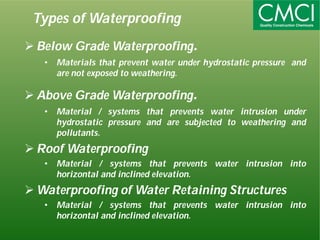

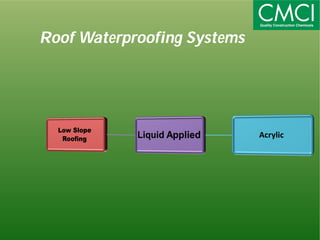

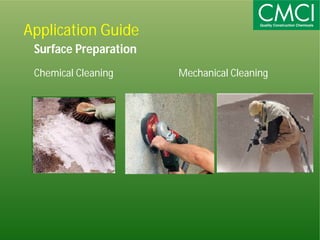

The document discusses different types of waterproofing for buildings. It describes below grade waterproofing systems like cementitious coatings and liquid applied membranes. It also covers above grade waterproofing and roof waterproofing systems. Specific products are mentioned for different applications along with their properties and coverage details. The document provides information on surface preparation methods before waterproofing and guidelines for application of waterproofing systems.