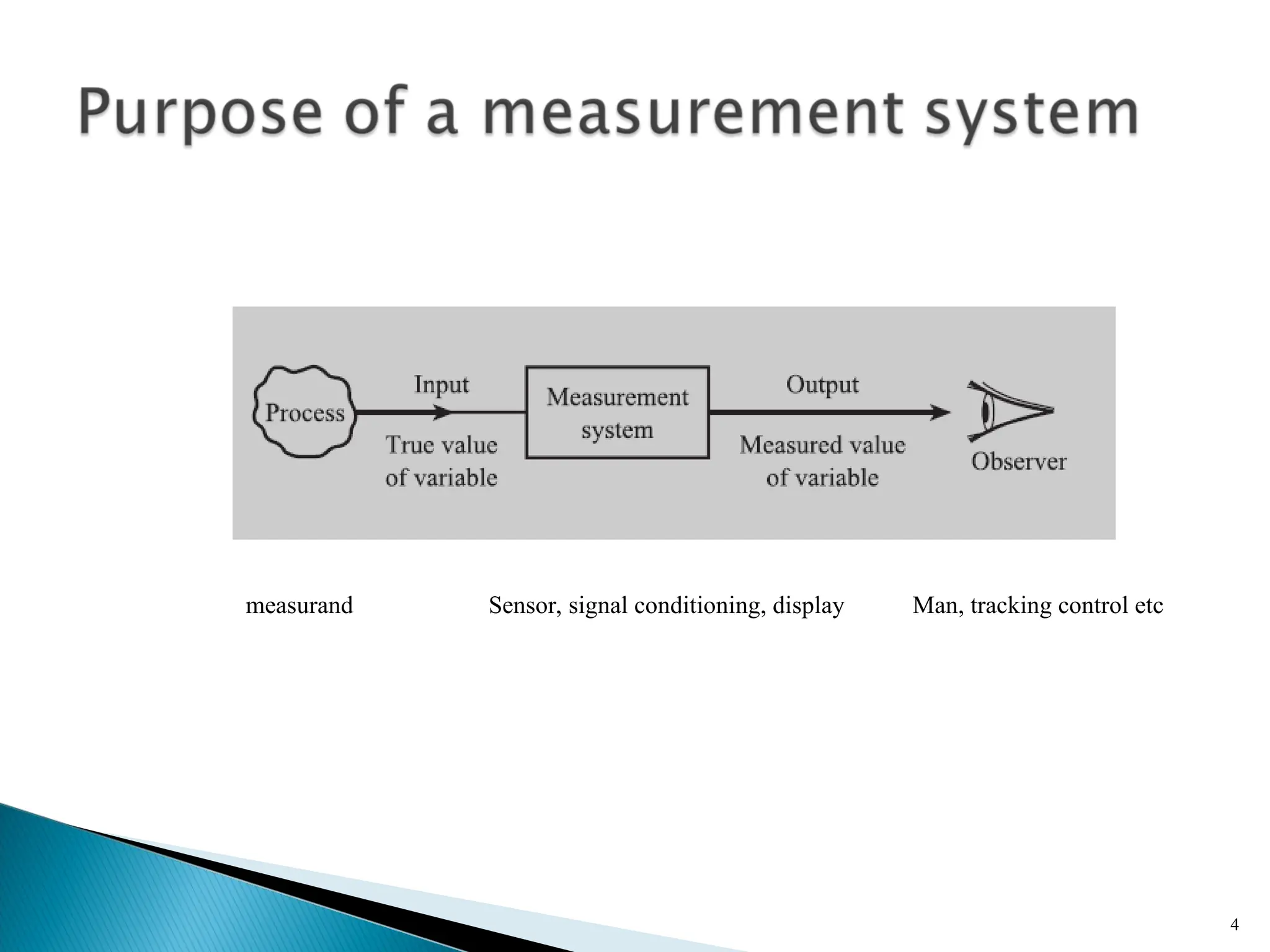

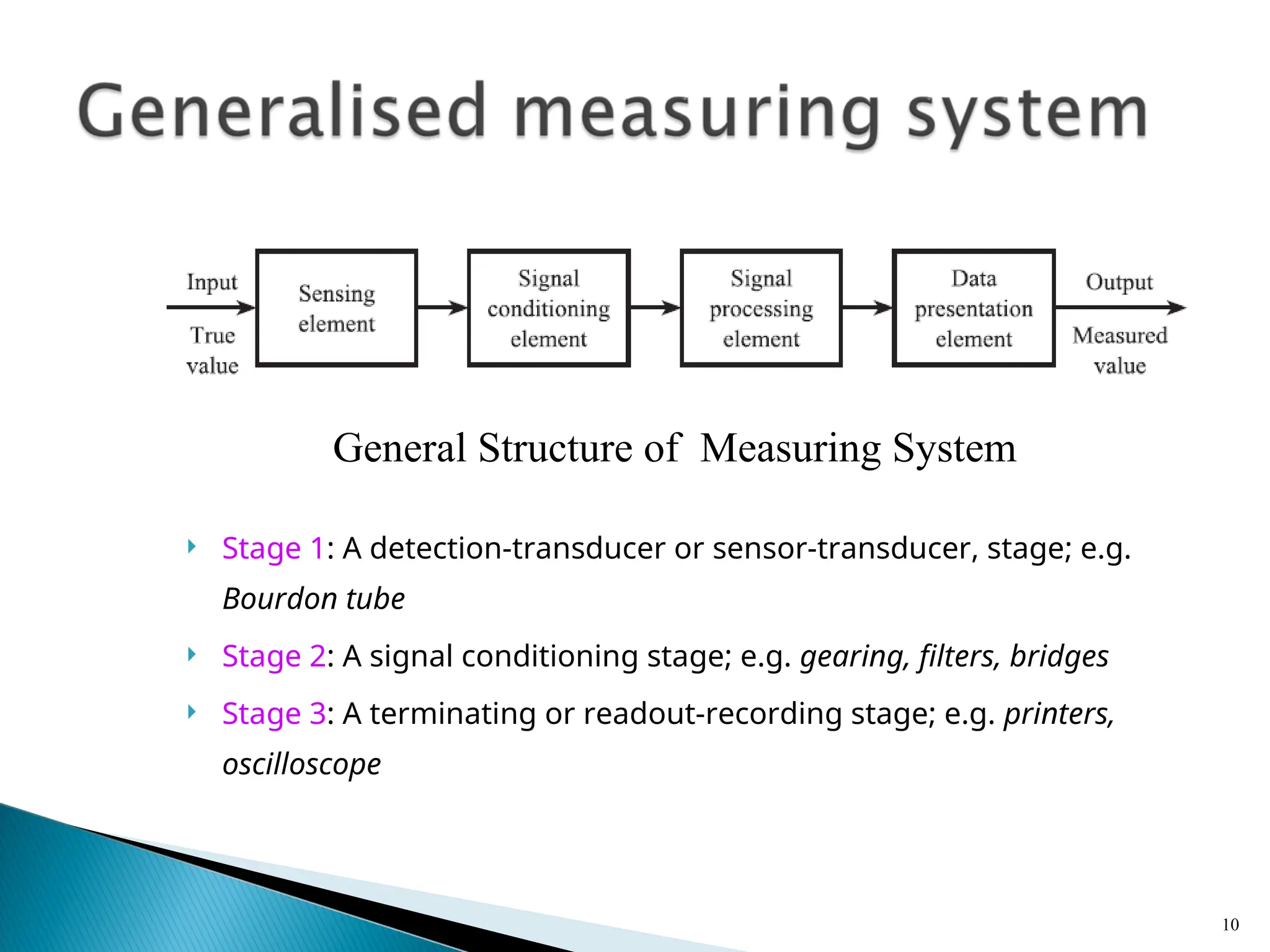

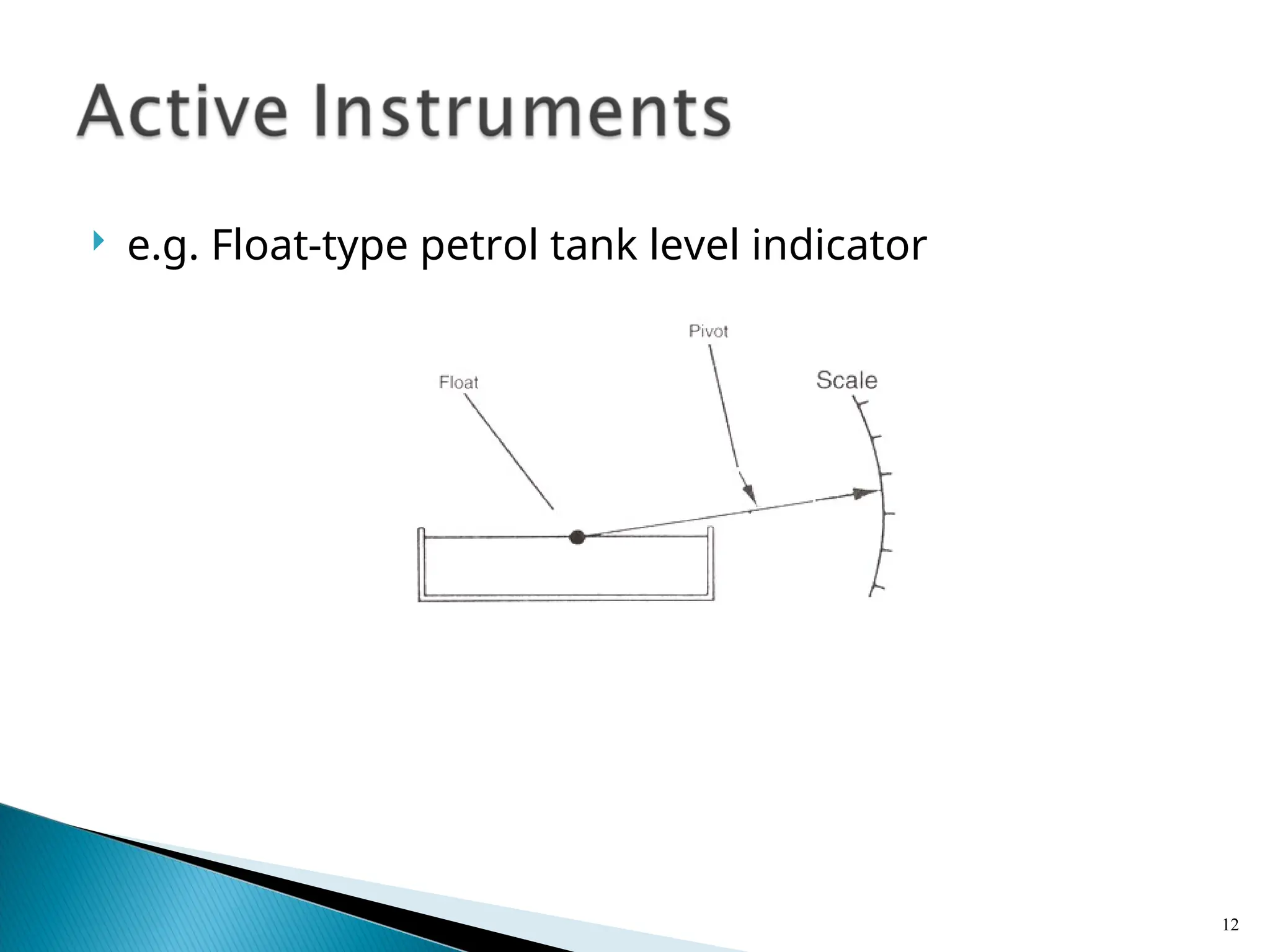

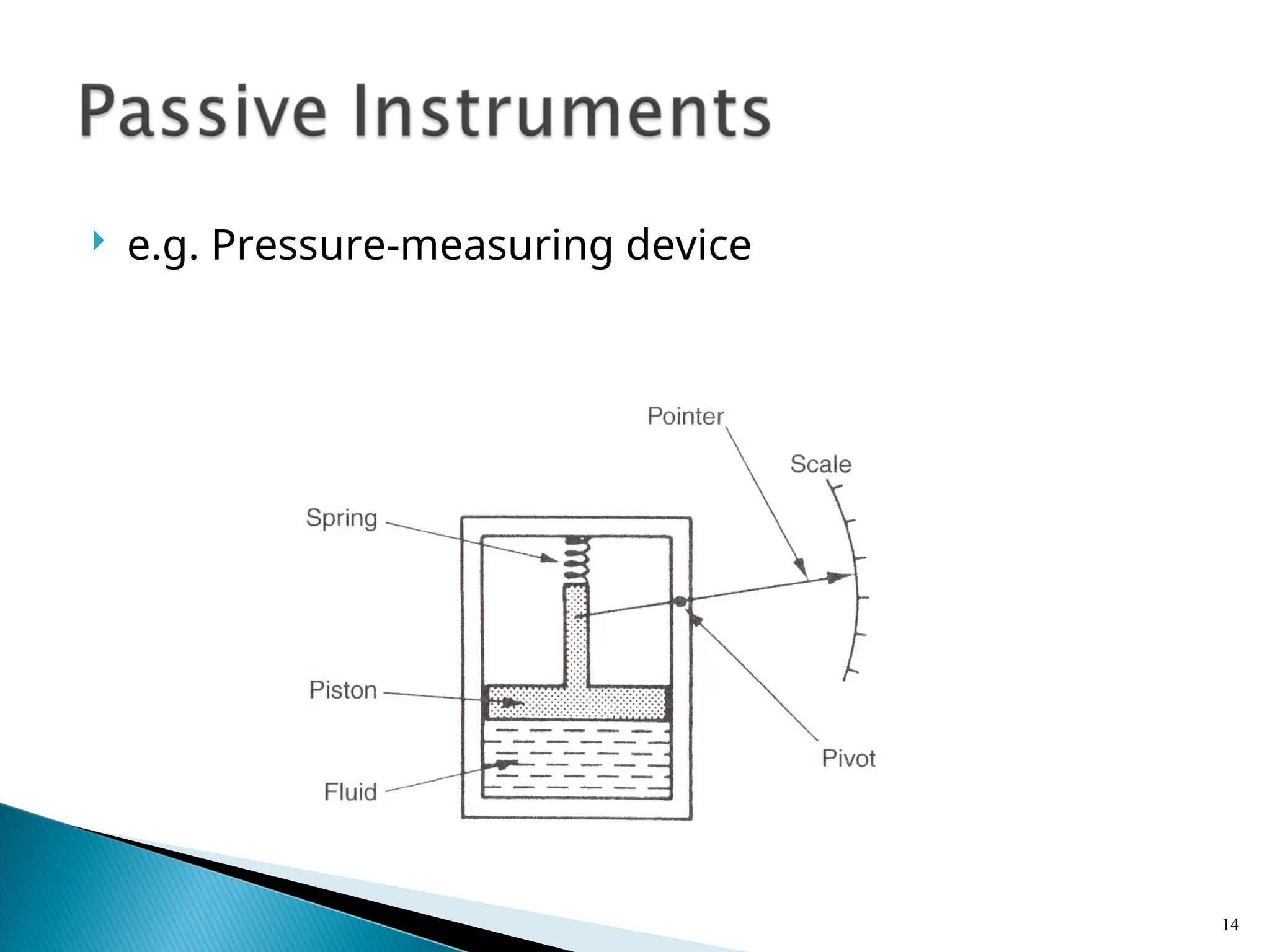

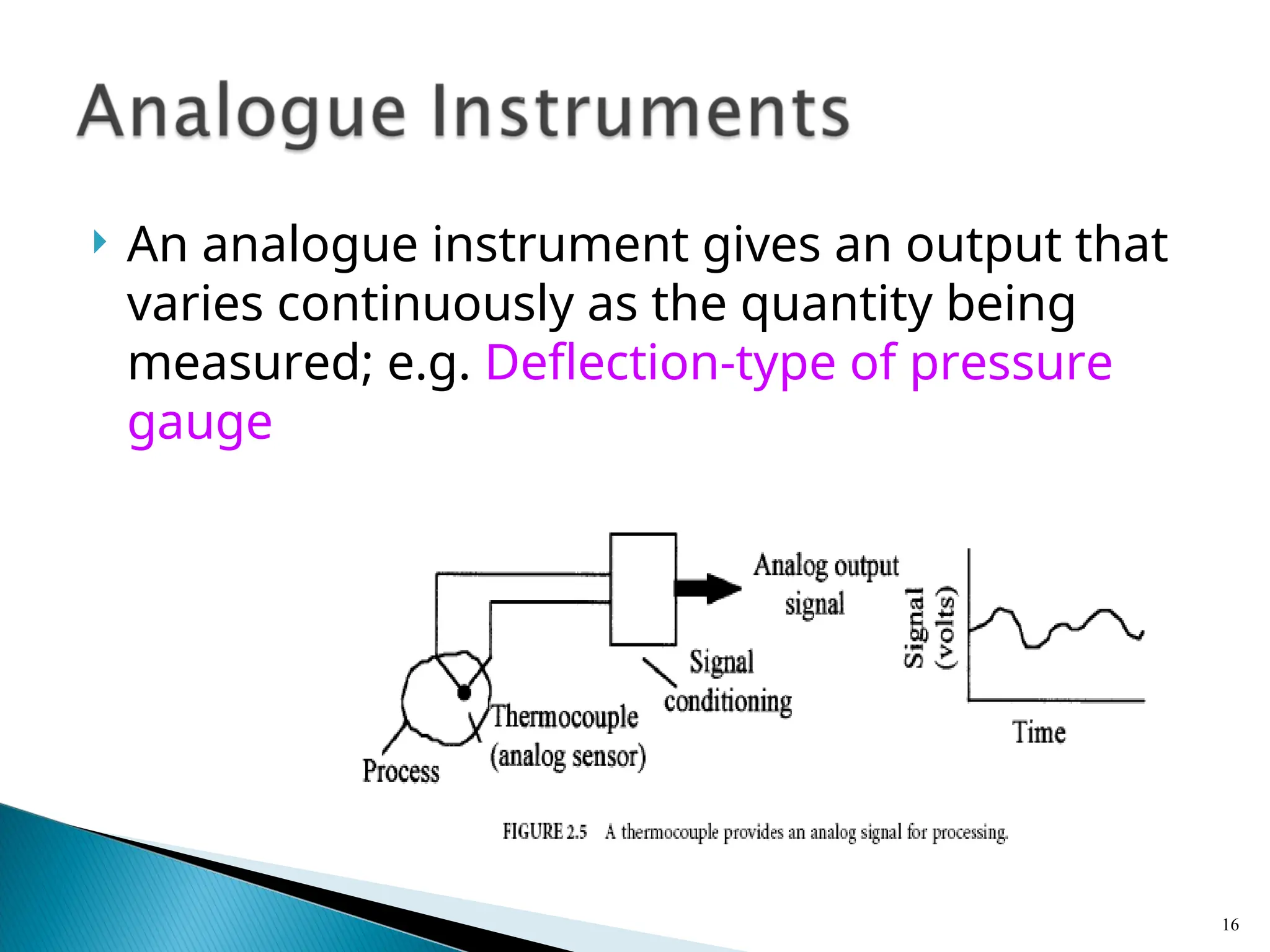

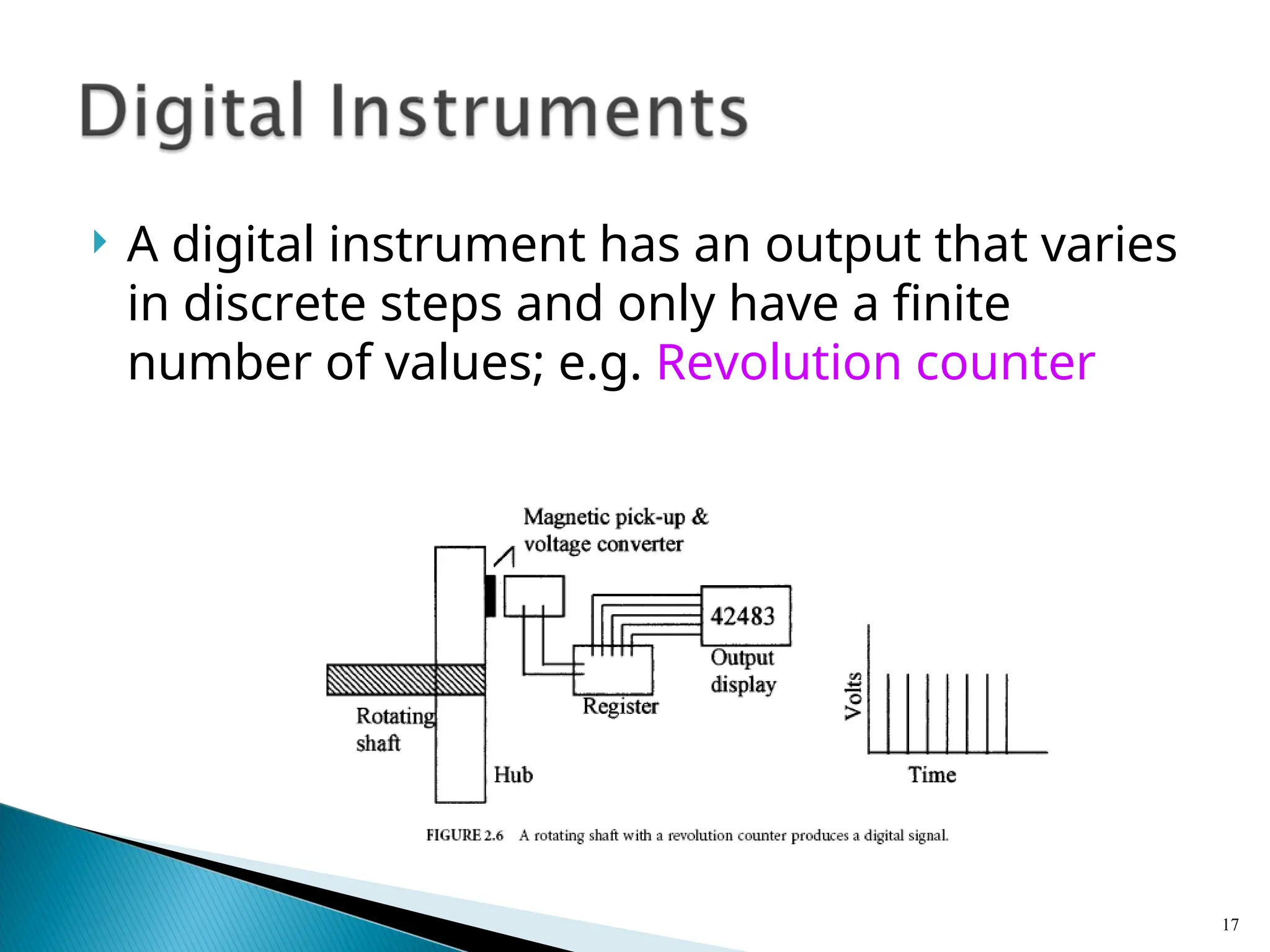

The document provides an introduction to instrumentation and measurement within engineering, detailing key concepts such as physical quantities, data acquisition, and the classification of sensors and transducers. It also covers various methods of measurement (e.g., temperature, pressure, and flow) and emphasizes the importance of accurate data collection for improving manufacturing efficiency and product quality. Additionally, it outlines errors in measurements, characteristics of measuring instruments, and presents a structured overview of different measurement units.