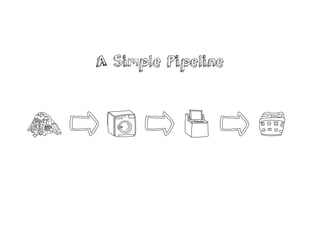

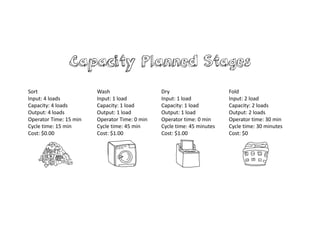

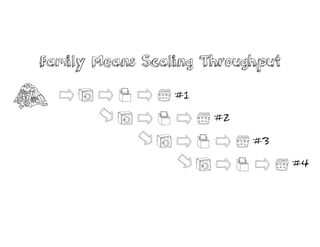

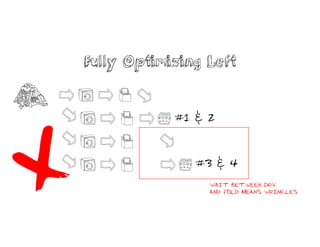

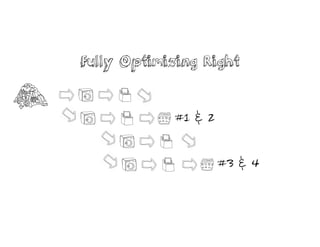

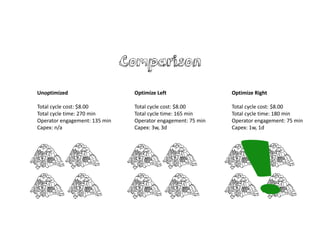

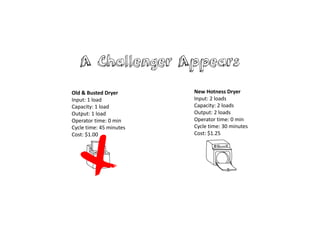

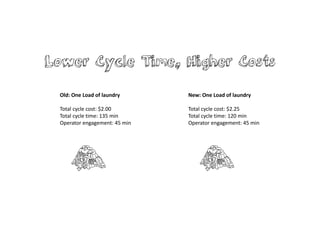

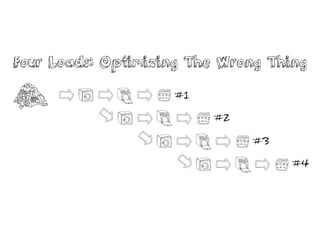

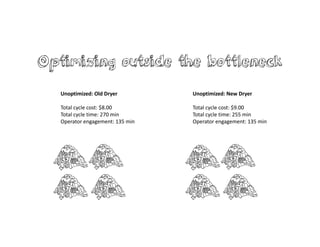

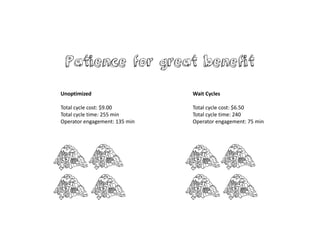

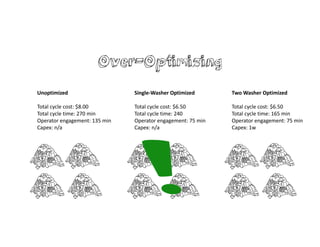

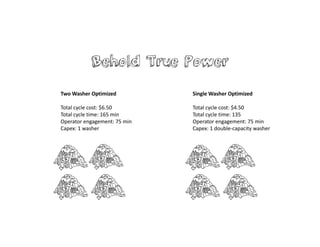

The document analyzes the complexities of laundry workflows, comparing various stages such as washing, drying, and folding. It presents metrics on total cycle costs, cycle times, operator engagement, and optimization strategies with different washing and drying setups. Key takeaways emphasize understanding metrics, the importance of simplicity, and the value of recognizing when to stop optimizing.