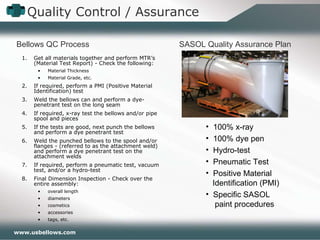

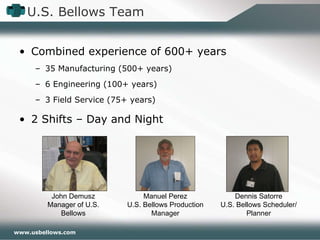

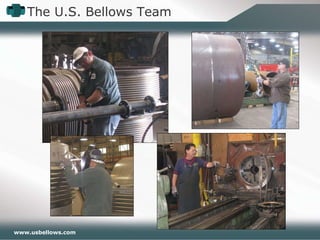

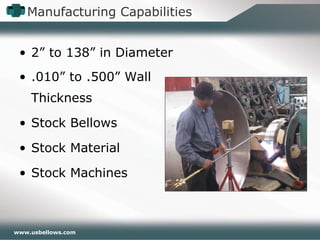

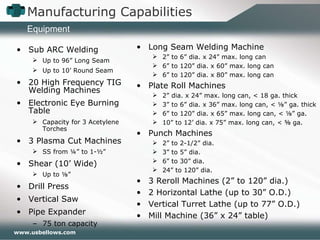

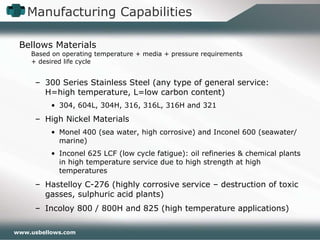

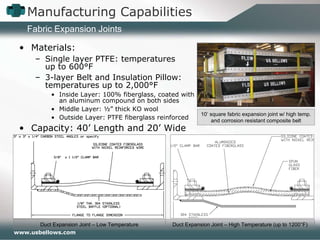

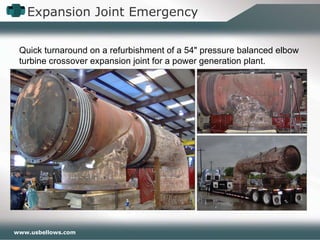

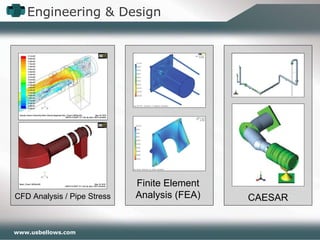

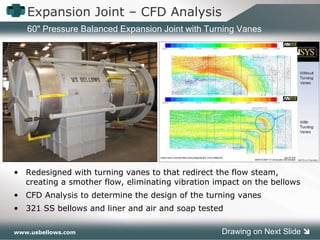

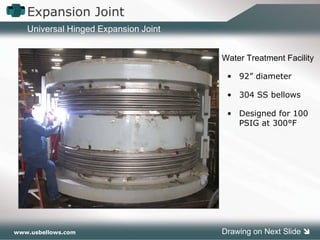

U.S. Bellows, Inc. is a leading manufacturer of metallic and fabric expansion joints with extensive capabilities and certifications, including ASME and ISO 9001:2008. The company has a rich history since the 1960s and specializes in quick delivery and emergency services, boasting over 600 years of combined team experience in manufacturing and engineering. Their facilities support various manufacturing techniques and materials to meet high-temperature and corrosive environment requirements while ensuring rigorous quality control through a comprehensive testing process.