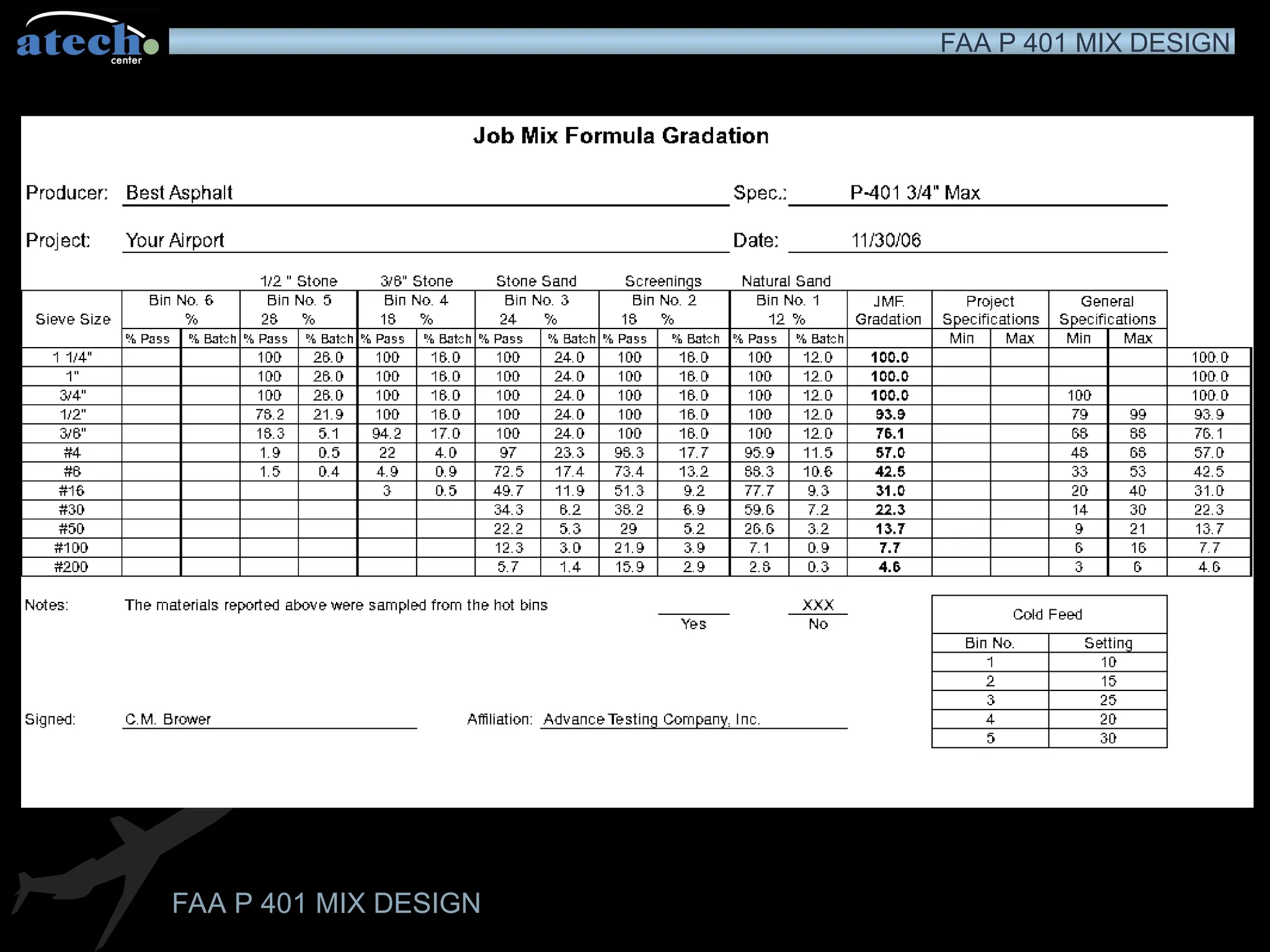

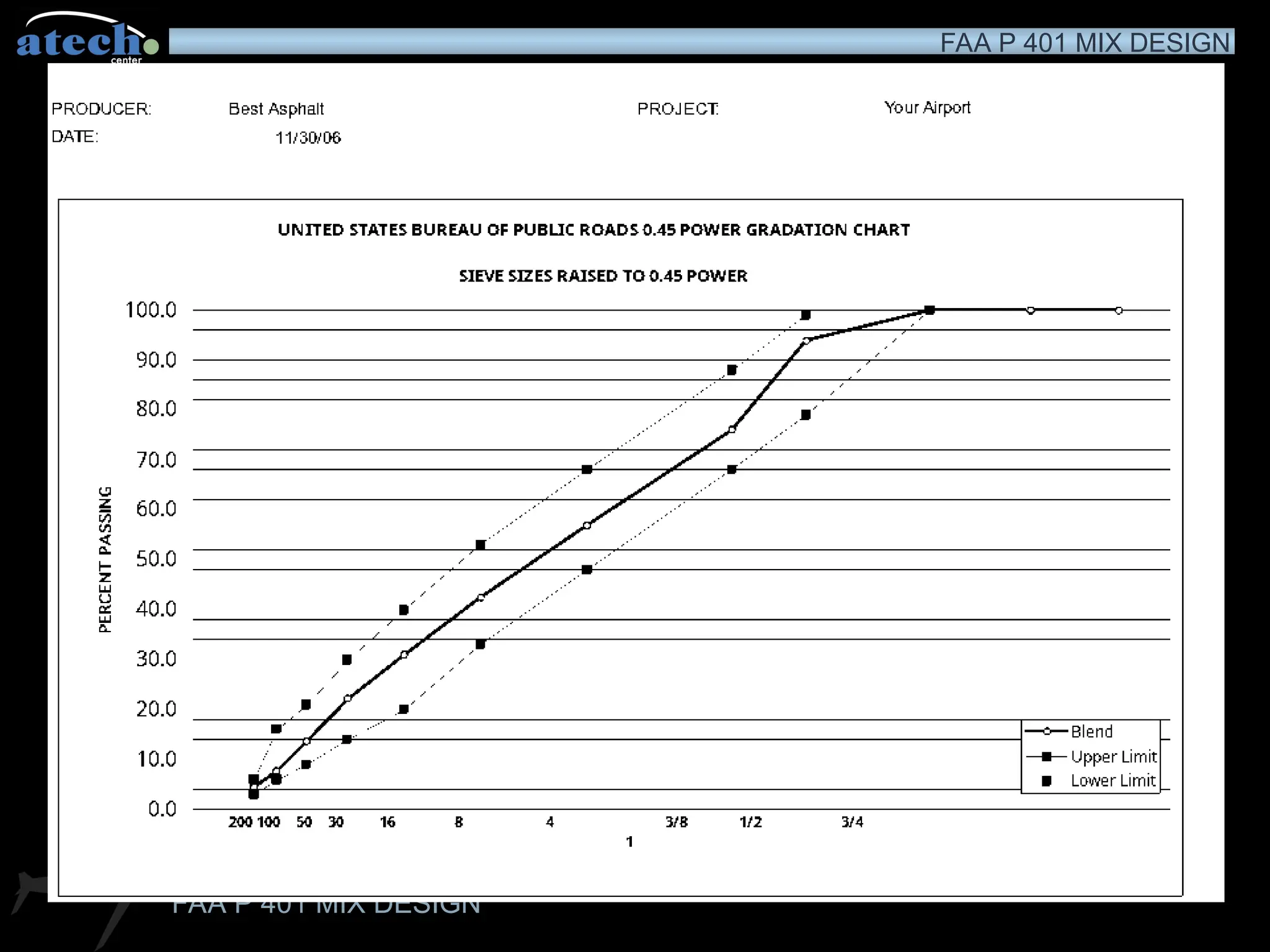

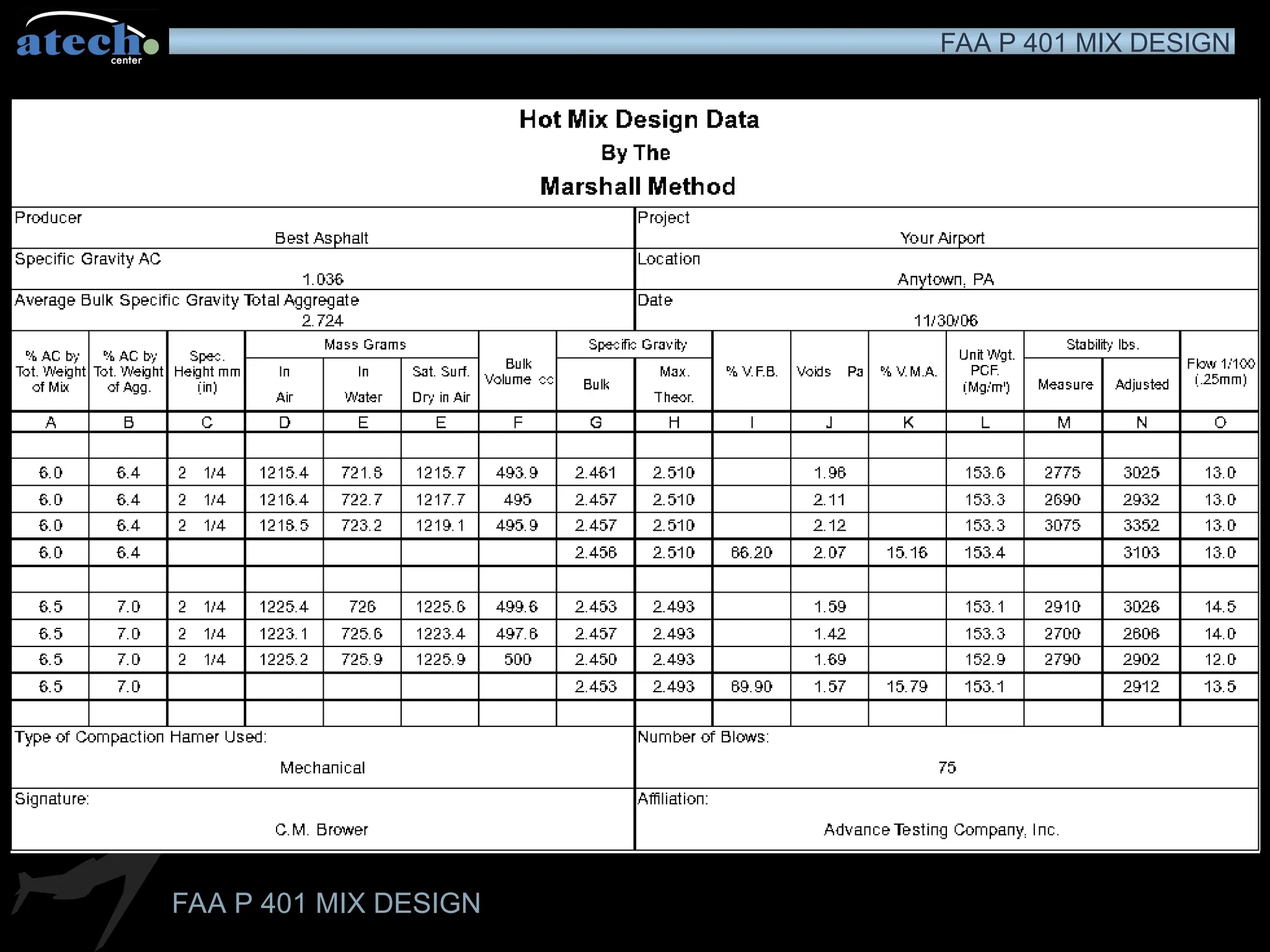

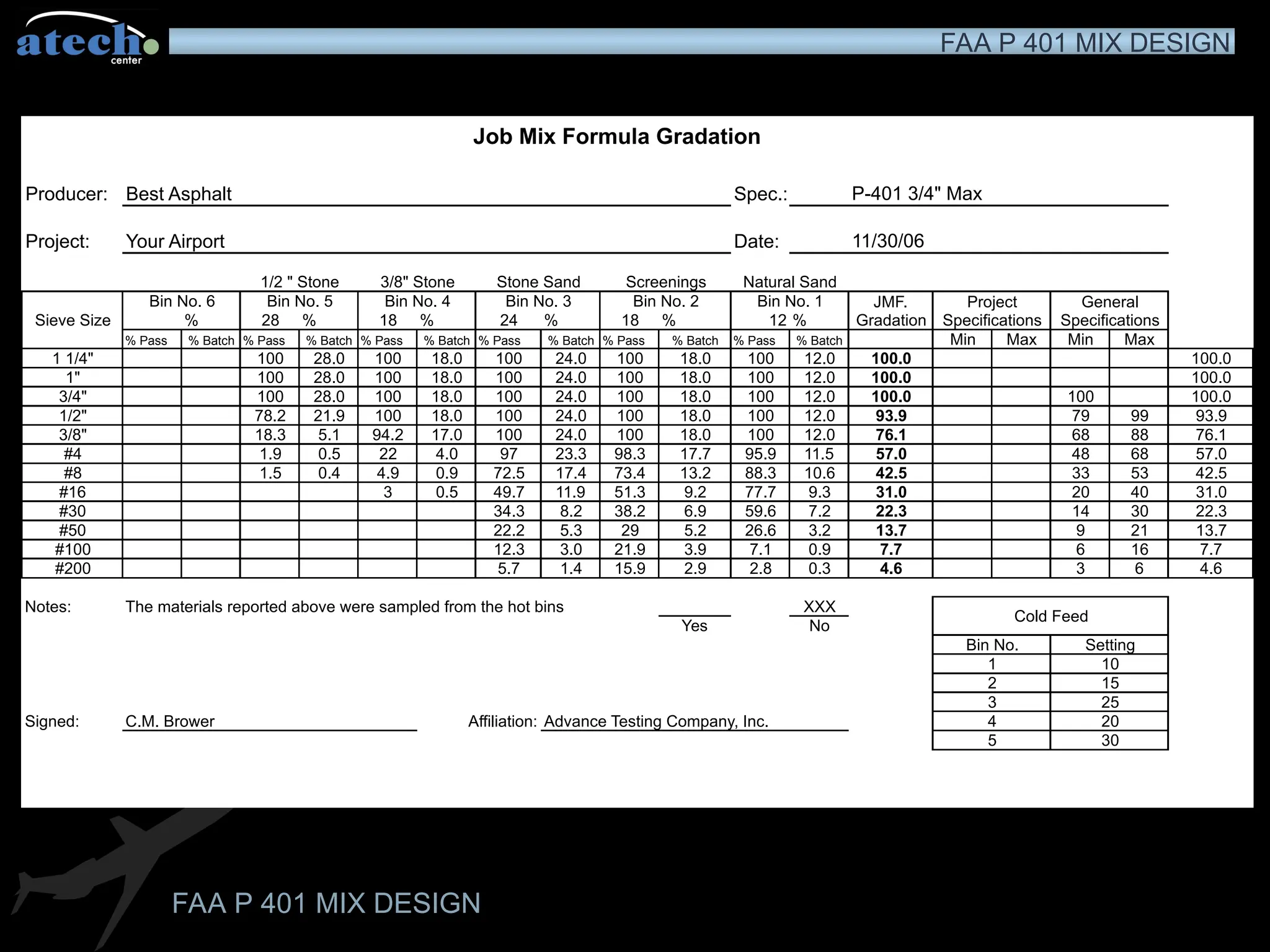

The document details the FAA P-401 mix design standards for hot mix asphalt used in airport construction, focusing on methodologies for aggregate testing, volumetric mix design, and job mix formulas. It outlines procedures for evaluating aggregate properties, preparing samples for testing, and determining the optimum asphalt content through extensive laboratory analyses. Additionally, it includes specific ASTM test methods used to assess various properties of materials involved in the mix design process.

![FAA P 401 MIX DESIGN

FAA P 401 MIX DESIGN

Air Void (Pa) Calculation

• Air Voids (Pa) are determined

using the following formula:

• Pa = 100– [100(Gmb/Gmm)]](https://image.slidesharecdn.com/faapres2008-241115194537-c387efb8/75/federal-aviation-administration-presentation-2008-ppt-88-2048.jpg)

![FAA P 401 MIX DESIGN

FAA P 401 MIX DESIGN

Air Void (Pa) Calculation

• Gmb = 2.334

• Gmm = 2.416

• Pa = 100 - [100(2.334/2.416)]

• Pa = 100 - (100 x 0.9661)

• Pa = 100 - 96.61

• Pa = 3.39](https://image.slidesharecdn.com/faapres2008-241115194537-c387efb8/75/federal-aviation-administration-presentation-2008-ppt-89-2048.jpg)

![FAA P 401 MIX DESIGN

FAA P 401 MIX DESIGN

VMA (Voids in Mineral Aggregate)

Calculation

• VMA is determined using the

following formula:

VMA= 100 – [(GmbxPs)/Gsb]](https://image.slidesharecdn.com/faapres2008-241115194537-c387efb8/75/federal-aviation-administration-presentation-2008-ppt-90-2048.jpg)

![FAA P 401 MIX DESIGN

FAA P 401 MIX DESIGN

VMA (Voids in Mineral Aggregate)

Calculation

• Gmb = 2.344

• Ps = 93.04

• Gsb = 2.651

• VMA = 100 - [(2.344 x 93.04)/2.651]

• VMA = 100 - (218.1/2.651)

• VMA = 100 - 82.26

• VMA = 17.74](https://image.slidesharecdn.com/faapres2008-241115194537-c387efb8/75/federal-aviation-administration-presentation-2008-ppt-91-2048.jpg)