail 7

90660-WC0 28 (27,7)

6

(150)

19.25

(488,9)

21.75

(552,4)

20.94

(531,9)

26.94

(684,3)

32.94

(836,7)

38.94

(989,1)

44.94

(1141,5)

See Detail 9

91206-WC0 8 (9,7)

12

(300)

25.25

(641,3)

27.75

(704,8)

See Detail 1

91212-WC0 10 (10,7)

18

(455)

31.25

(793,7)

33.75

(857,2)

See Detail 2

91218-WC0 14 (15,0)

24

(605)

37.25

(946,1)

39.75

(1009,6)

See Detail 3

91224-WC0 16 (17,2)

30

(760)

43.25

(1098,5)

45.75

(1162,0)

See Detail 4

91230-WC0 18

36

(910)

43.0

(19,5)

49.25

(1250,9)

51.75

(1466,8)

50.94

(1293,9)

See Detail 5

91236-WC0 24 (21,8)

48

(1215)

33.0

38.0

48.0

61.25

(1555,7)

63.75

(1619,2)

62.94

(1598,7)

74.94

(1903,5)

See Detail 6

91248-WC0 28 (26,3)

60

(1520)

73.25

(1860,5)

75.75

(1924,0)

See Detail 8

91260-WC0 30 (30,8)

Sold & Serviced By:

Specifications subject to change without notice

(kg)

inches

(mm)

D

inches

(mm)

Mounting Dimensions

13.3

A

13.25

(336,5)

M

90606-WC0 6

(6,0)

Table

Weight

16.8

20.0

31.0

36.0

41.0

51.0

61.0

21.3

23.5

58.0

68.0

See Detail 10

06 = Carriage length is 06 inch (152,4 mm) with 4 bearings; Carriage weight = 5.25 lbs. (2,38 kg)

12 = Carriage length is 12 inch (304,8 mm) with 4 bearings; Carriage weight = 8.00 lbs. (3,63 kg)

(1)

Footnotes:

(1) Weight shown is with a 0.625 inch (16 mm) diameter screw, a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a C100 style [0.09 lbs (0,04 kg)] coupling.

When using a 0.750 inch (20 mm) diameter screw add 0.042 lbs per inch (0,00075 kg per mm) of screw length for a given model number. When using a

1.000 inch diameter screw add 0.117 lbs per inch (0,0021 kg per mm) of screw length for a given model number.

version: 01/2014

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-157-2048.jpg)

![Technical Reference - Screw Drive - 90-WC0 Series

Dimensions - Without Waycovers -

1.125

(28,58)

1.625 D E

(41,28)

6 inch (152,4 mm) FOUR bearing carriage shown.

12 inch (304,8 mm) FOUR bearing carriage will have

individual bearings mounted towards carriage edges.

X

Optional NEMA 23 Motor Mount Shown:

(1) This value is center to center distance (spread)

between the two rails (d1).

(2) This value is center to center distance (spacing) of

the bearings on a single rail (d2) [see page D-5].

Specifications subject to change without notice

(2)

See Detail 1 - 10 (below)

A

B

(3)

Threaded Stainless Steel Inserts:

English Inserts (-1): 1/4-20 x .50 inch deep TYP

Metric Inserts (-2): M6 thd. x 12 mm deep TYP

5.000

(127,00)

EOT & HOME

Switch Cable Egress 1.502 (38,15) Pilot Dia. TYP

5.500

(139,70)

3.250

(82,55)

4.500

(114,30)

5.500

(139,70)

.625

(15,87)

2.937

(74,60)

.500

(12,70)

(4) Holes on 2.625 (66,68) Bolt Circle Dia.

English Mount (M02): #10-24 thd.

Metric Mount (M03): M5 thd.

inches

(mm)

.375

(9,53)

0.500 TYP

(12,70) TYP

1.250

(31,75)

o

1.068

(27,13)

.375

(9,52)

o

.375 (9,53)

304 Woodruff

Keyway

(1)

8.000

(203,2)

d2

.625

(15,87)

C

M # of Thru Holes

.201 (5,11) Dia.

Mounting Details 1 through 10

1.625

(41,28)

W W 1.625

(41,28)

X

2

3

4

5

7

9

10

1.437

(36,50)

2.438

(61,93)

4 Holes; 6 inch (152,4 mm) carriage

Carriage Length

6 Holes; 12 inch (304,8 mm) carriage

.625

(15,87)

For optional coupling info

see pages D-26 & D-27.

Also, coupling cover in-cluded

on top of optional

motor mounts.

X

1.625

(41,28)

Z

Z

Z

Z

Z Z

Z

W 1.625

(41,28)

X X W

Z

W X X W W X X W

1.625

(41,28)

1.625

(41,28)

1.625

(41,28)

W 1.625

(41,28)

X X W W X X W

1.625

(41,28)

W 1.625

(41,28)

X X W W X X

1.625

(41,28)

W 1.625

(41,28)

W Y X X W

1.625

(41,28)

W 1.625

(41,28)

Y X X

(3) This value is center distance of the bearing to top of

carriage plate surface (dr).

Note: Any 90 series table can be mounted on top

of any second 90 series, in order to create X-Y

multiple axis configurations. The carriage's threaded

stainless steel insert hole pattern DOES NOT ex-actly

match the base mounting hole pattern on each

table, therefore machining of the bottom axis car-riage

plate is required. Please contact LINTECH.

W = 6.00

(152,4) X = 5.00

(127,0)

Y = 4.00

(101,6) Z = 2.00

(50,8)

Z

Z Z

1.625

(41,28)

W 1.625

(41,28)

X

1

Y

6

1.625

(41,28)

W 1.625

(41,28)

X X W W X X

8

1.625

(41,28)

W 1.625

(41,28)

X X W W X X W

Y

W

W

W

X X W

Z

W X X W W X X W](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-158-2048.jpg)

![Technical Reference - Screw Drive - 90-WC1 Series

Dimensions & Specifications - With Waycovers -

Travel

Length

Table Dimensions

Screw

Length

Model

Number lbs

inches

(mm)

4.7

(119)

9.7

(246)

E

B

15.75

(400,0)

19.25

(488,9)

21.75

(552,4)

inches

(mm)

C

10.00

(254)

16.00

(406,4)

22.00

(558,8)

28.00

(711,2)

34.00

(863,6)

40.00

(1016,0)

52.00

(1320,8)

64.00

(1625,6)

16.00

(406,4)

22.00

(558,8)

28.00

(711,2)

34.00

(863,6)

40.00

(1016,0)

46.00

(1168,4)

58.00

(1473,2)

70.00

(1778,0)

14.94

(379,4)

20.94

(531,9)

26.94

(684,3)

32.94

(836,7)

38.94

(989,1)

44.94

(1141,5)

56.94

(1446,3)

68.94

(1751,1)

6.00

(152,4)

4.00

(101,6)

90609-WC1 (8,3)

25.25

(641,3)

27.75

(704,8)

8

See Detail 1

90614-WC1 (9,9) 14.8

(375)

31.25

(793,7)

33.75

(857,2)

10

See Detail 2

90619-WC1 (15,1) 19.8

(502)

37.25

(946,1)

39.75

(1009,6)

14

See Detail 3

90624-WC1 (17,5) 24.9

(632)

43.25

(1098,5)

45.75

(1162,0)

16

See Detail 4

90629-WC1 (20,0) 29.9

(759)

55.25

(1403,3)

57.75

(1466,8)

18

See Detail 5

90640-WC1 (24,9) 40.2

(1021)

67.25

(1708,1)

69.75

(1771,6)

24

See Detail 7

90650-WC1 (29,8) 50.2

(1275)

19.25

(488,9)

21.75

(552,4)

20.94

(531,9)

26.94

(684,3)

32.94

(836,7)

38.94

(989,1)

44.94

(1141,5)

28

See Detail 9

91204-WC1 (10,1) 4.7

(119)

25.25

(641,3)

27.75

(704,8)

8

See Detail 1

91209-WC1 (11,3) 9.7

(246)

34.8

31.25

(793,7)

33.75

(857,2)

10

See Detail 2

91214-WC1 (15,8) 14.8

(375)

40.2

37.25

(946,1)

39.75

(1009,6)

14

See Detail 3

91219-WC1 (18,2) 19.8

(502)

91224-WC1 24.9

(632)

45.6

(20,7)

51.0

43.25

(1098,5)

45.75

(1162,0)

49.25

(1250,9)

51.75

(1466,8)

50.94

(1293,9)

16

18

See Detail 4

See Detail 5

91229-WC1 (23,1) 29.9

(759)

61.25

(1555,7)

63.75

(1619,2)

62.94

(1598,7)

74.94

(1903,5)

24

See Detail 6

91240-WC1 (28,1) 40.2

(1021)

73.25

(1860,5)

75.75

(1924,0)

28

See Detail 8

91250-WC1 (33,0) 50.2

(1275)

Specifications subject to change without notice

(kg)

inches

(mm)

D

inches

(mm)

Mounting Dimensions

14.2

A

13.25

(336,5)

M

90604-WC1 6

(6,5)

Table

Weight

18.2

21.8

33.2

38.6

44.0

54.9

65.7

22.3

24.9

61.9

72.7

30

See Detail 10

06 = Carriage length is 06 inch (152,4 mm) with 4 bearings; Carriage weight = 5.75 lbs. (2,61 kg)

12 = Carriage length is 12 inch (304,8 mm) with 4 bearings; Carriage weight = 8.75 lbs. (3,97 kg)

(1)

Footnotes:

(1) Weight shown is with a 0.625 inch (16 mm) diameter screw, a NEMA 23 motor mount [0.34 lbs (0,16 kg)], and a C100 style [0.09 lbs (0,04 kg)] coupling.

When using a 0.750 inch (20 mm) diameter screw add 0.042 lbs per inch (0,00075 kg per mm) of screw length for a given model number. When using a

1.000 inch diameter screw add 0.117 lbs per inch (0,0021 kg per mm) of screw length for a given model number.](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-159-2048.jpg)

![Technical Reference - Screw Drive - 90-WC1 Series

Optional NEMA 23 Motor Mount Shown:

(1) This value is center to center distance (spread)

between the two rails (d1).

(2) This value is center to center distance (spacing) of

the bearings on a single rail (d2) [see page D-5].

Specifications subject to change without notice

Dimensions - With Waycovers -

1.125

(28,58)

1.625 D E

(41,28) M # of Thru Holes

C

6 inch (152,4 mm) FOUR bearing carriage shown.

12 inch (304,8 mm) FOUR bearing carriage will have

individual bearings mounted towards carriage edges.

(2)

(3)

Threaded Stainless Steel Inserts:

English Inserts (-1): 1/4-20 x .50 inch deep TYP

Metric Inserts (-2): M6 thd. x 12 mm deep TYP

5.000

(127,00)

EOT & HOME

Switch Cable Egress 1.502 (38,15) Pilot Dia. TYP

5.500

(139,70)

3.250

(82,55)

4.500

(114,30)

5.500

(139,70)

2.937

(74,60)

.500

(12,70)

(4) Holes on 2.625 (66,68) Bolt Circle Dia.

English Mount (M02): #10-24 thd.

Metric Mount (M03): M5 thd.

inches

(mm)

.375

(9,53)

0.500 TYP

(12,70) TYP

1.250

(31,75)

o

1.068

(27,13)

.375

(9,52)

o

.375 (9,53)

304 Woodruff

Keyway

(1)

8.000

(203,2)

d2

.201 (5,11) Dia.

1.437

(36,50)

2.438

(61,93)

4 Holes; 6 inch (152,4 mm) carriage

Carriage Length

6 Holes; 12 inch (304,8 mm) carriage

.625

(15,87)

For optional coupling info

see pages D-26 & D-27.

Also, coupling cover in-cluded

on top of optional

motor mounts.

A

B

.625

(15,87)

.625

(15,87)

See Detail 1 - 10 (below)

X Mounting Details 1 through 10

1.625

(41,28)

W W 1.625

(41,28)

X

2

3

4

5

7

9

Sold & Serviced By:

10

X

1.625

(41,28)

Z

Z

Z

Z

Z Z

Z

W 1.625

(41,28)

X X W

Z

W X X W W X X W

1.625

(41,28)

1.625

(41,28)

1.625

(41,28)

W 1.625

(41,28)

X X W W X X W

1.625

(41,28)

W 1.625

(41,28)

X X W W X X

1.625

(41,28)

W 1.625

(41,28)

W Y X X W

1.625

(41,28)

W 1.625

(41,28)

Y X X

(3) This value is center distance of the bearing to top of

carriage plate surface (dr).

Note: Any 90 series table can be mounted on top

of any second 90 series, in order to create X-Y

multiple axis configurations. The carriage's threaded

stainless steel insert hole pattern DOES NOT ex-actly

match the base mounting hole pattern on each

table, therefore machining of the bottom axis car-riage

plate is required. Please contact LINTECH.

W = 6.00

(152,4) X = 5.00

(127,0)

Y = 4.00

(101,6) Z = 2.00

(50,8)

Z

Z Z

1.625

(41,28)

W 1.625

(41,28)

X

1

Y

6

1.625

(41,28)

W 1.625

(41,28)

X X W W X X

8

1.625

(41,28)

W 1.625

(41,28)

X X W W X X W

Y

W

W

W

X X W

Z

W X X W W X X W

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-160-2048.jpg)

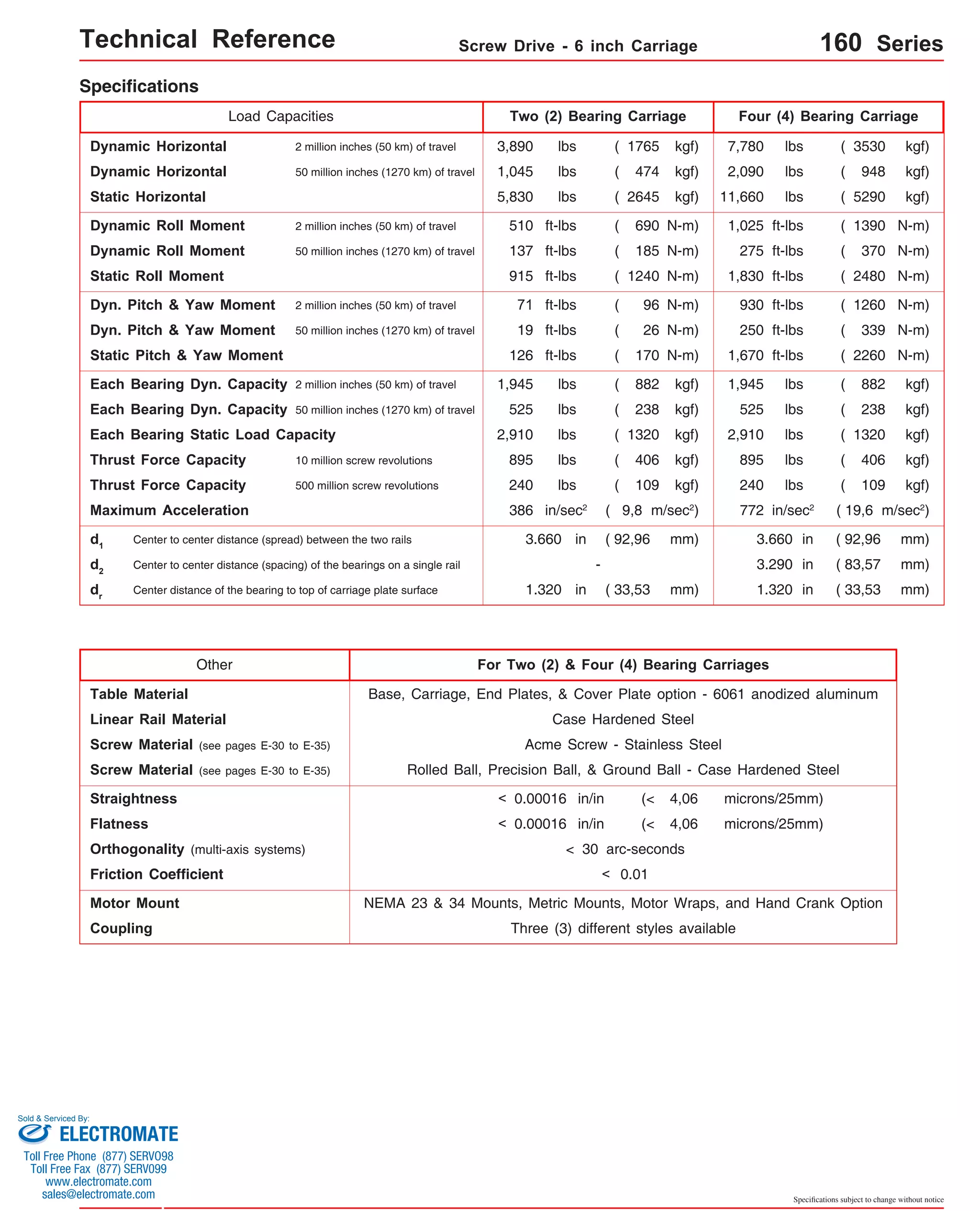

![Technical Reference Screw Drive - 6 inch Carriage 160-CP0 Series

Dimensions & Specifications

Travel

Length

Table Dimensions

Model

Number lbs

inches

(mm)

16x648-CP0 48

(1215)

Sold & Serviced By:

Specifications subject to change without notice

(kg)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

A

16x606-CP0

12.125

14.2

(308,0)

(6,4) B

16.688

(423,9)

Screw

Length

inches

(mm)

16.00

(406)

Table

Weight

54.125

(1374,8)

58.688

(1490,7)

58.00

(1473) 17 36 29.6

(13,4)

x = 2; Carriage has 2 bearings; Carriage weight = 3.3 lbs. (1,50 kg)

x = 4; Carriage has 4 bearings; Carriage weight = 4.1 lbs. (1,86 kg)

(1)

16x612-CP0 18.125

(460,4)

6

(150)

12

(300)

16x618-CP0 18

(455)

16x624-CP0 24

(605)

16x630-CP0 30

(760)

16x636-CP0 36

(910)

16x642-CP0 42

(1060)

16x654-CP0 54

(1370)

16x660-CP0 60

(1520)

- With T-Slot Load Mounting -

M

3 8

22.688

(576,3)

22.00

(559) 5 12

24.125

(612,8)

28.688

(728,7)

28.00

(711) 7 16

30.125

(765,2)

34.688

(881,1)

34.00

(864) 9 20

36.125

(917,6)

40.688

(1033,5)

40.00

(1016) 11 24

42.125

(1070,0)

46.688

(1185,9)

46.00

(1168) 13 28

48.125

(1222,4)

52.688

(1338,3)

52.00

(1321) 15 32

60.125

(1527,1)

64.688

(1643,0)

64.00

(1625) 19 40

66.125

(1679,6)

70.688

(1795,5)

70.00

(1778) 21 44

16.4

(7,4)

18.6

(8,4)

20.8

(9,4)

23.0

(10,4)

25.2

(11,4)

27.4

(12,4)

31.8

(14,4)

34.0

(15,4)

Footnotes:

(1) Weight shown is with a 0.625 inch (16 mm) diameter screw, a NEMA 23 motor mount [0.42 lbs (0,19 kg)], a C100 style [0.09 lbs (0,04 kg)] coupling,

and a 2 bearing carriage. When using a 0.750 inch (20 mm) diameter screw add 0.042 lbs per inch (0,00075 kg per mm) of screw length for a given

model number. When using a 4 bearing carriage add 0.8 lbs (0,36 kg) to each value.

version: 01/2014

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com](https://image.slidesharecdn.com/lintechpositioningsystemscatalog-141018113223-conversion-gate01/75/Lintech-positioning-systems_catalog-189-2048.jpg)

![Technical Reference Screw Drive - 6 inch Carriage 170-CP0 Series

Dimensions & Specifications

Travel

Length

Table Dimensions

Model

Number lbs

17x648-CP0 48

(1215)

17x654-CP0 54

(1370)

Sold & Serviced By:

Specifications subject to change without notice

(kgf)

inches

(mm)

C

inches

(mm)

Mounting Dimensions

17x606-CP0

inches

(mm)

A

B

16.688

(423,9)

Screw

Length

inches

(mm)

Table

Weight

12.125

(308,0)

18.125

(460,4)

24.125

(612,8)

30.125

(765,2)

36.125

(917,6)

42.125

(1070,0)

48.125

(1222,4)

54.125

(1374,8)

60.125

(1527,1)

66.125

(1679,6)

58.688

(1490,7) 17 36 26.8

(12,2)

64.688

(1643,0)

19 40 (1625) 28.6

(13,0)

x = 2; Carriage has 2 bearings; Carriage weight = 2.5 lbs. (1,13 kg)

x = 4; Carriage has 4 bearings; Carriage weight = 3.3 lbs. (1,50 kg)

(1)

17x612-CP0

6

(150)

12

(300)

17x618-CP0 18

(455)

17x624-CP0 24

(605)

17x630-CP0 30

(760)

17x636-CP0 36

(910)

17x642-CP0 42

(1060)

17x660-CP0 60

(1520)

- Without Cover Plates -

M

3 8

22.688

(576,3) 5 12

28.688

(728,7) 7 16

34.688

(881,1) 9 20

40.688

(1033,5) 11 24

46.688

(1185,9) 13 28

52.688

(1338,3) 15 32

70.688

(1795,5) 21 44

14.2

(6,4)

16.0

(7,3)

17.8

(8,1)

19.6

(8,9)

21.4

(9,7)