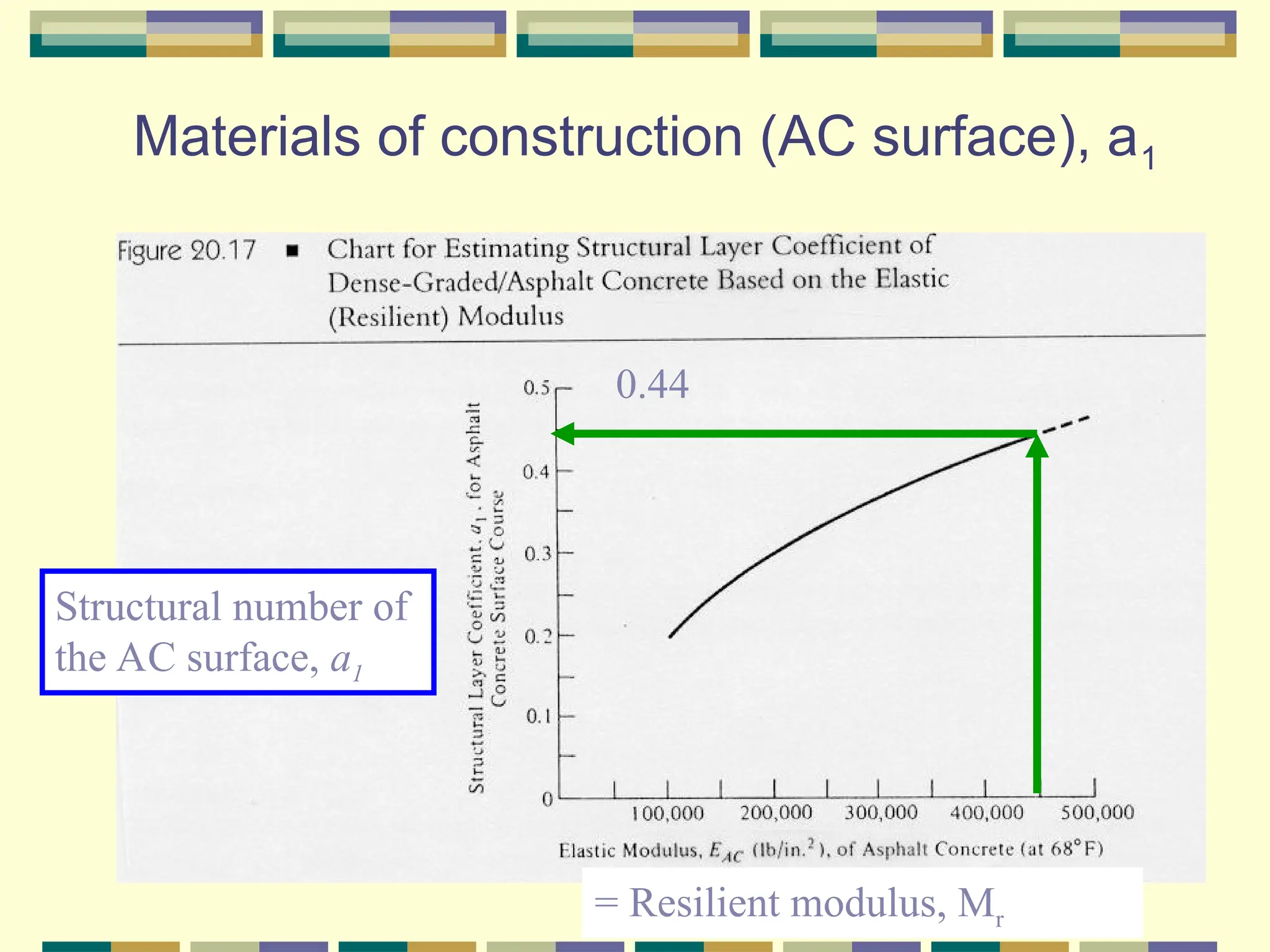

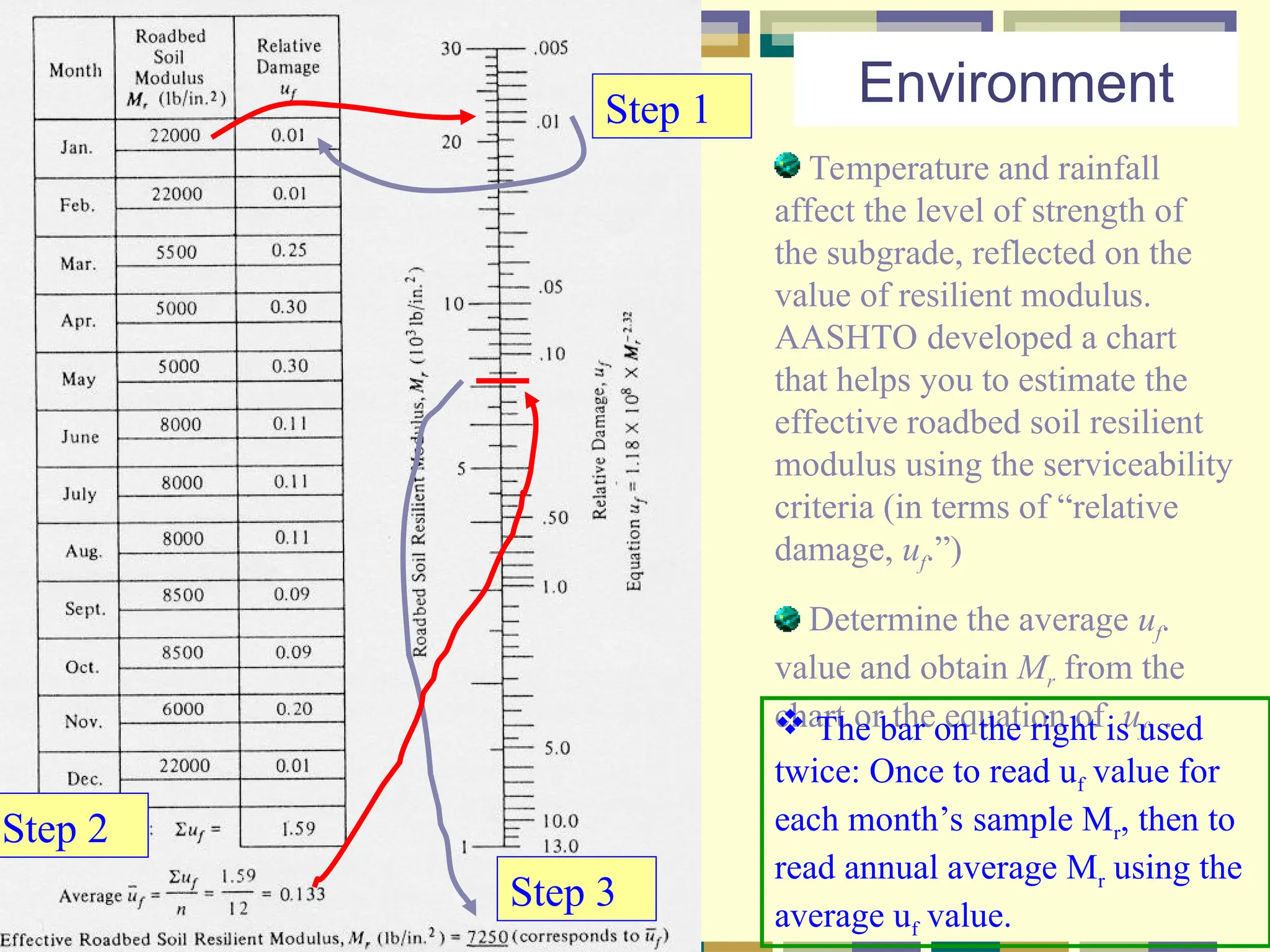

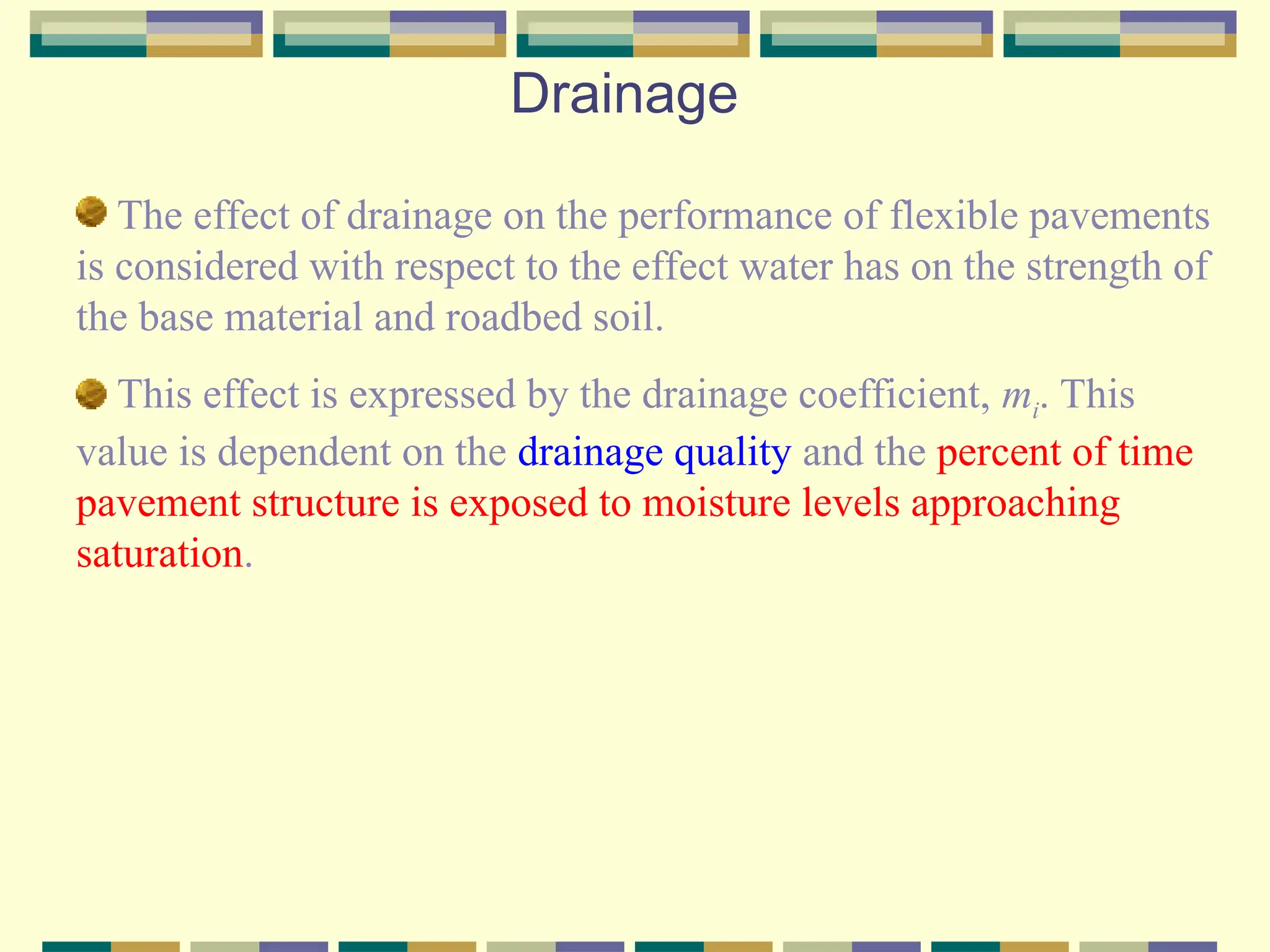

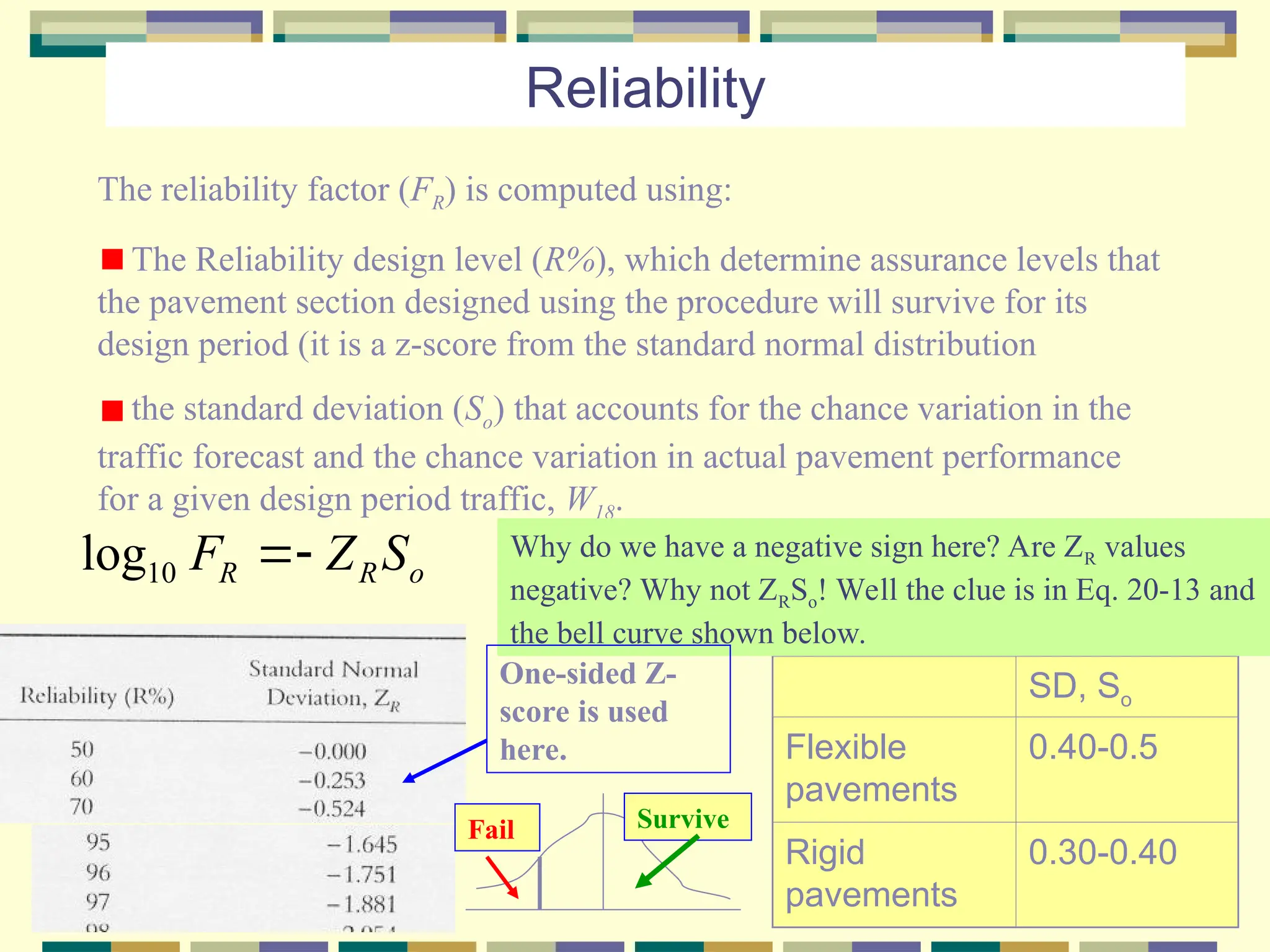

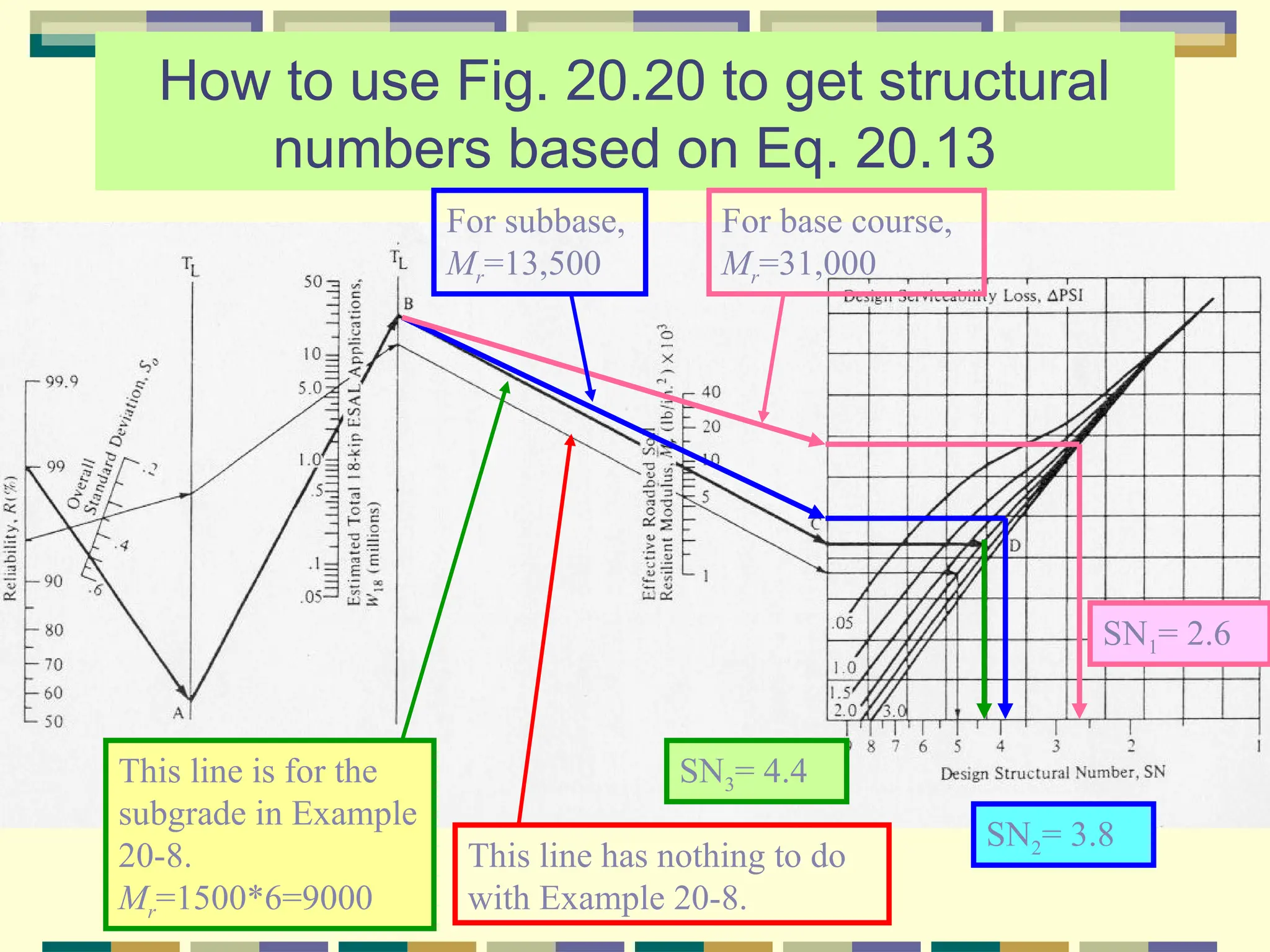

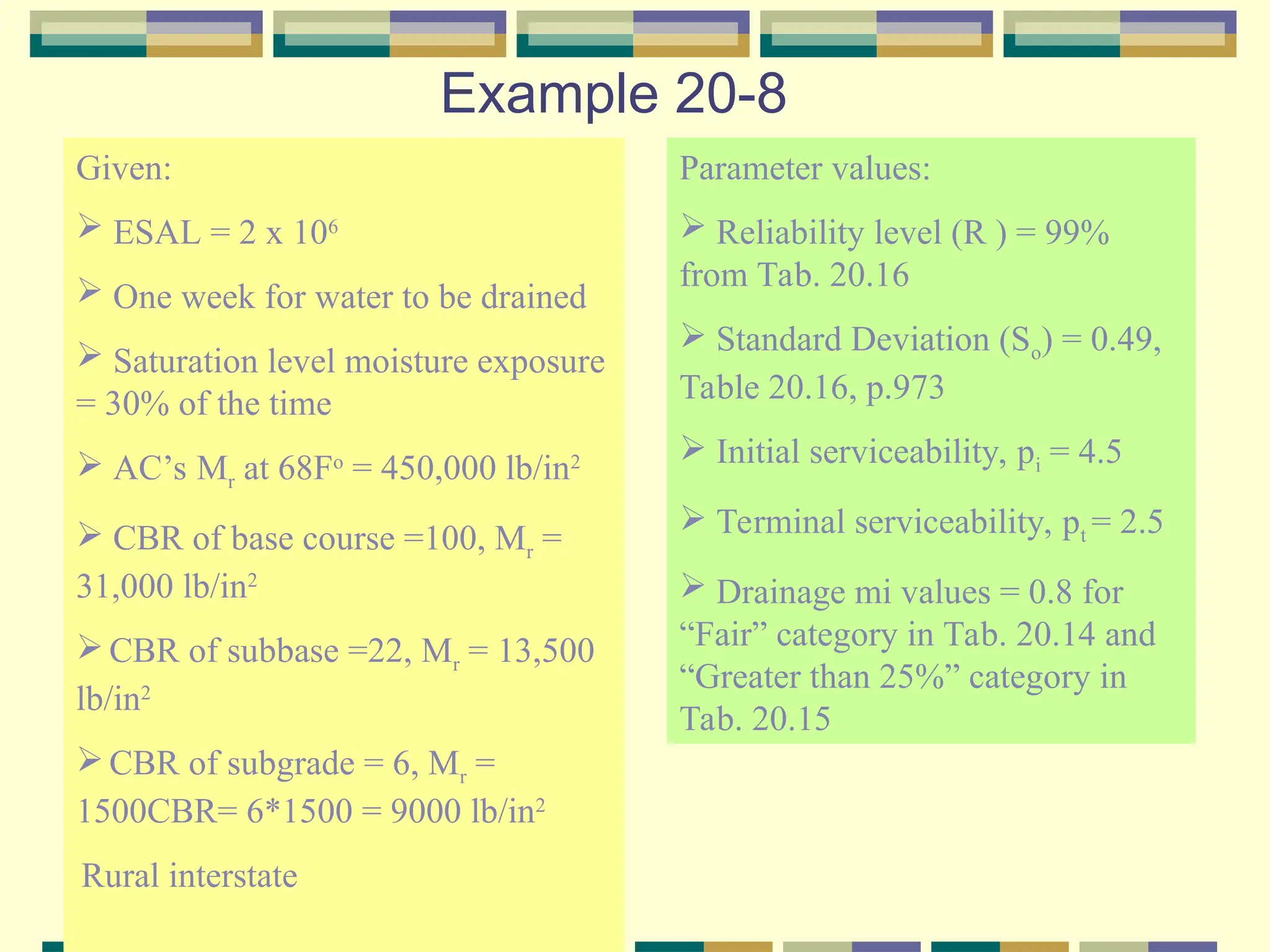

The document outlines the AASHTO flexible pavement design method, detailing factors such as pavement performance, traffic, roadbed soils, materials of construction, environment, drainage, and reliability that affect pavement thickness design. It emphasizes the calculation of structural numbers using tables and figures and the need for adequate thickness to withstand projected traffic loads. Additionally, it discusses how to account for variations in design parameters through reliability factors and performance indices.