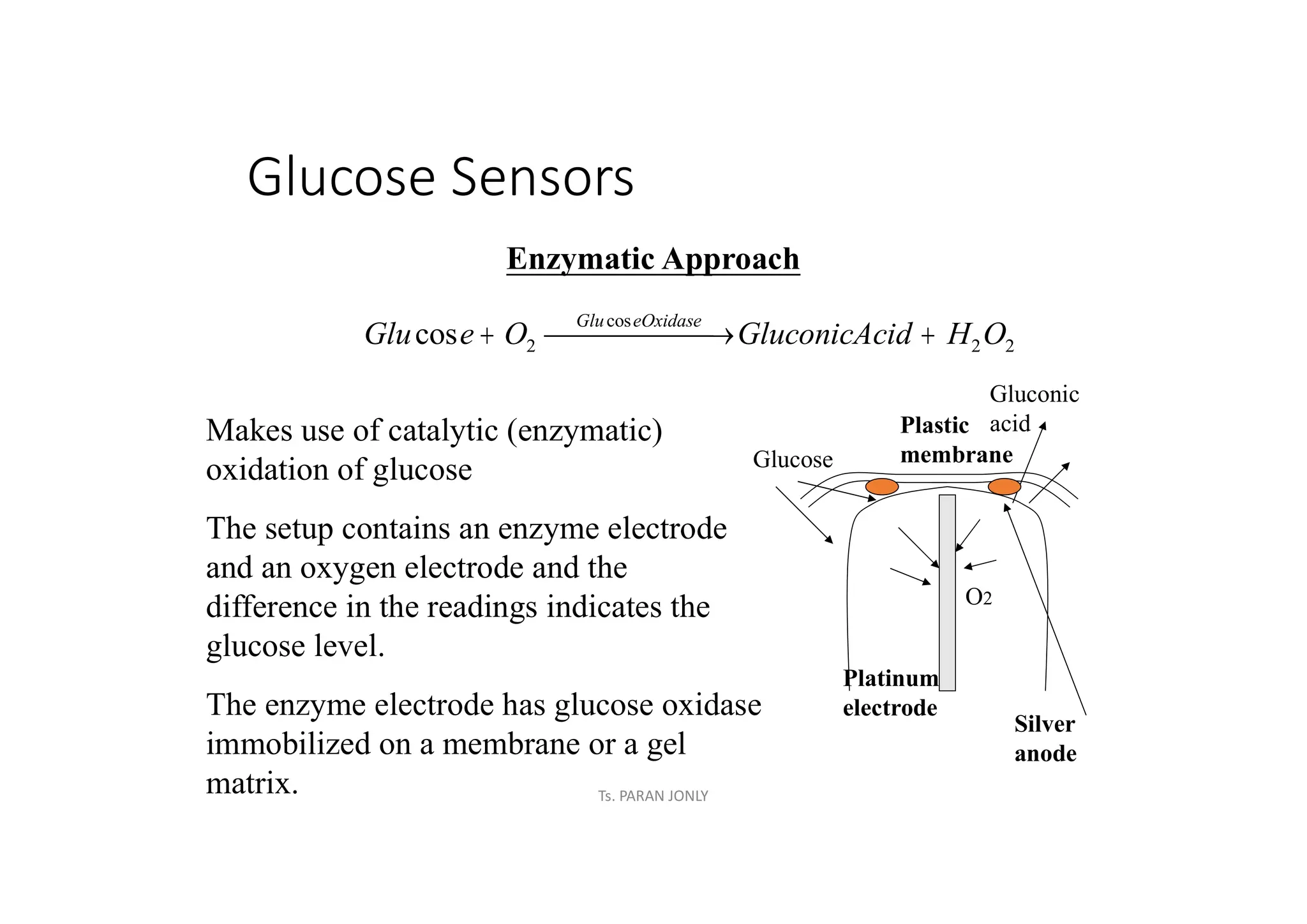

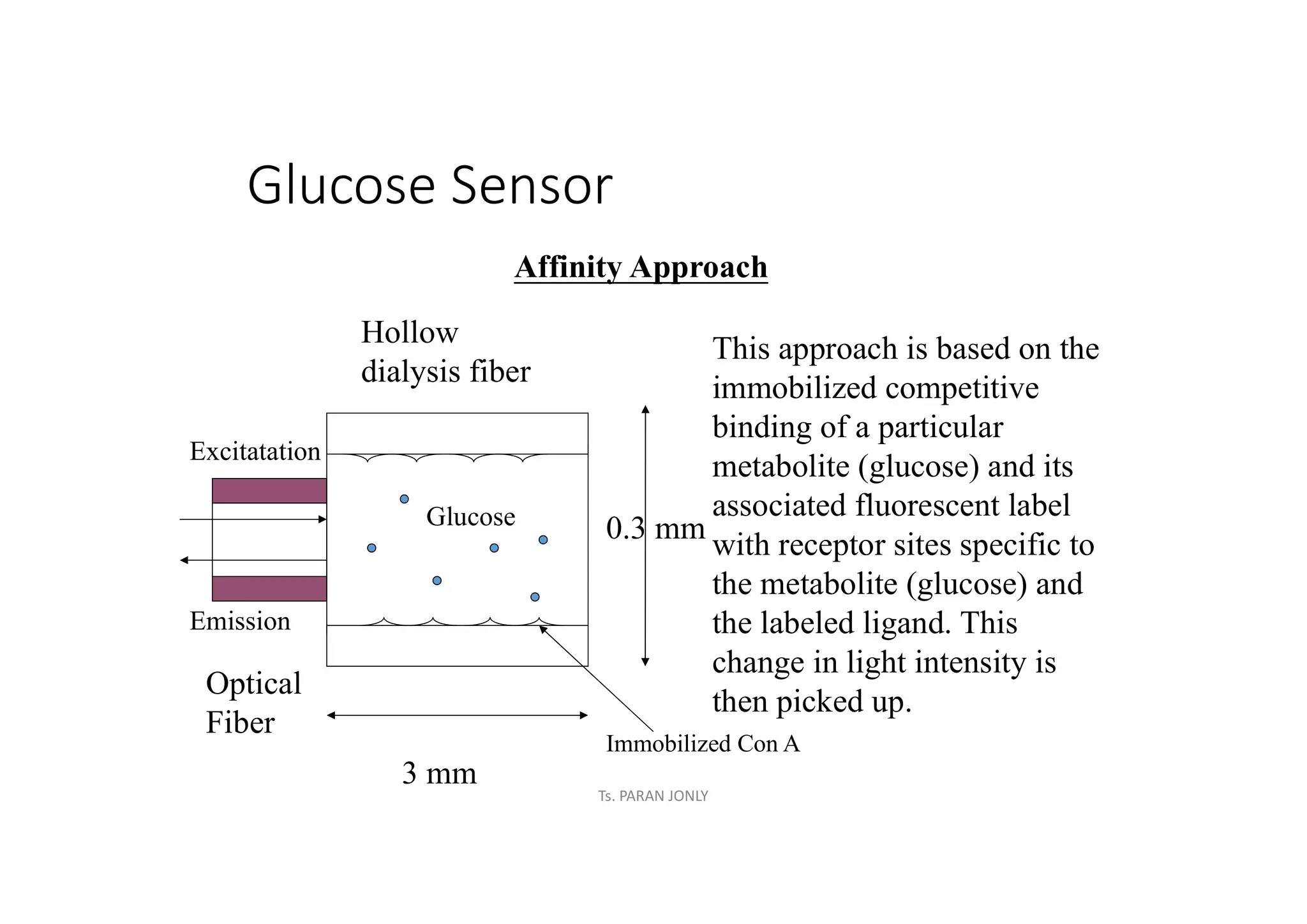

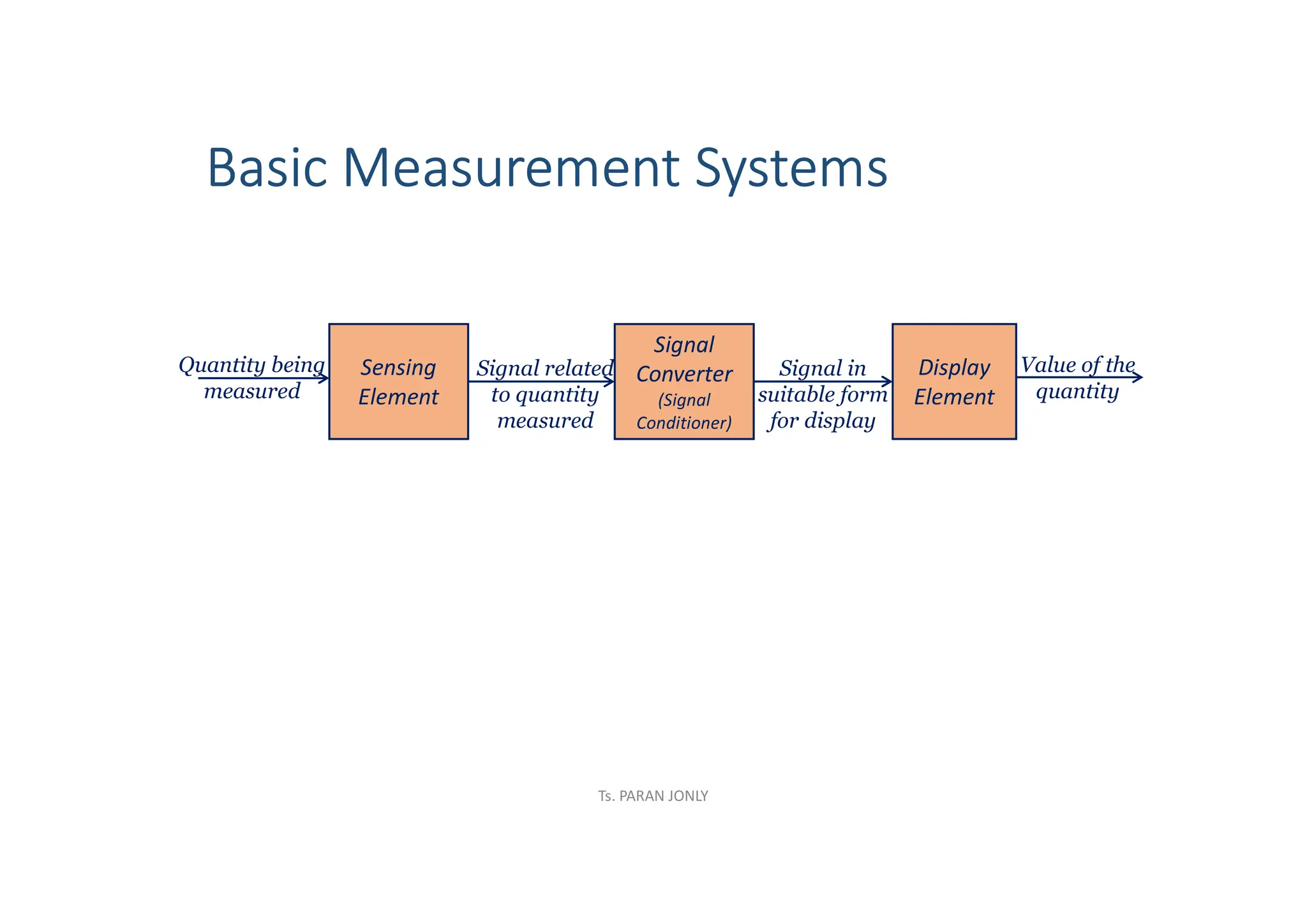

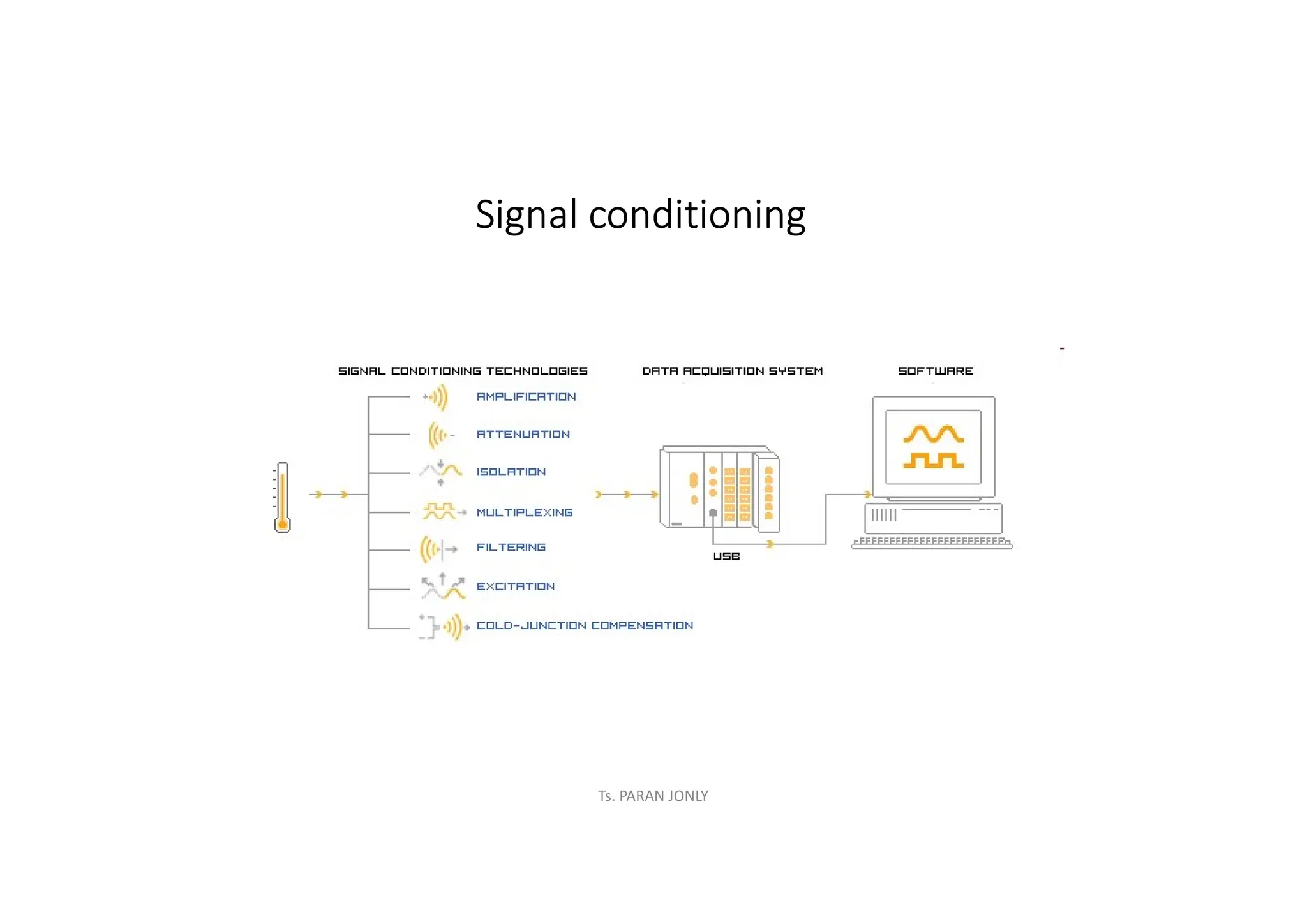

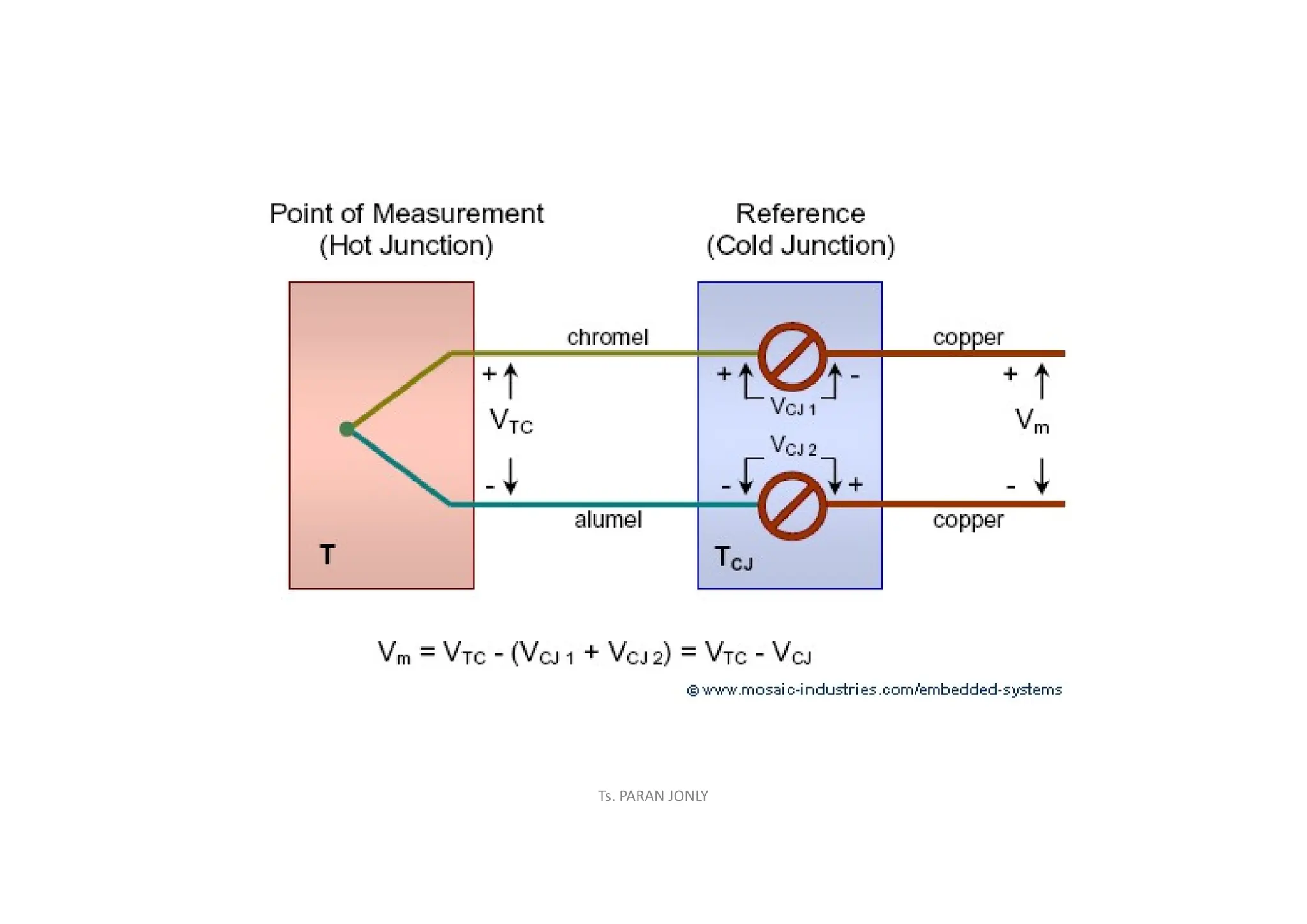

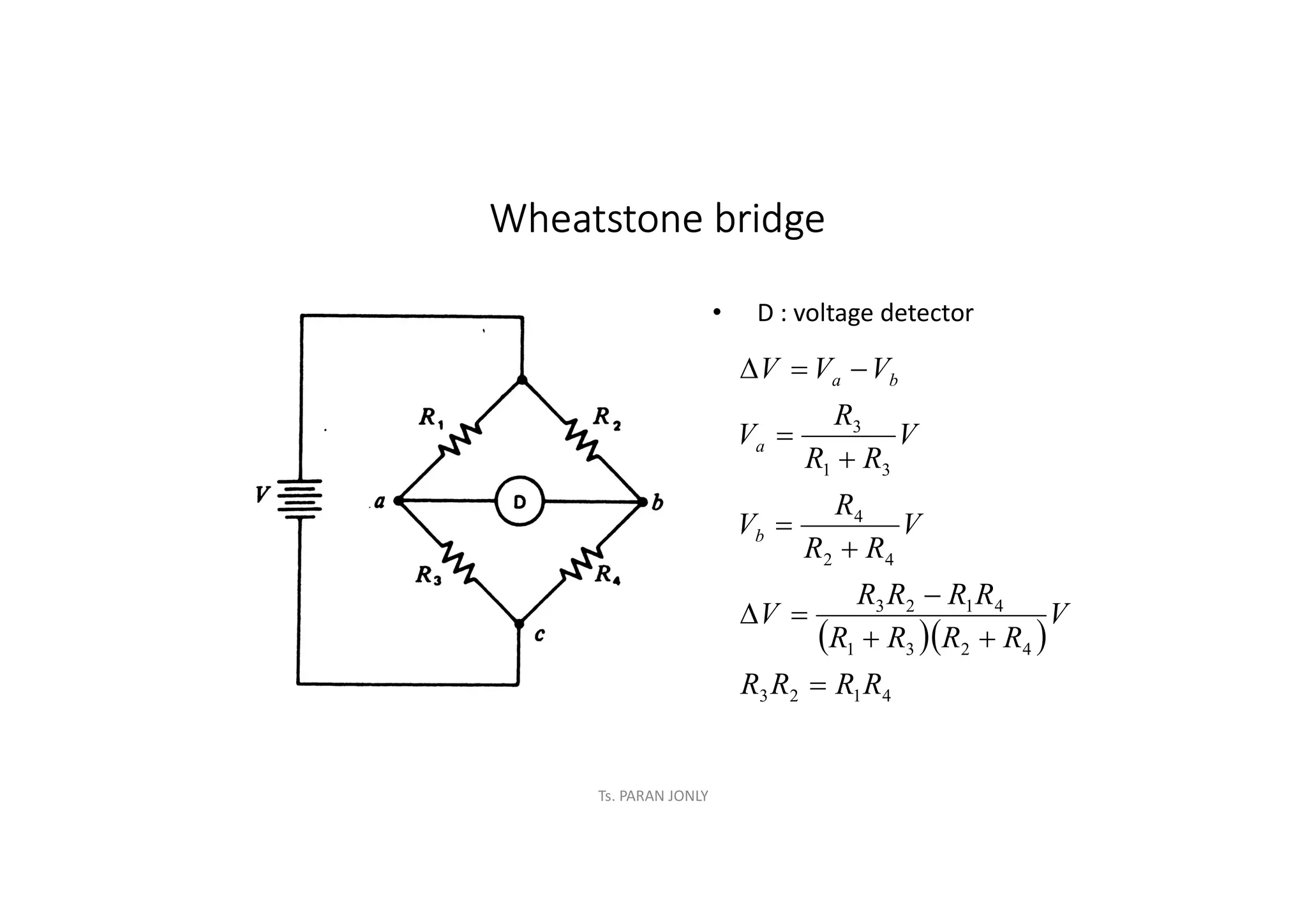

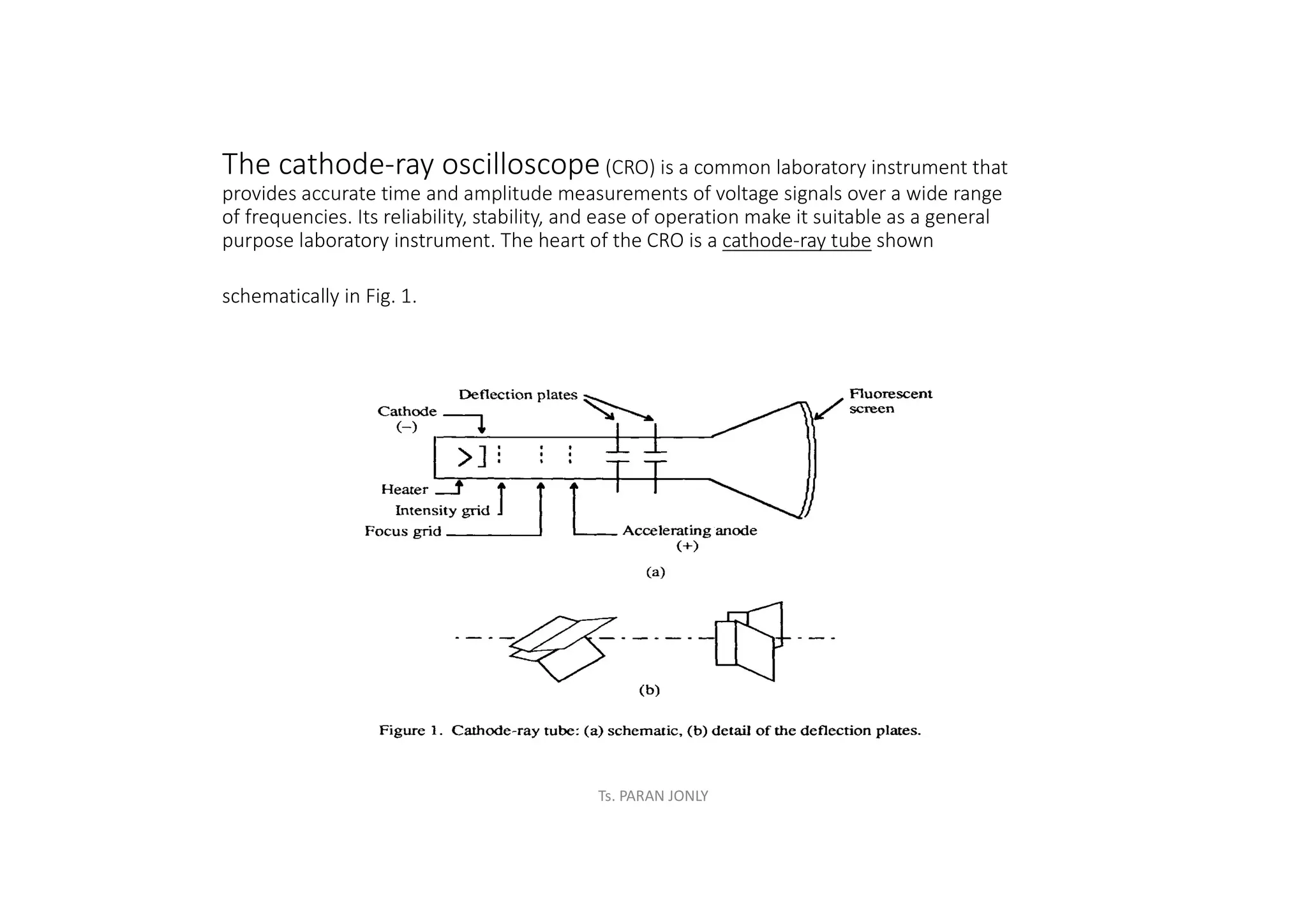

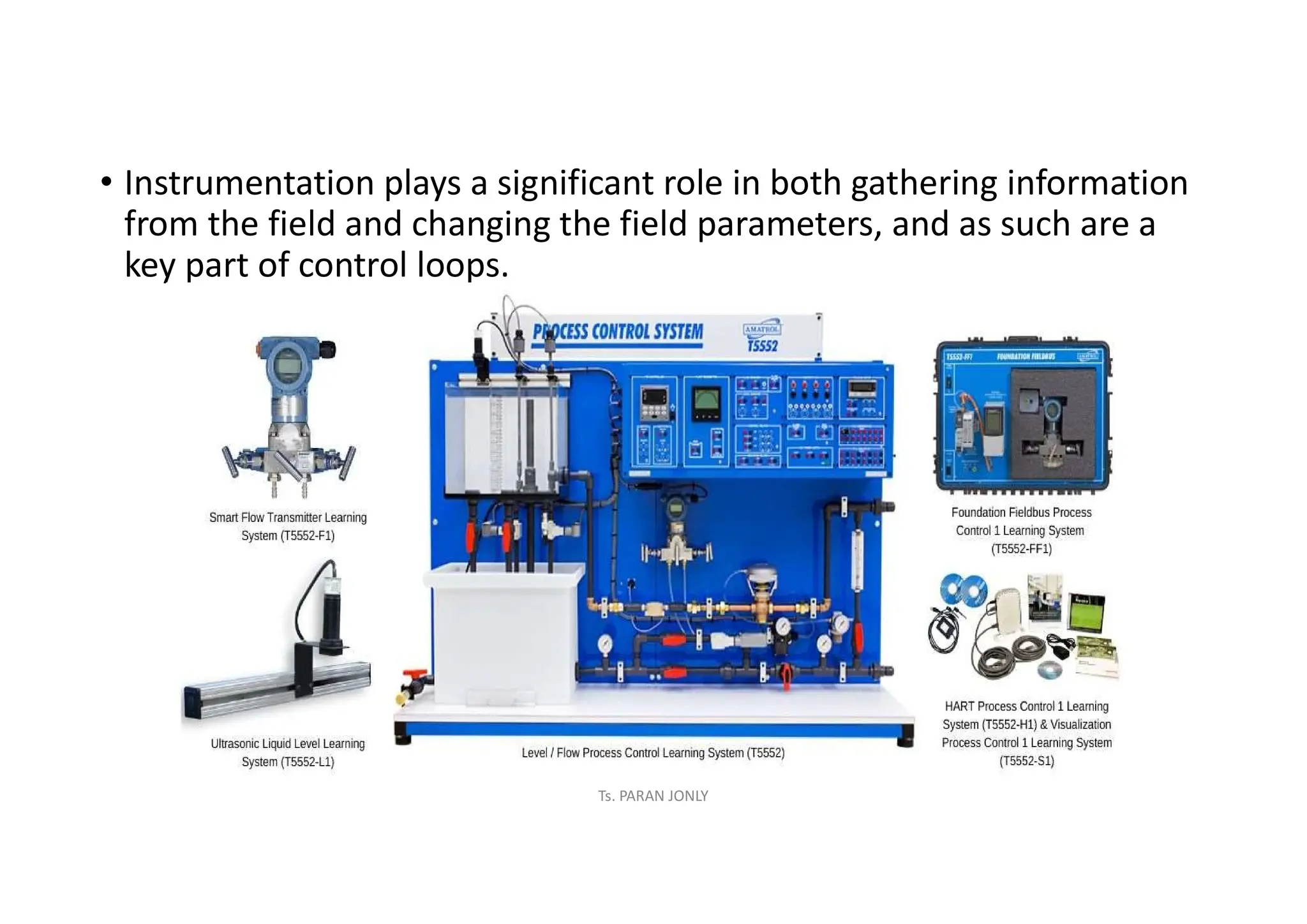

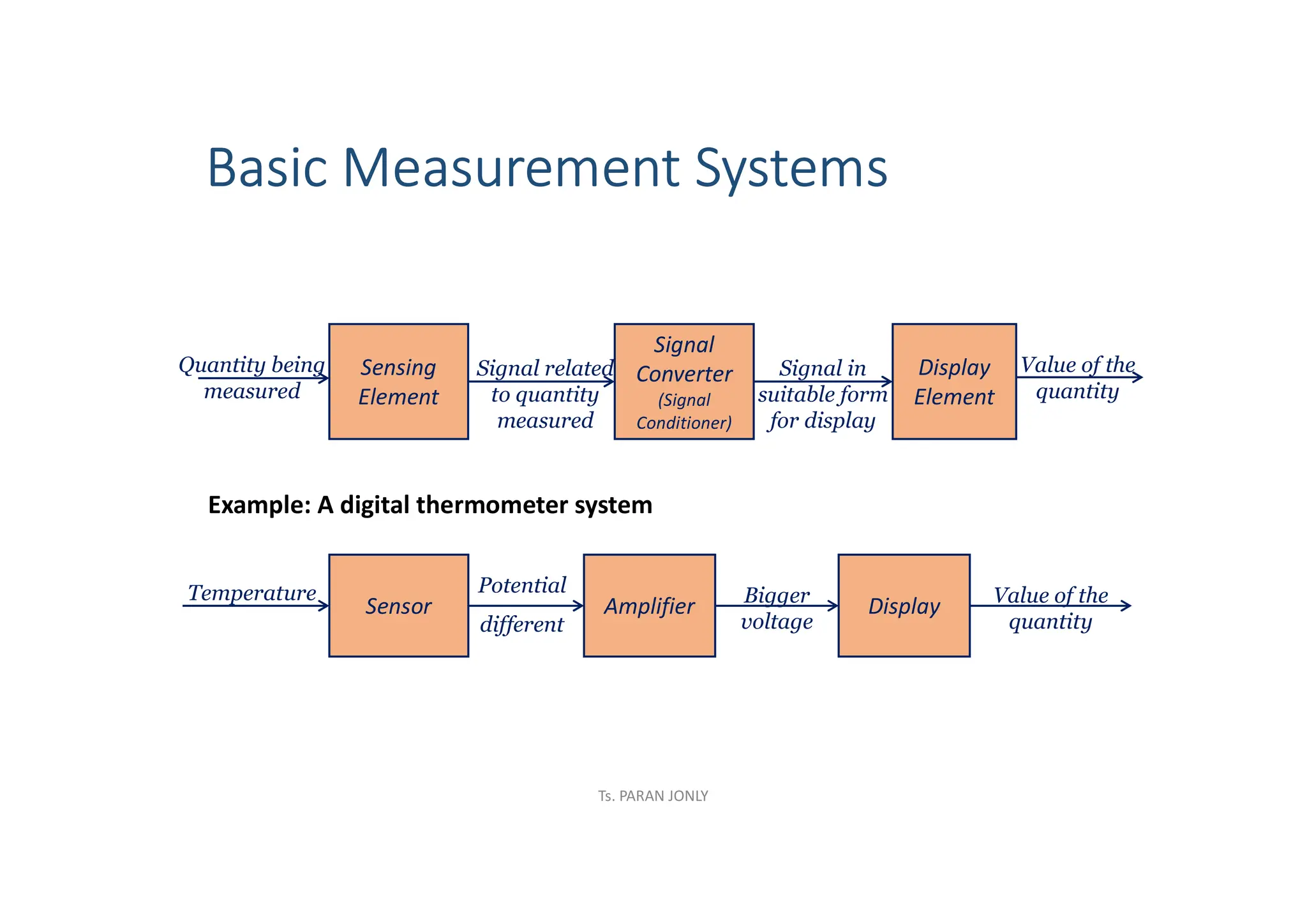

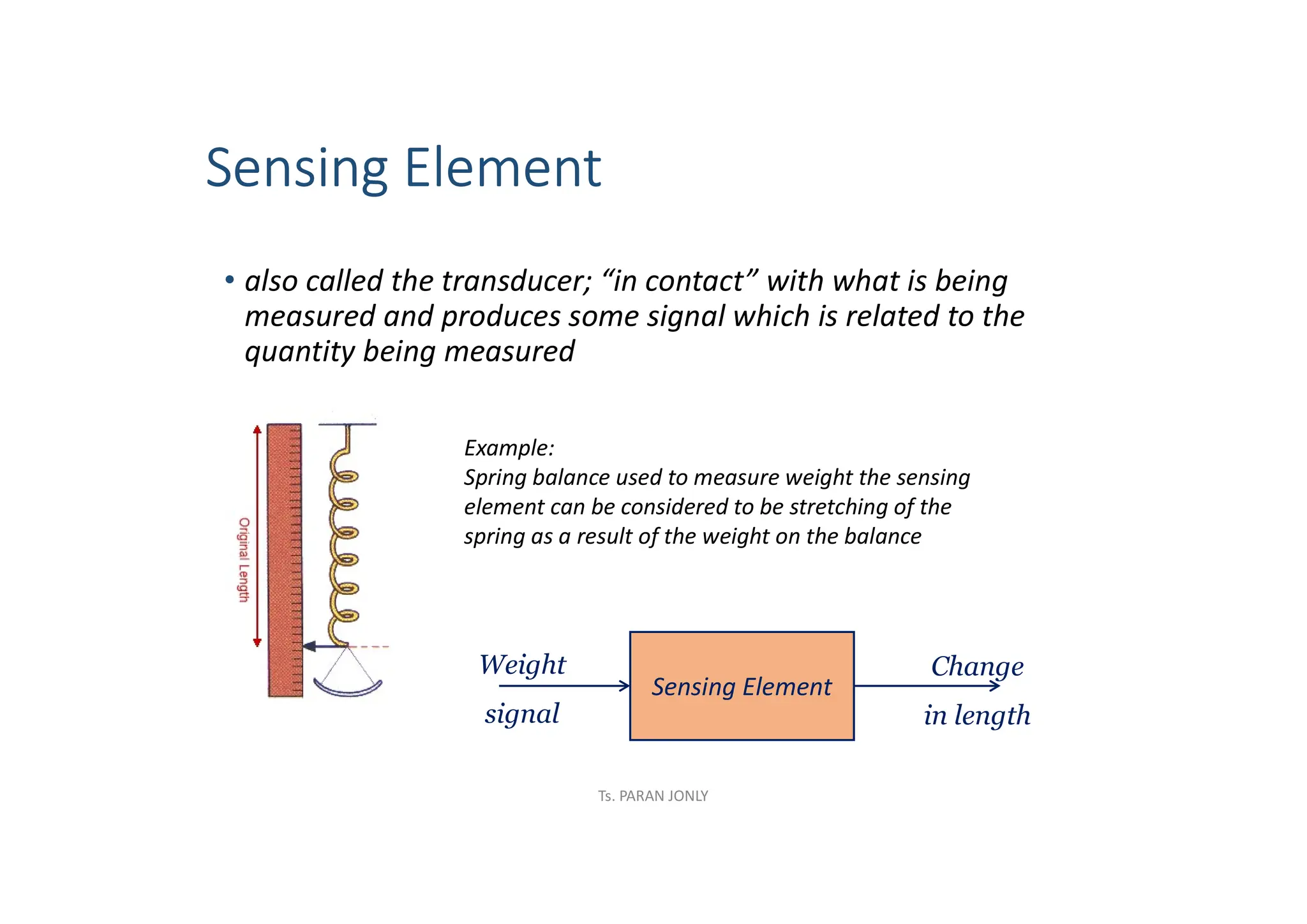

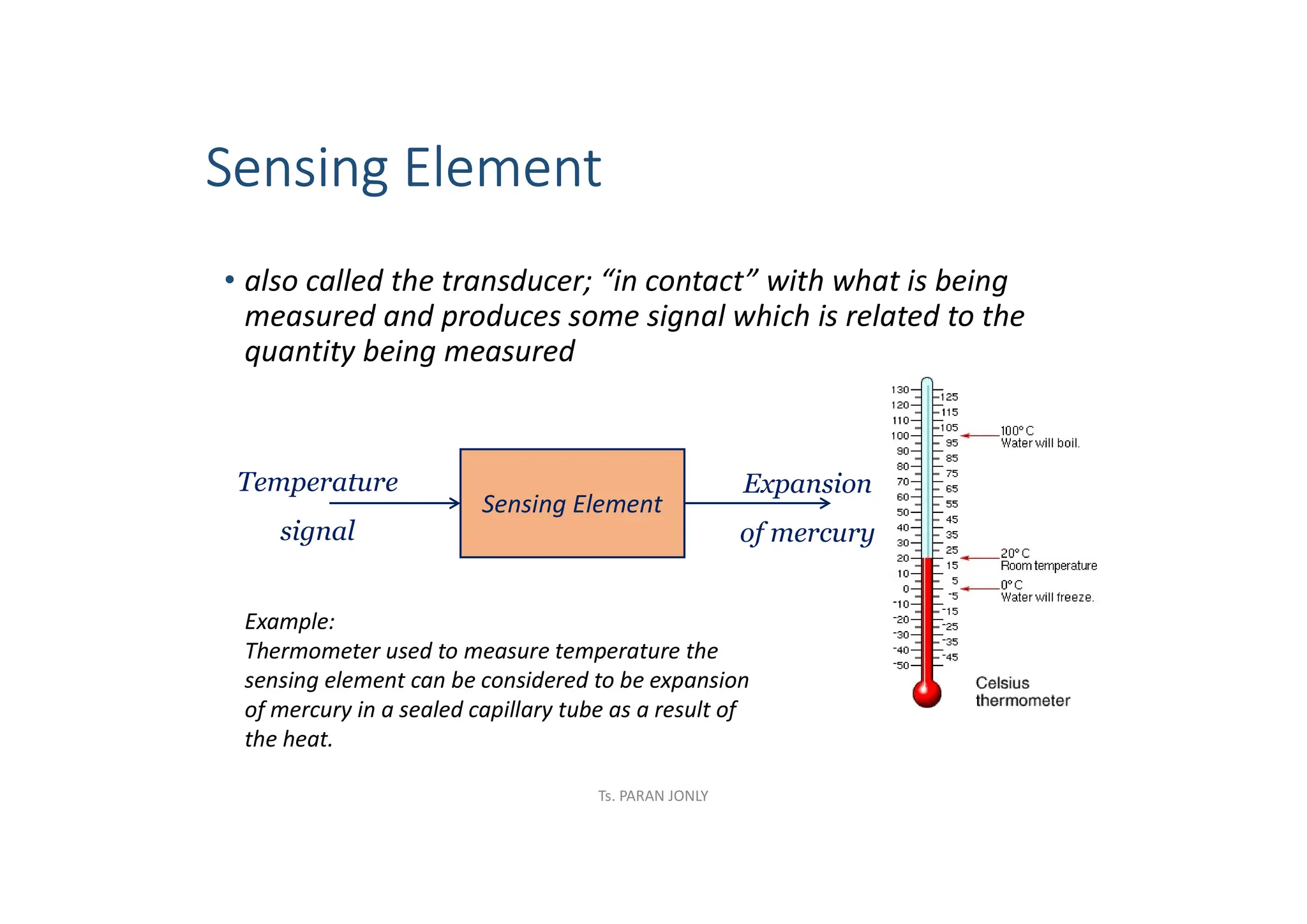

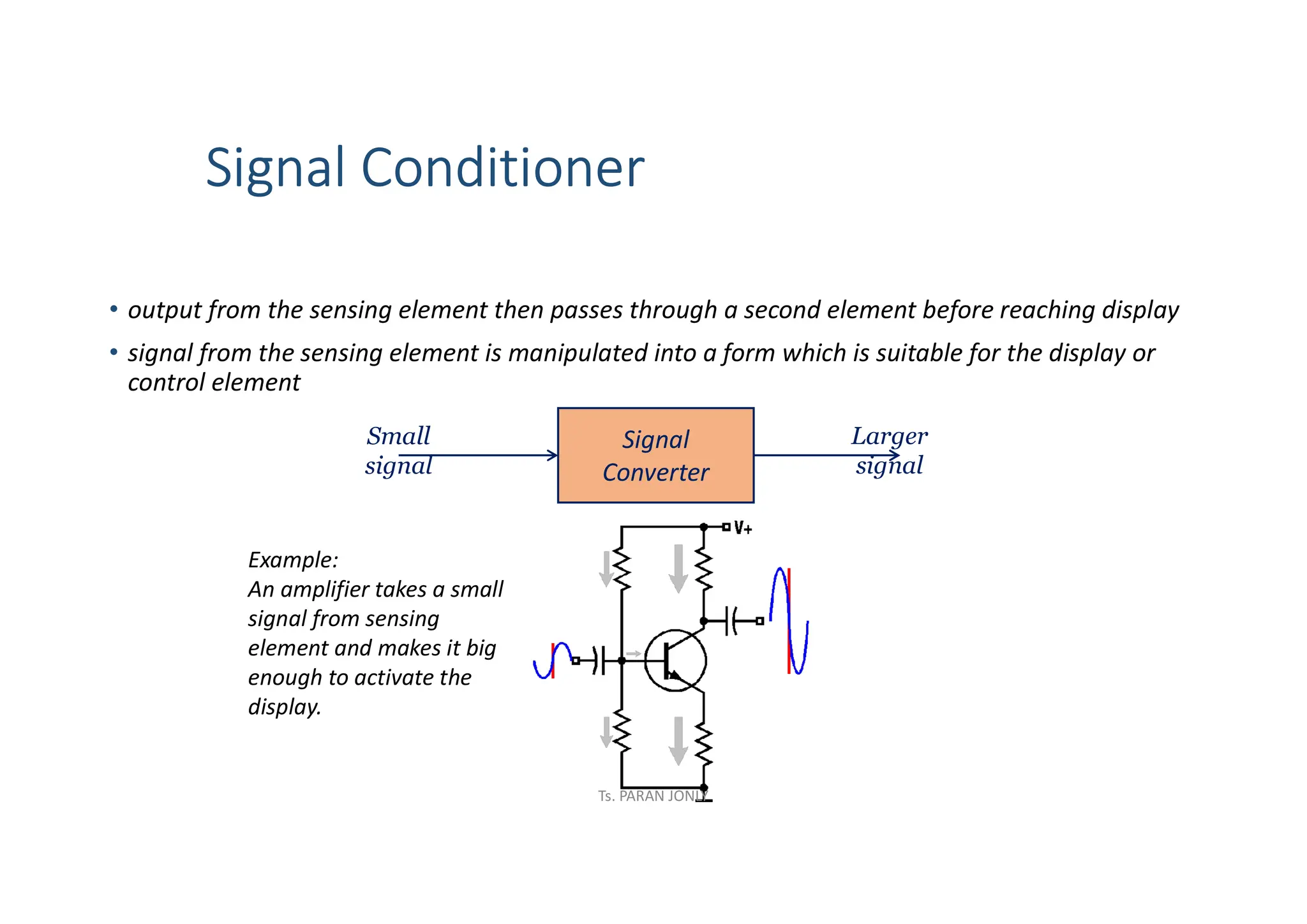

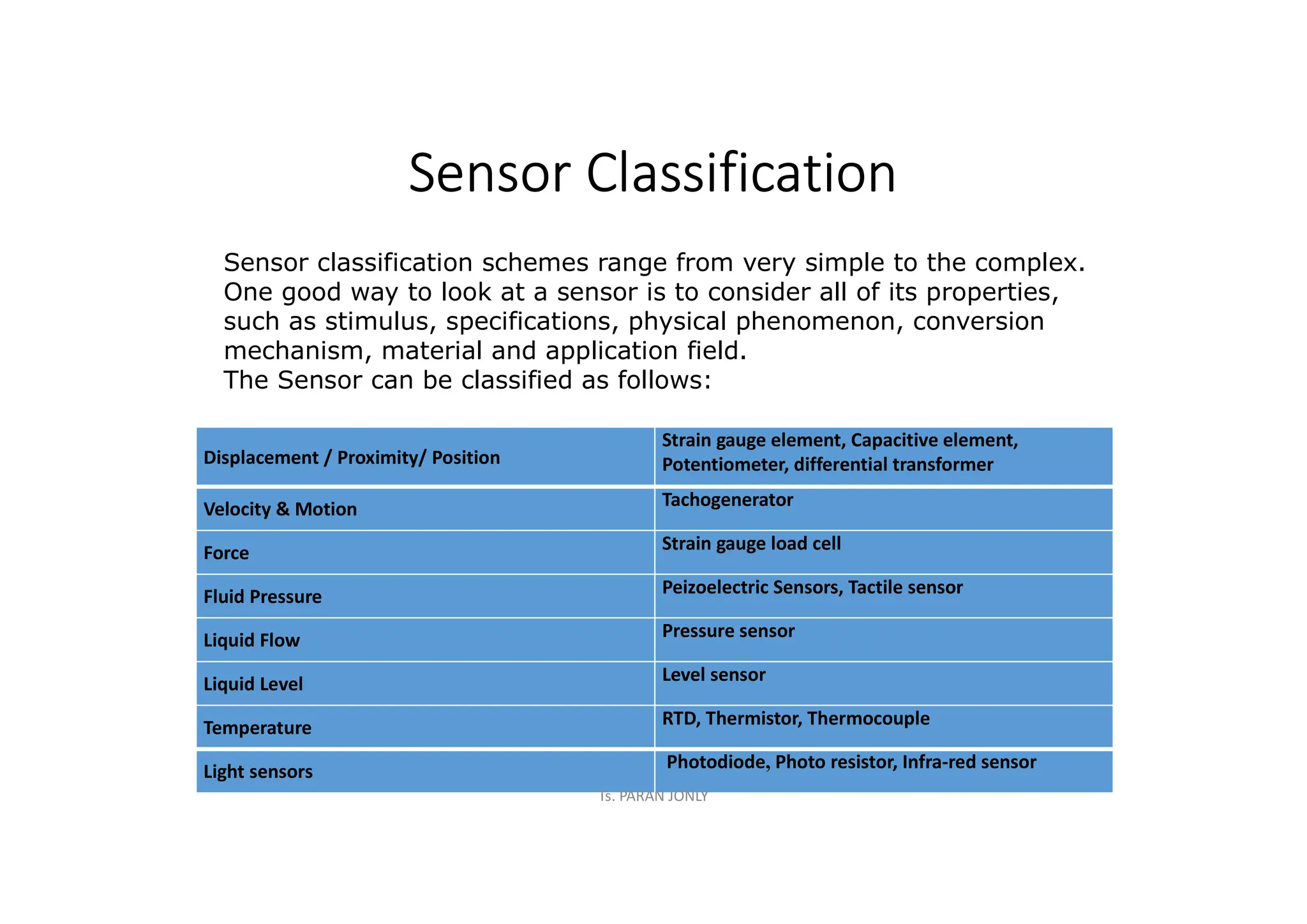

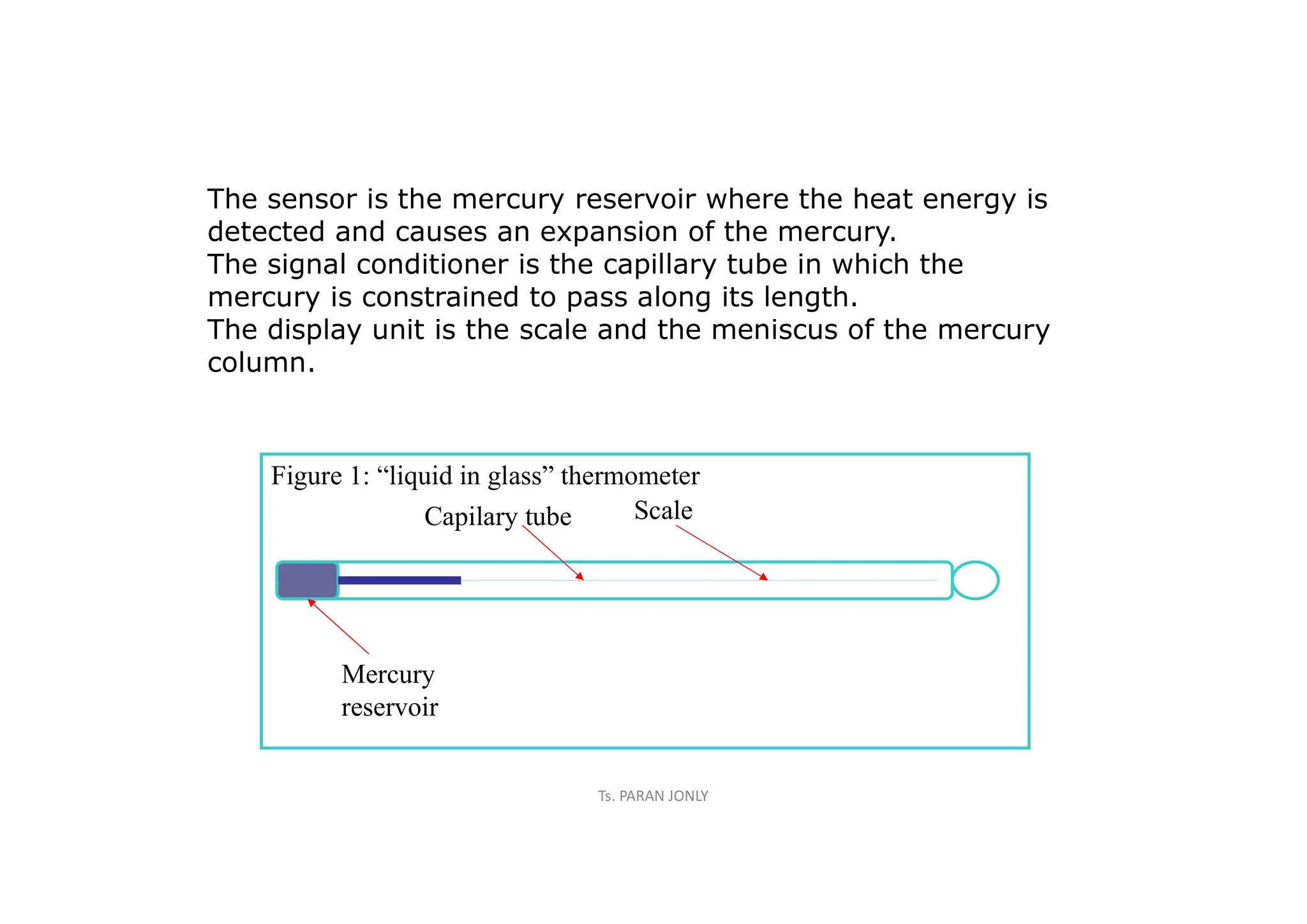

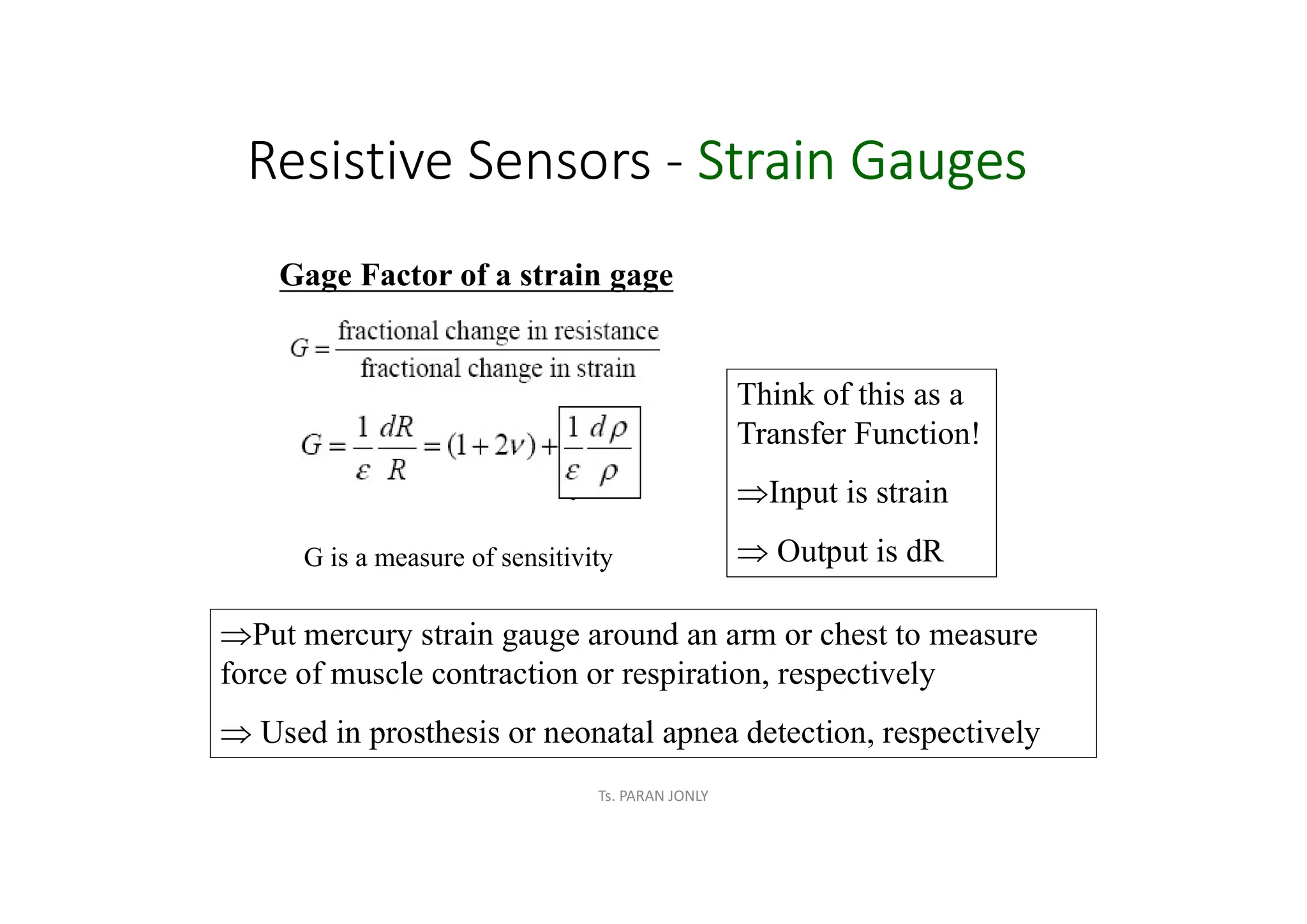

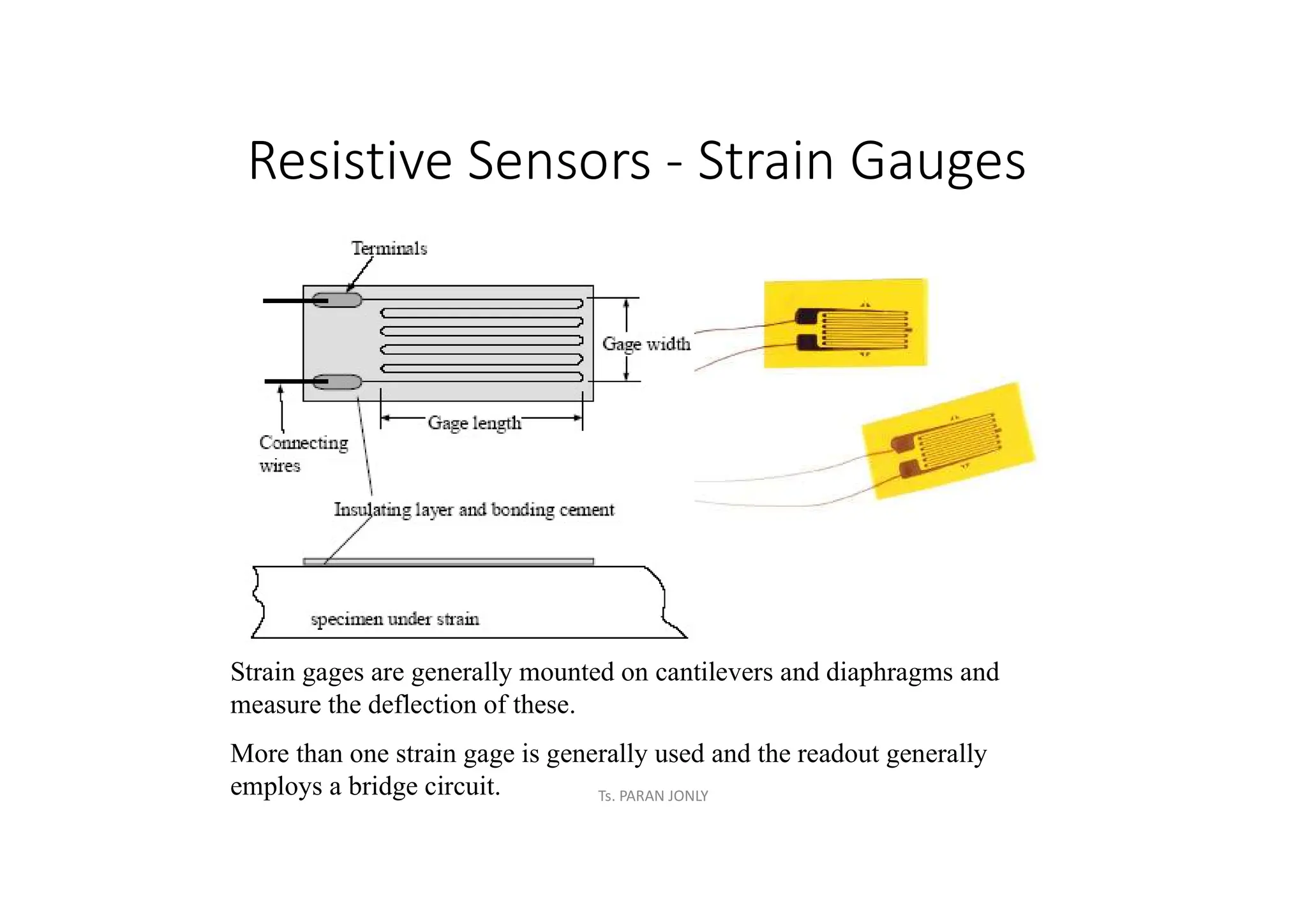

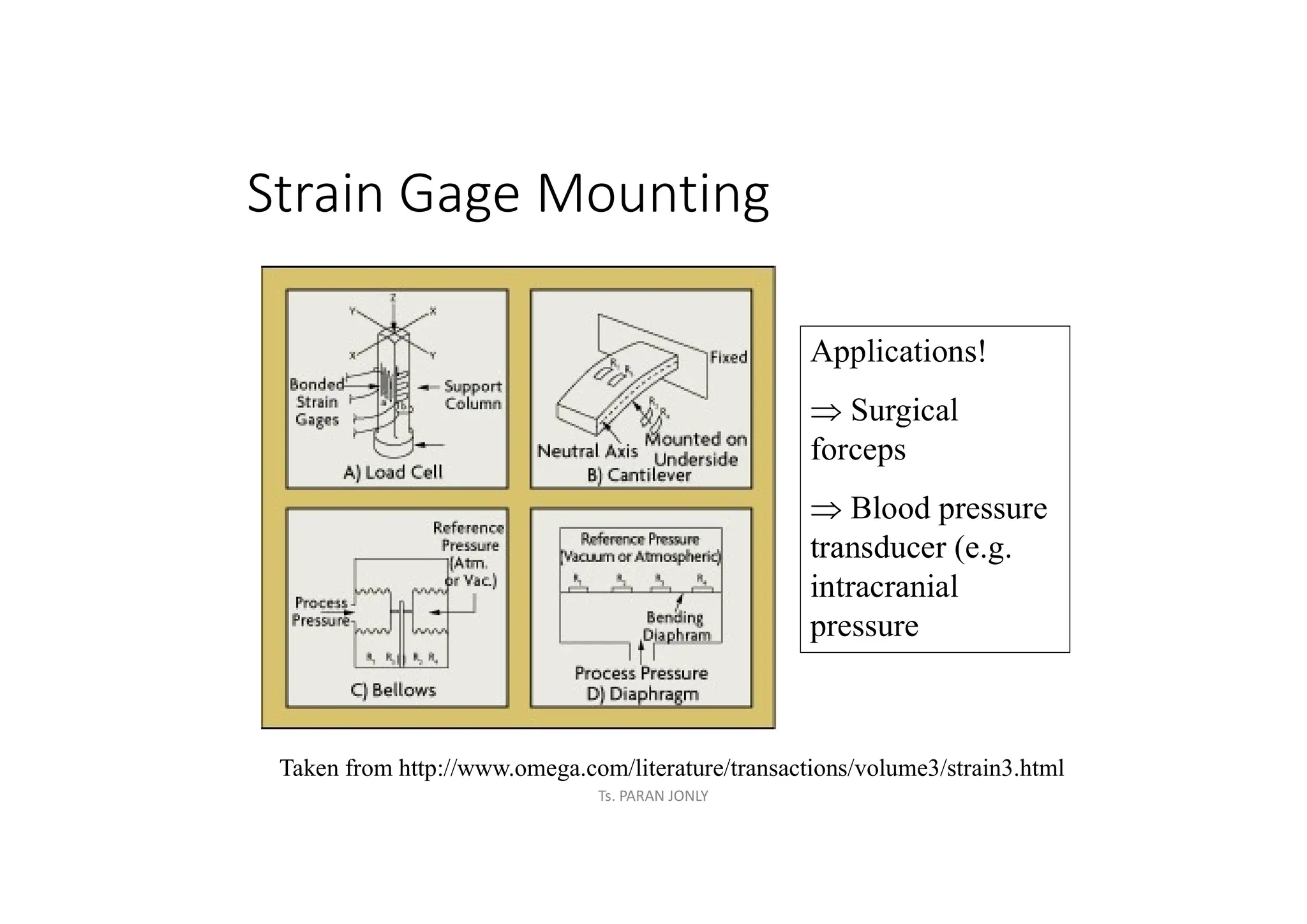

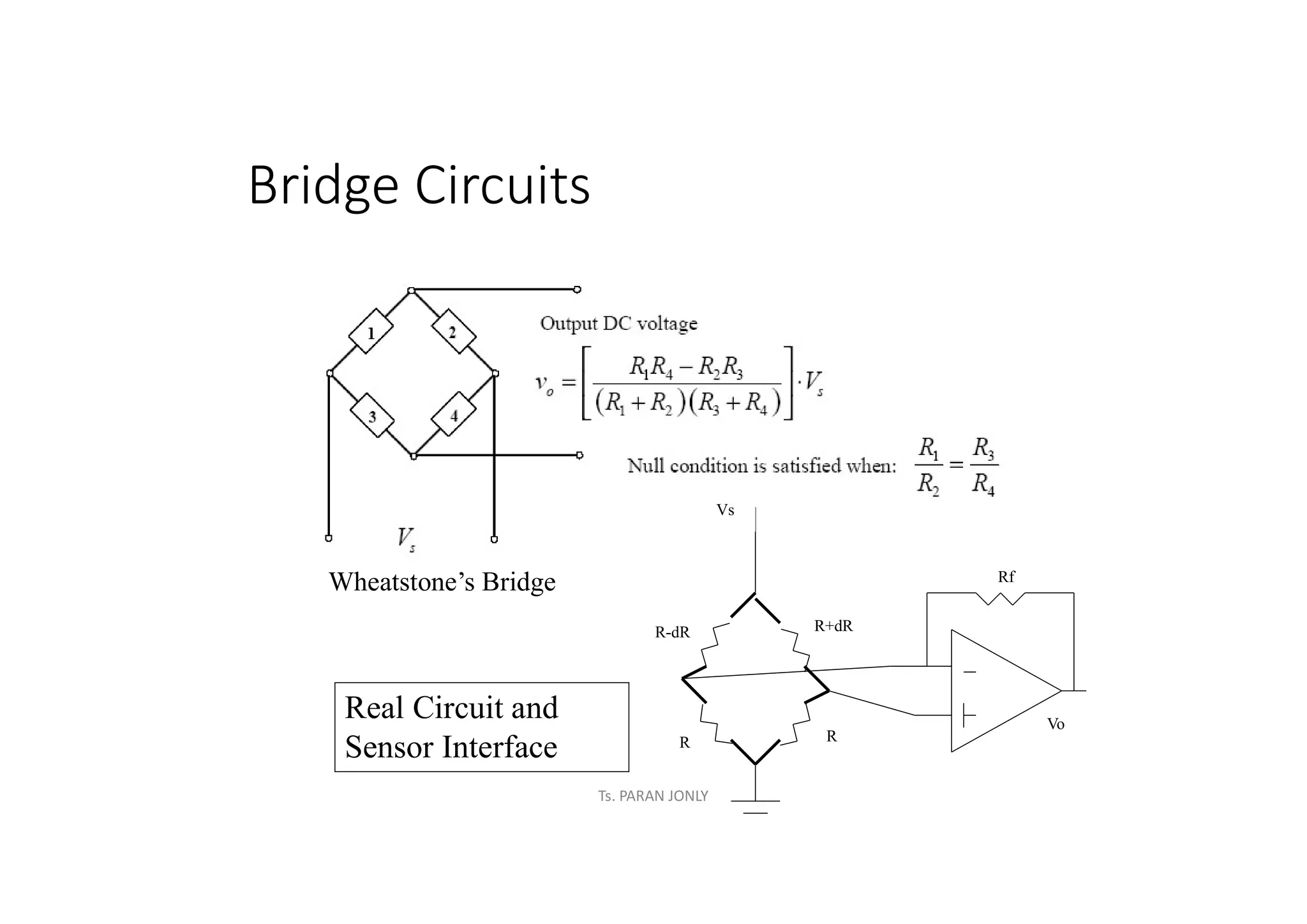

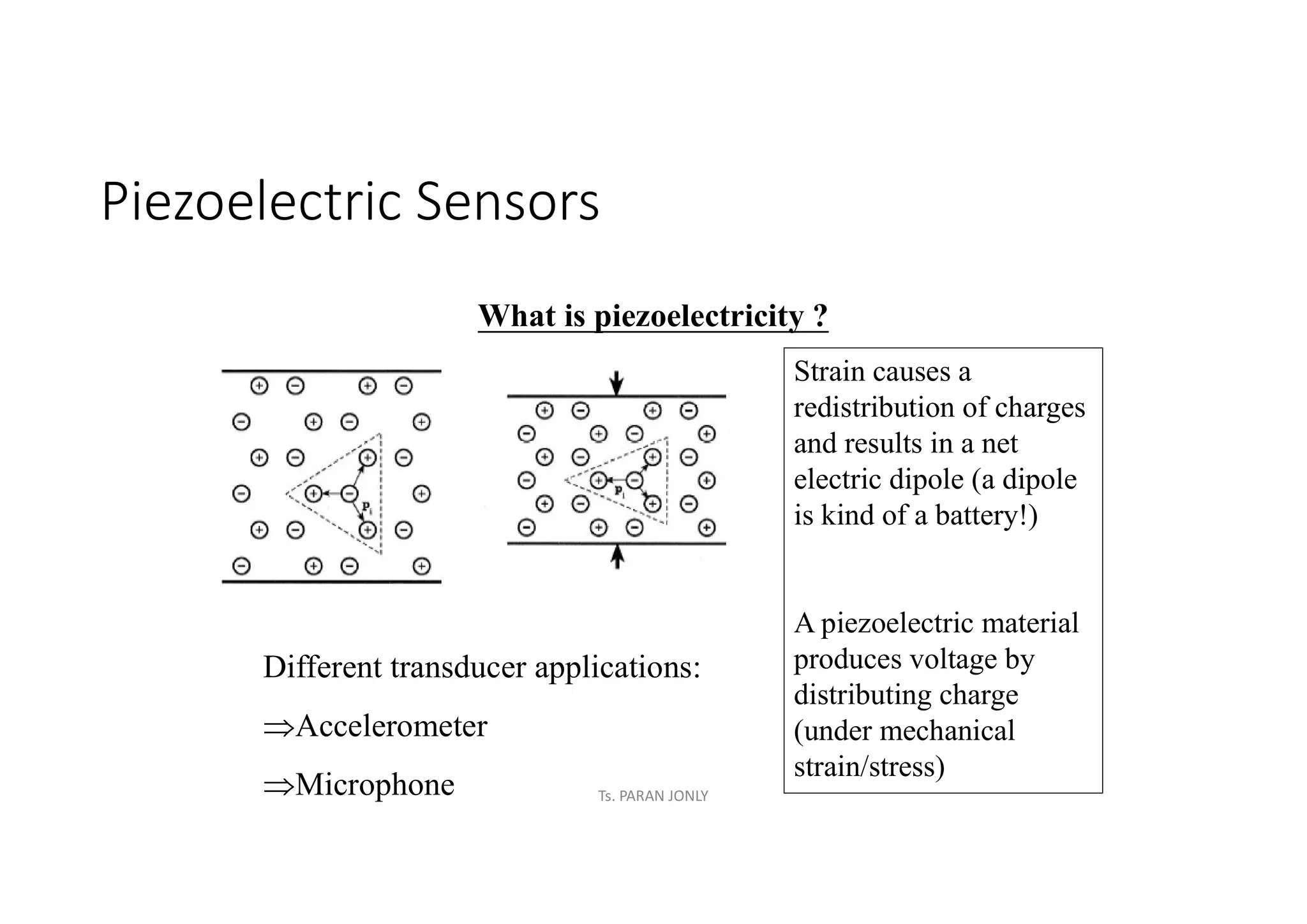

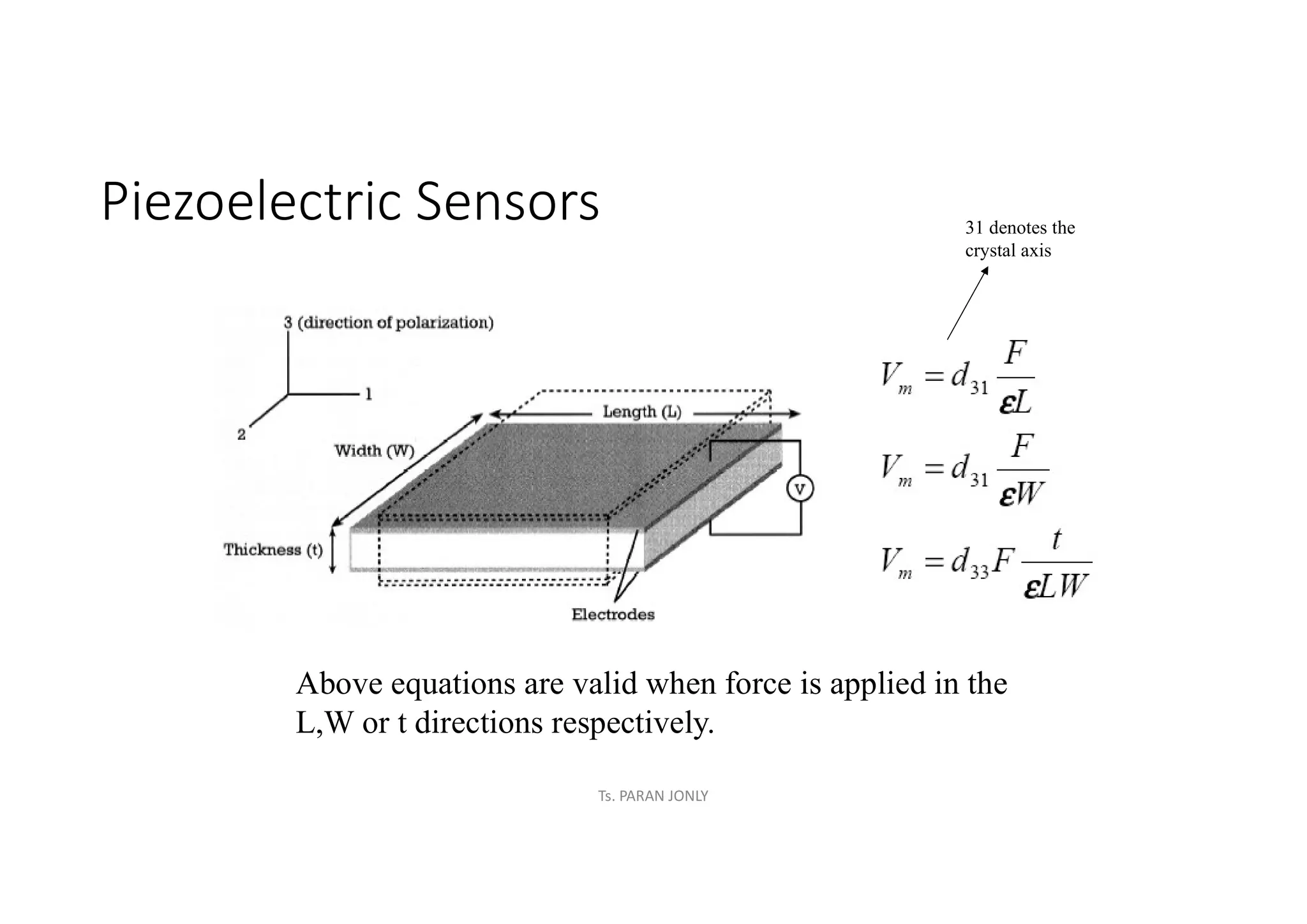

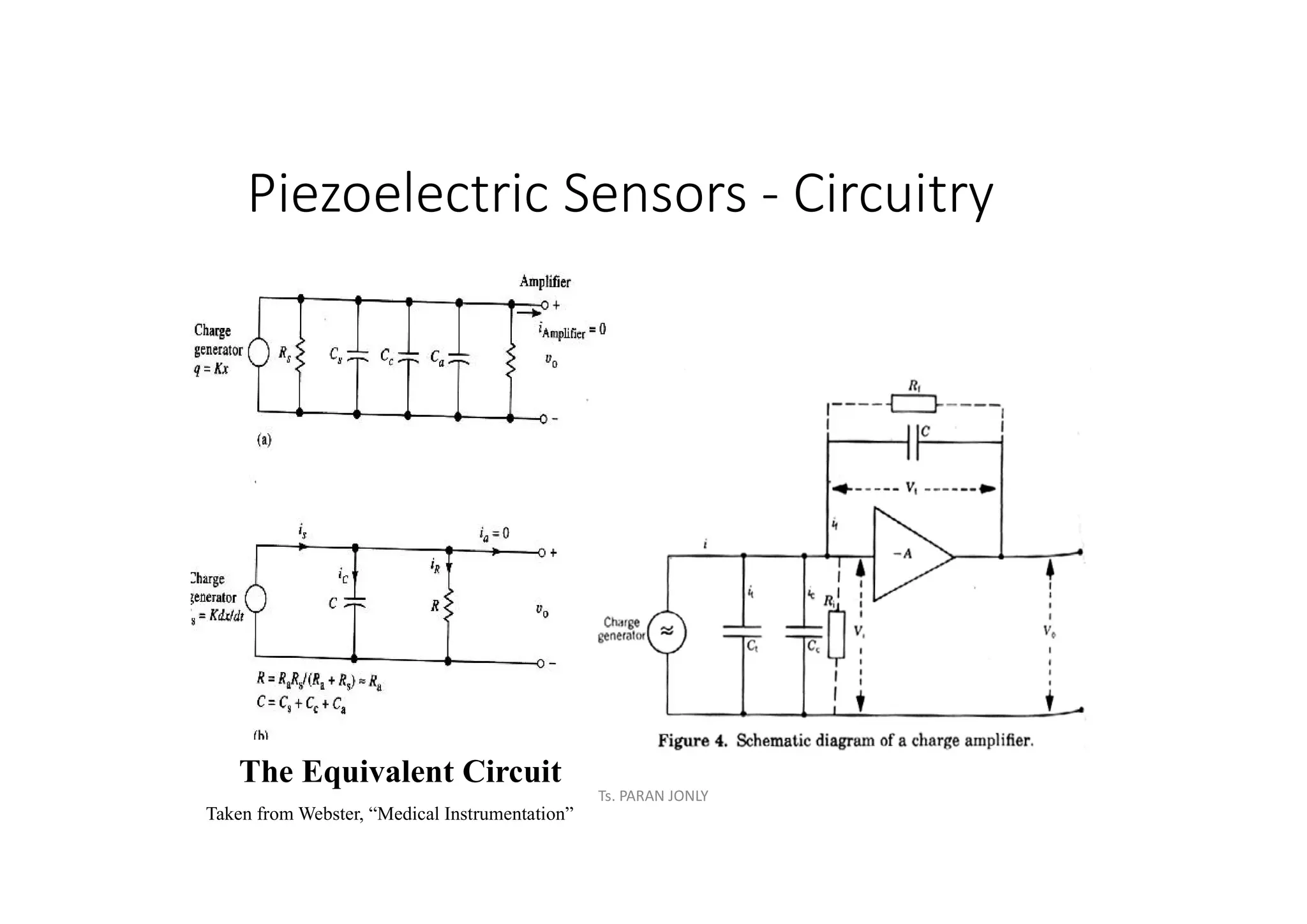

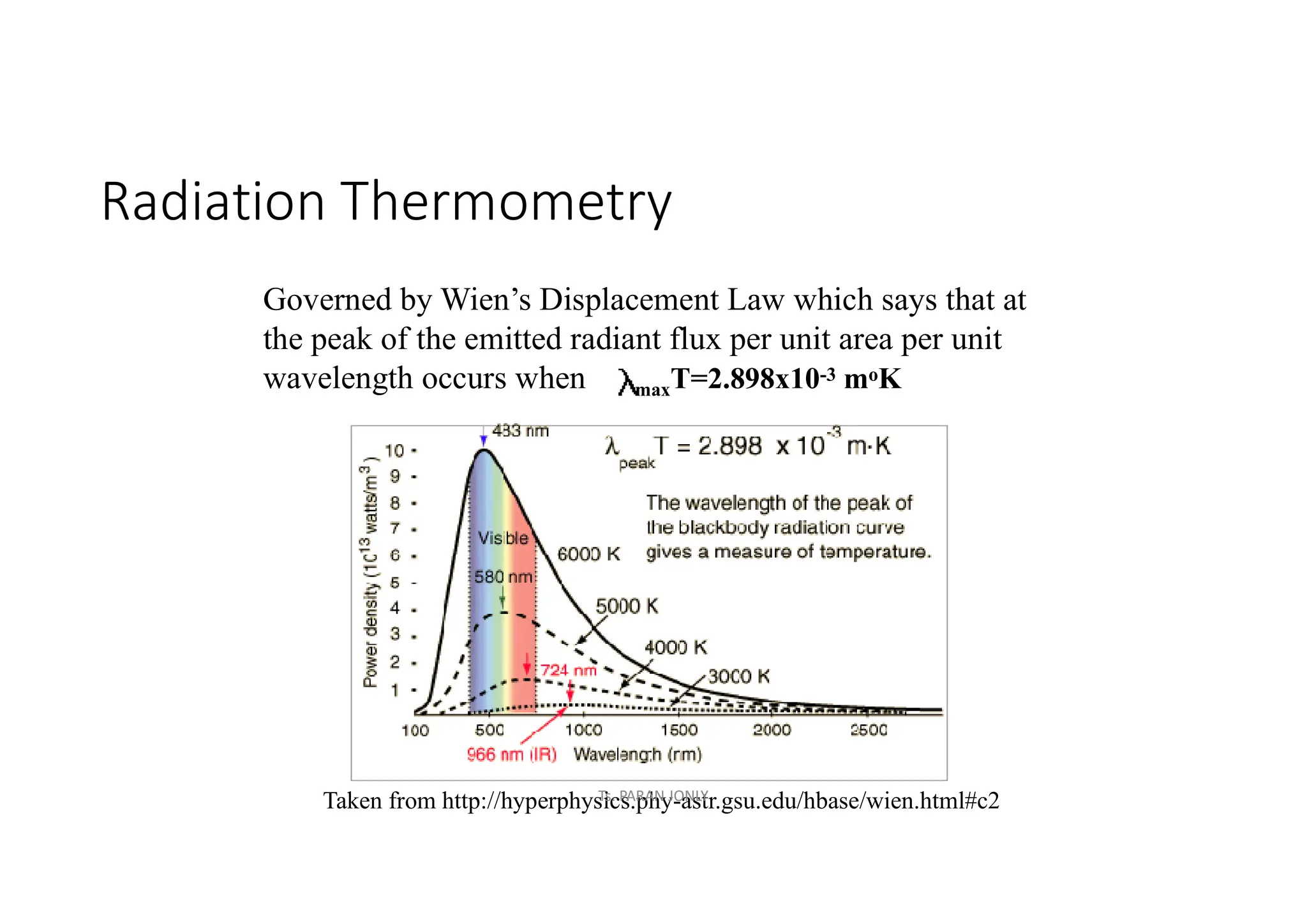

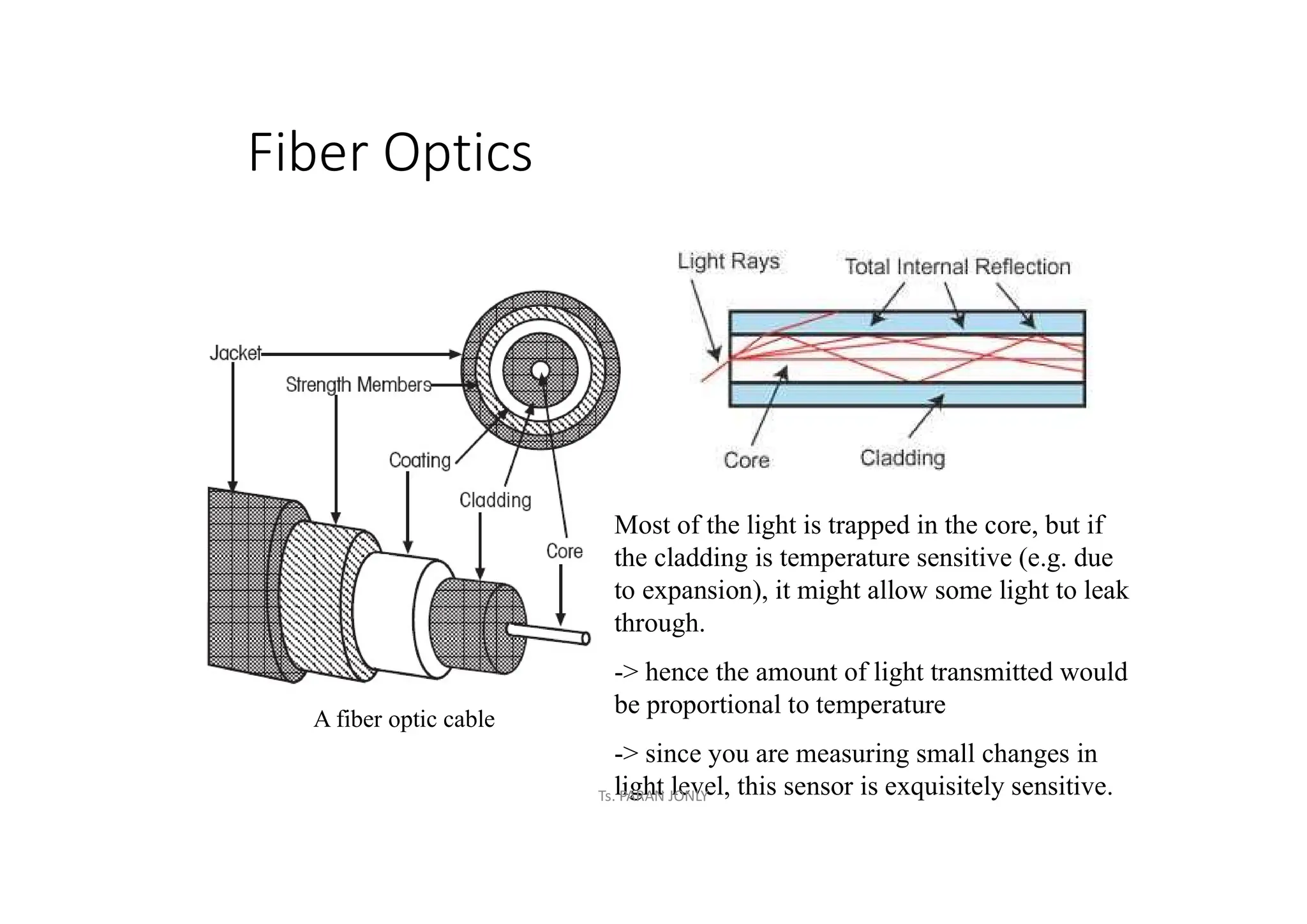

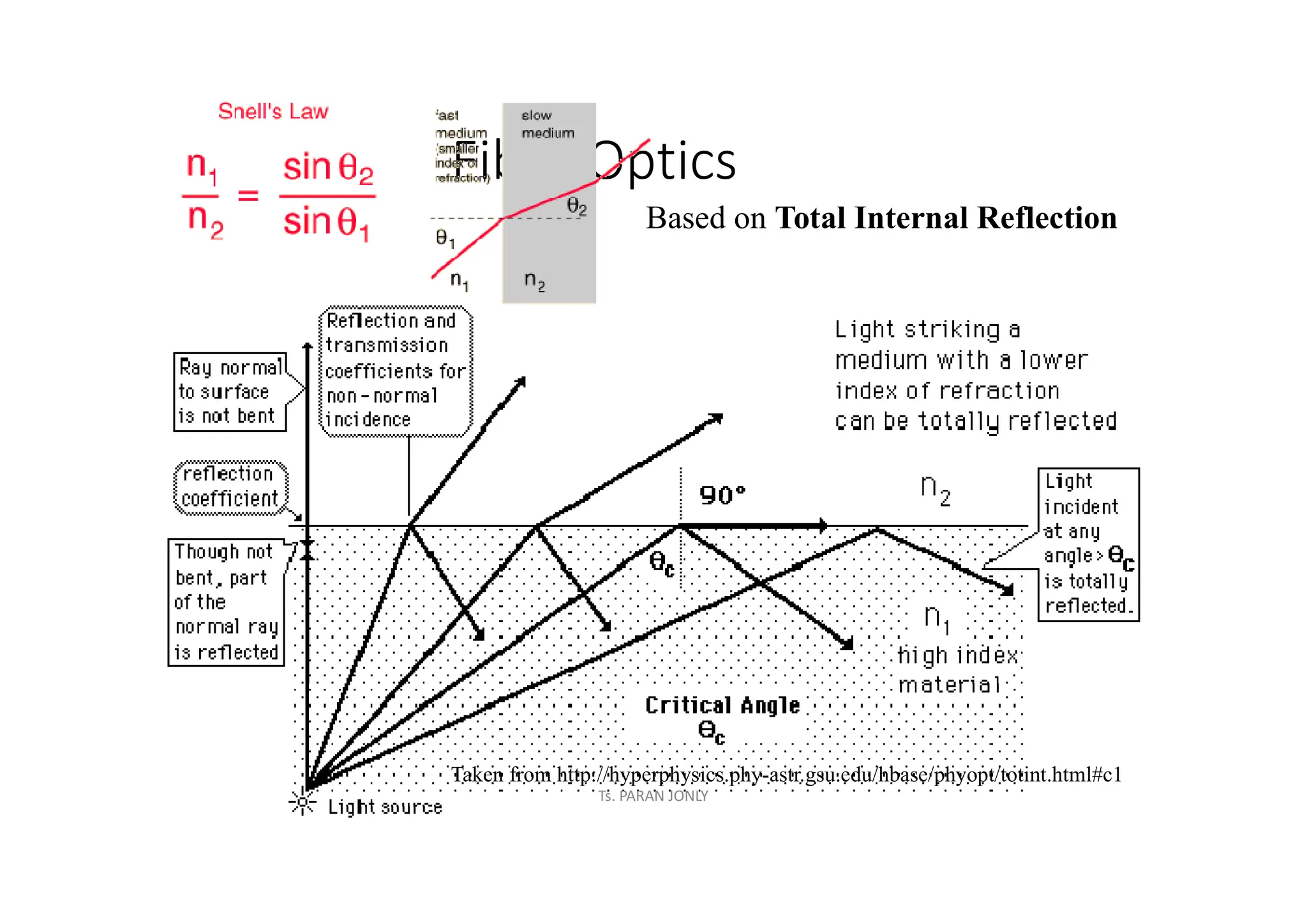

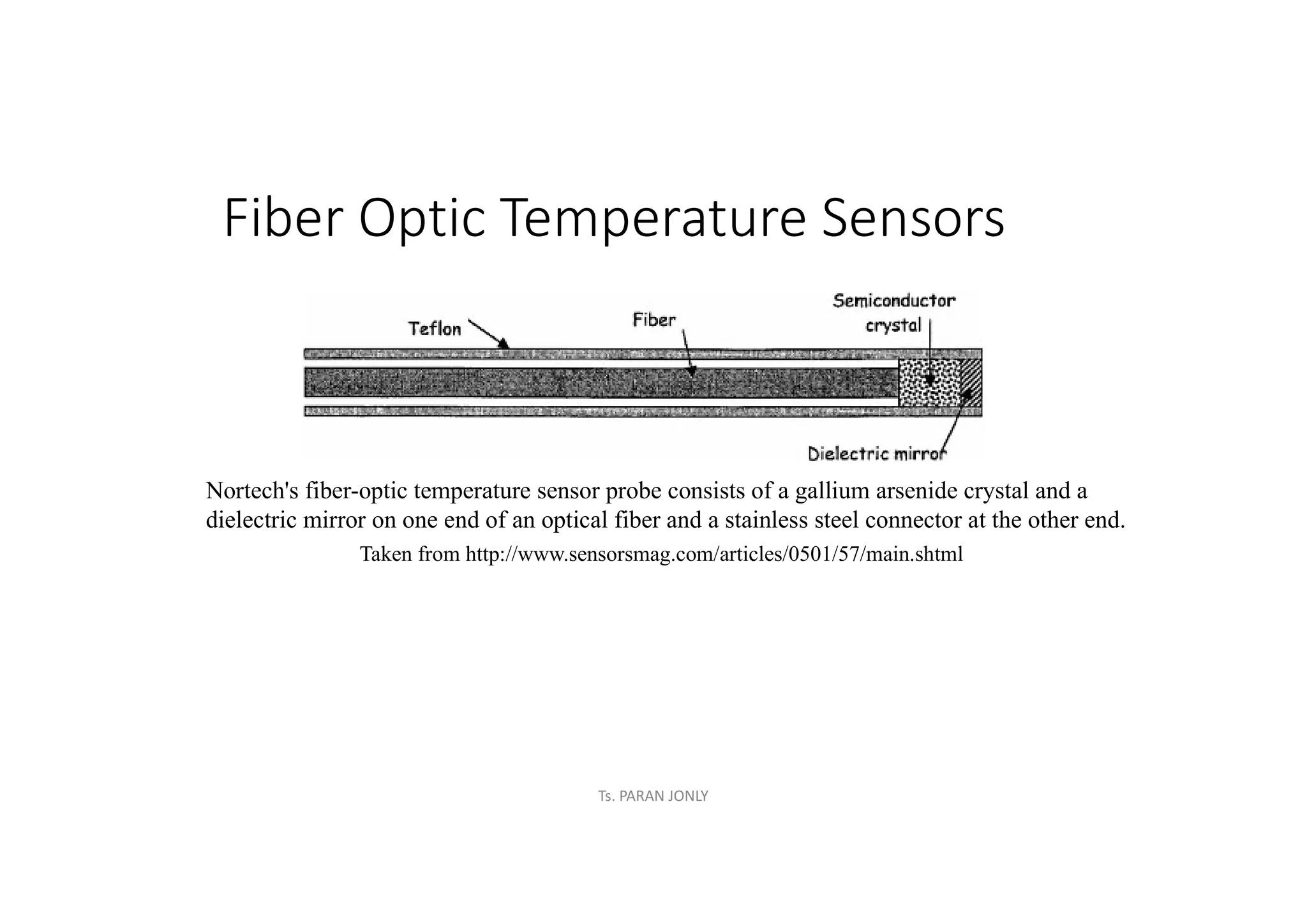

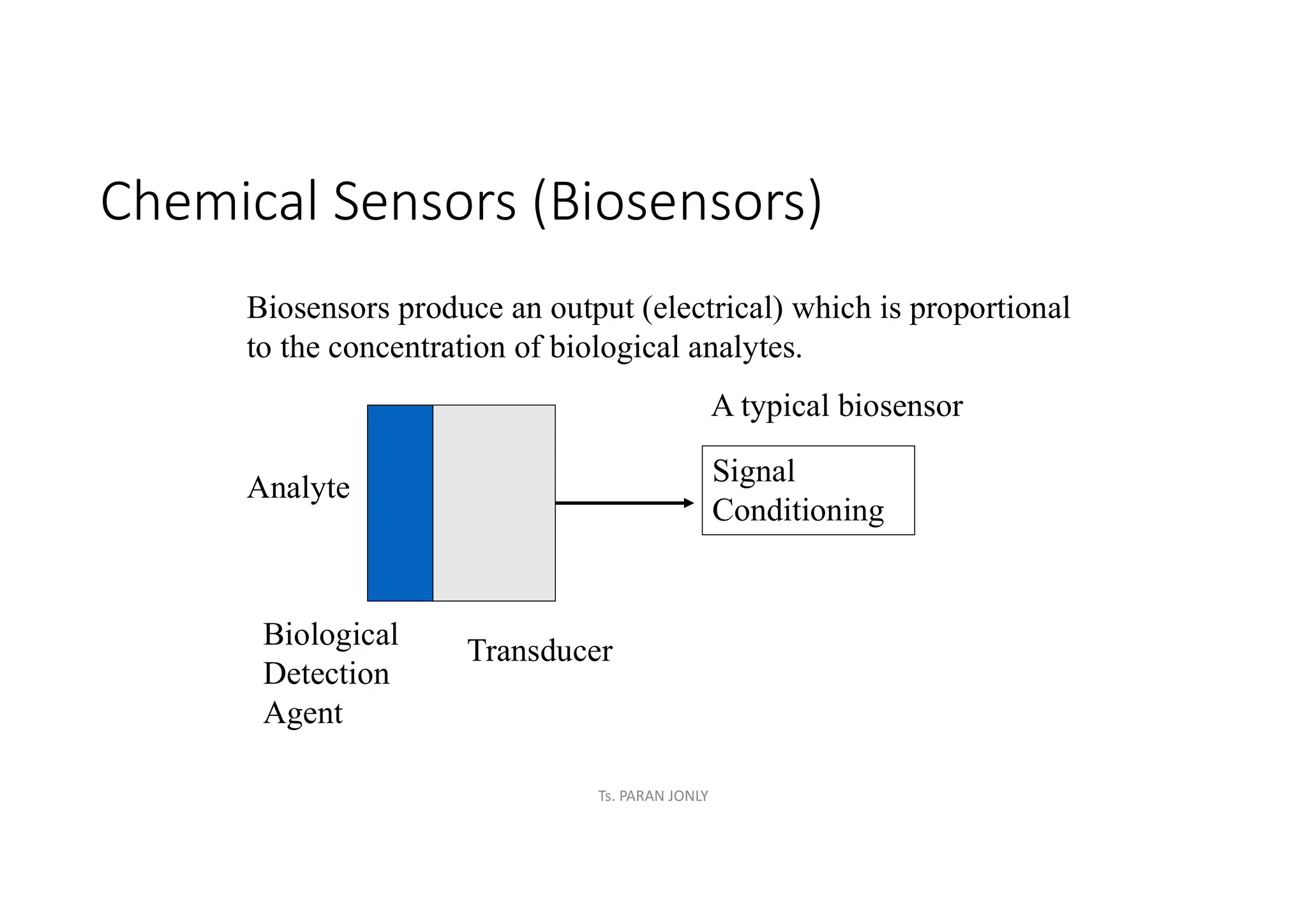

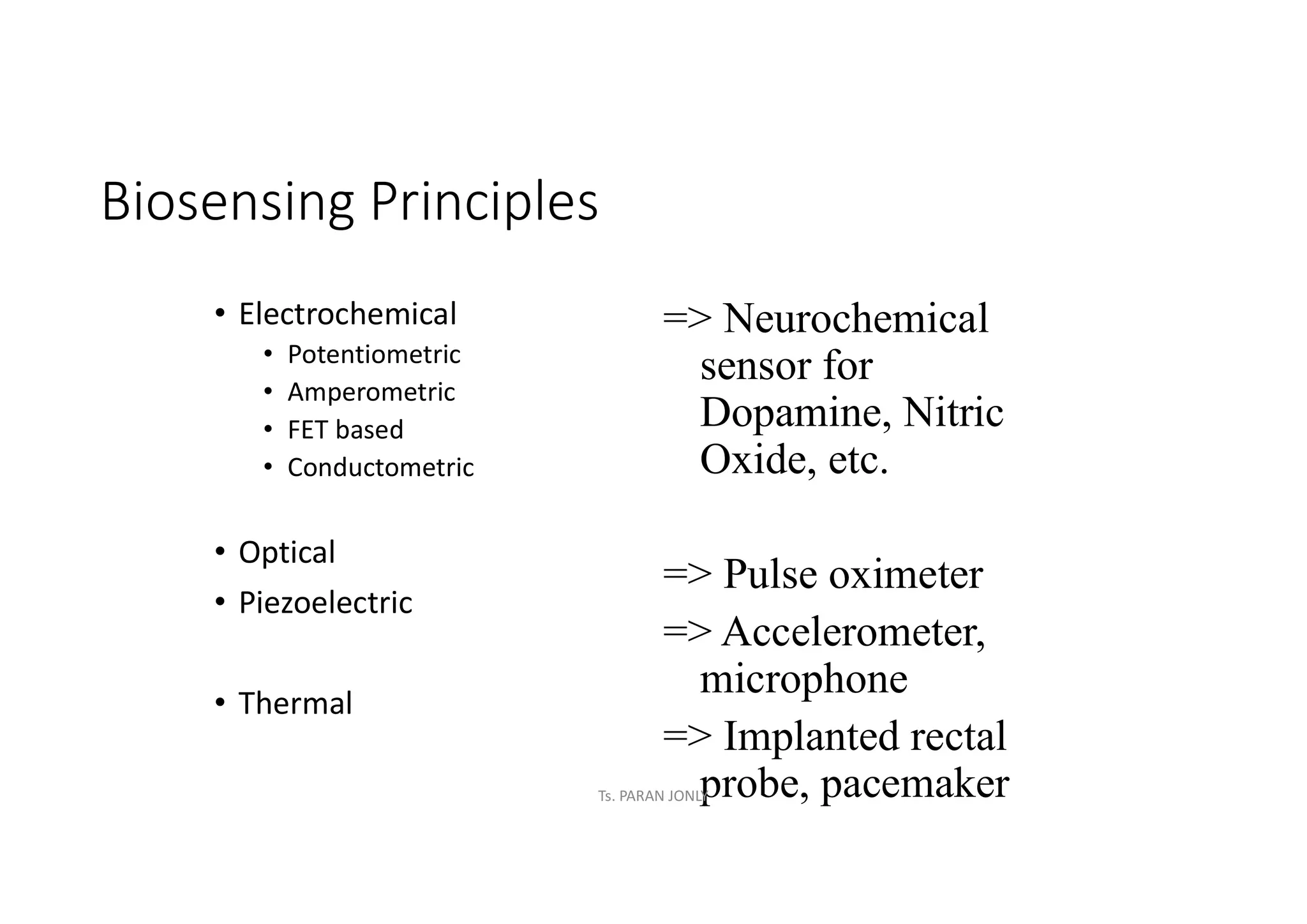

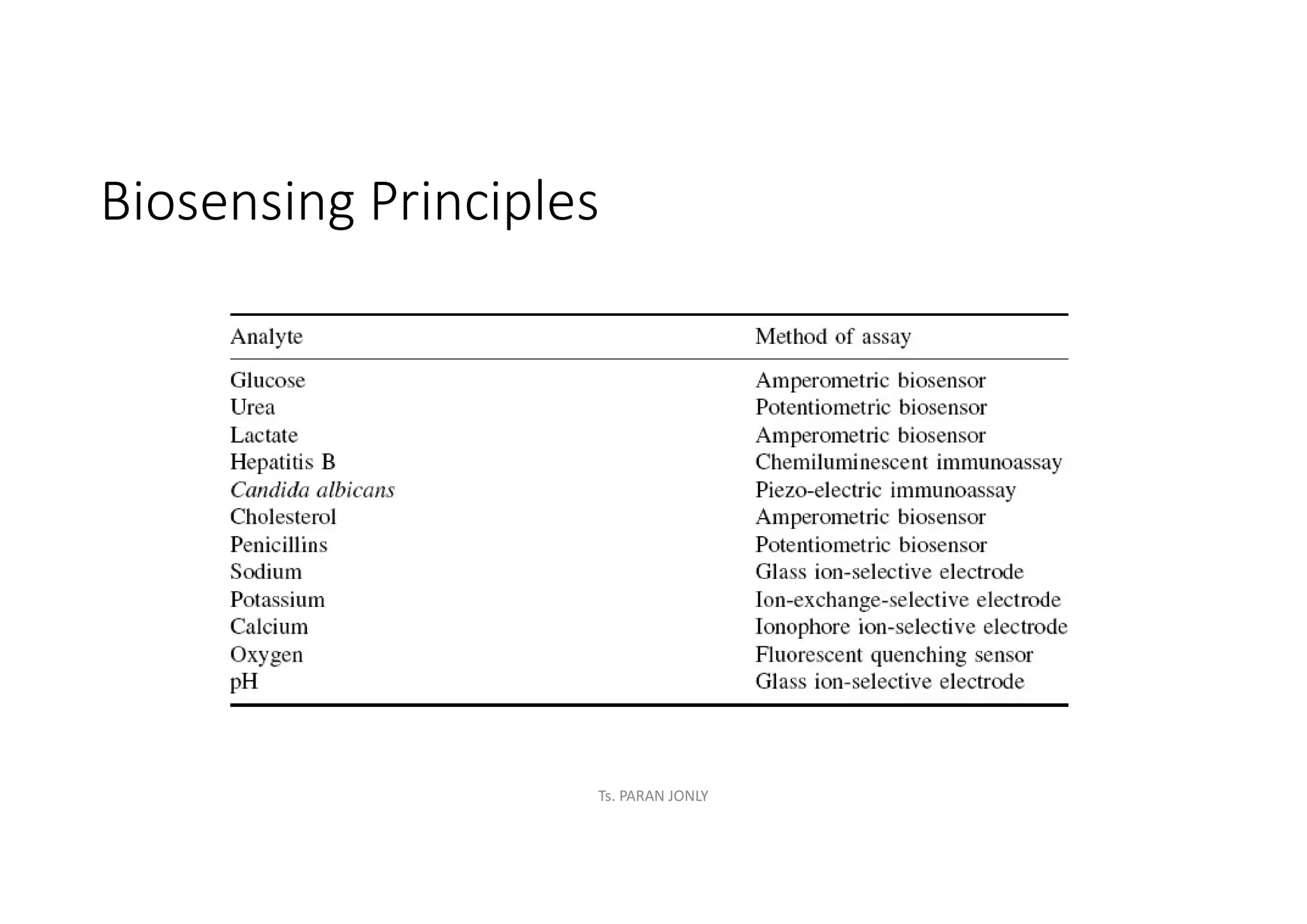

The document provides an overview of engineering measurement systems, particularly within electrical and electronic engineering instrumentation and control. It covers essential concepts of instrumentation, including definitions of key components like sensors and transducers, their classifications, performance terminologies, and common sources of measurement errors. Additionally, it emphasizes the roles and needs of instrumentation in obtaining data, inspecting items, and ensuring process control.

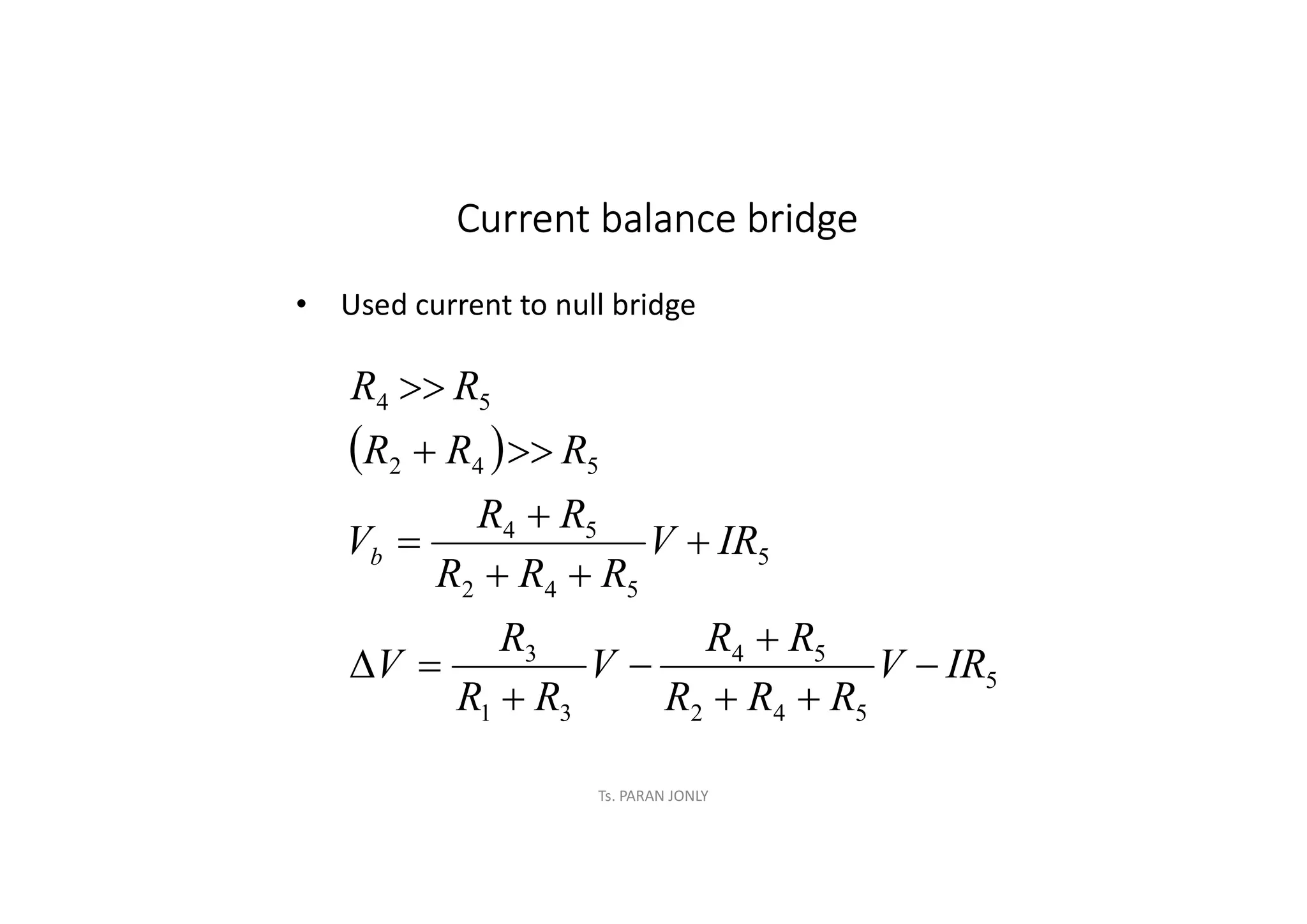

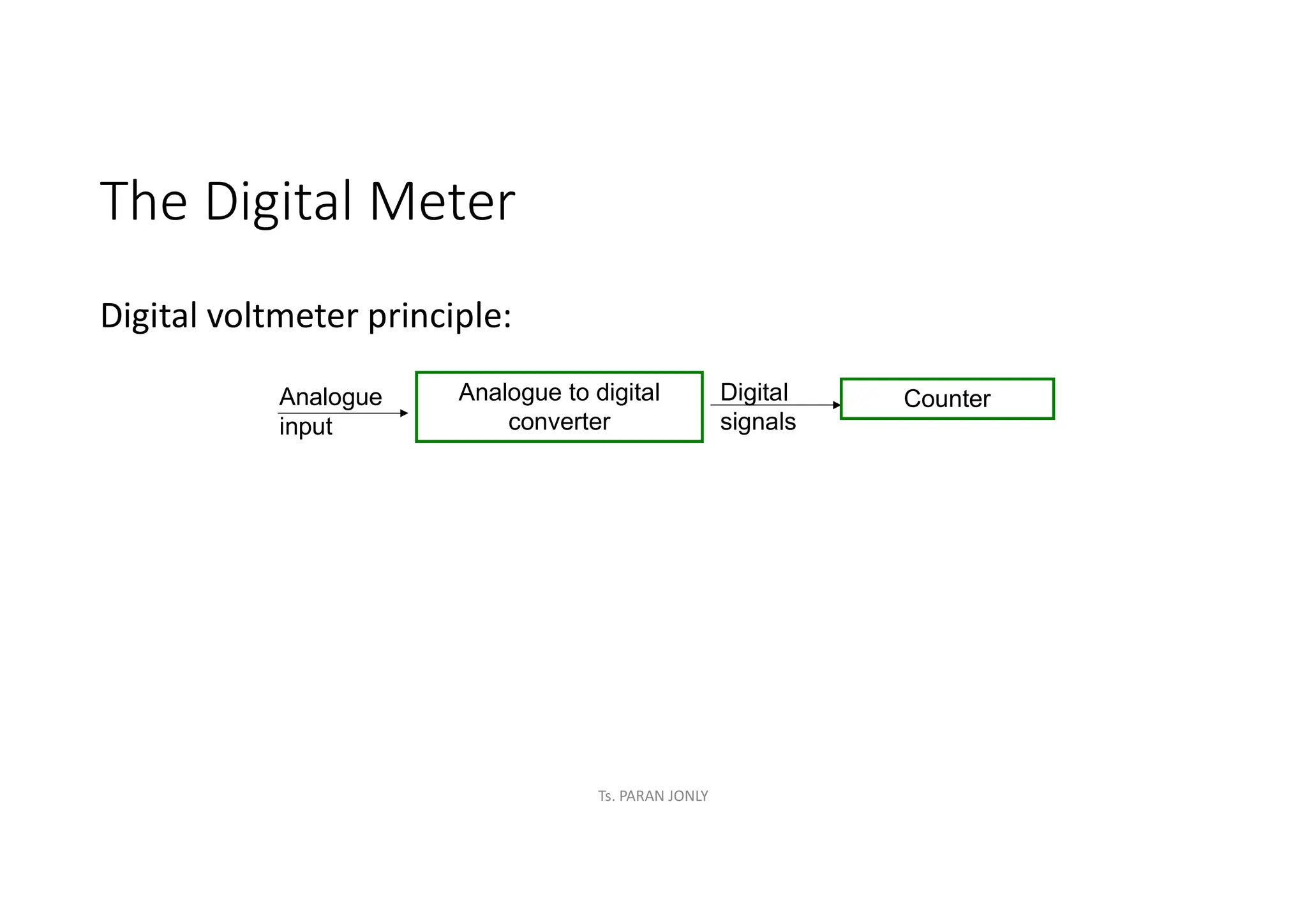

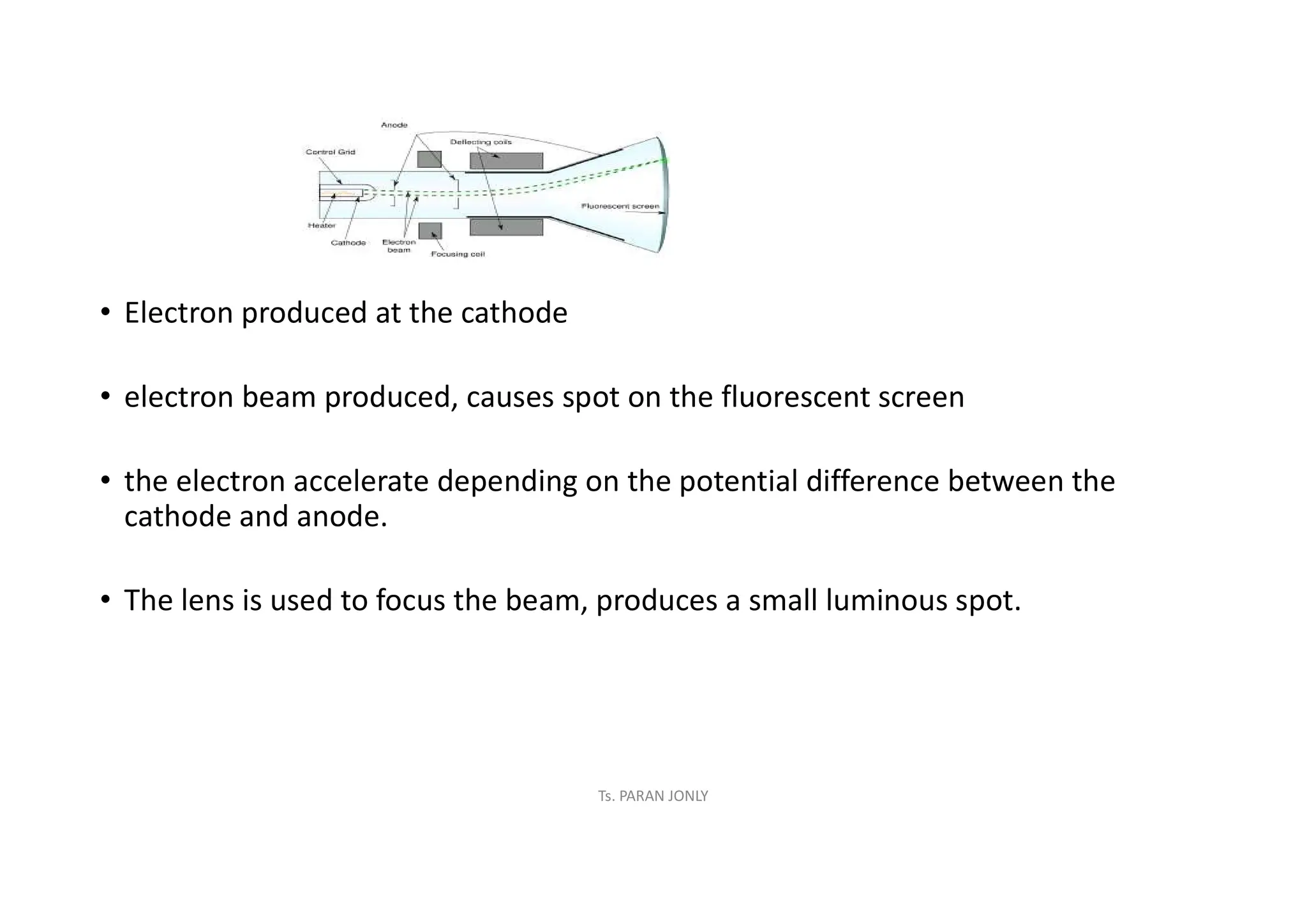

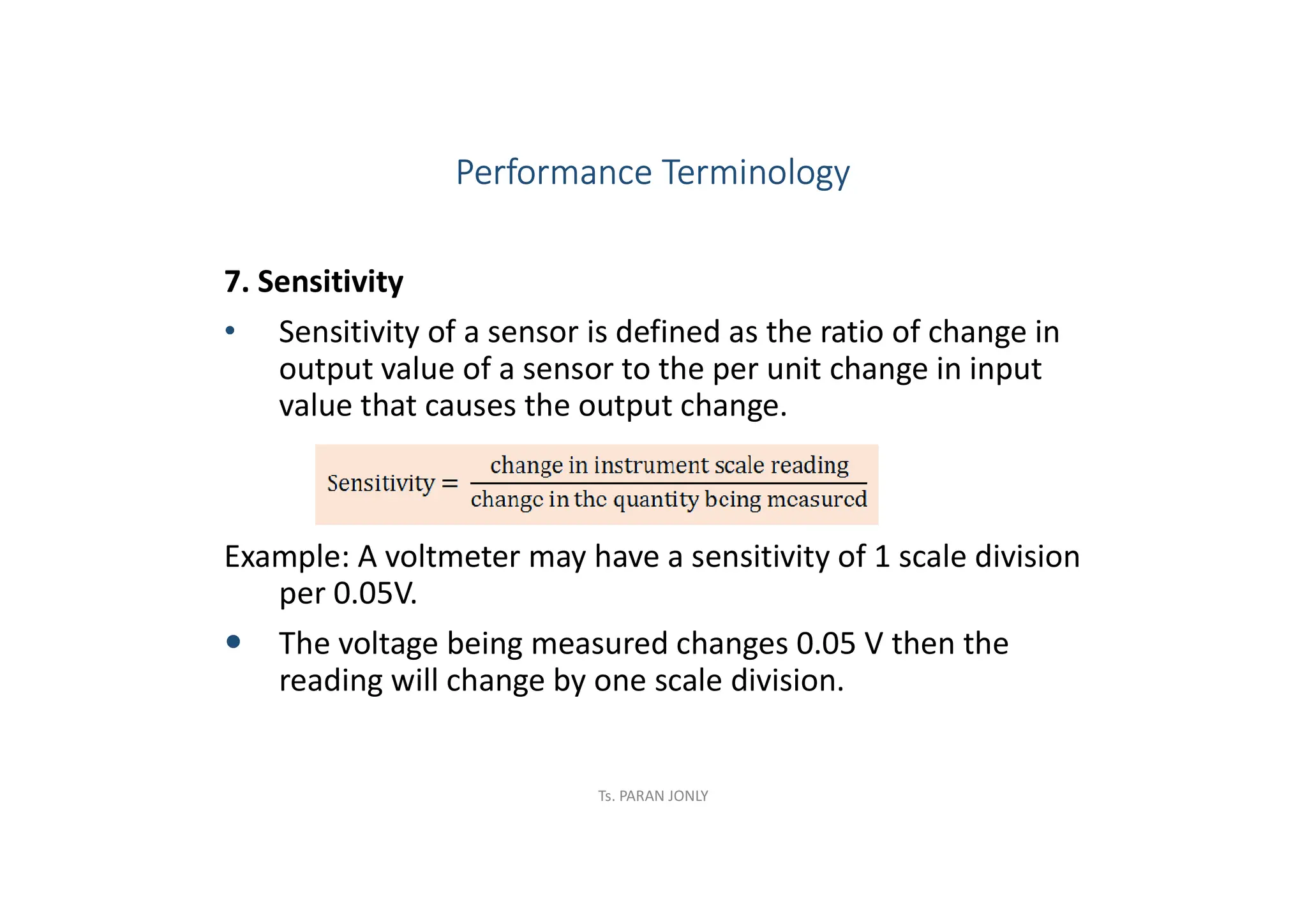

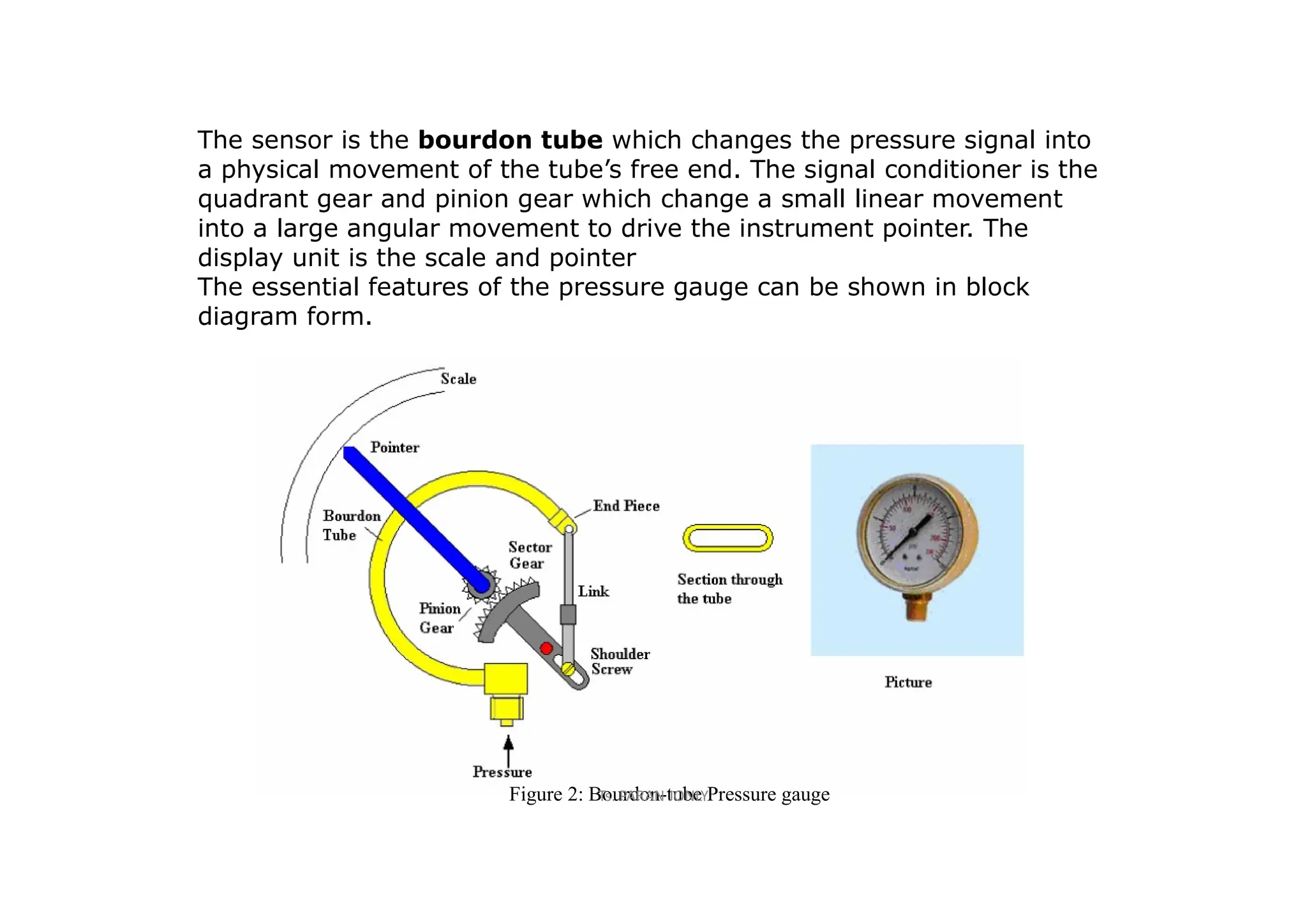

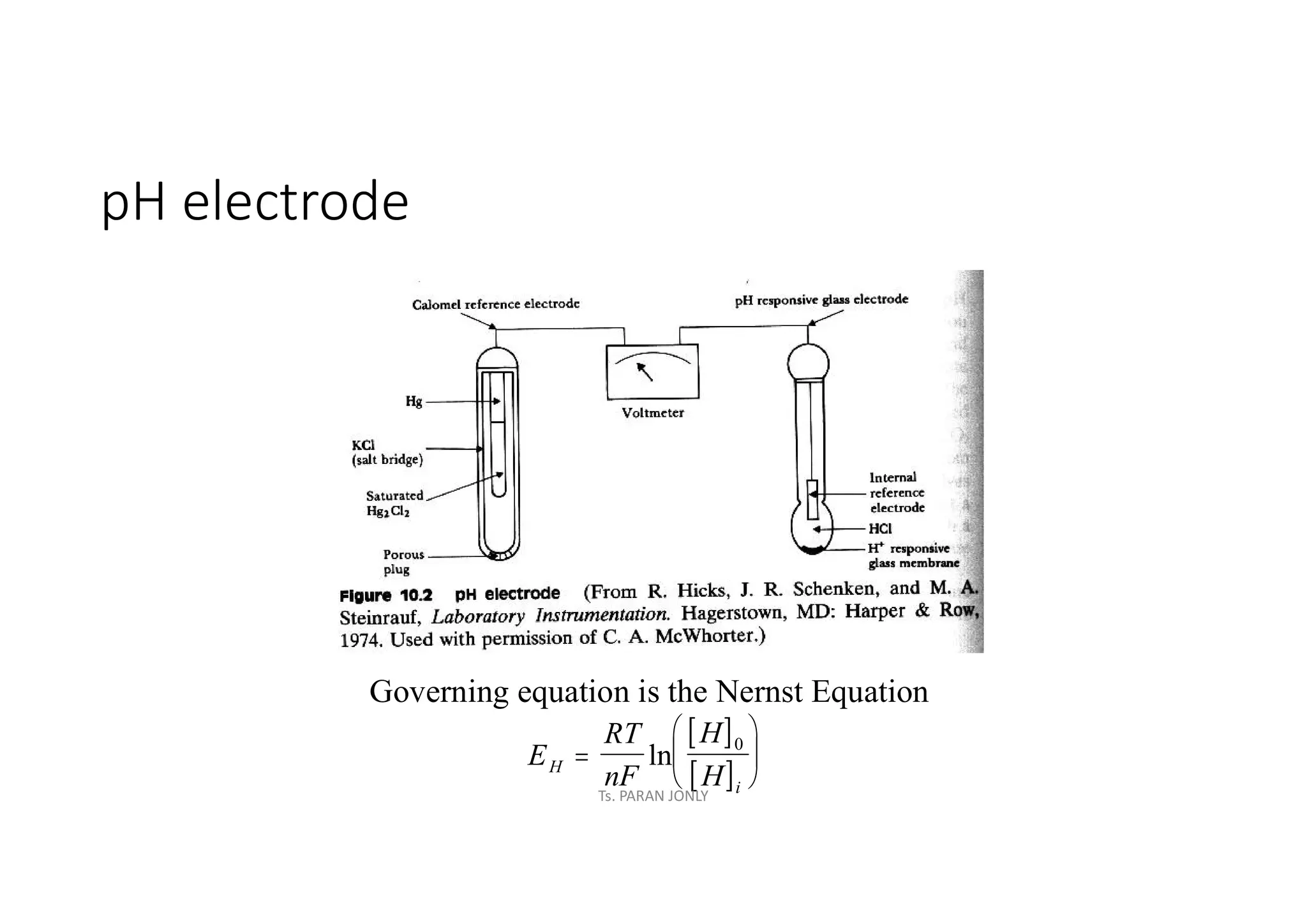

![pCO2 Electrode

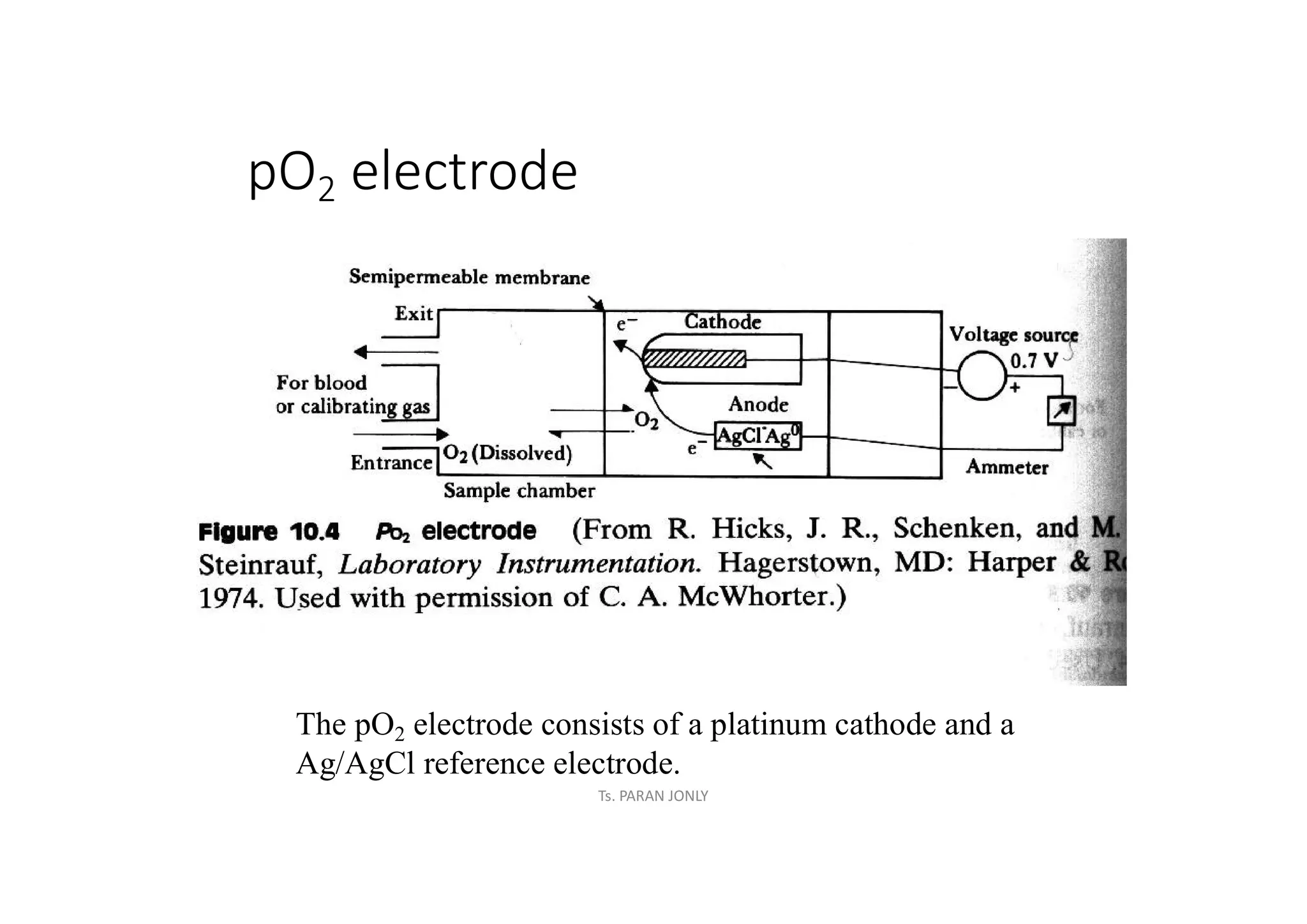

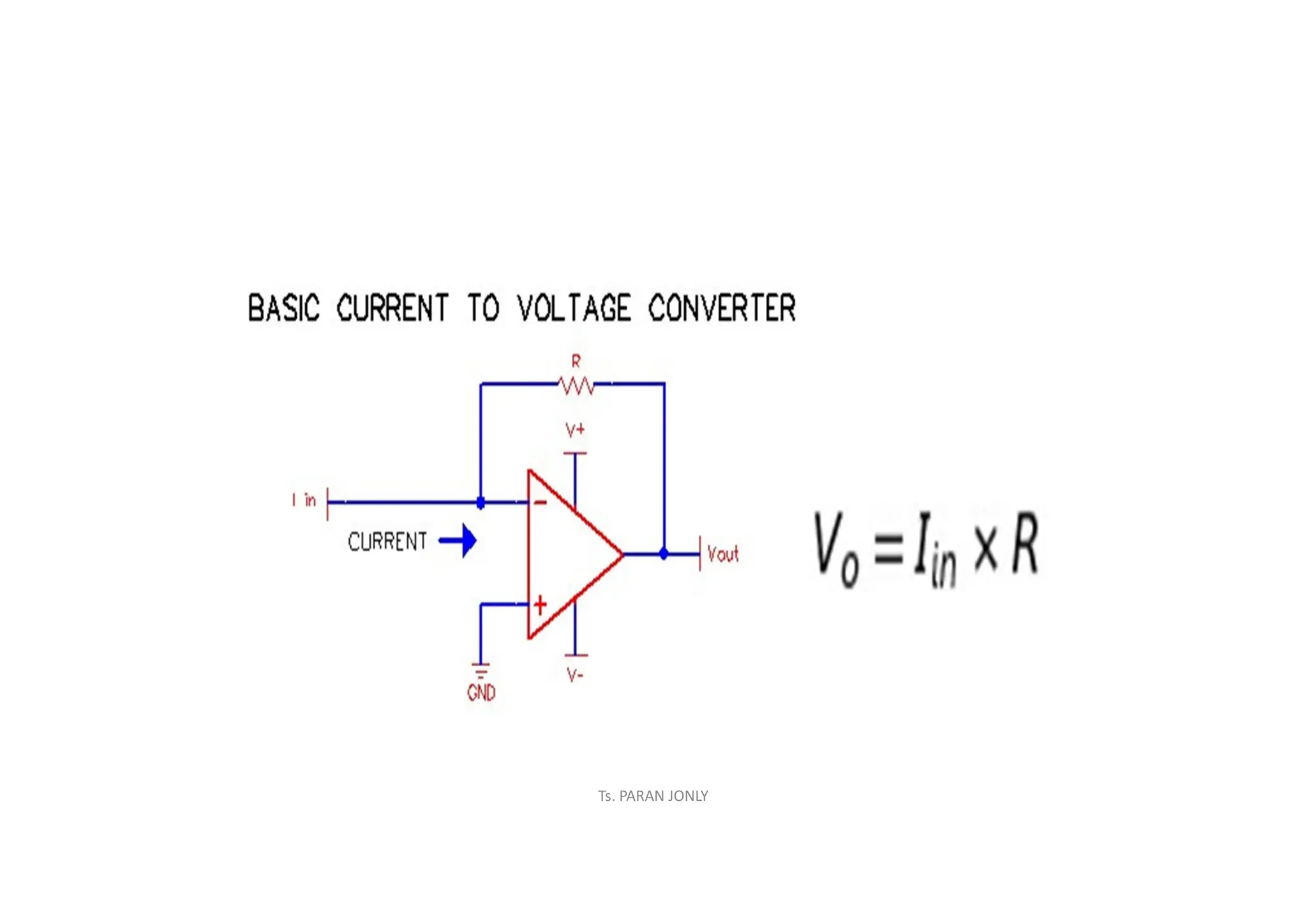

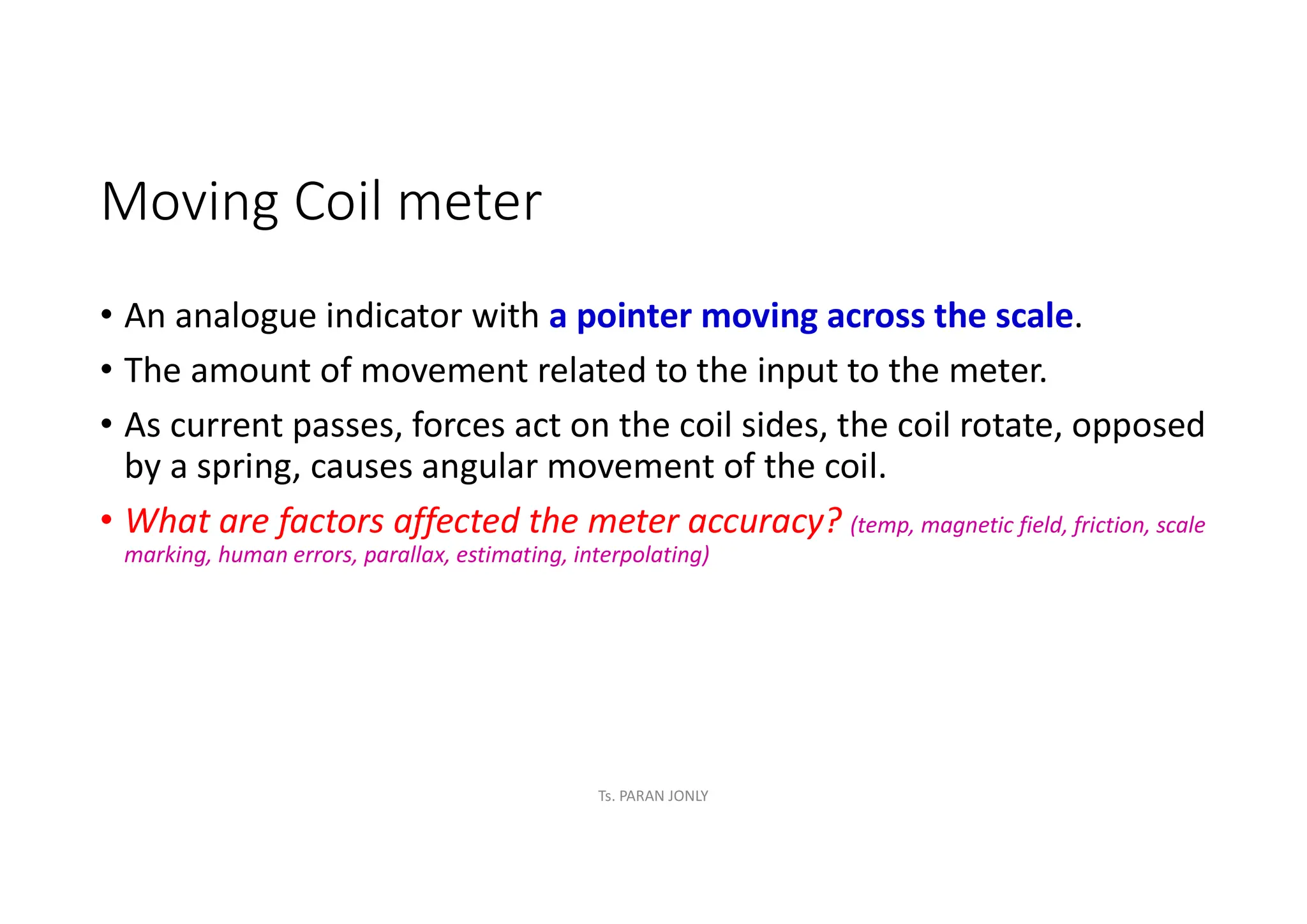

The measurement of pCO2 is based on its linear relationship

with pH over the range of 10 to 90 mm Hg.

H O CO H CO H HCO

2 2 2 3 3

The dissociation constant is given by

k

H HCO

a pCO

3

2

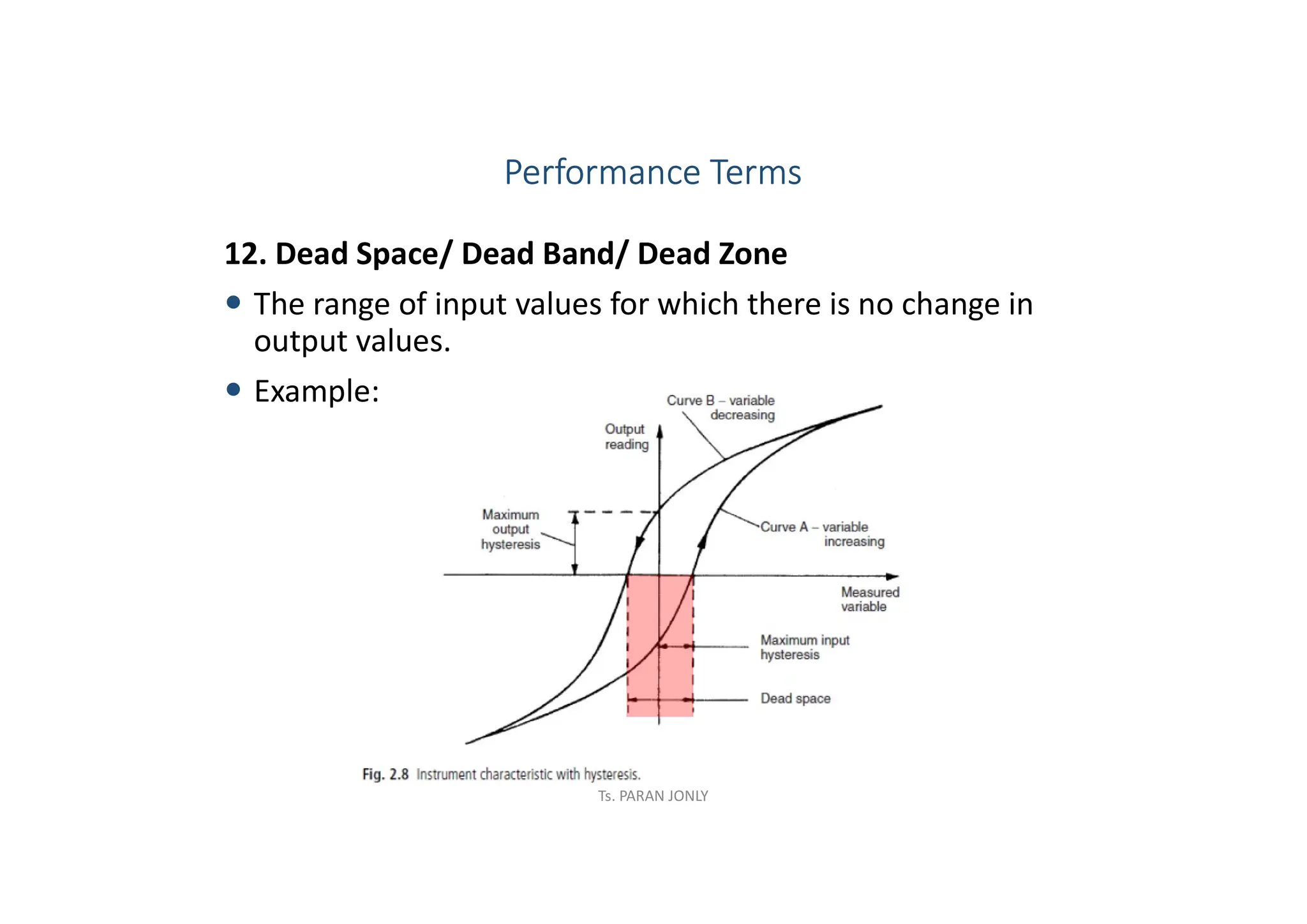

Taking logarithms

pH = log[HCO3

-] – log k – log a – log pCO2

Ts. PARAN JONLY](https://image.slidesharecdn.com/learningoutcome1-241119151738-92807747/75/Investigate-Engineering-Measurement-Systems-80-2048.jpg)