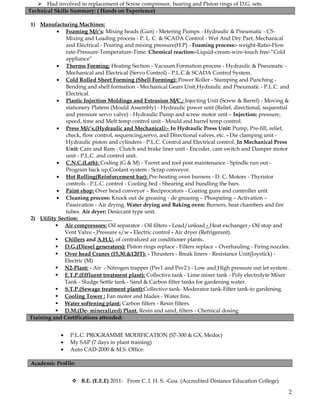

D. Nagaraj has over 14 years of experience in engineering projects, machine maintenance, sourcing and procurement. He currently works as Deputy Manager of Plant Engineering and Sourcing at Techno Electronic Ltd, where he is responsible for project planning, cost estimation, vendor development and achieving procurement targets. Previously, he has worked in management roles overseeing maintenance at various manufacturing companies. He has expertise in many industrial machines and utilities, and aims to minimize costs while improving productivity, safety, and skills of his team members.