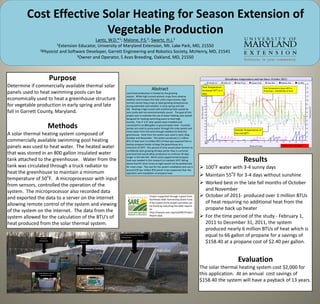

A study evaluated using commercially available solar thermal panels designed for swimming pools to heat a greenhouse and extend the growing season. An 800-gallon insulated water tank heated by 5 solar panels maintained the greenhouse at 50°F. The system produced over 3 million BTUs of heat during the study period and required 1.6 million additional BTUs from a propane backup heater. The solar system cost $2,000 and provided over $150 in annual savings on propane, resulting in a payback period of 13 years.