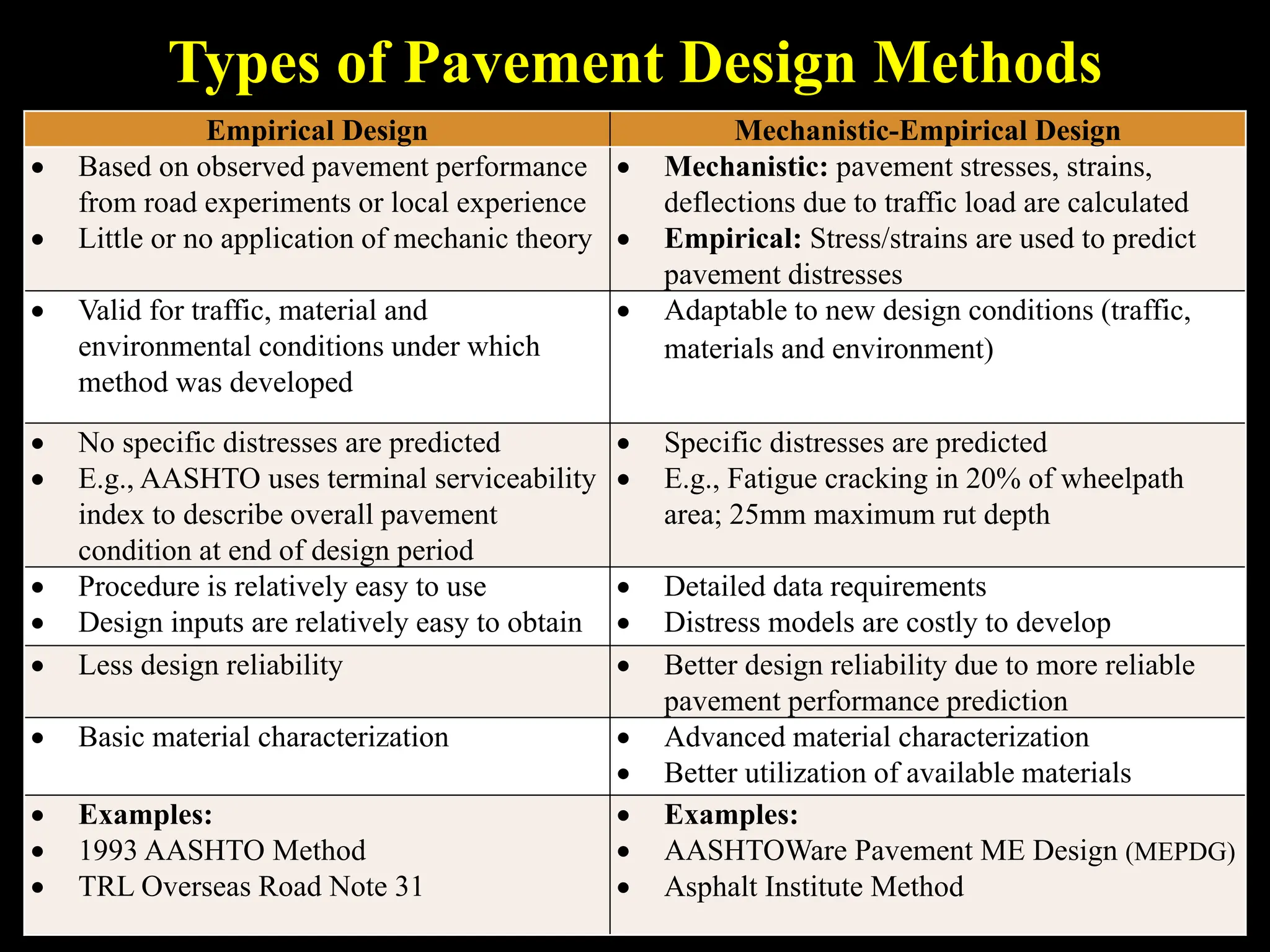

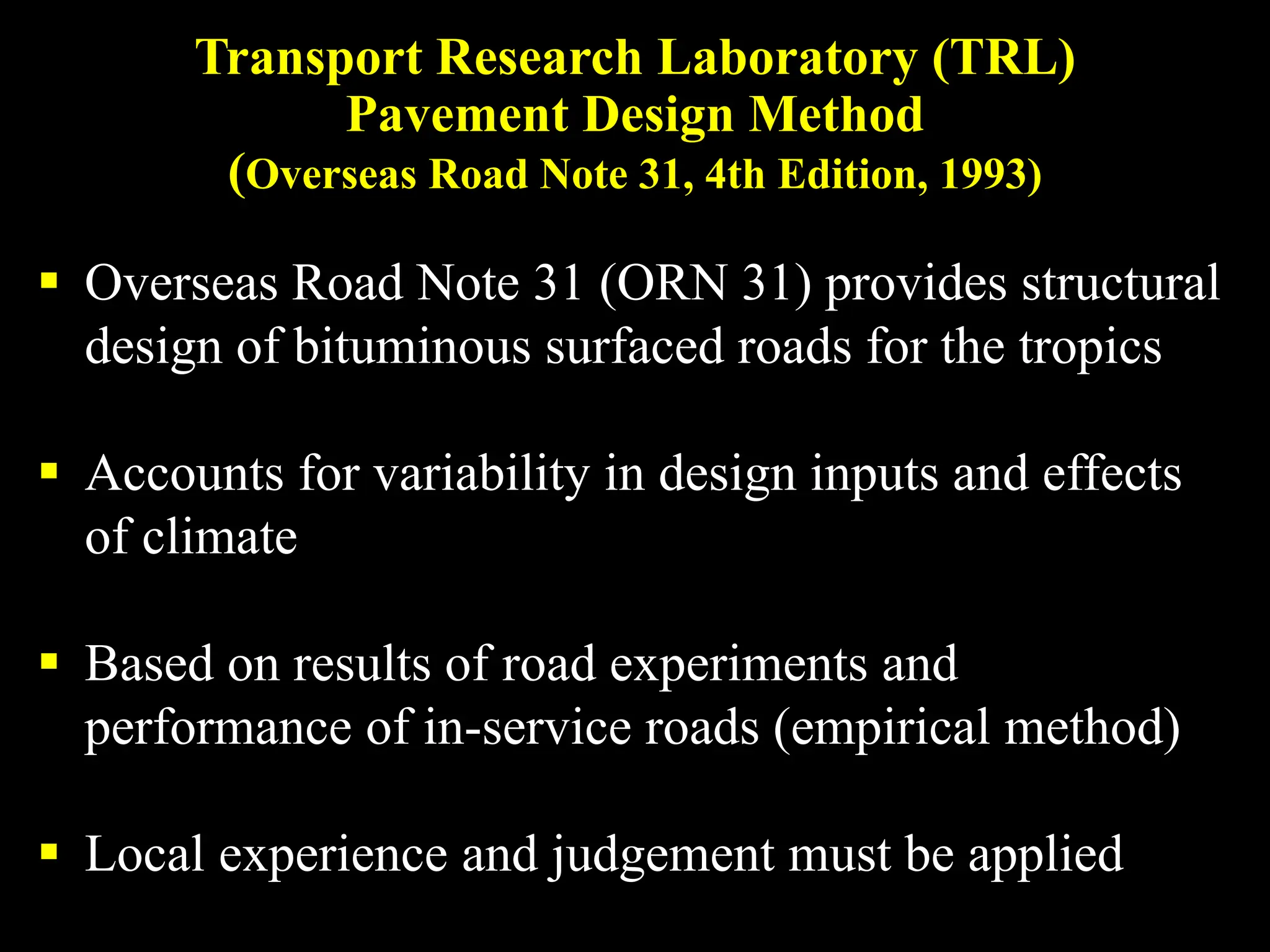

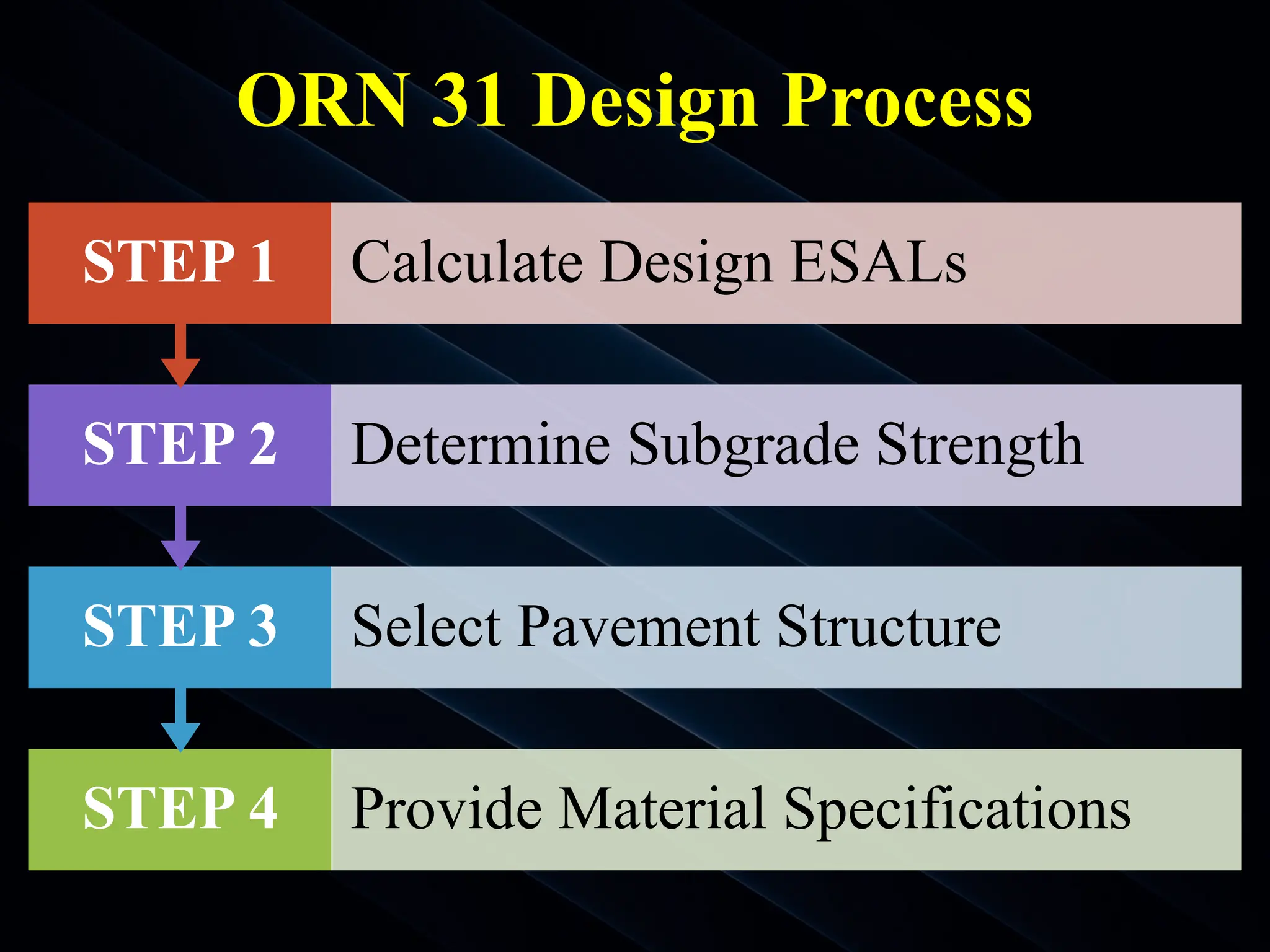

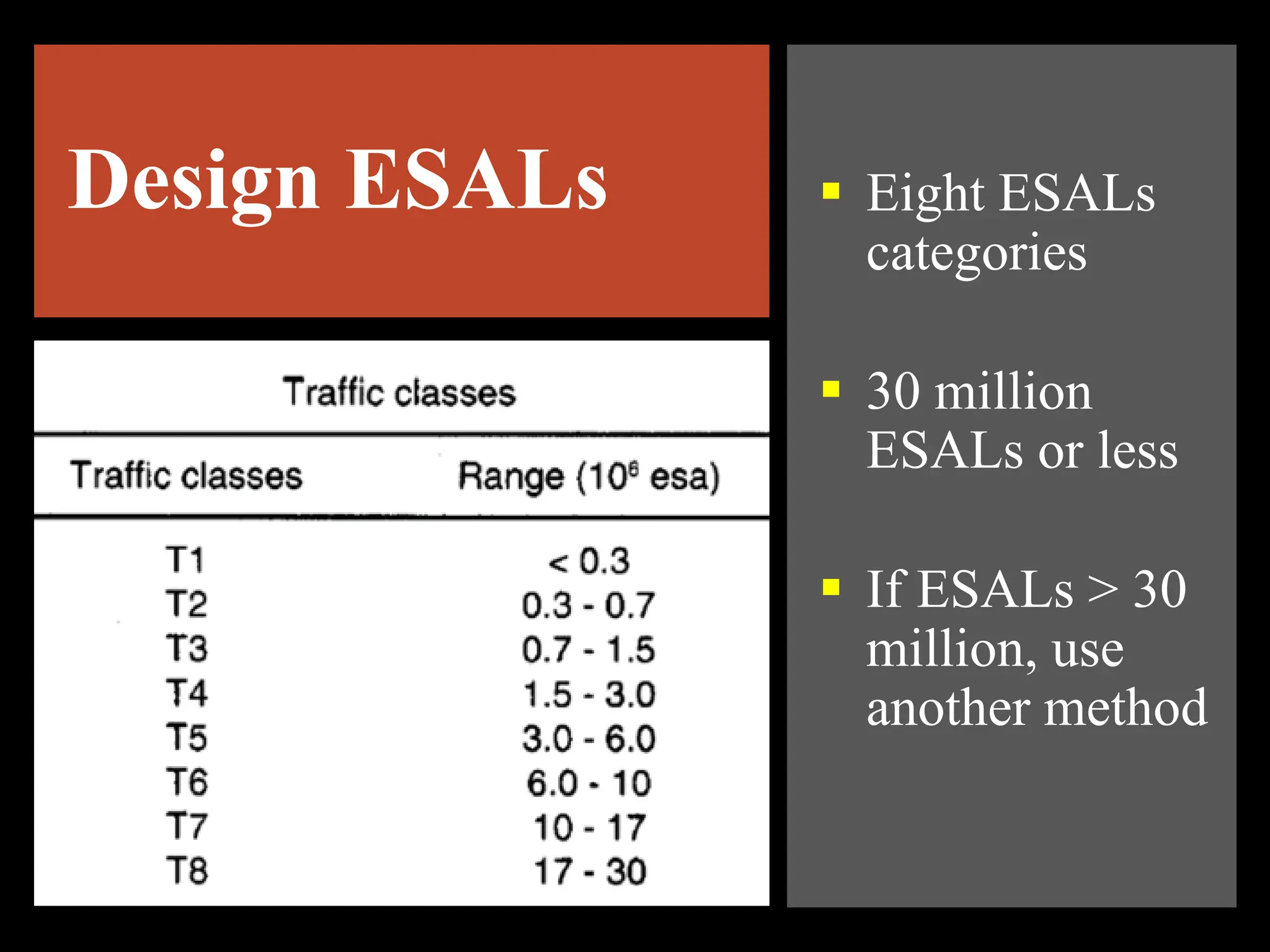

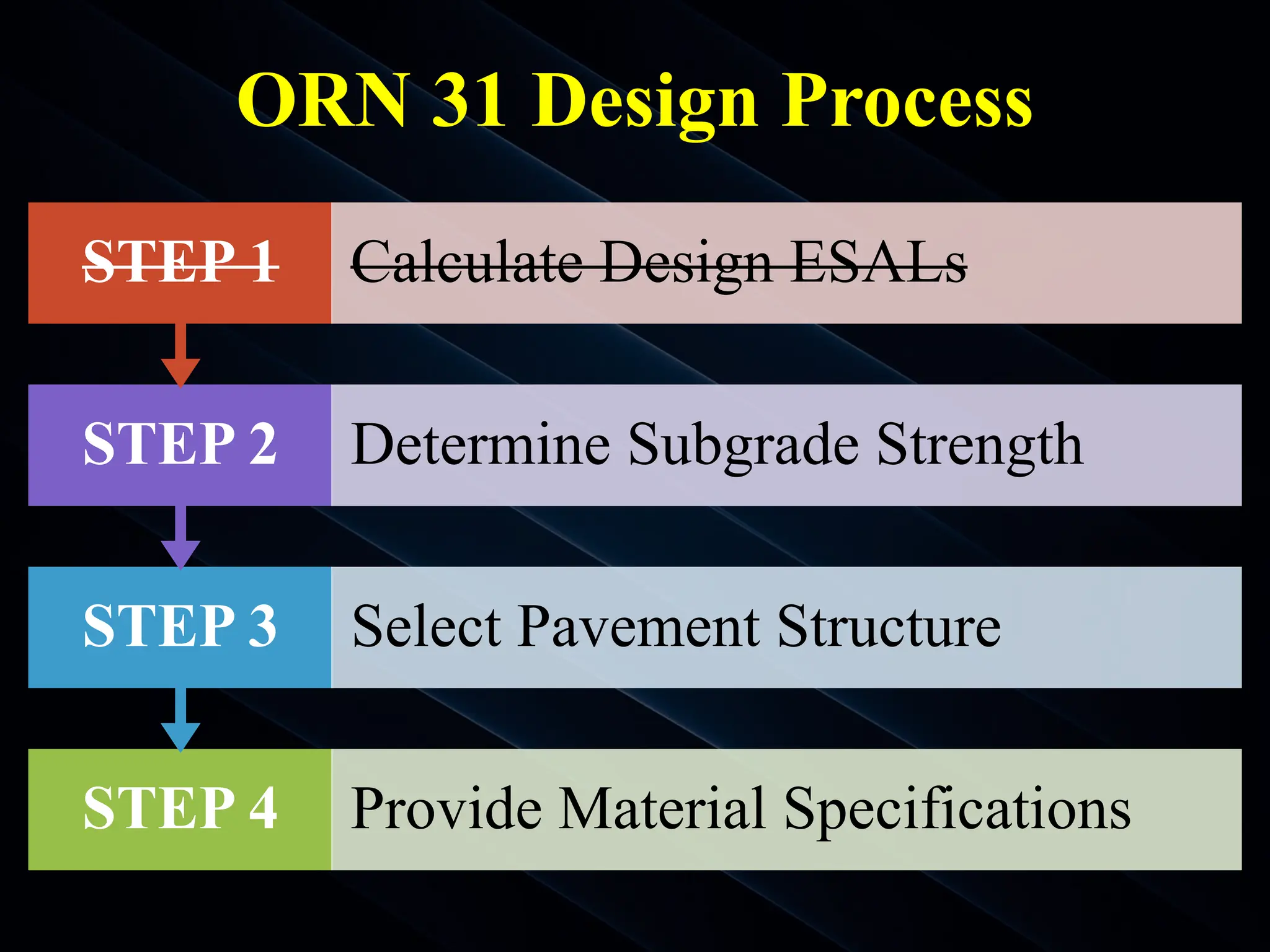

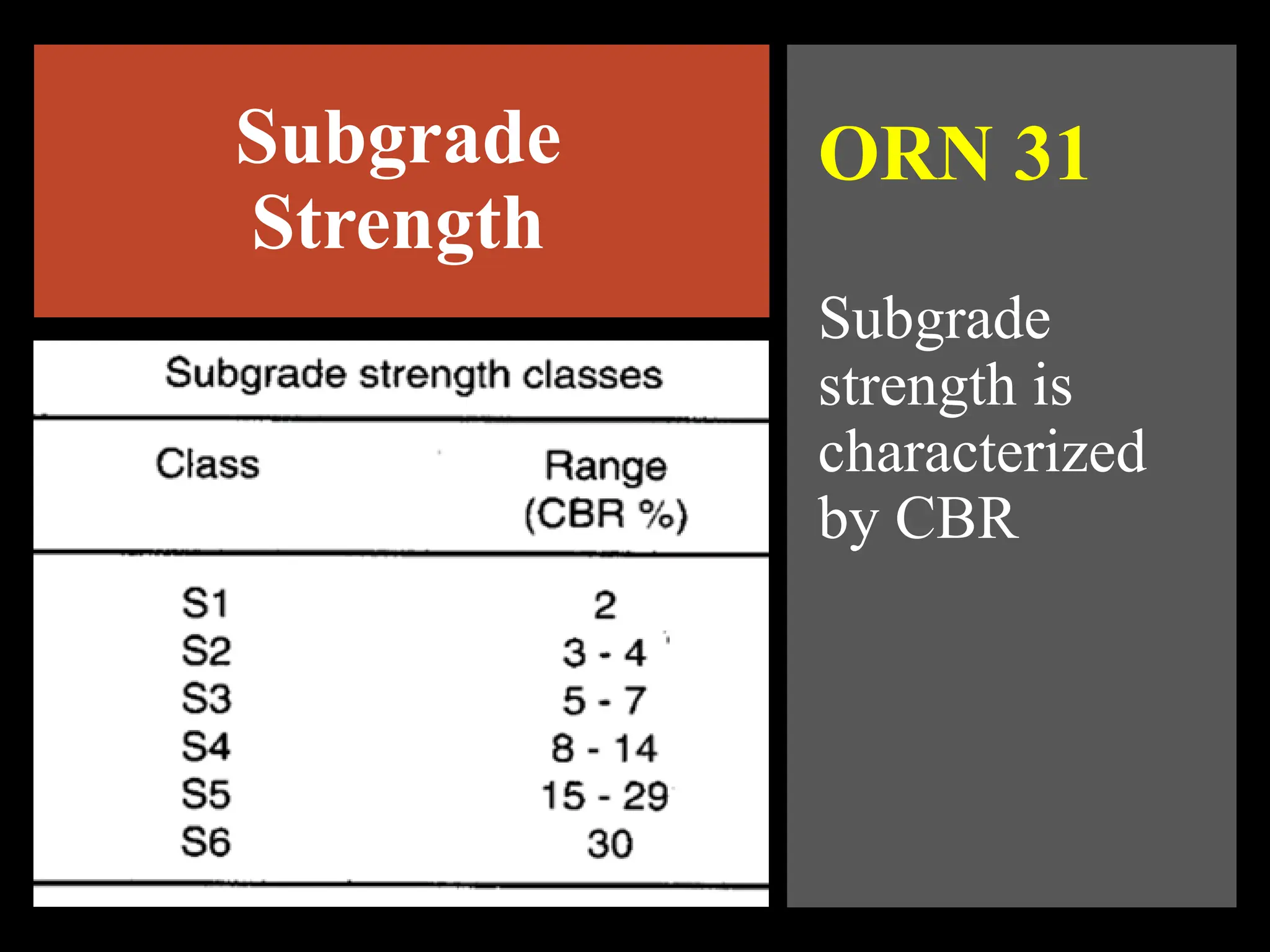

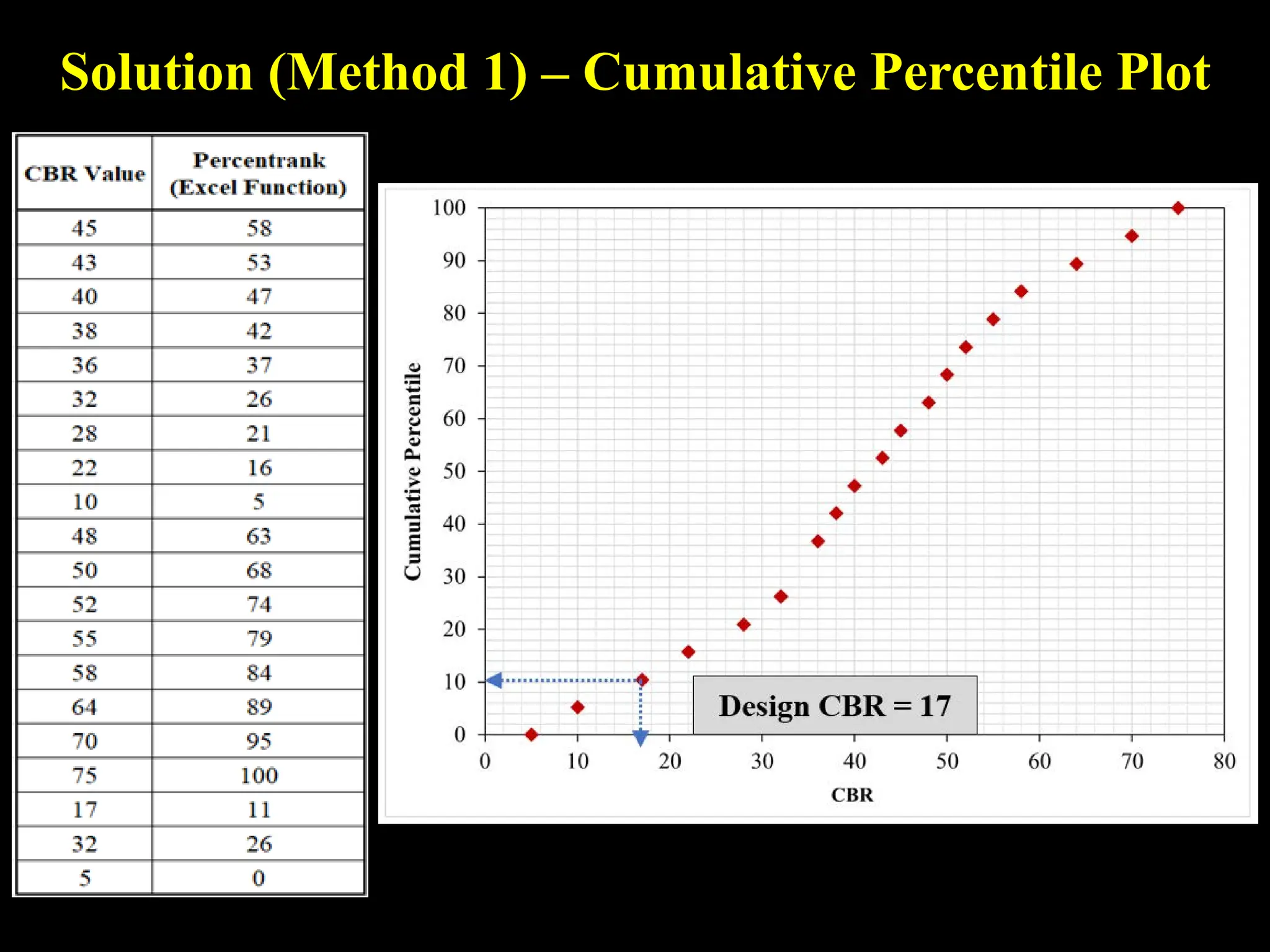

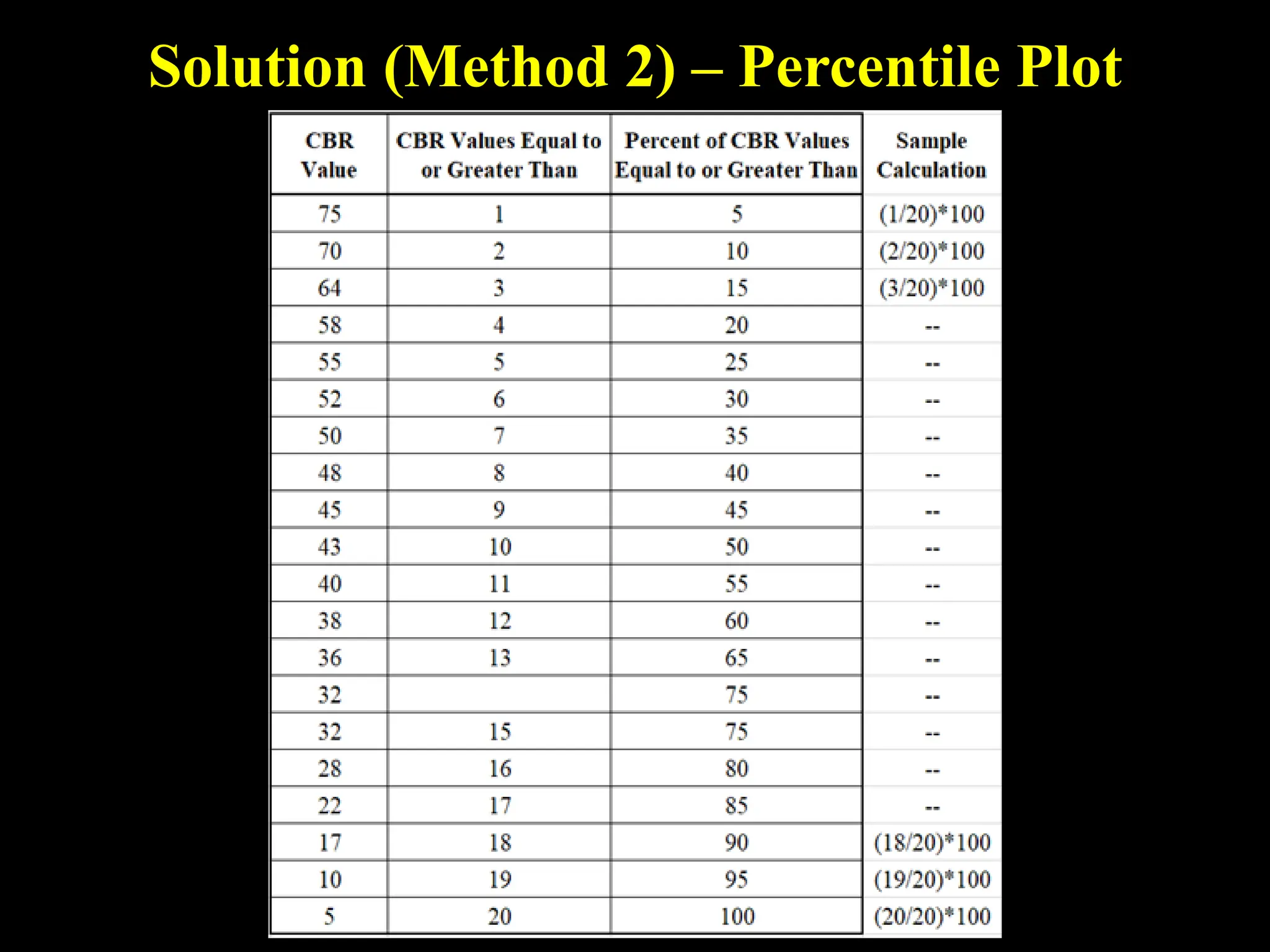

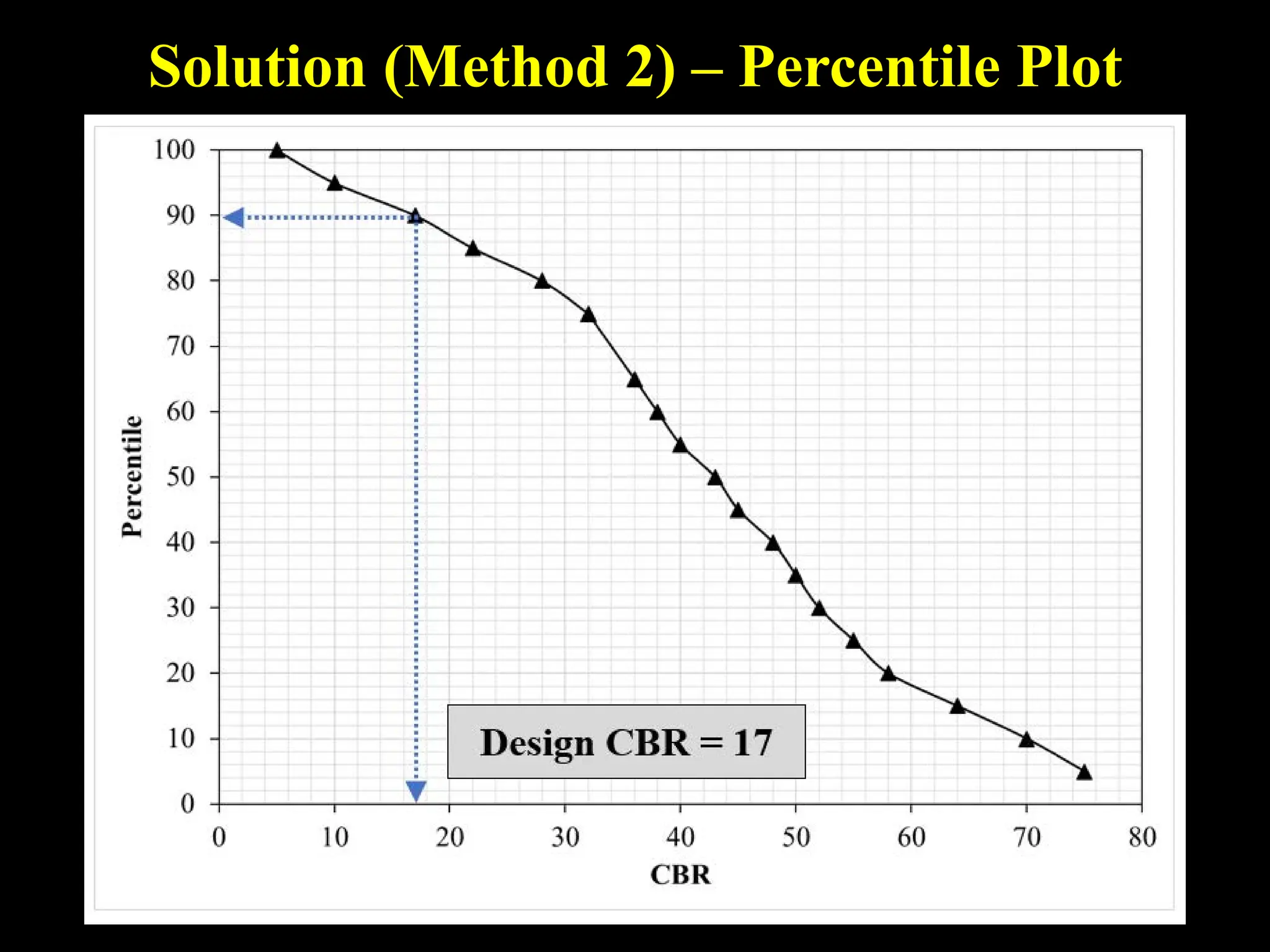

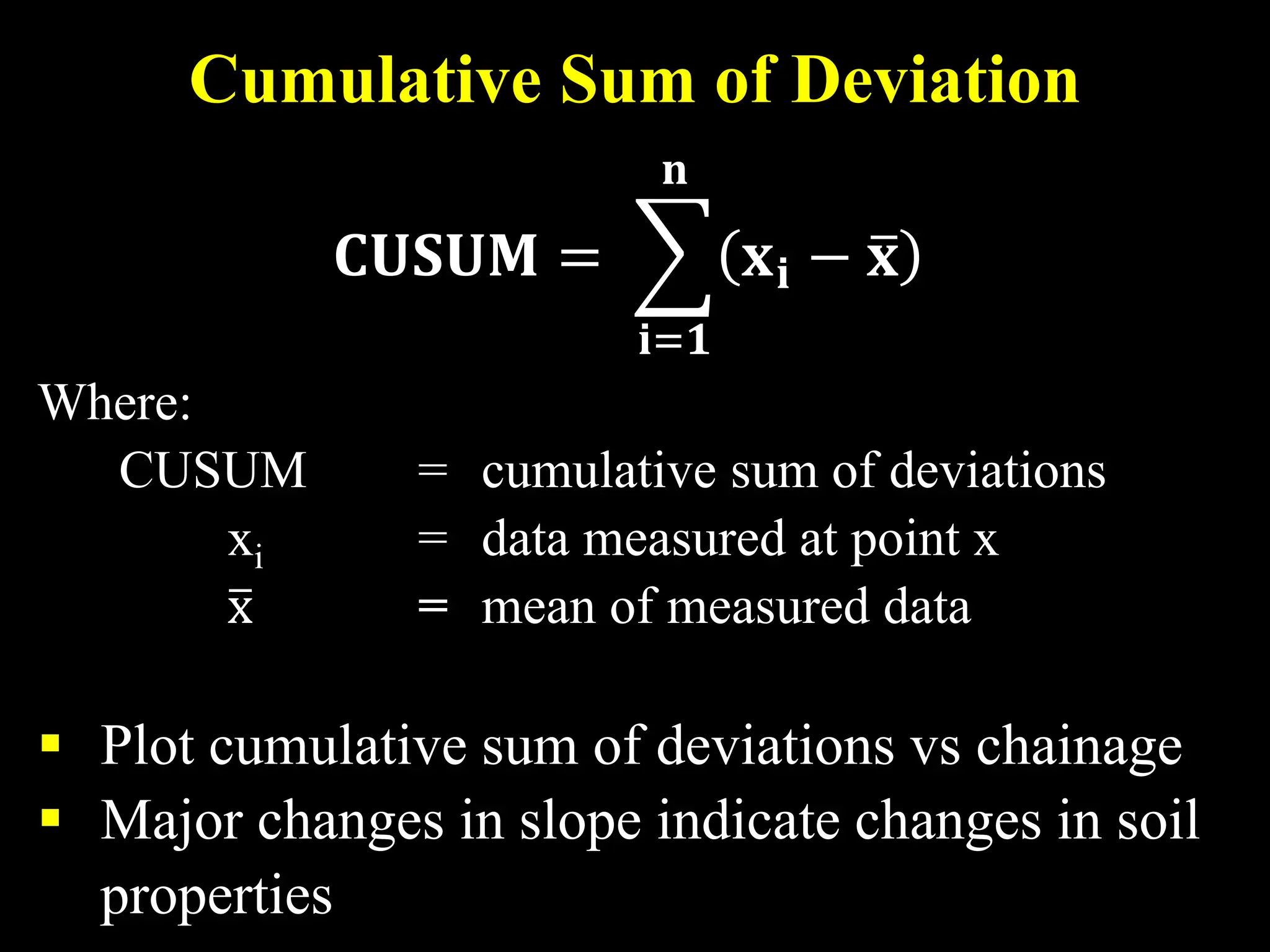

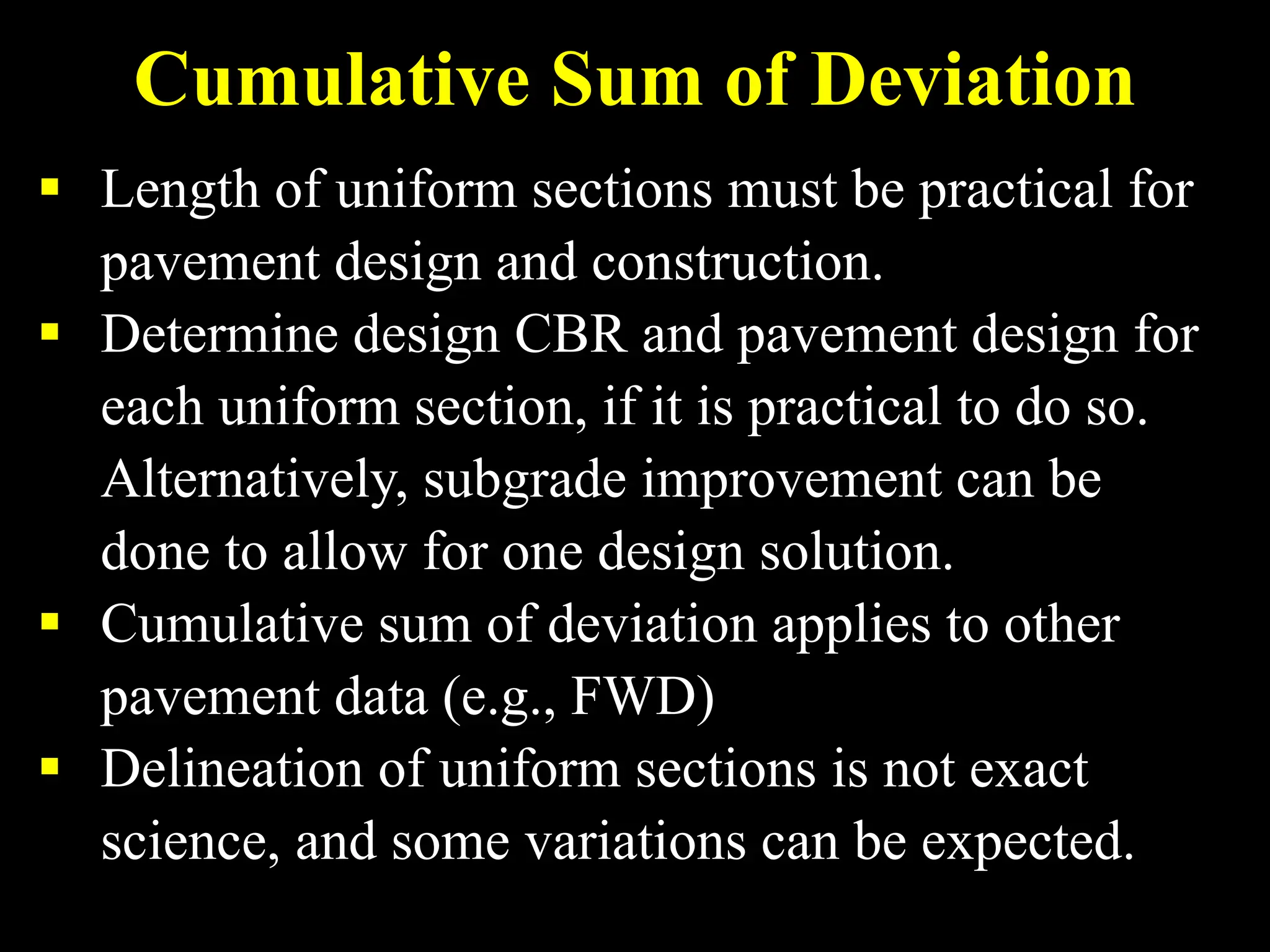

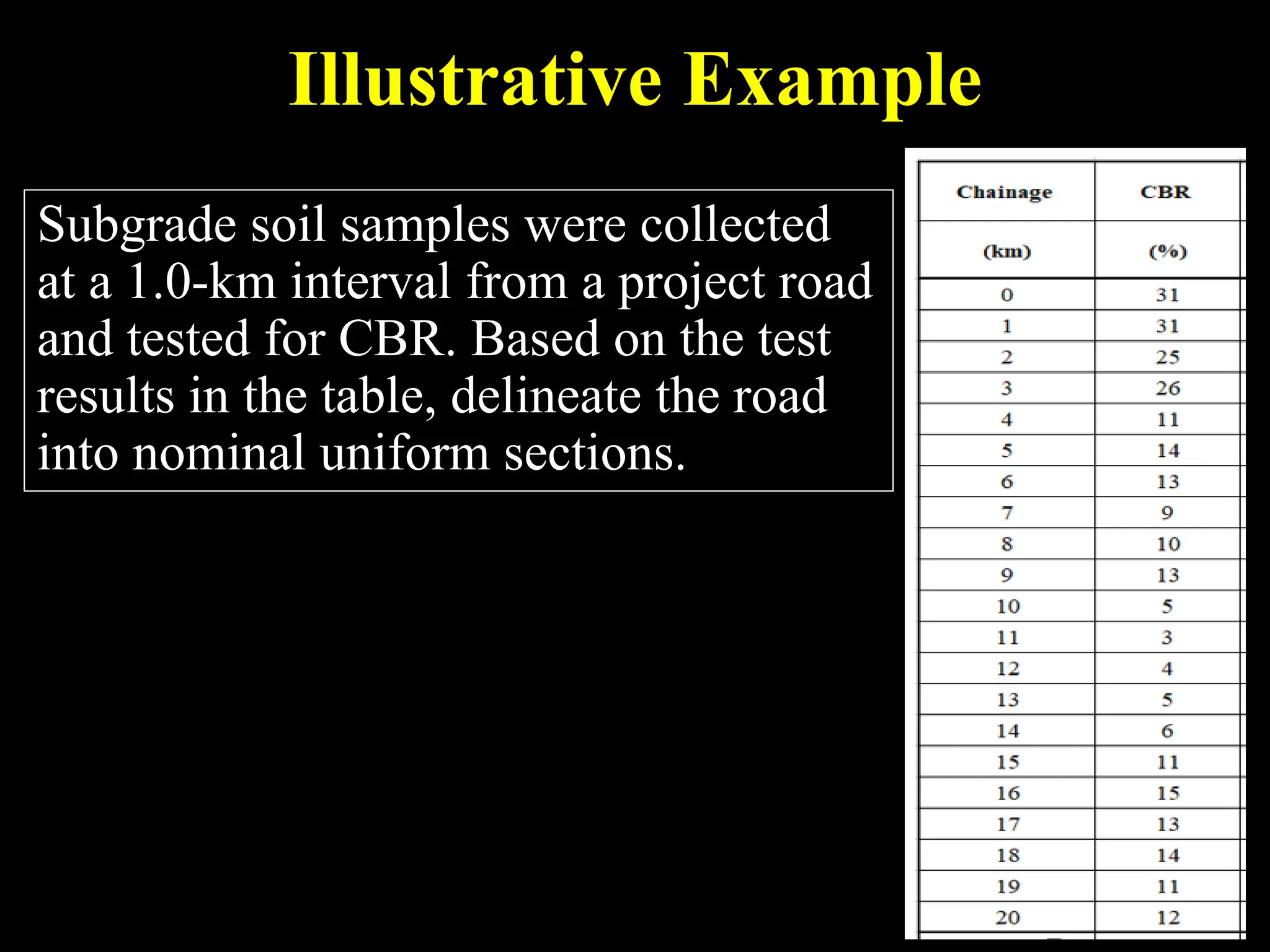

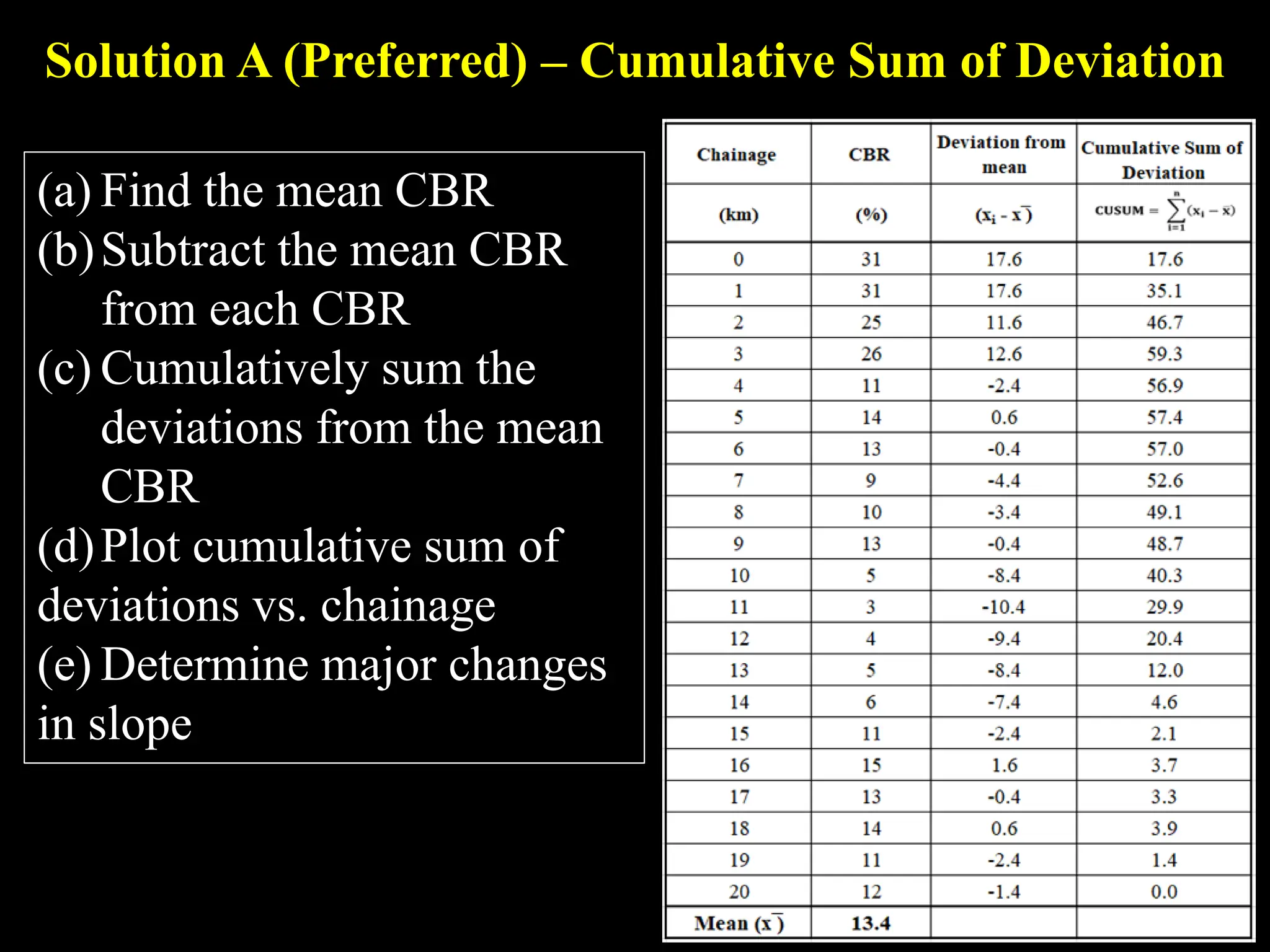

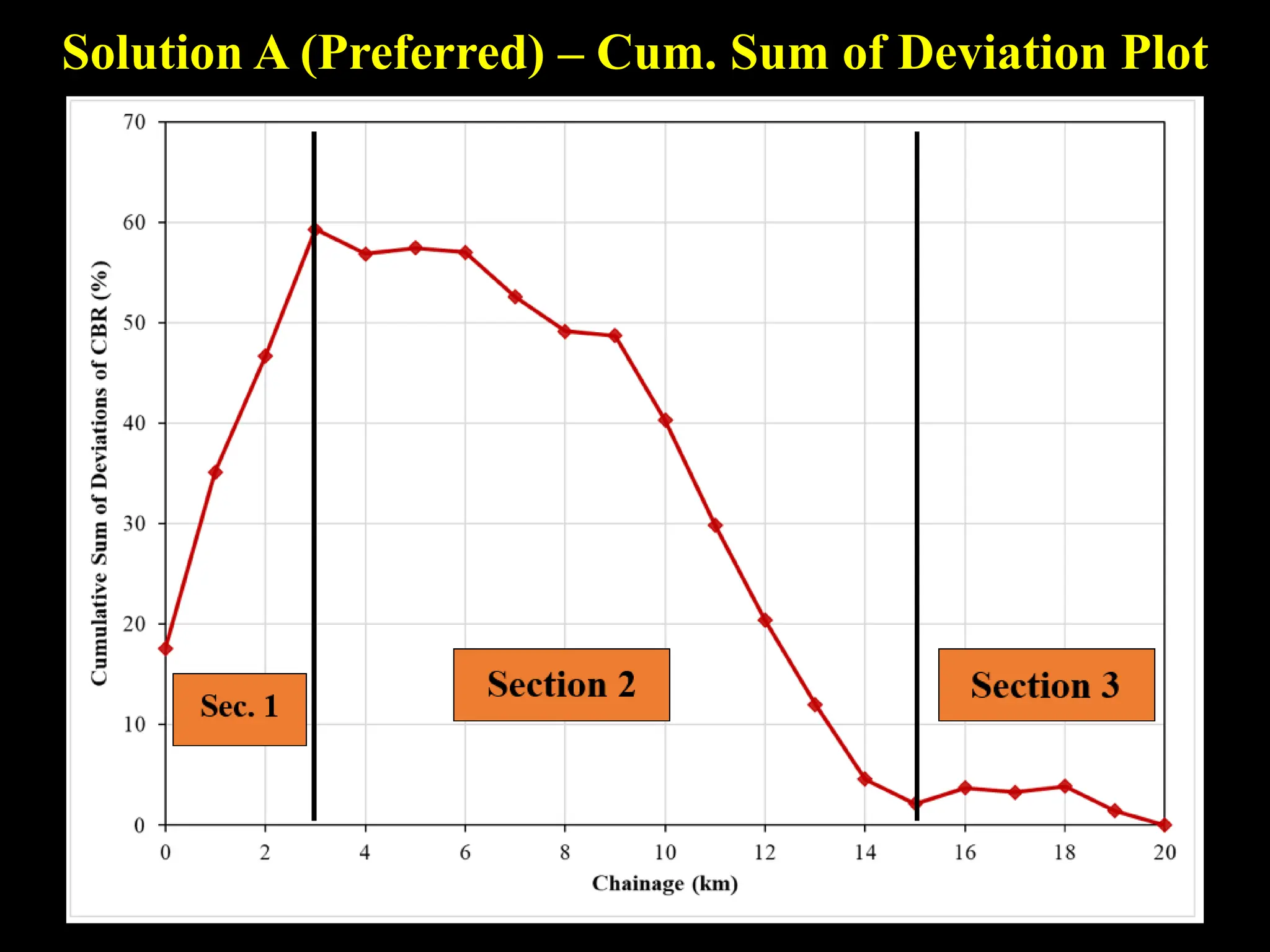

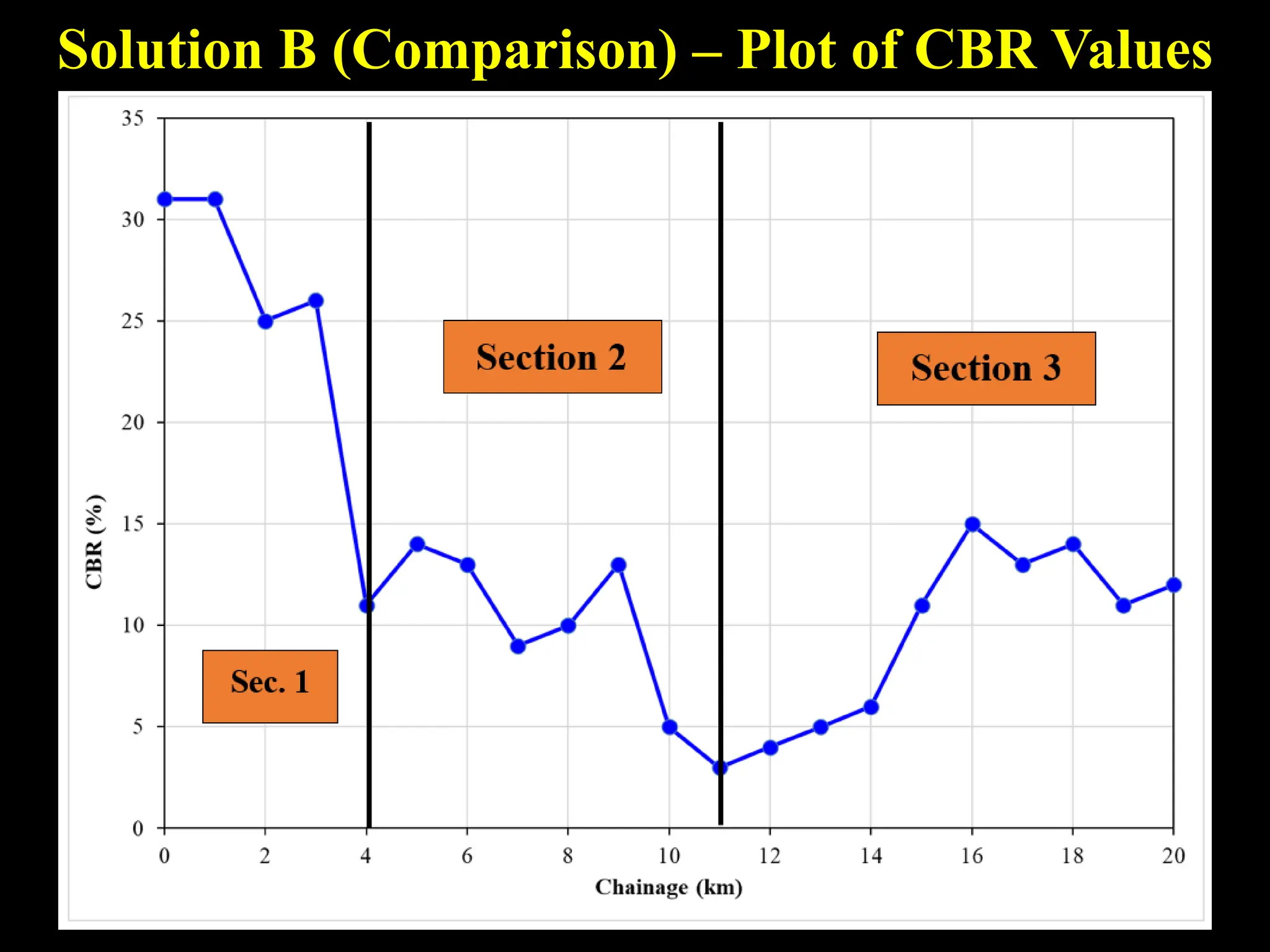

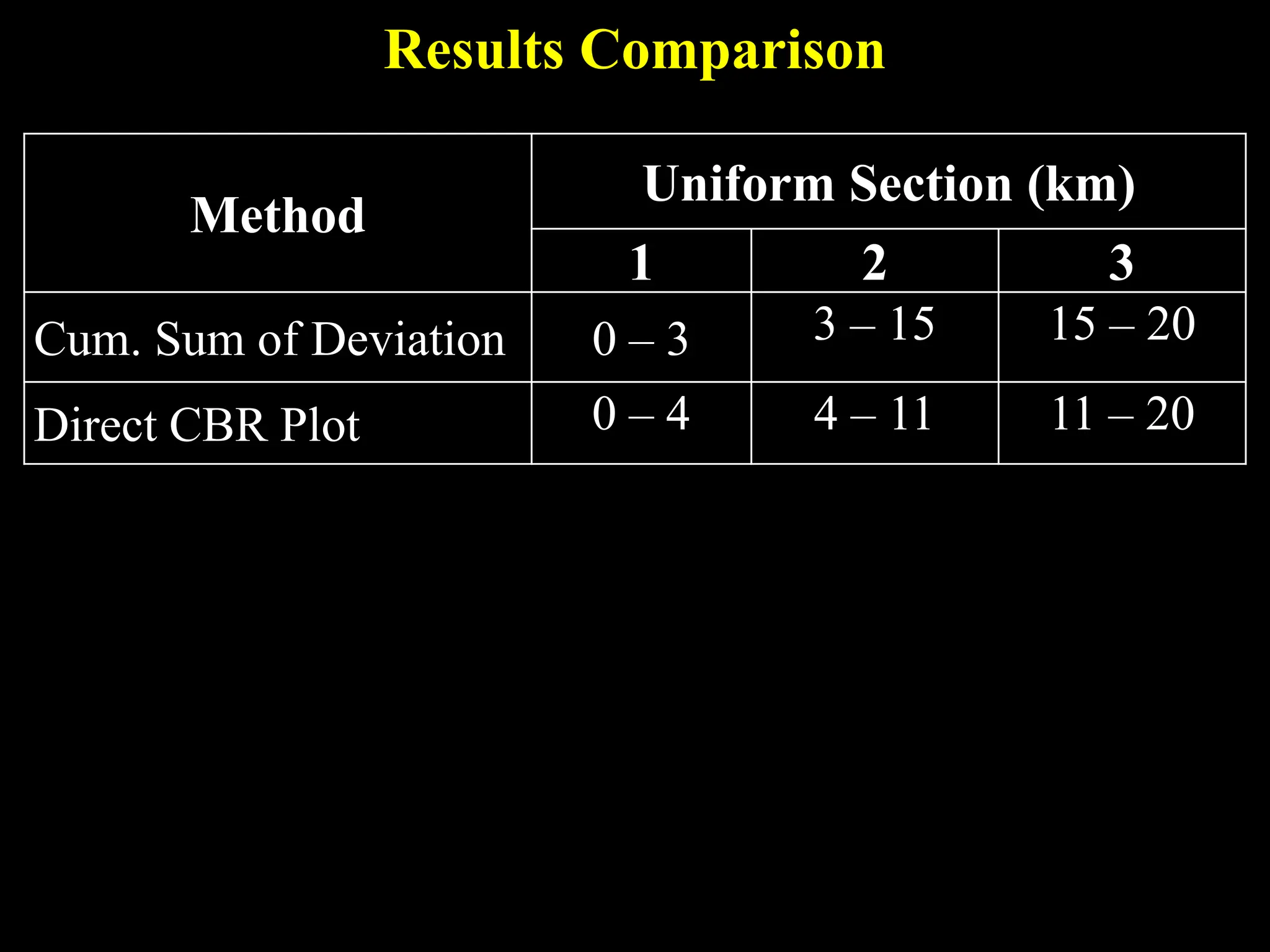

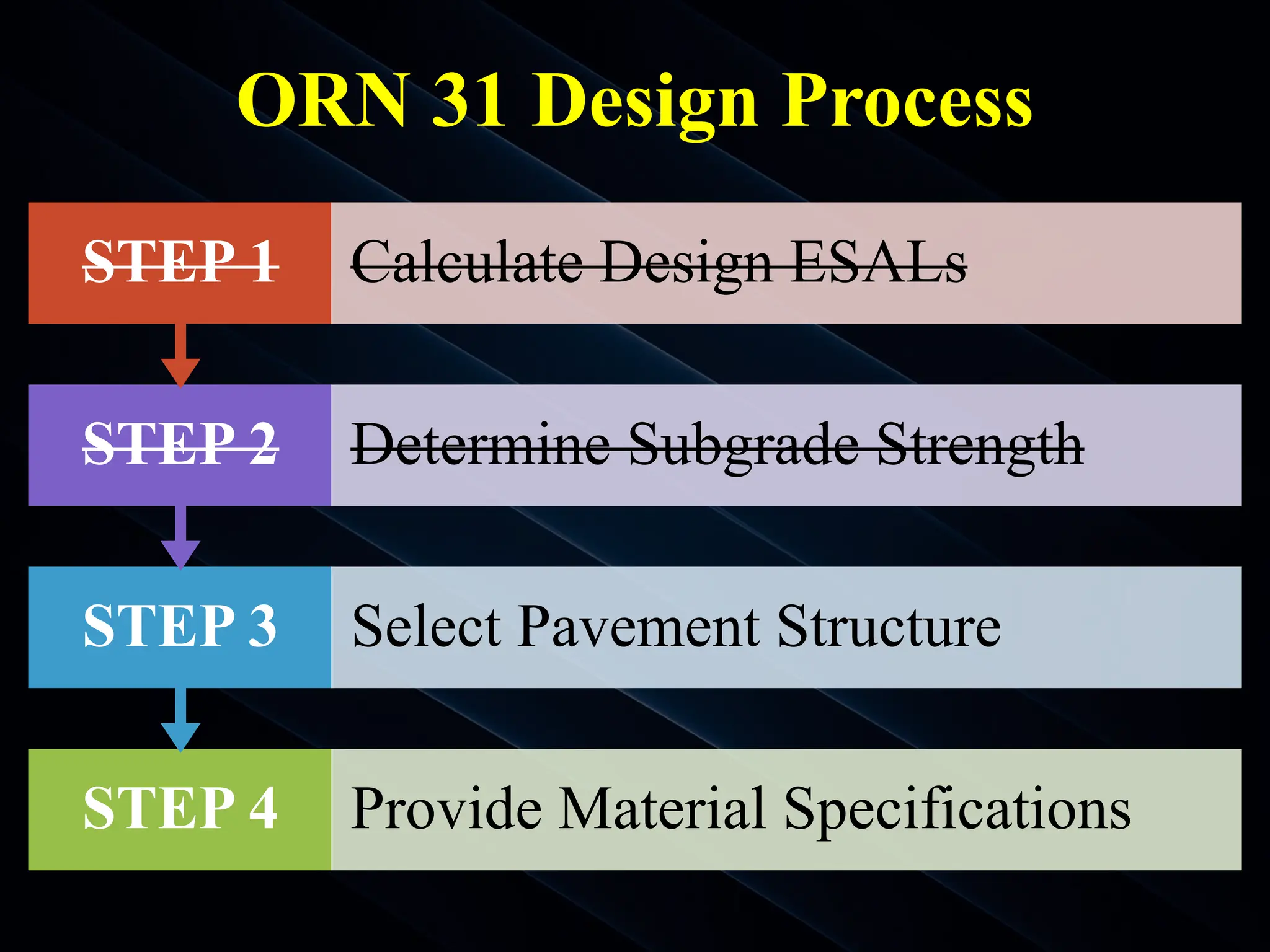

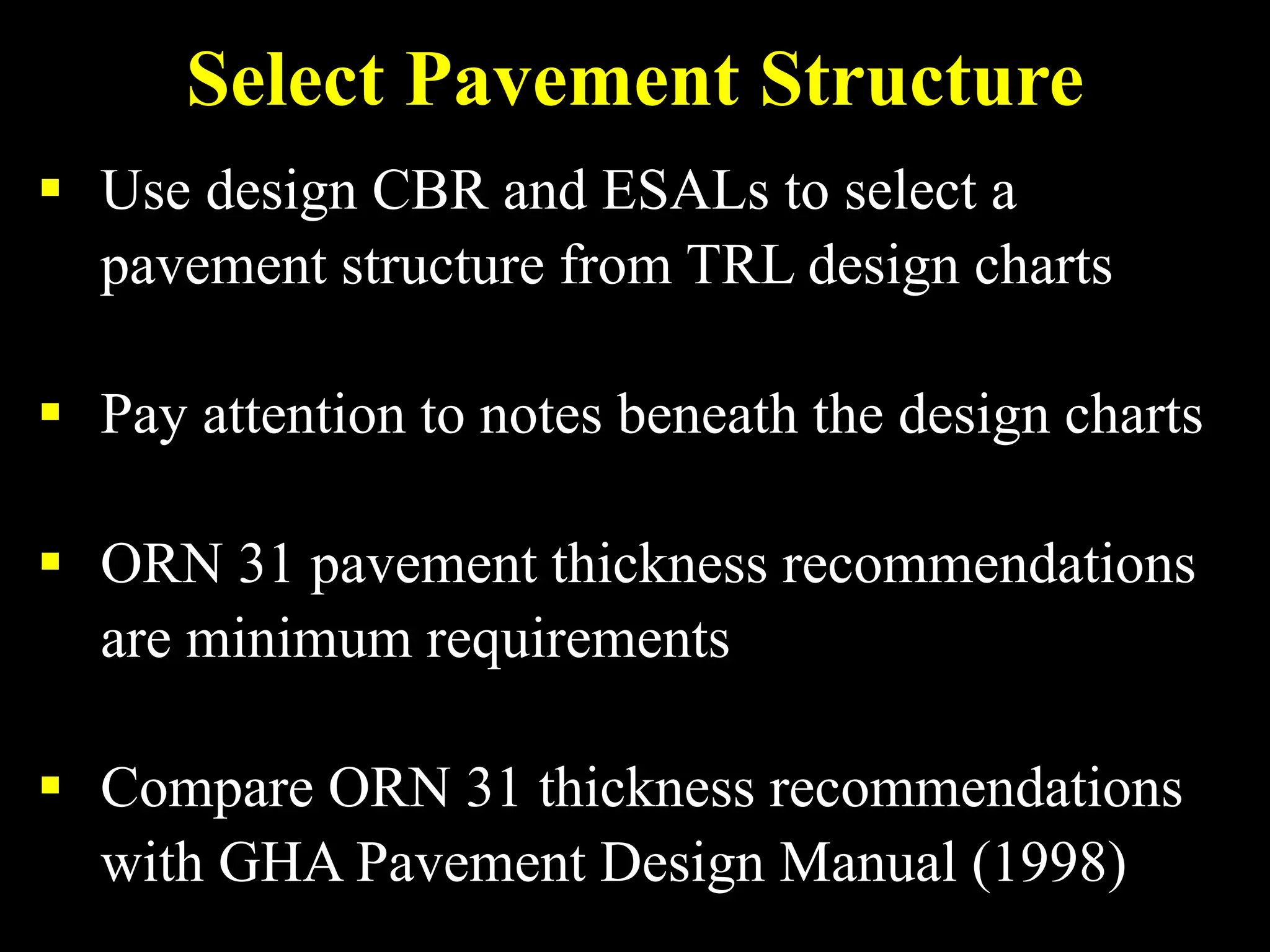

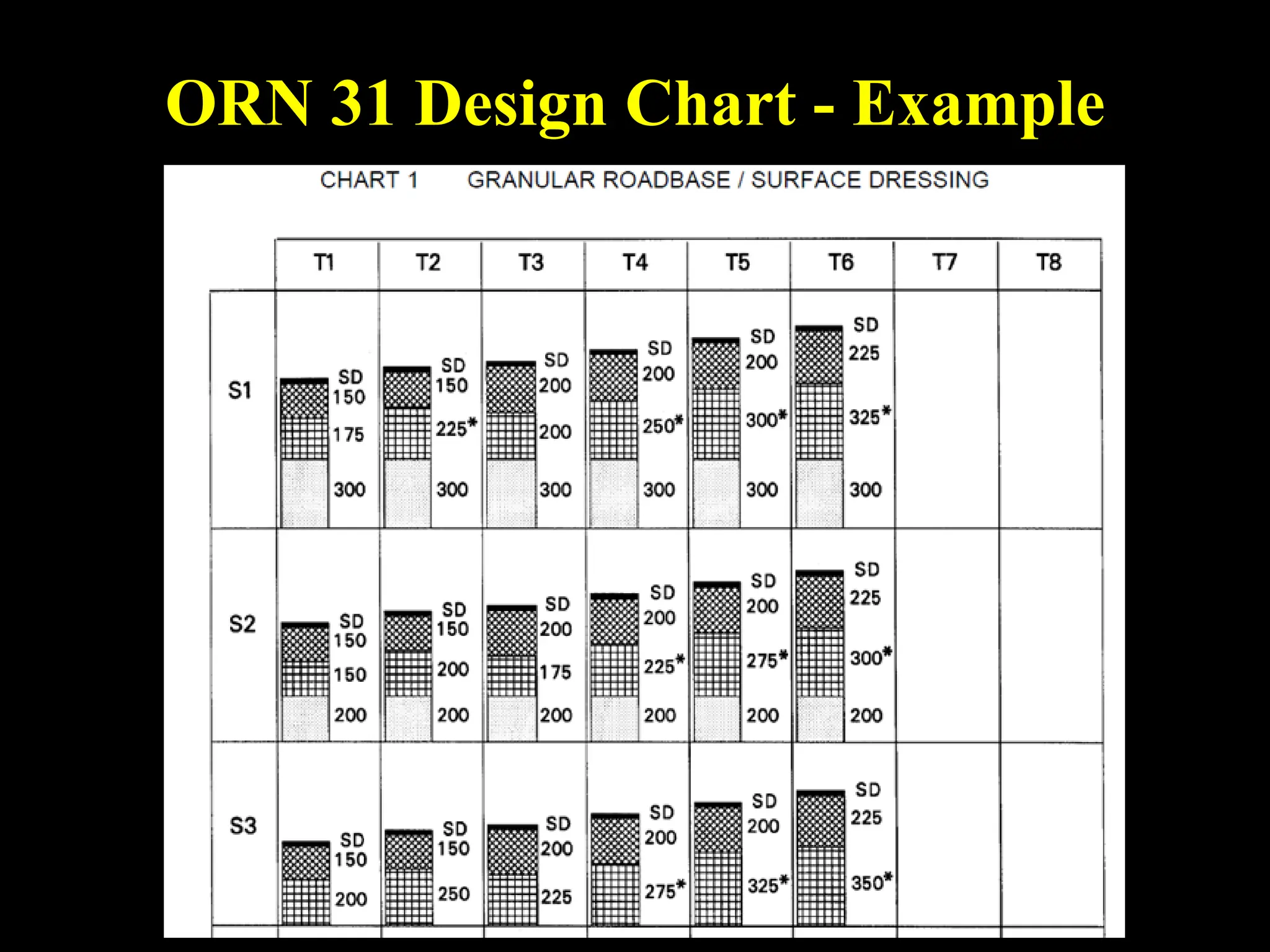

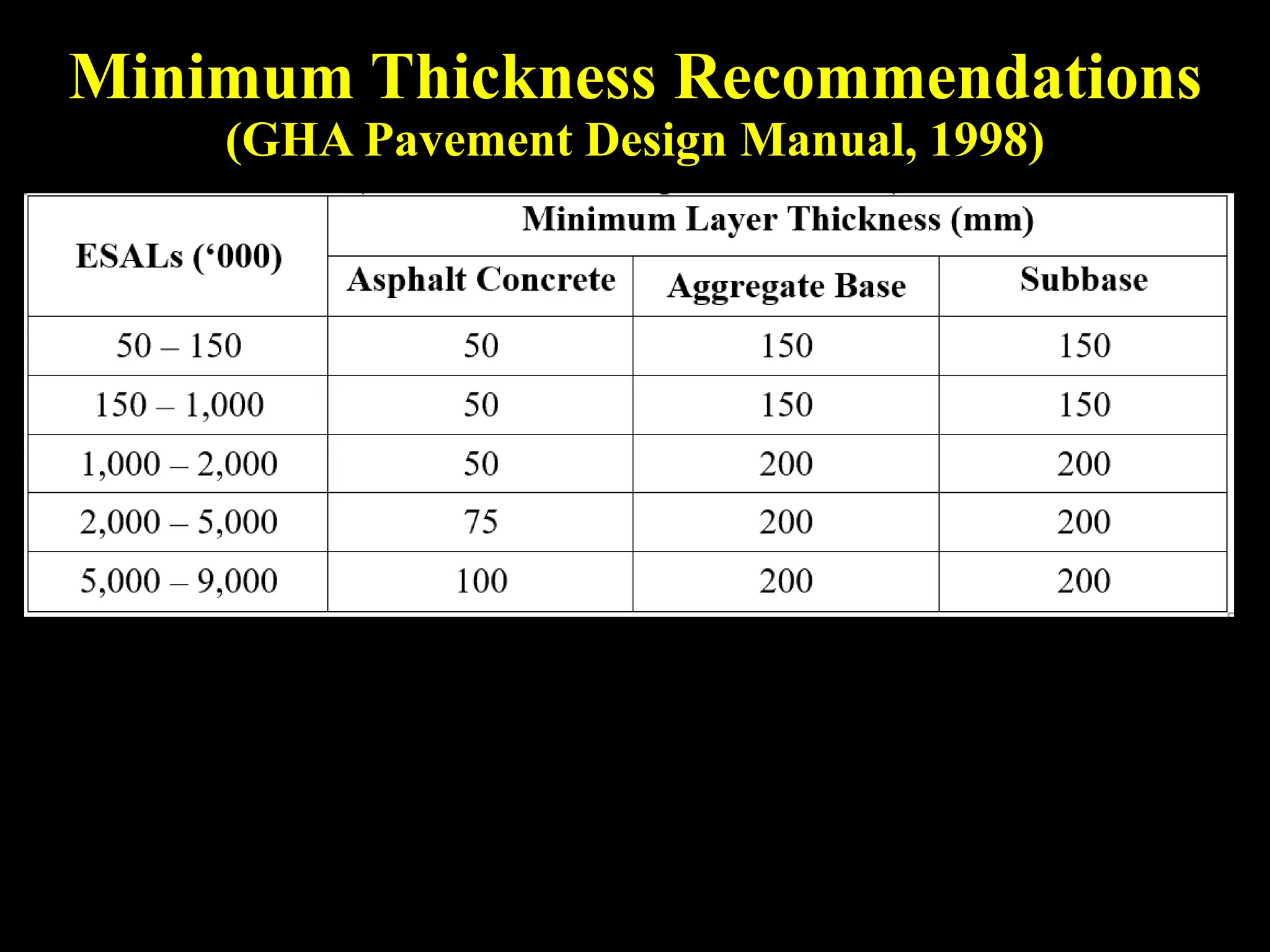

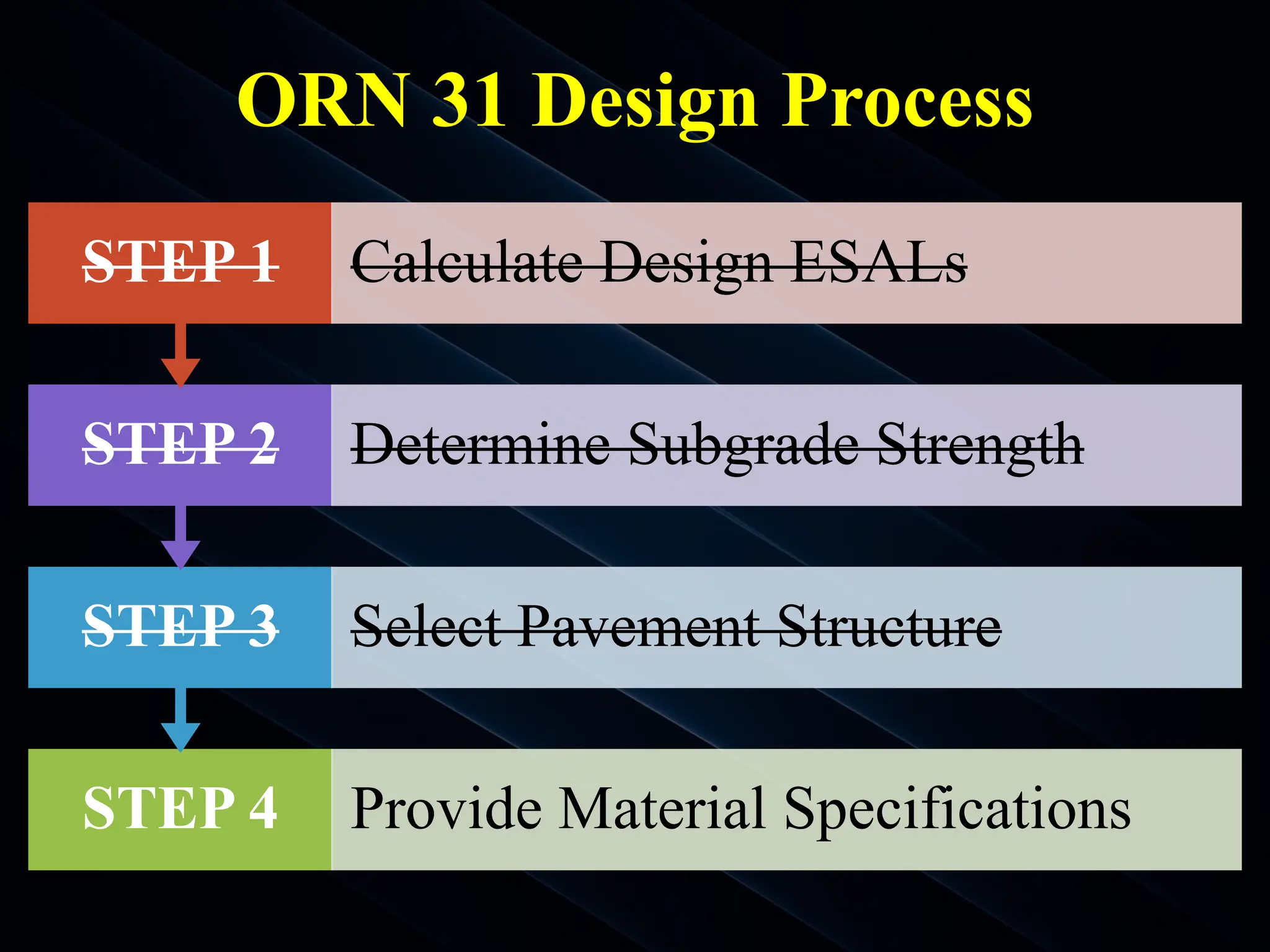

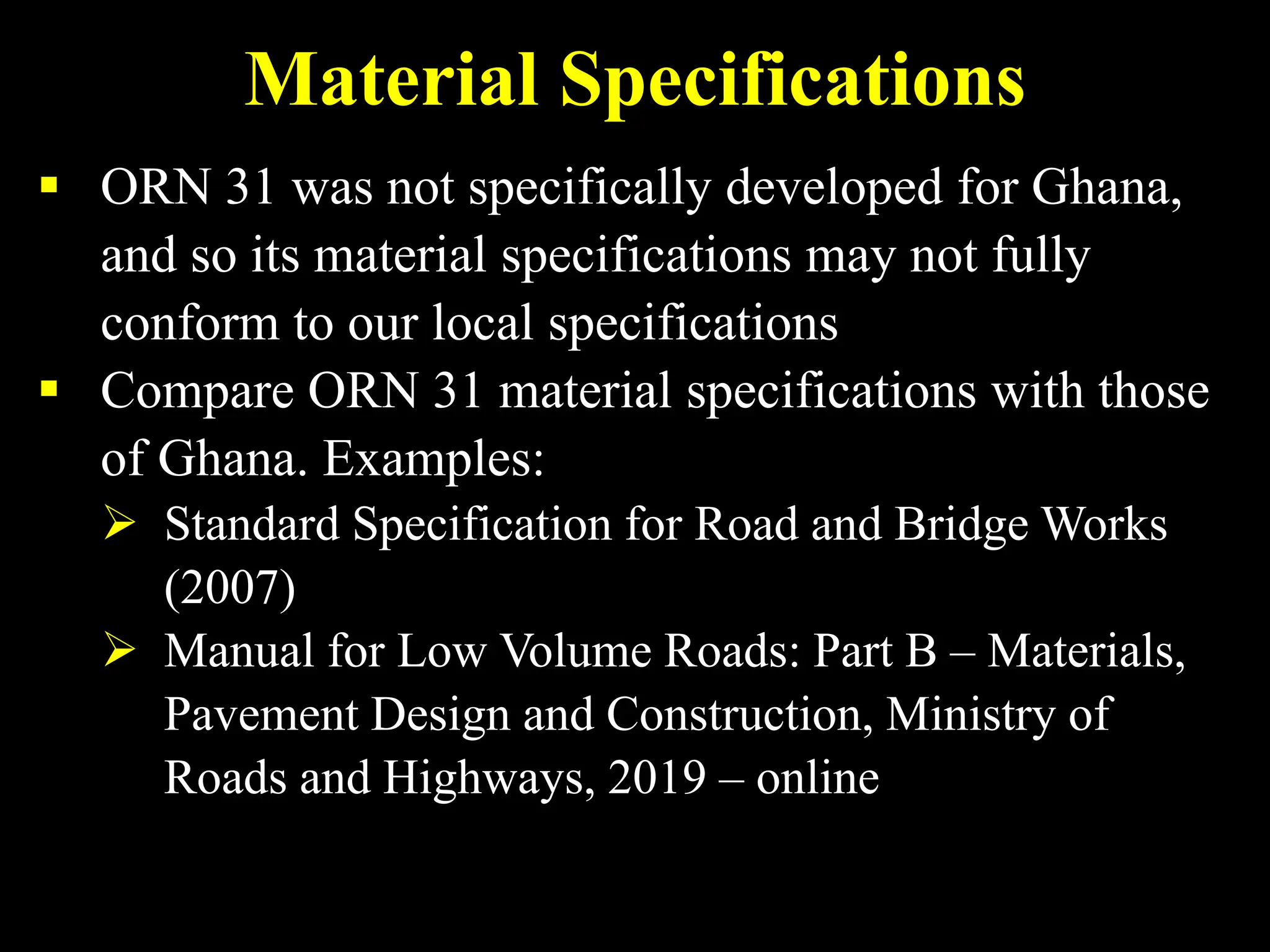

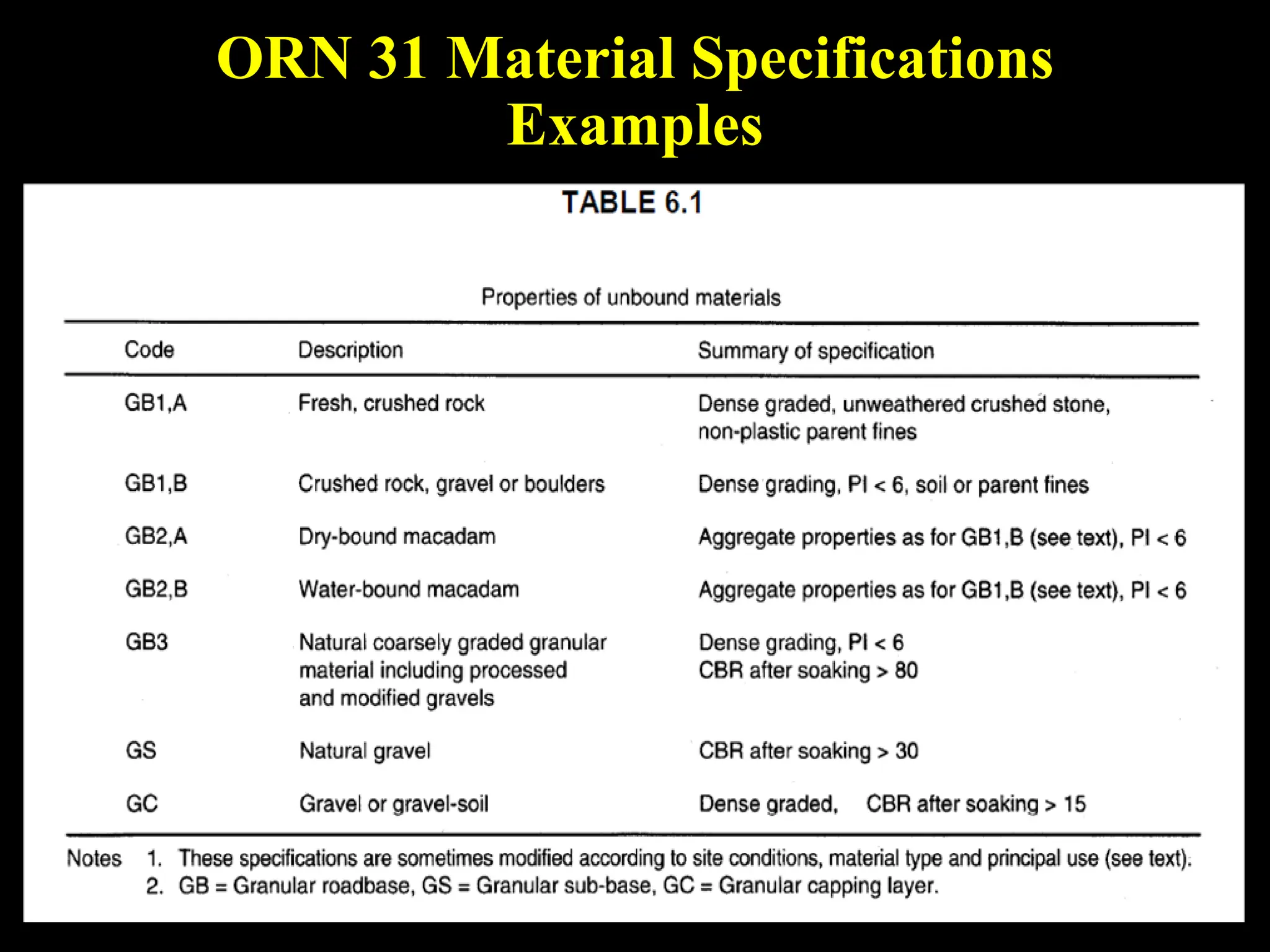

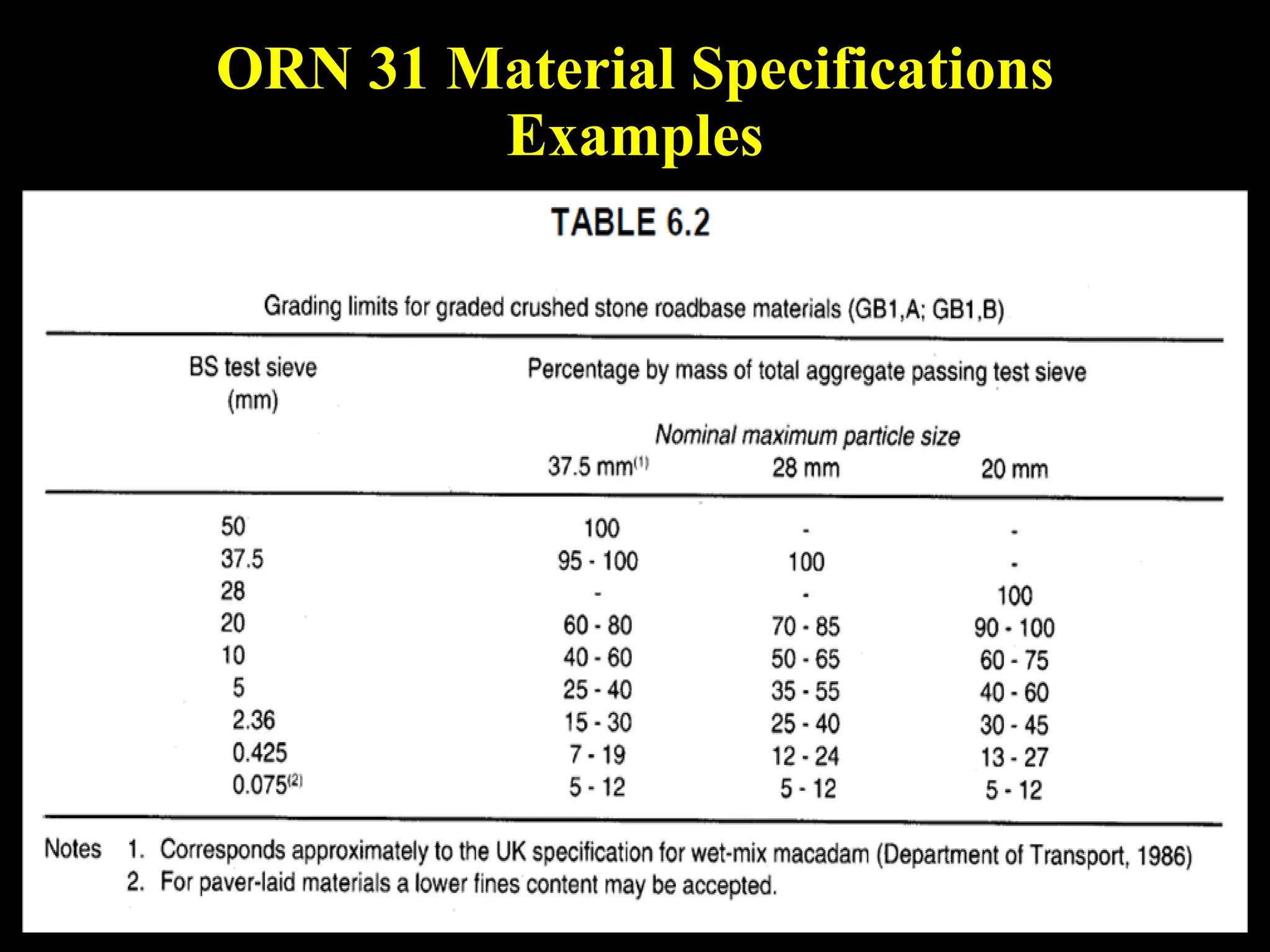

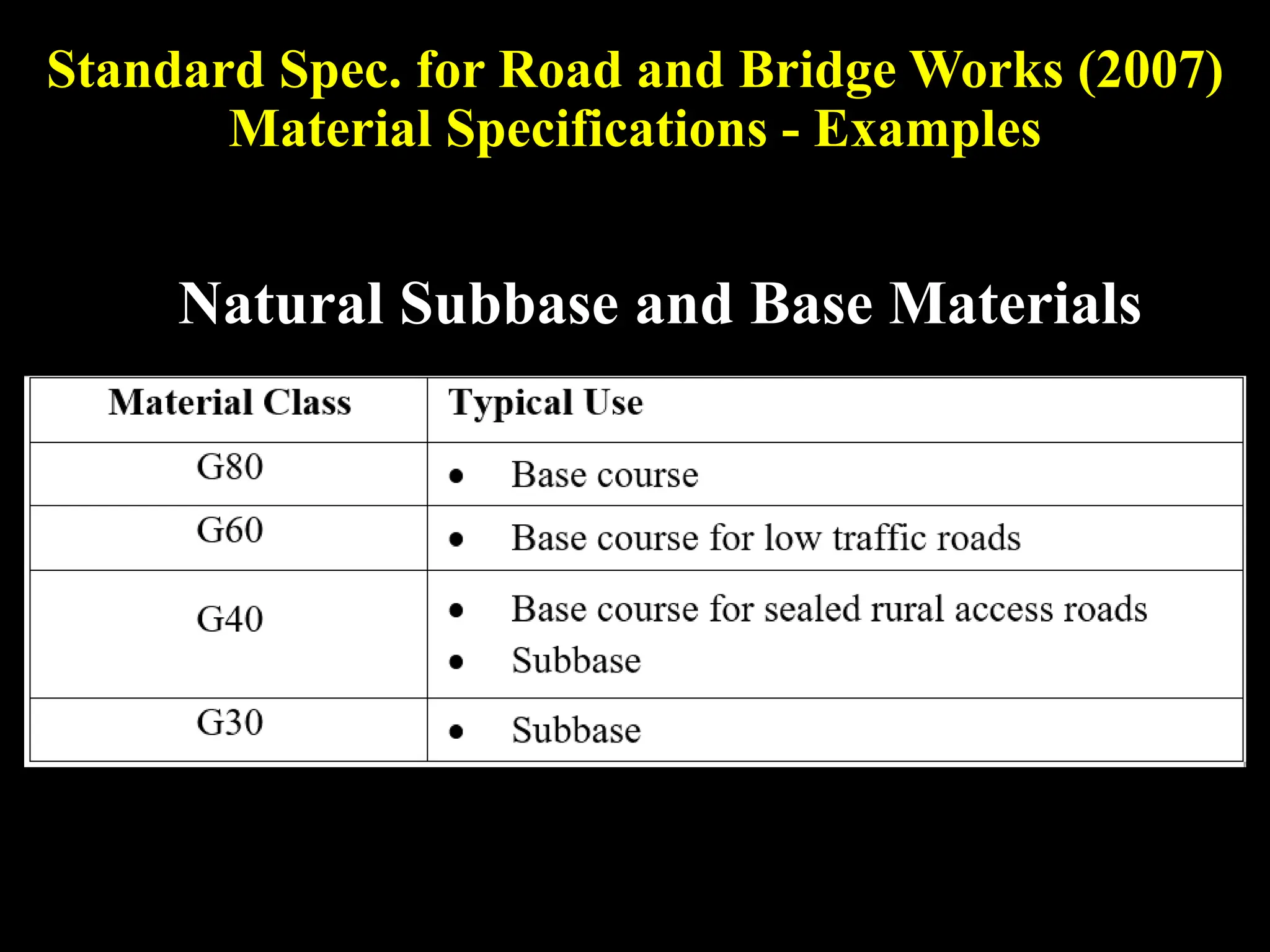

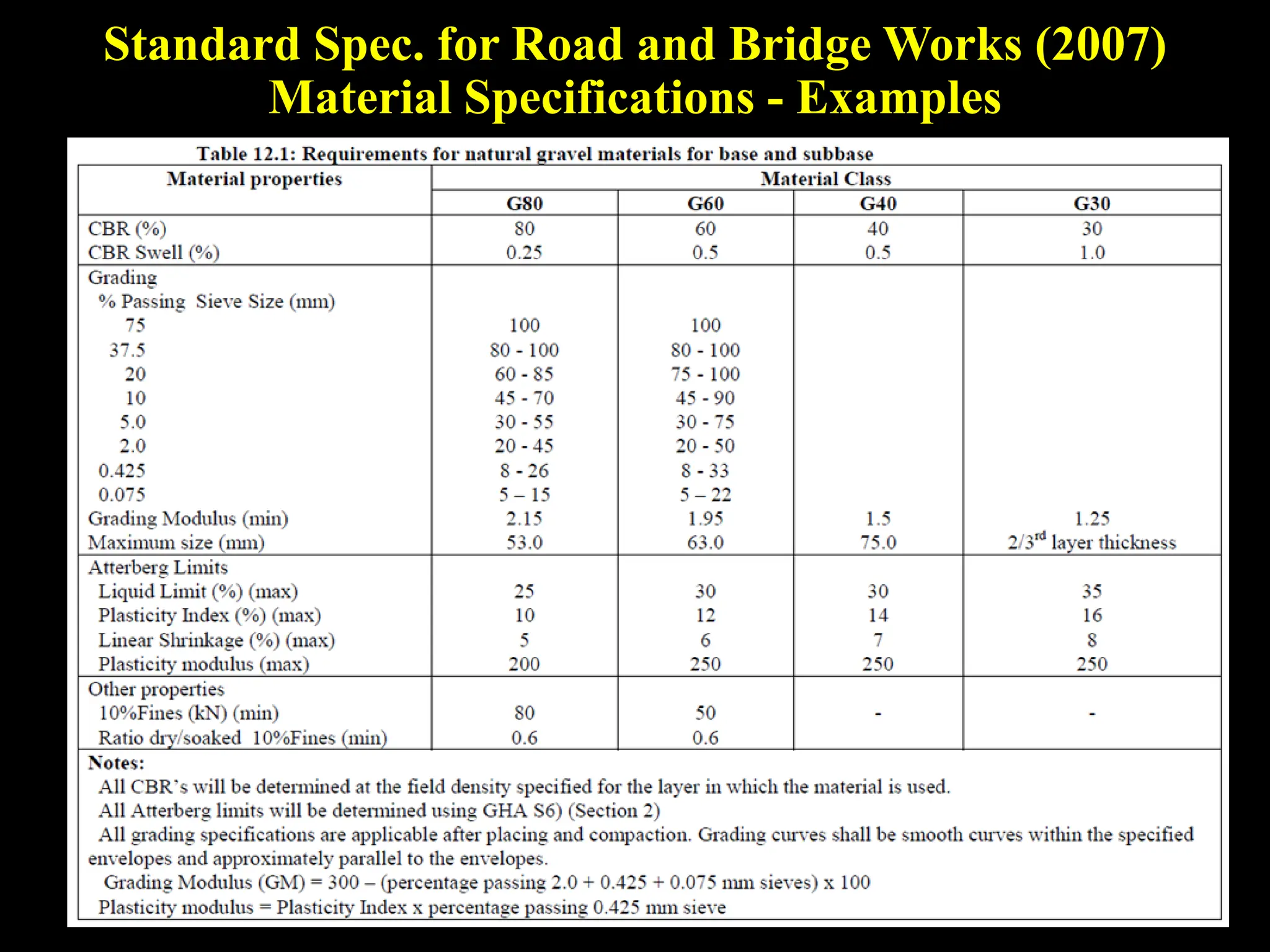

The document discusses flexible pavement design methods, focusing on the TRL (Transport Research Laboratory) method, which integrates empirical and mechanistic approaches for reliable performance predictions. It outlines the design process steps, including calculating design ESALs, determining subgrade strength, and selecting pavement structures, while emphasizing the importance of material specifications. Additionally, it details methods for estimating design CBR values and techniques for identifying uniform subgrade sections for cost-effective pavement design.