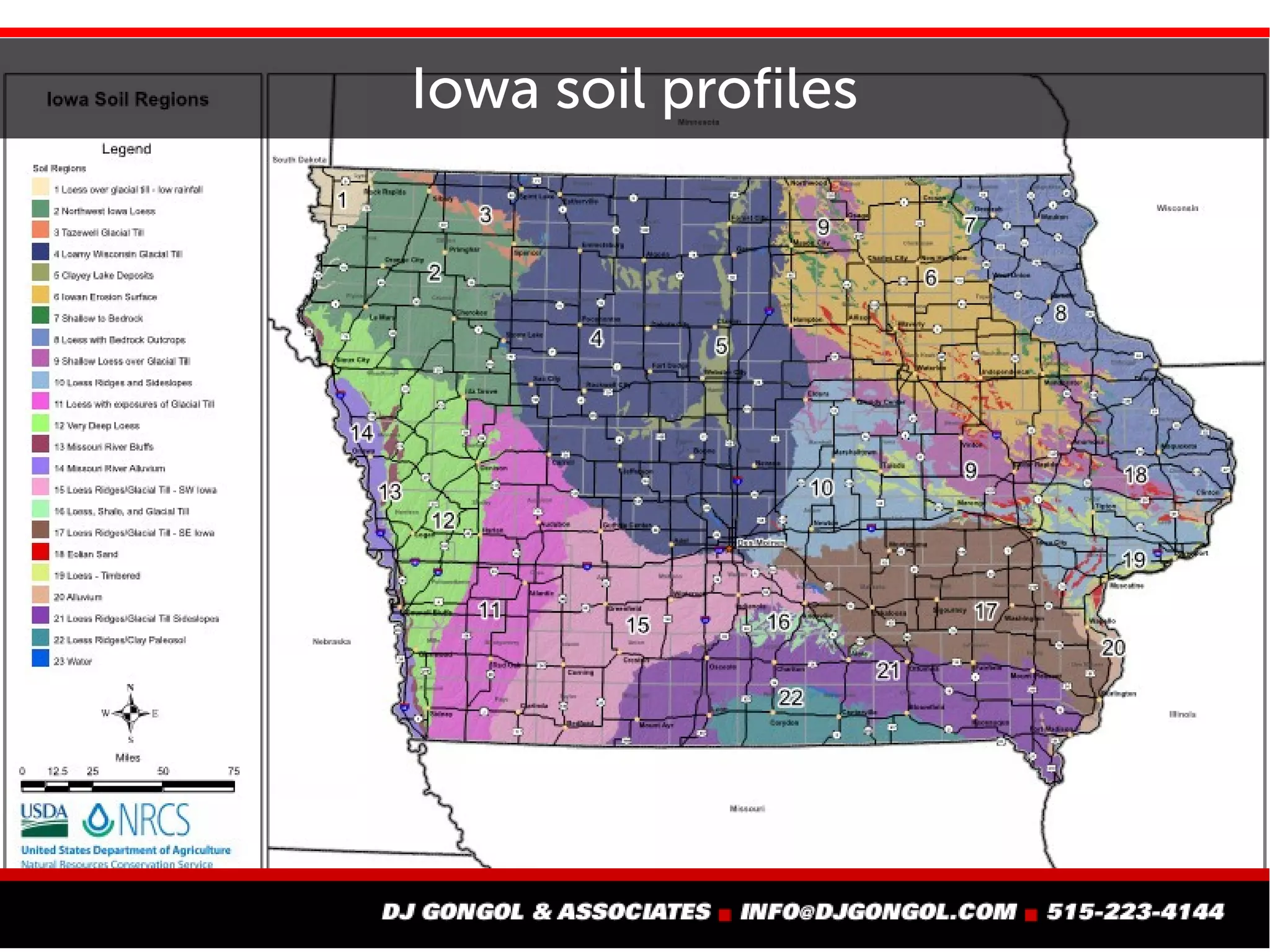

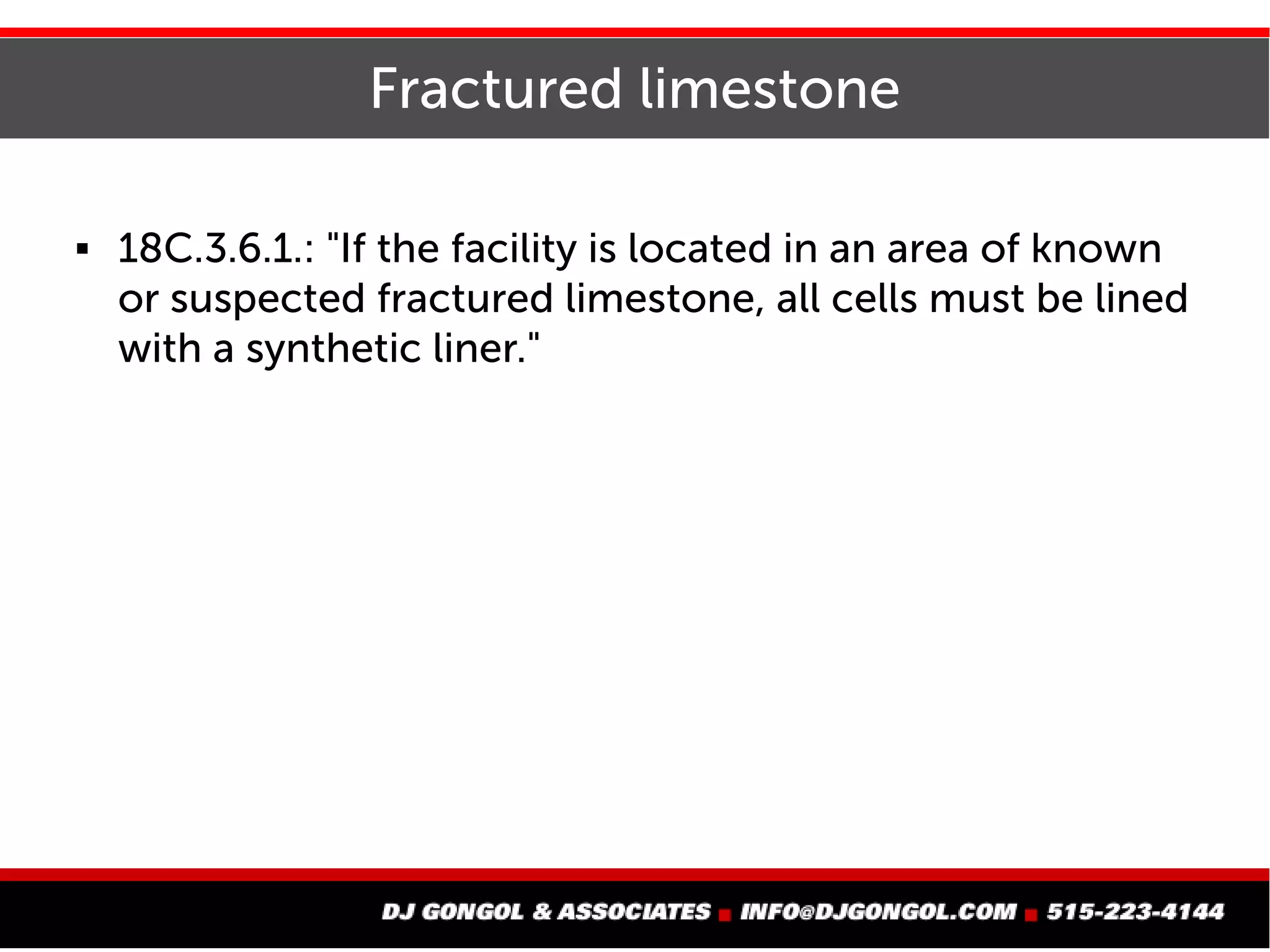

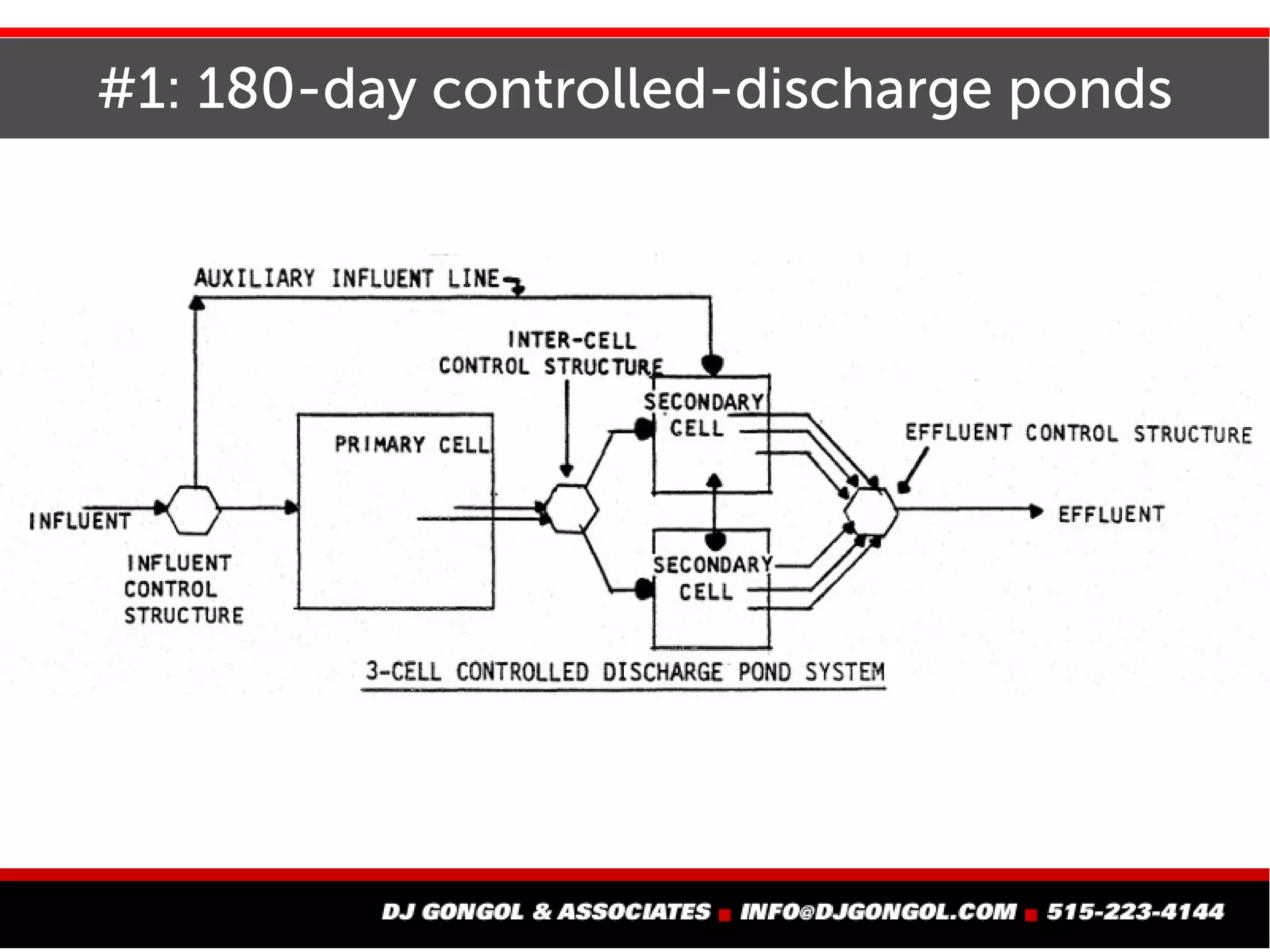

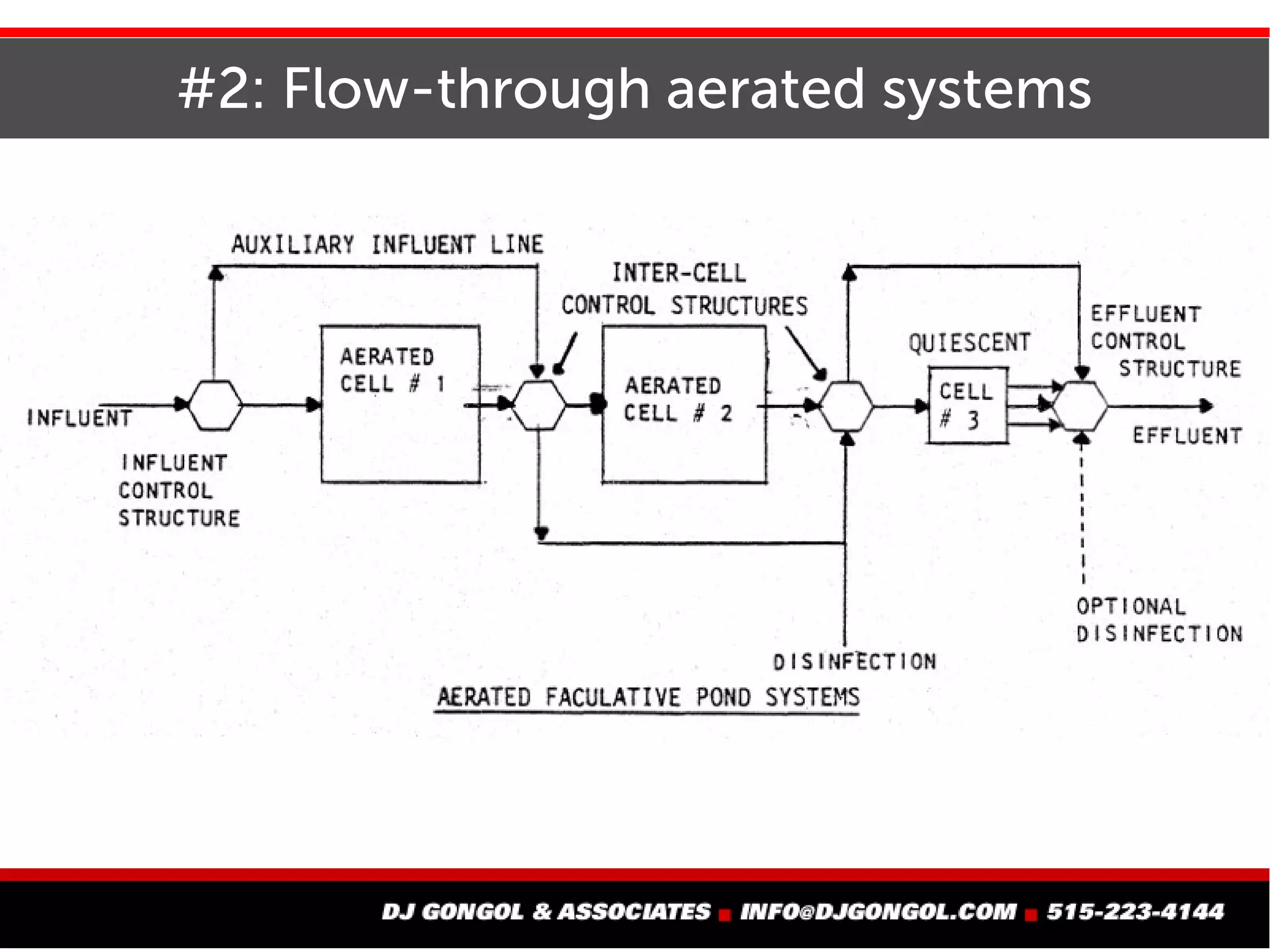

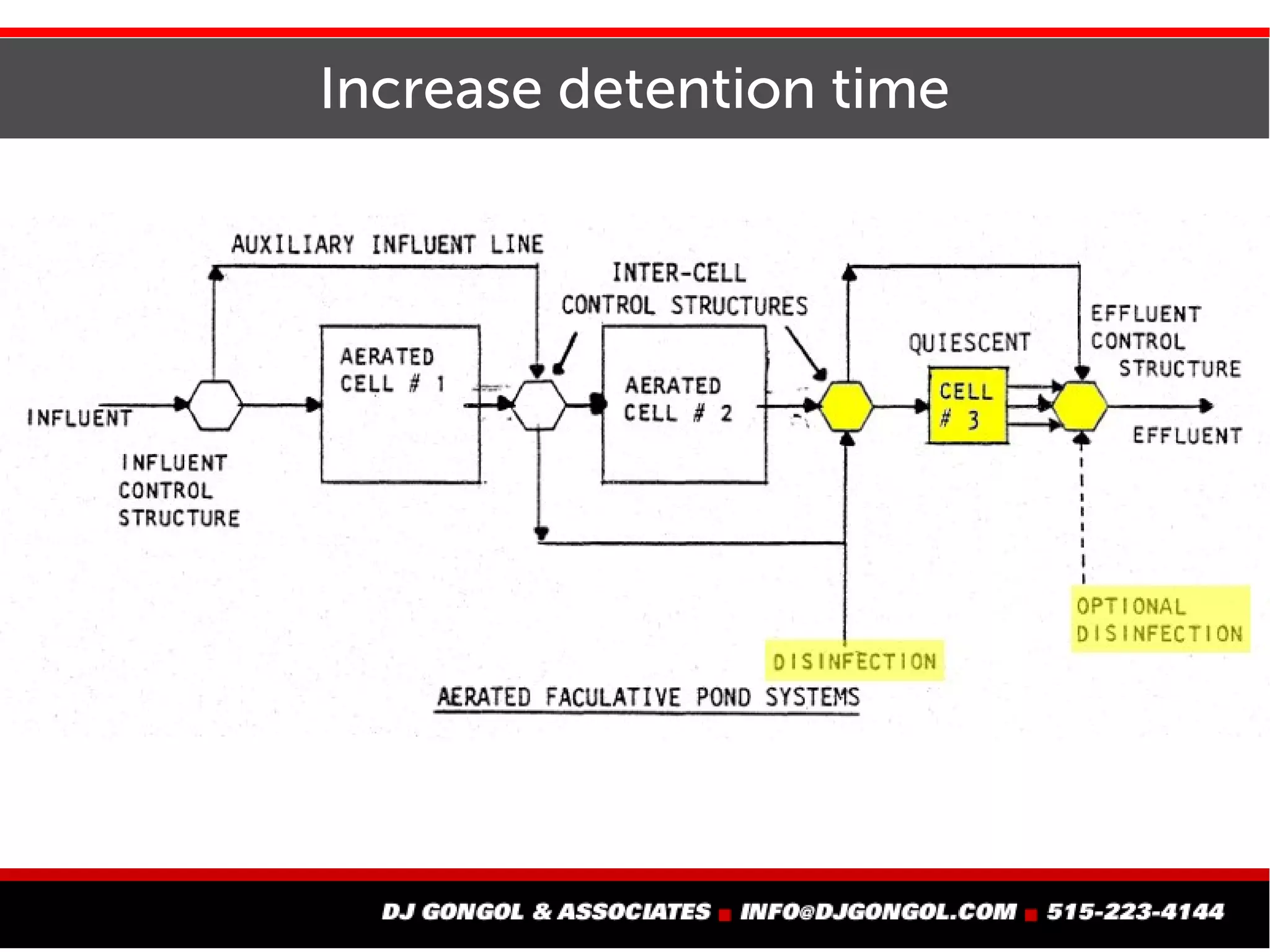

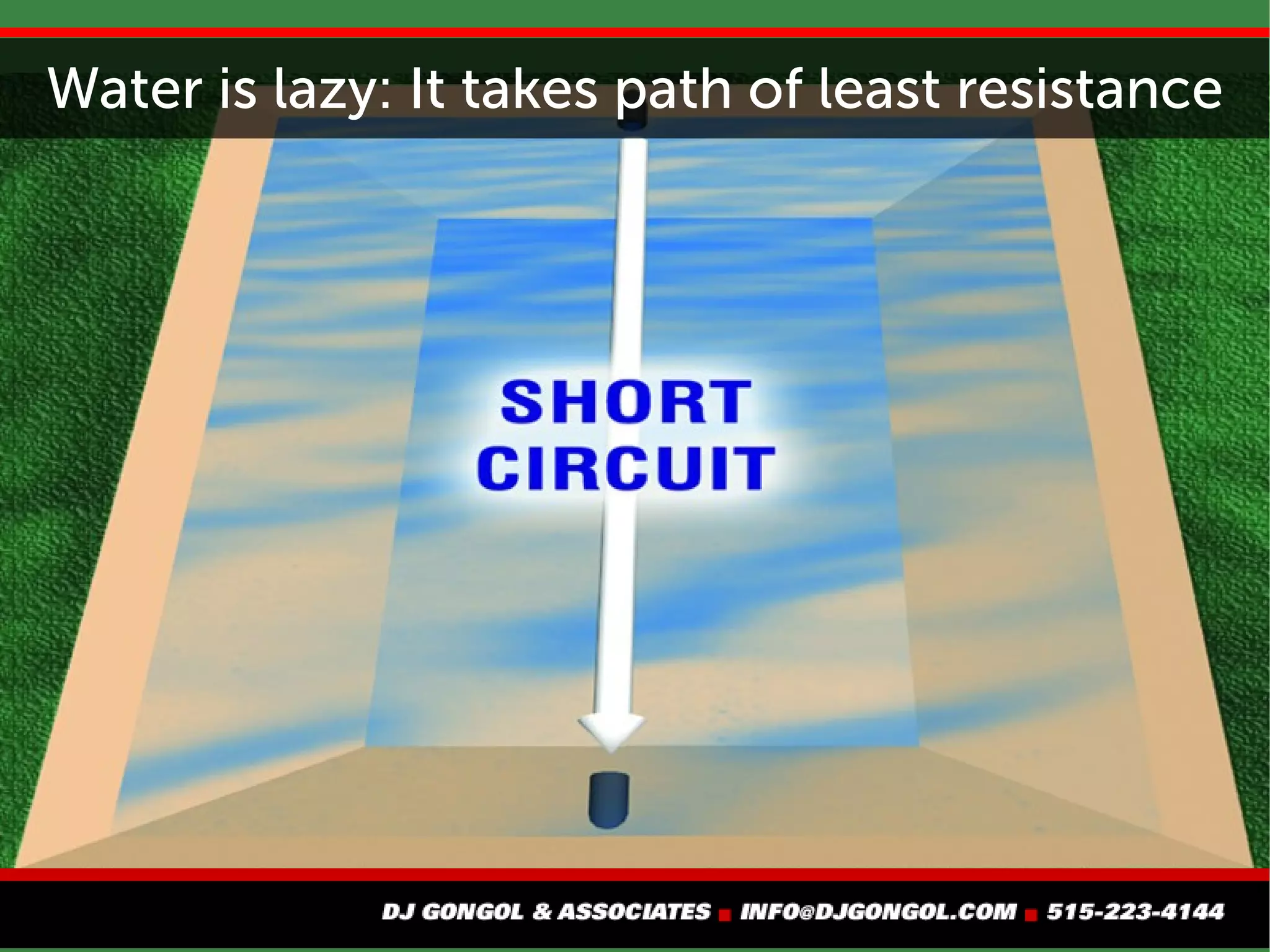

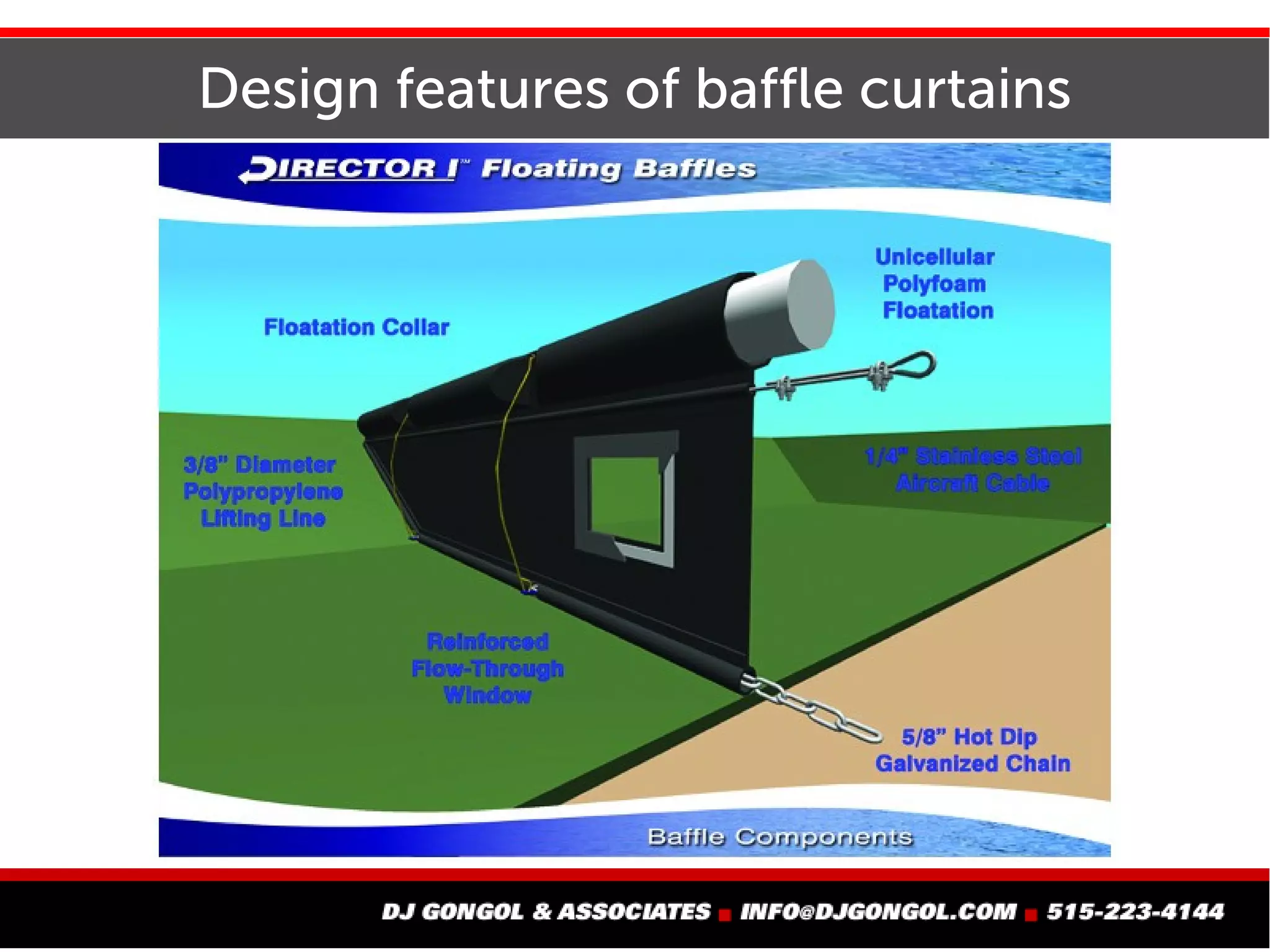

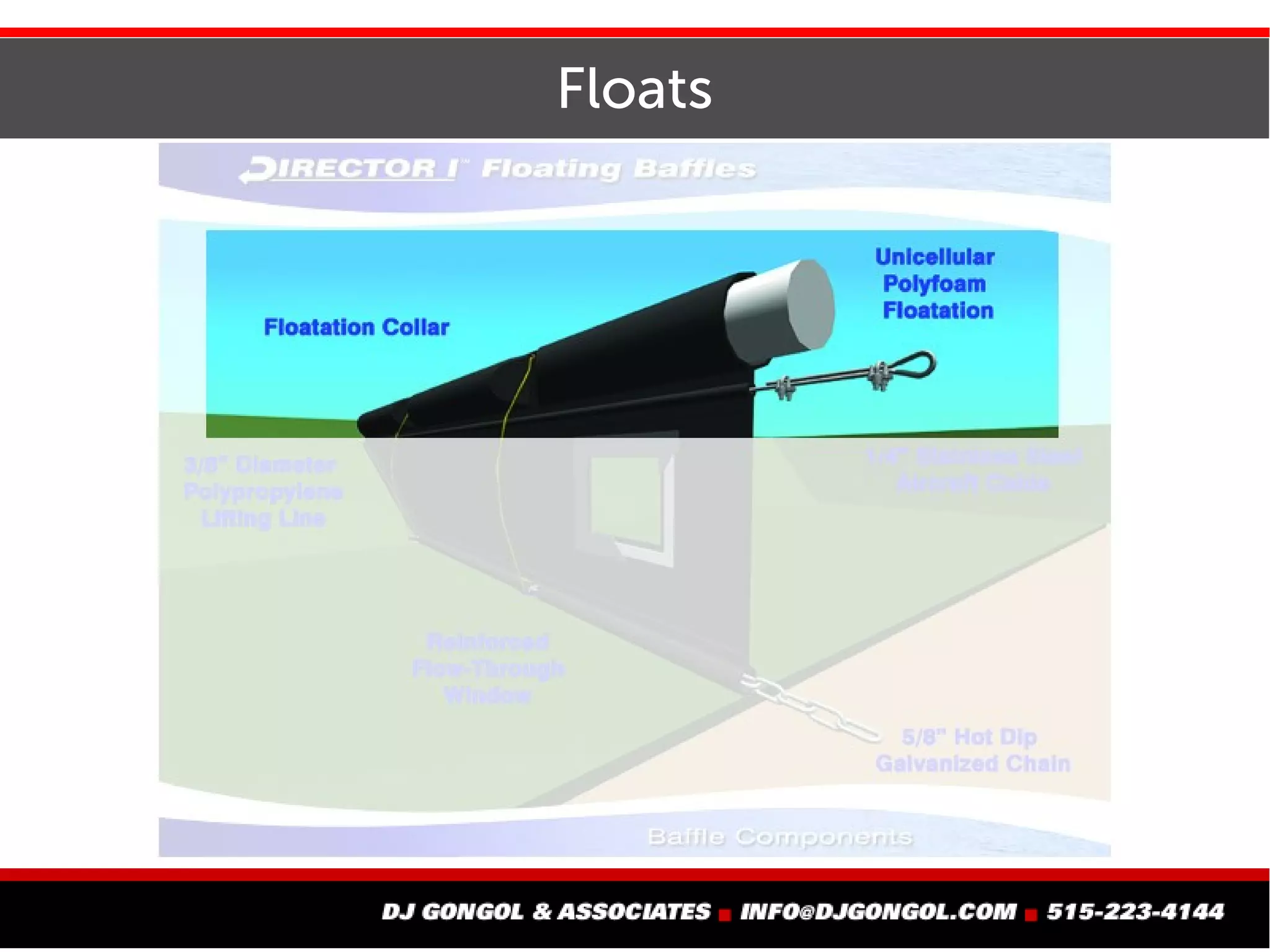

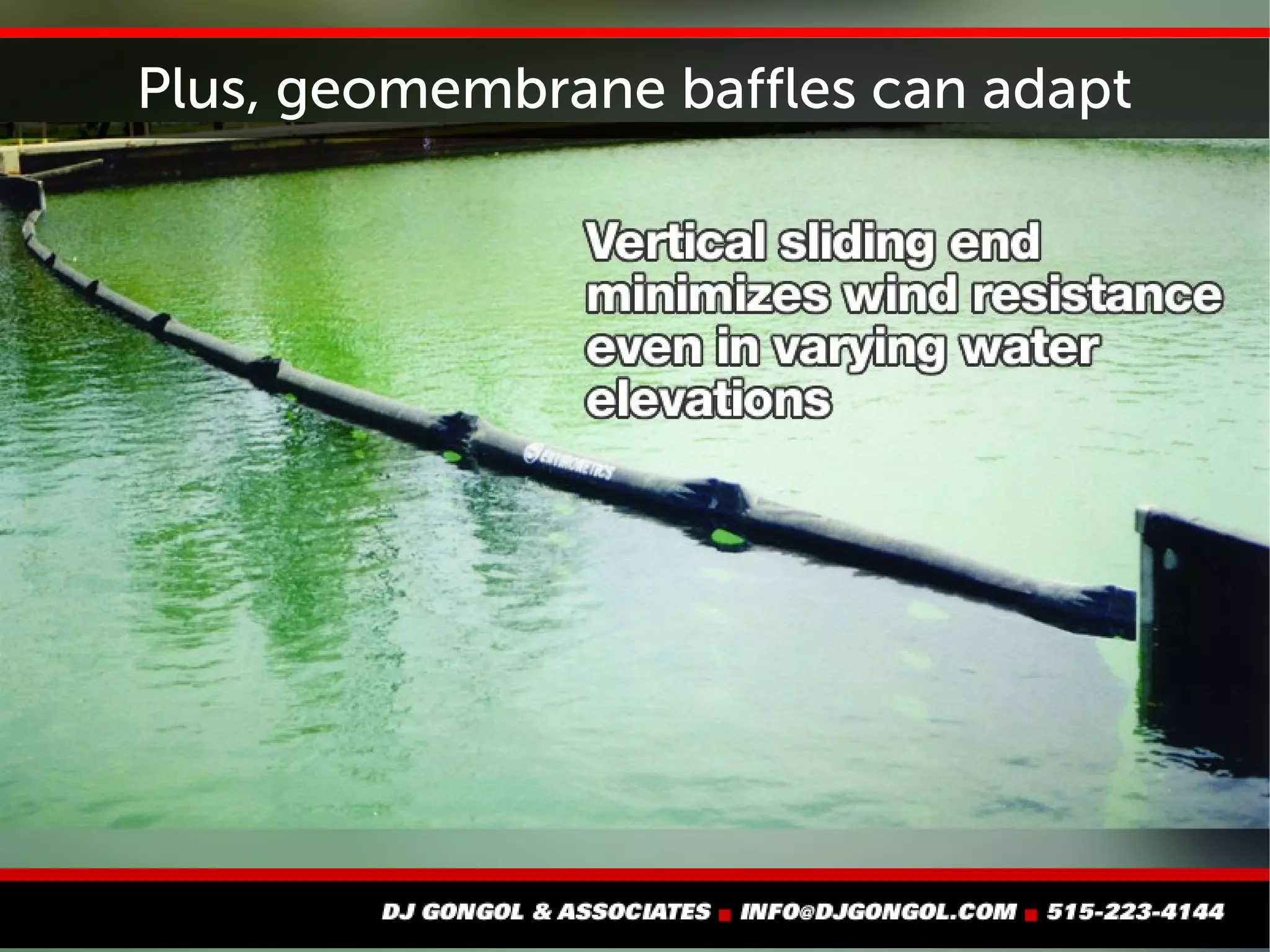

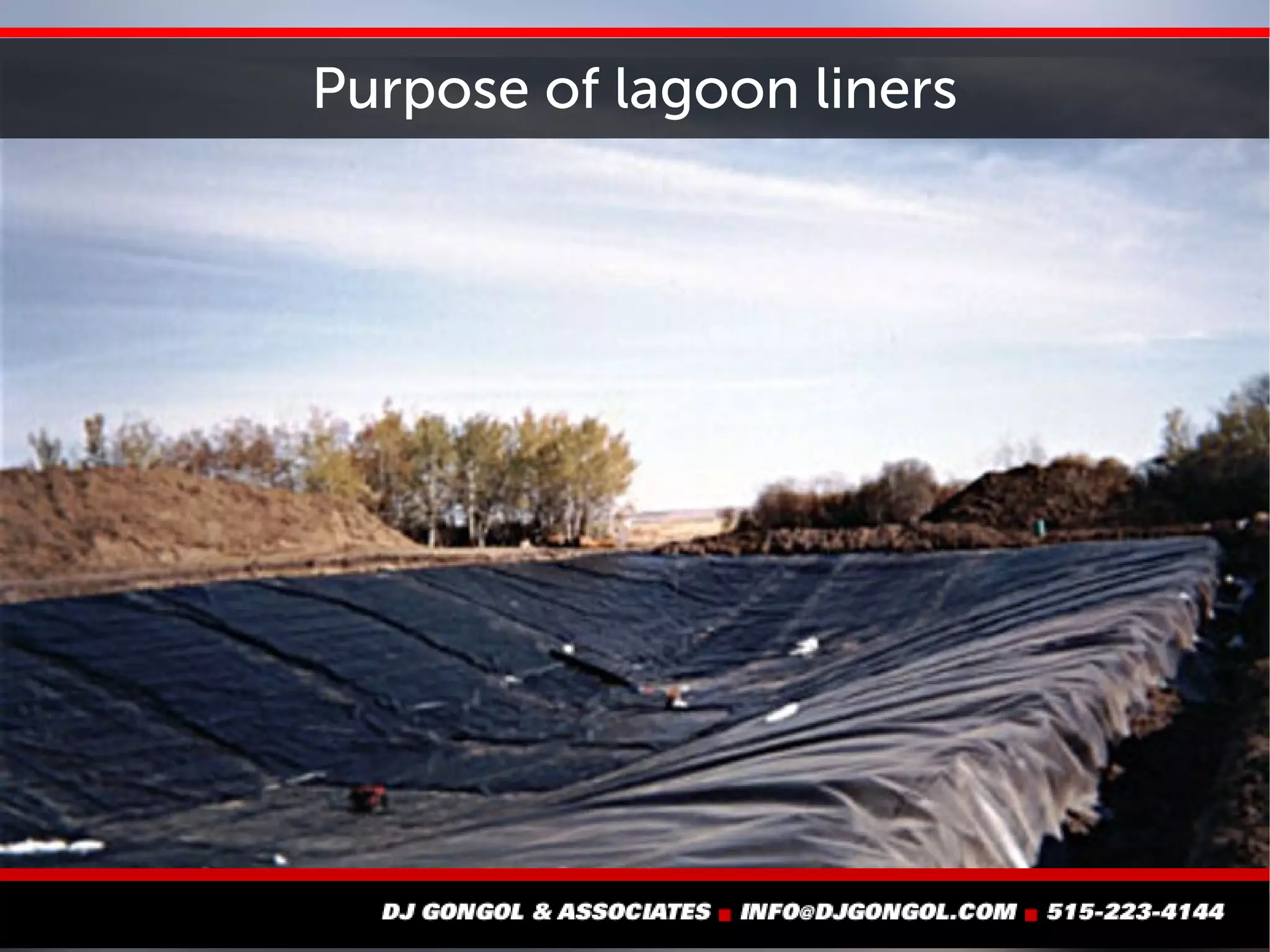

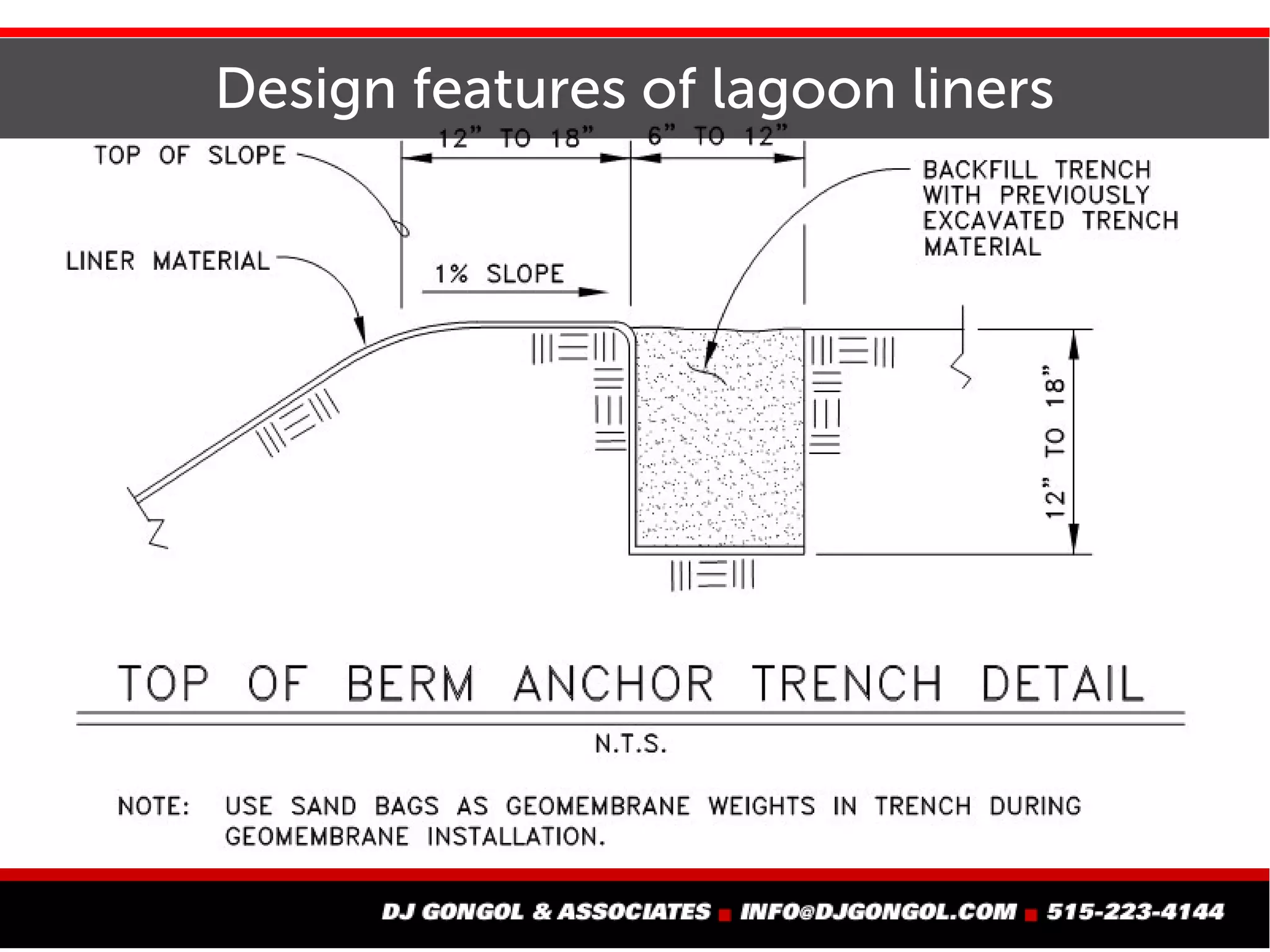

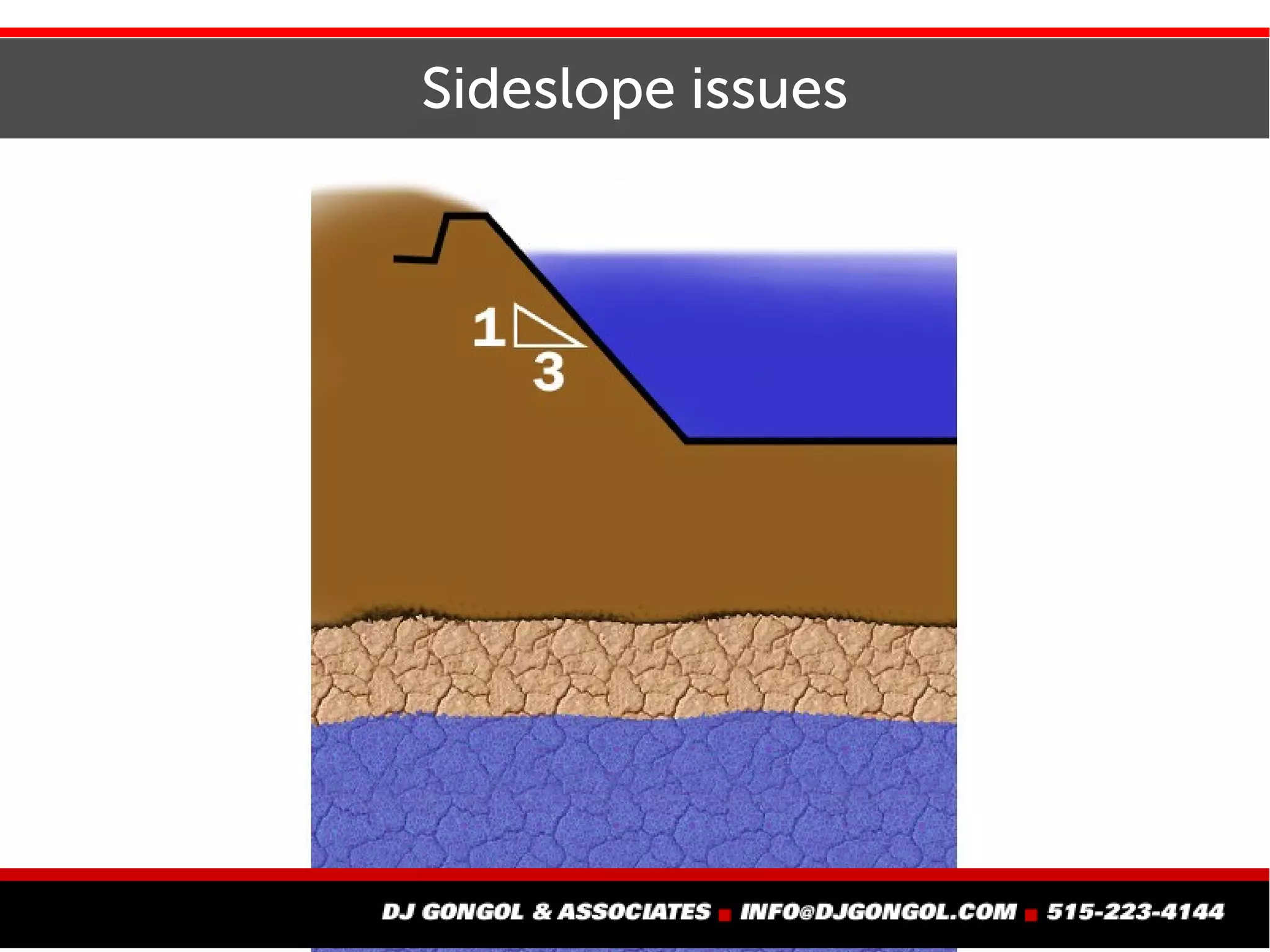

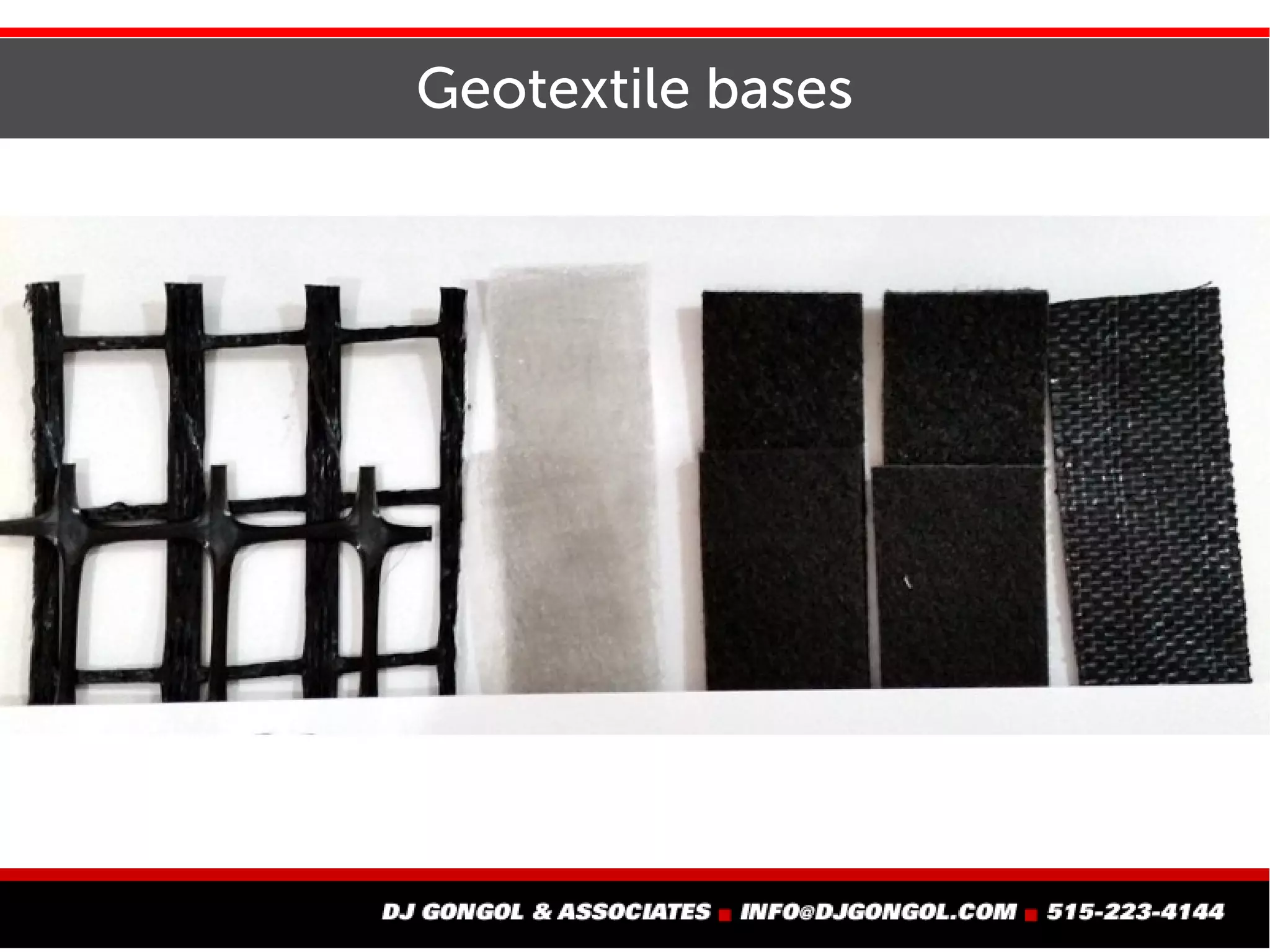

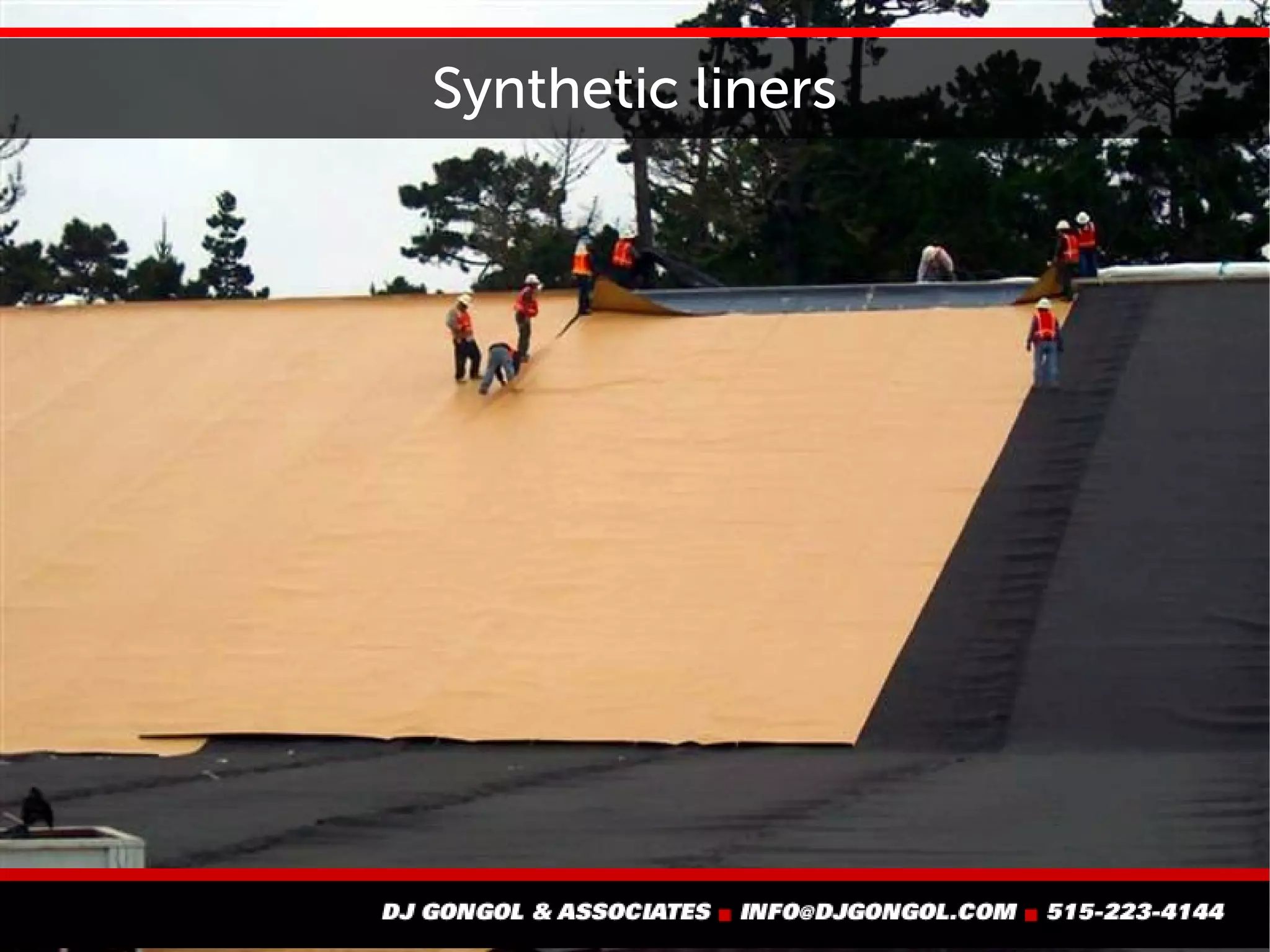

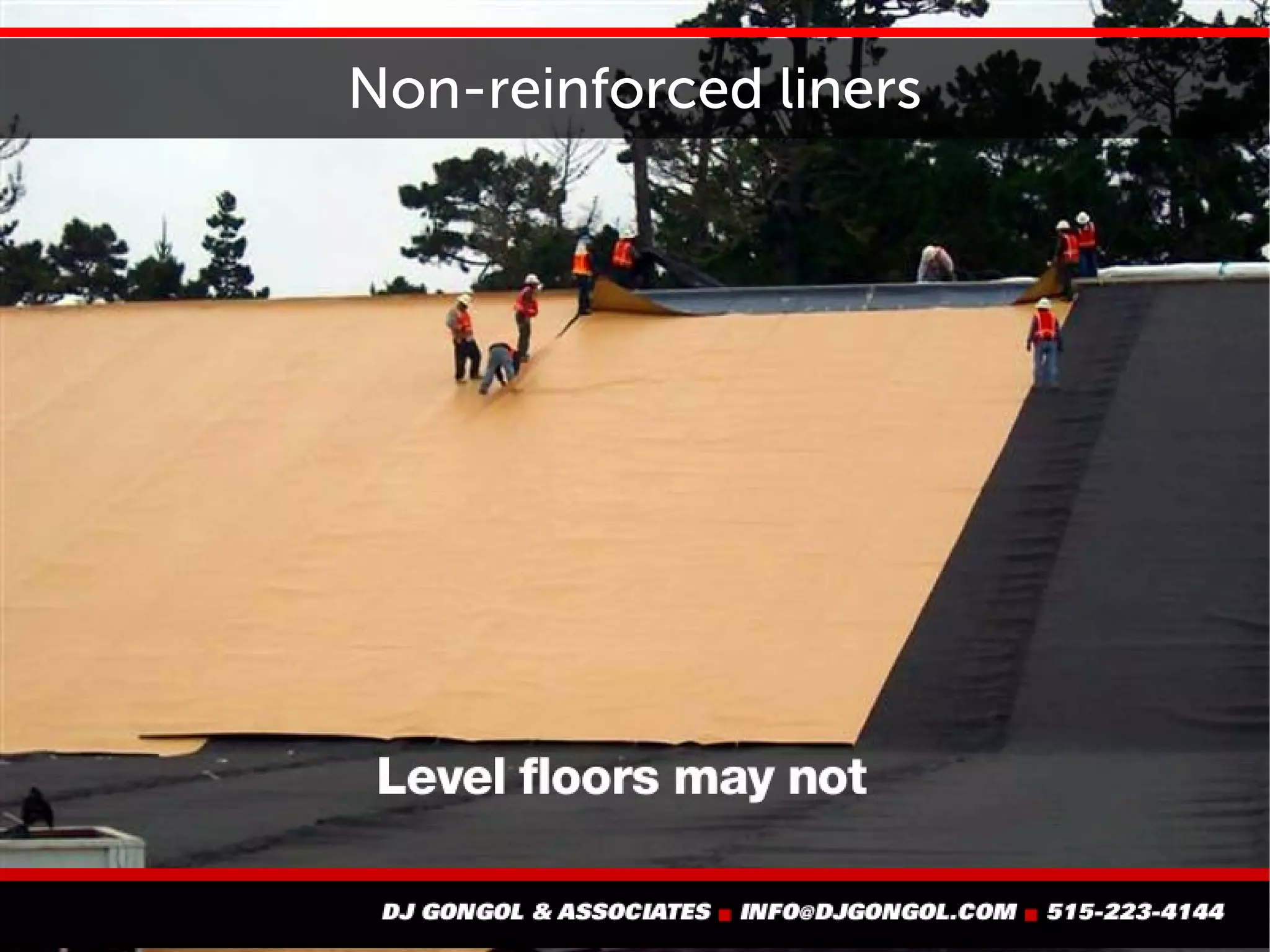

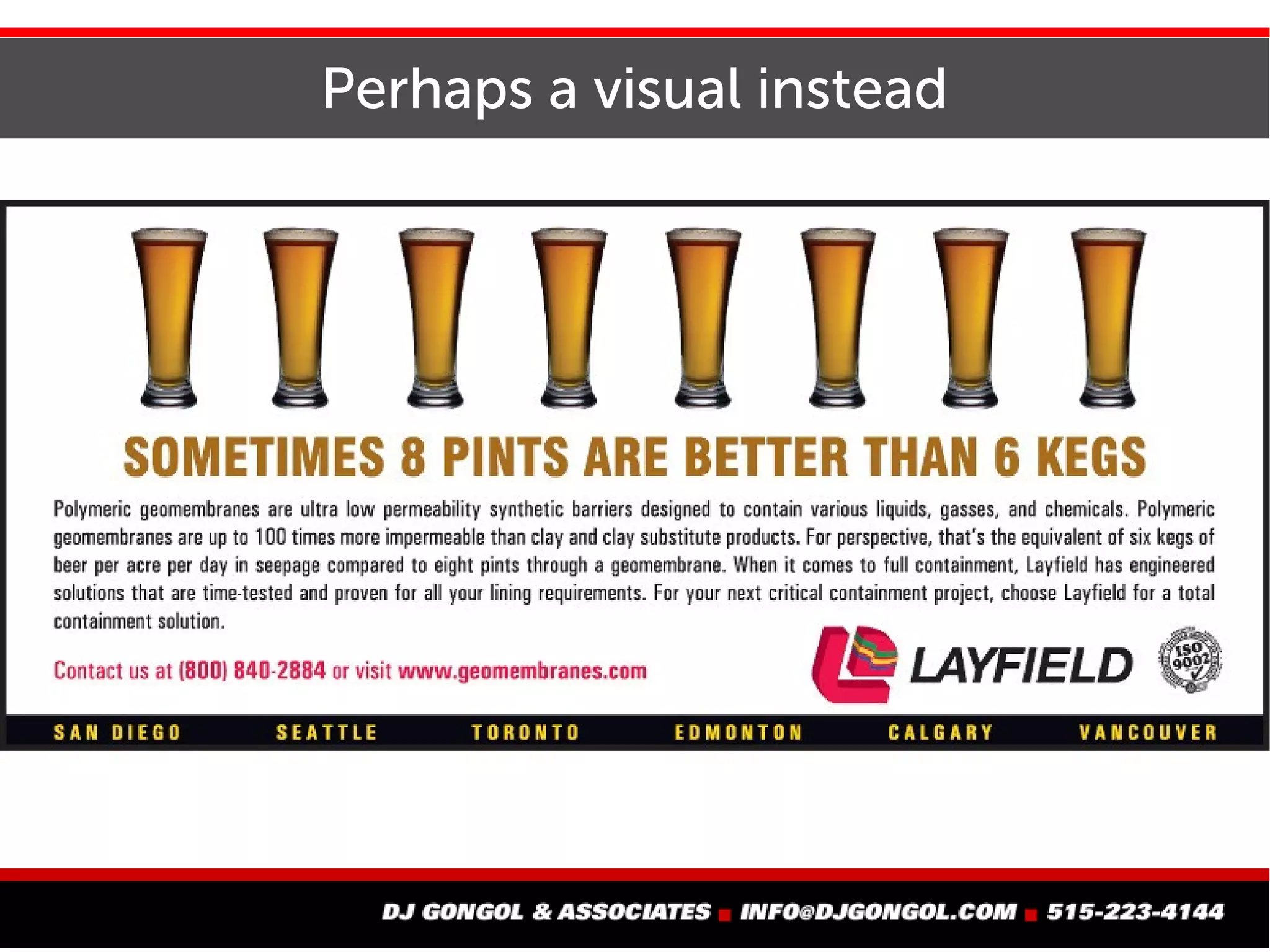

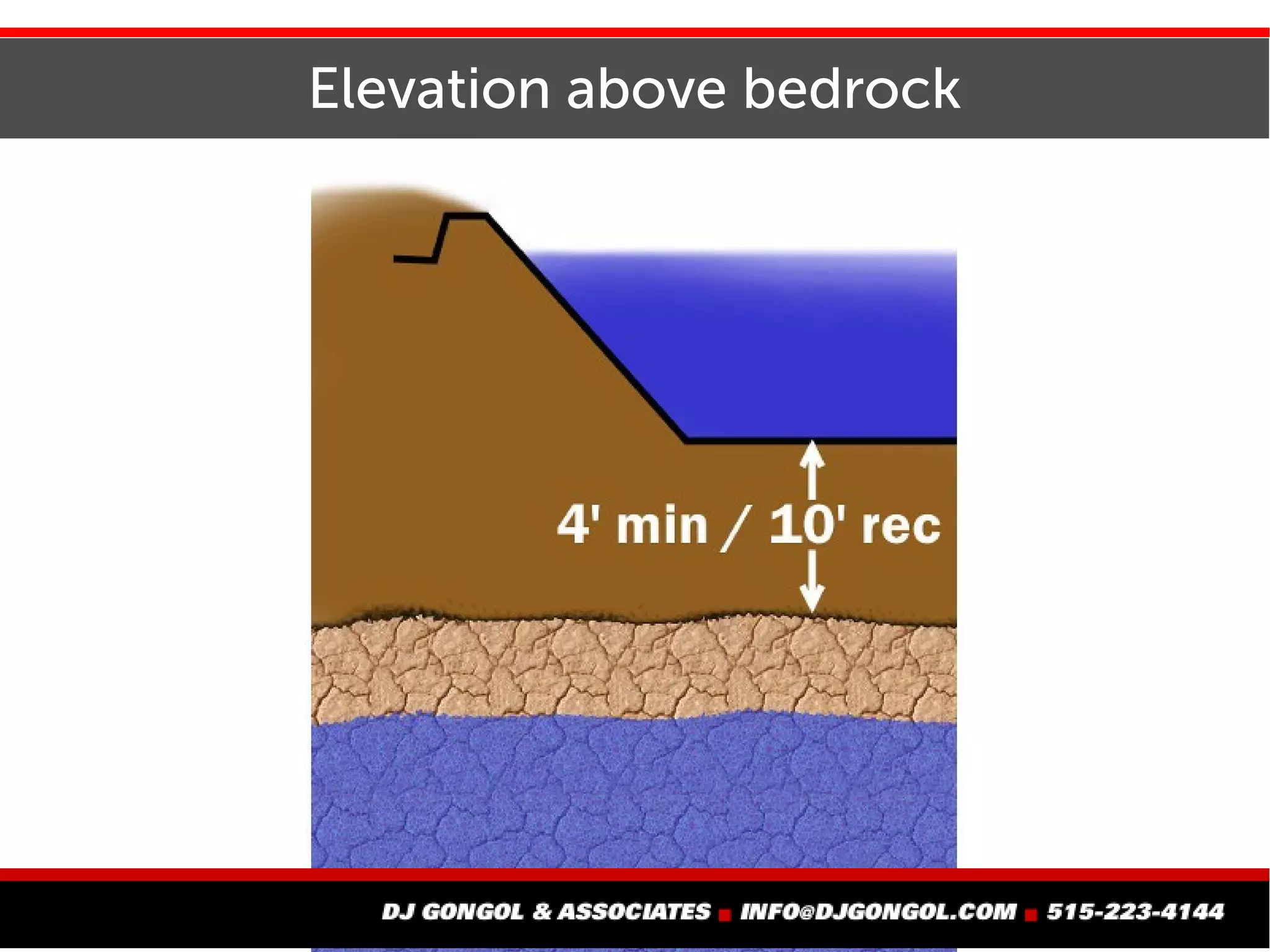

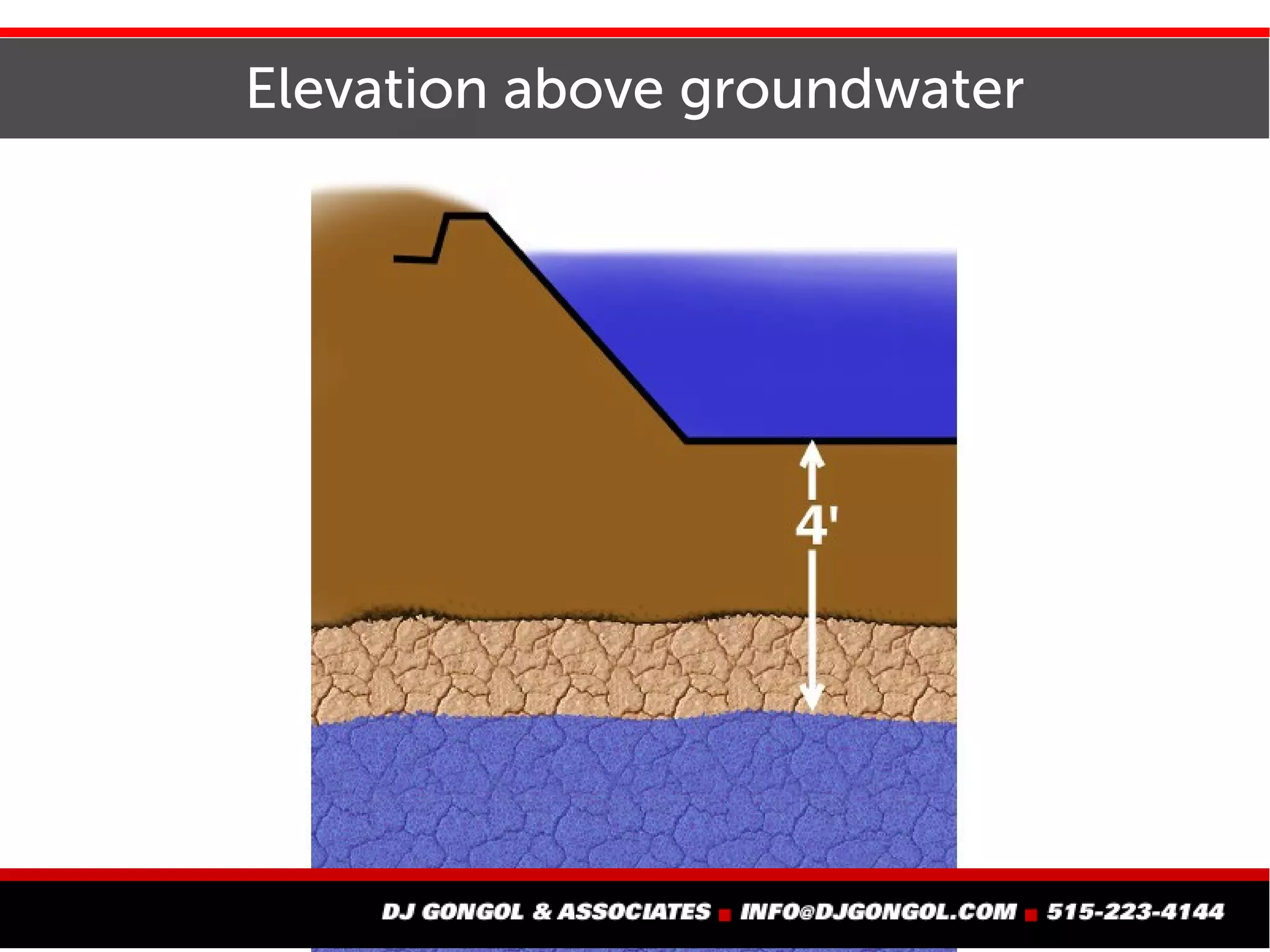

The document discusses the design and implementation of lagoon liners and baffles in Iowa, detailing methods to enhance water flow, prevent short-circuiting, and improve aeration efficiency. It outlines the regulatory framework for lagoon construction, including materials choices such as geomembranes and additional sealing options to protect groundwater. The text emphasizes the importance of proper installation techniques and environmental considerations in lagoon management.

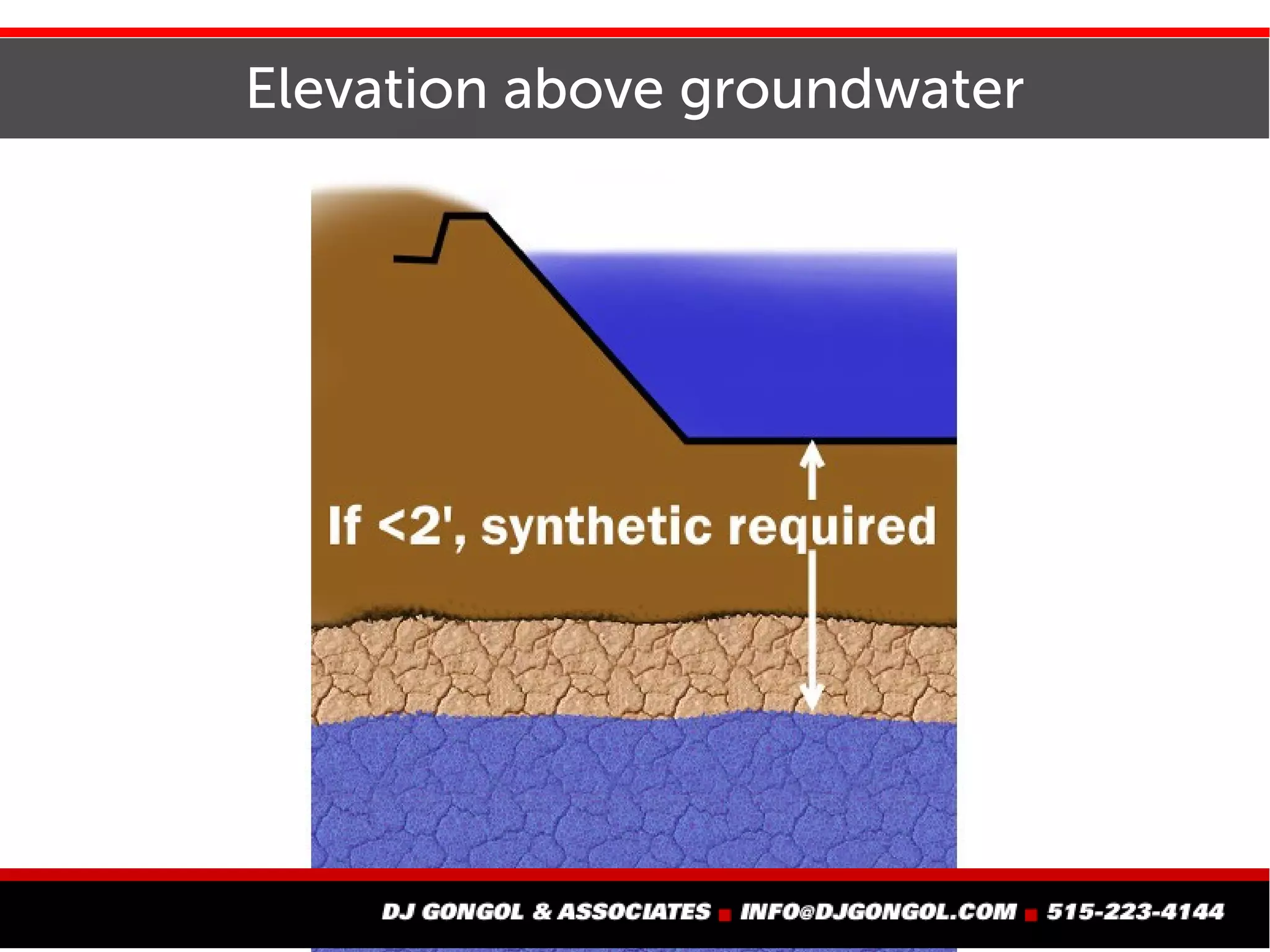

![Elevation above extraordinary groundwater

18C.3.5.3.: "Perched groundwater layers shall be

considered as those distinct layers of groundwater of

limited area caused by the blockage of normal seepage

of rainwater/snowmelt/runoff by an impervious soil

layer [...] If the perched groundwater table after

permanent lowering is less than two feet below the

bottom of the lagoon, the lagoon shall be provided with

a synthetic liner."](https://image.slidesharecdn.com/2016-0913presentation-lagoonlinersandbaffles-v0006-160914064436/75/Lagoon-liners-and-baffle-curtains-75-2048.jpg)