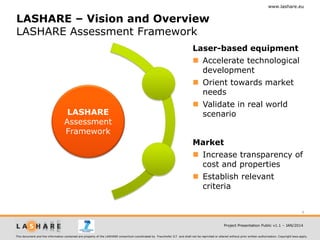

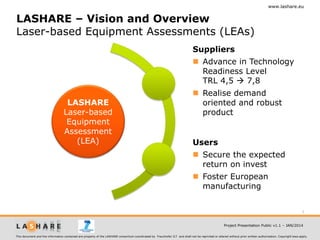

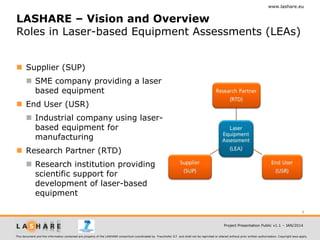

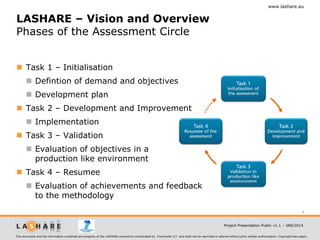

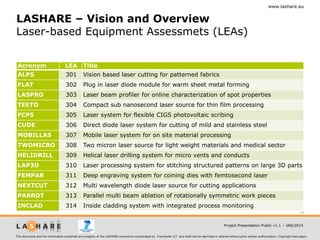

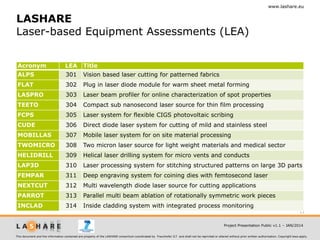

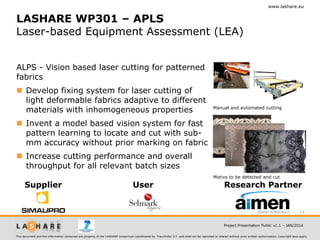

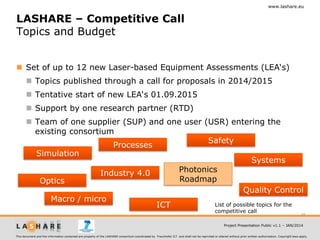

The LASHARE project aims to accelerate innovation in manufacturing SMEs through laser-based equipment assessments, focusing on market needs and advancing technology readiness. It involves partnerships among suppliers, end users, and research institutions to enhance laser processes, provide independent information, and foster European manufacturing. The project encompasses various laser-based assessments (LEAs) for applications in diverse sectors including textiles, photovoltaics, and medical technologies.