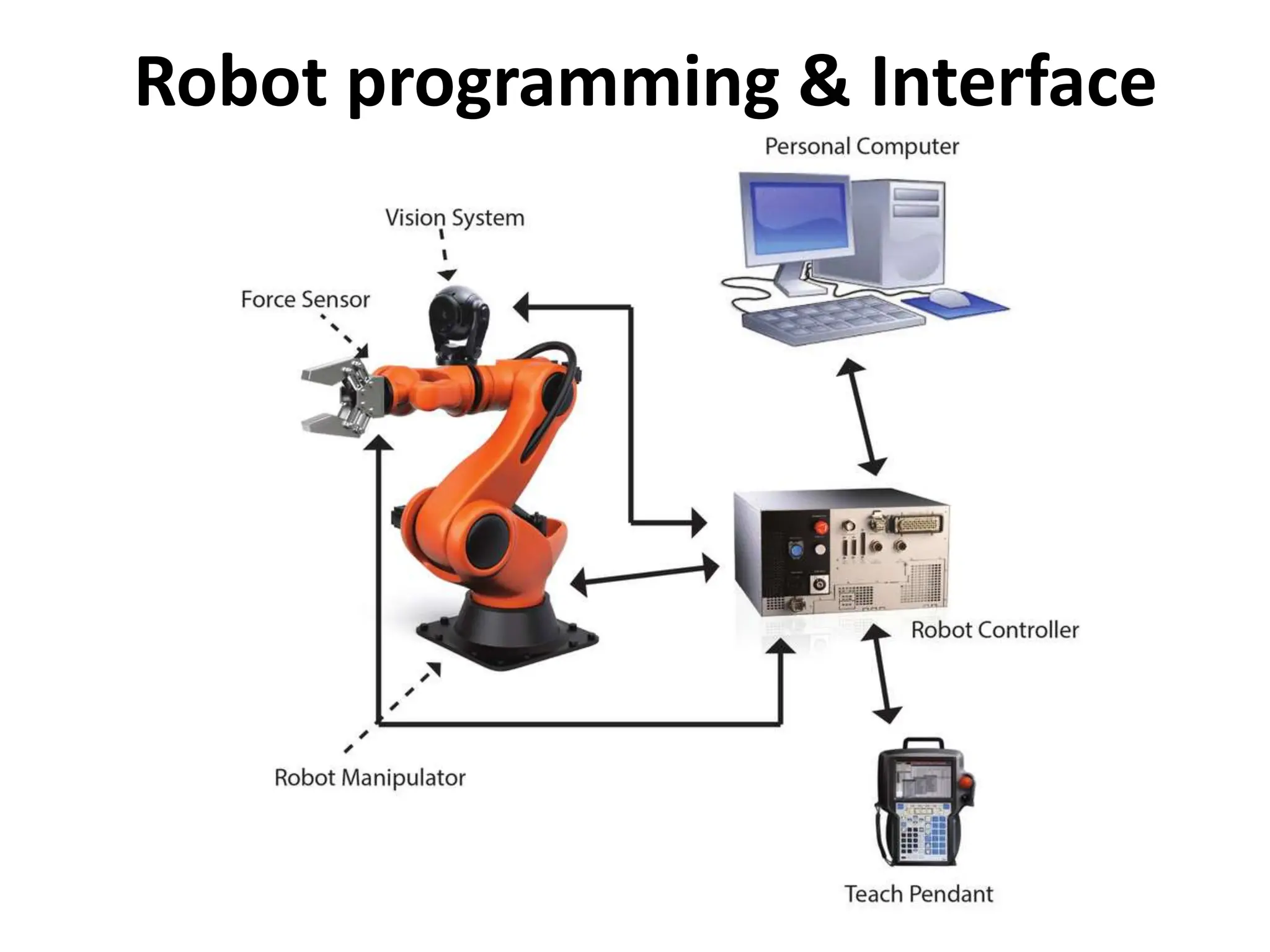

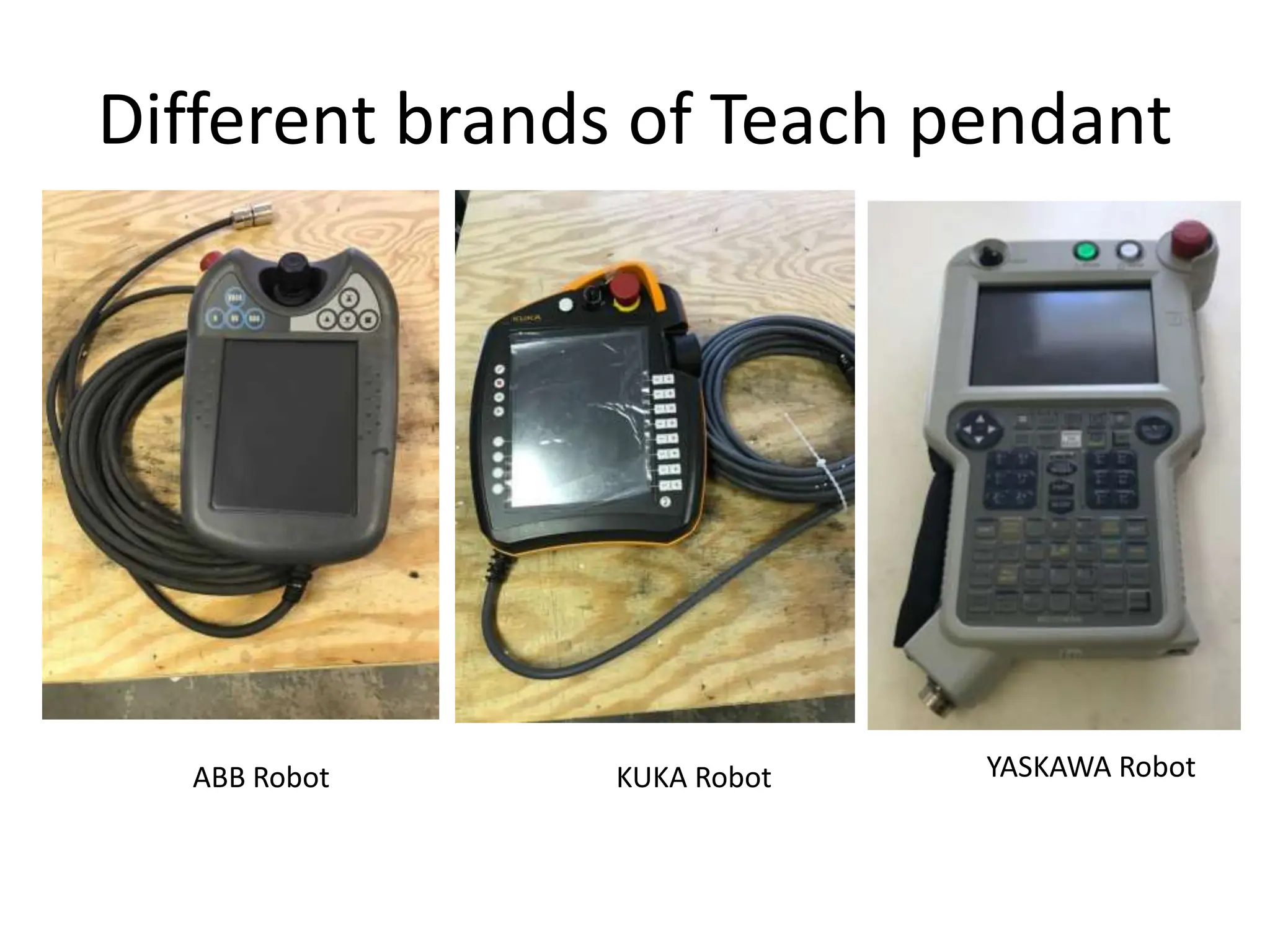

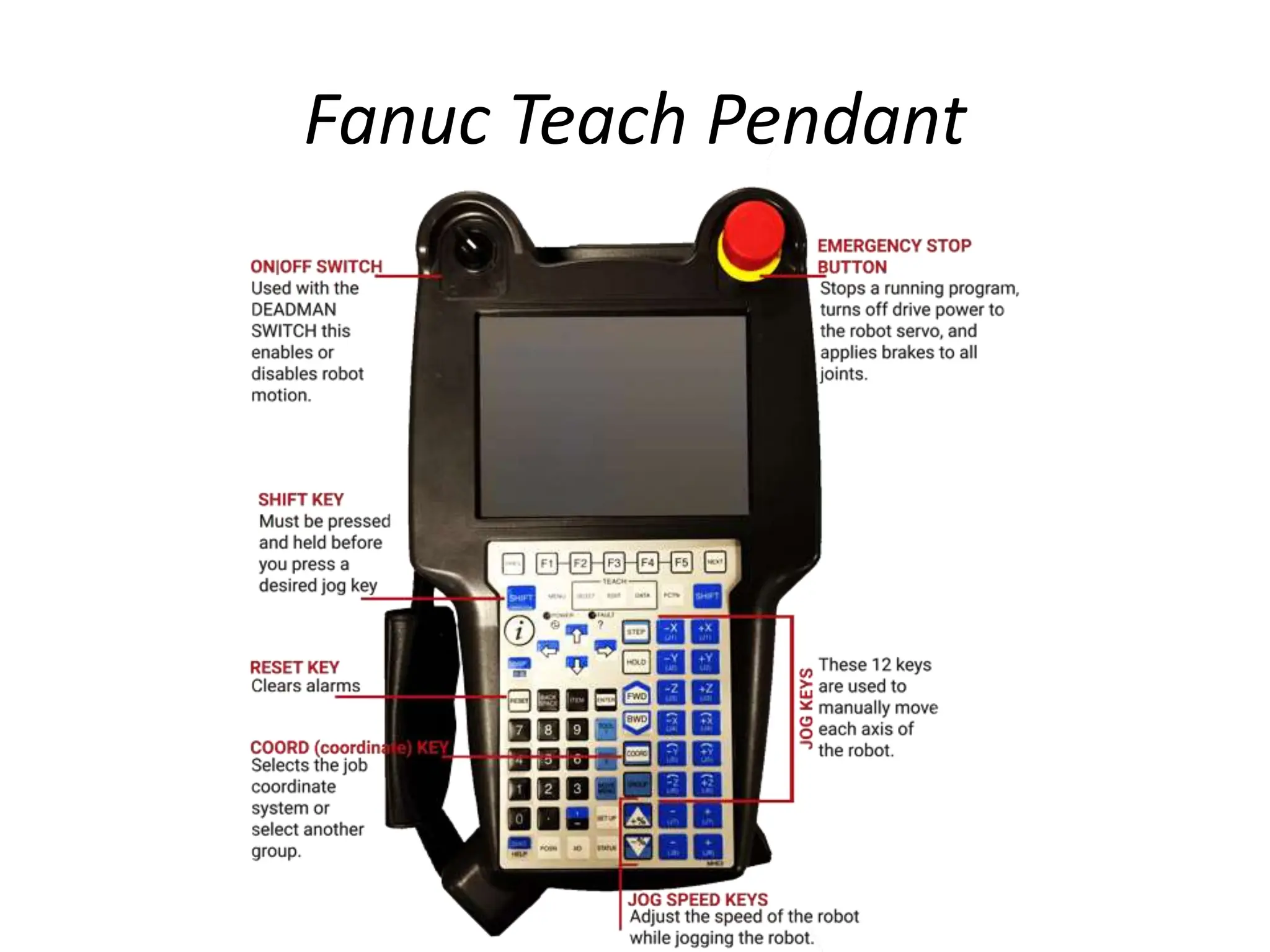

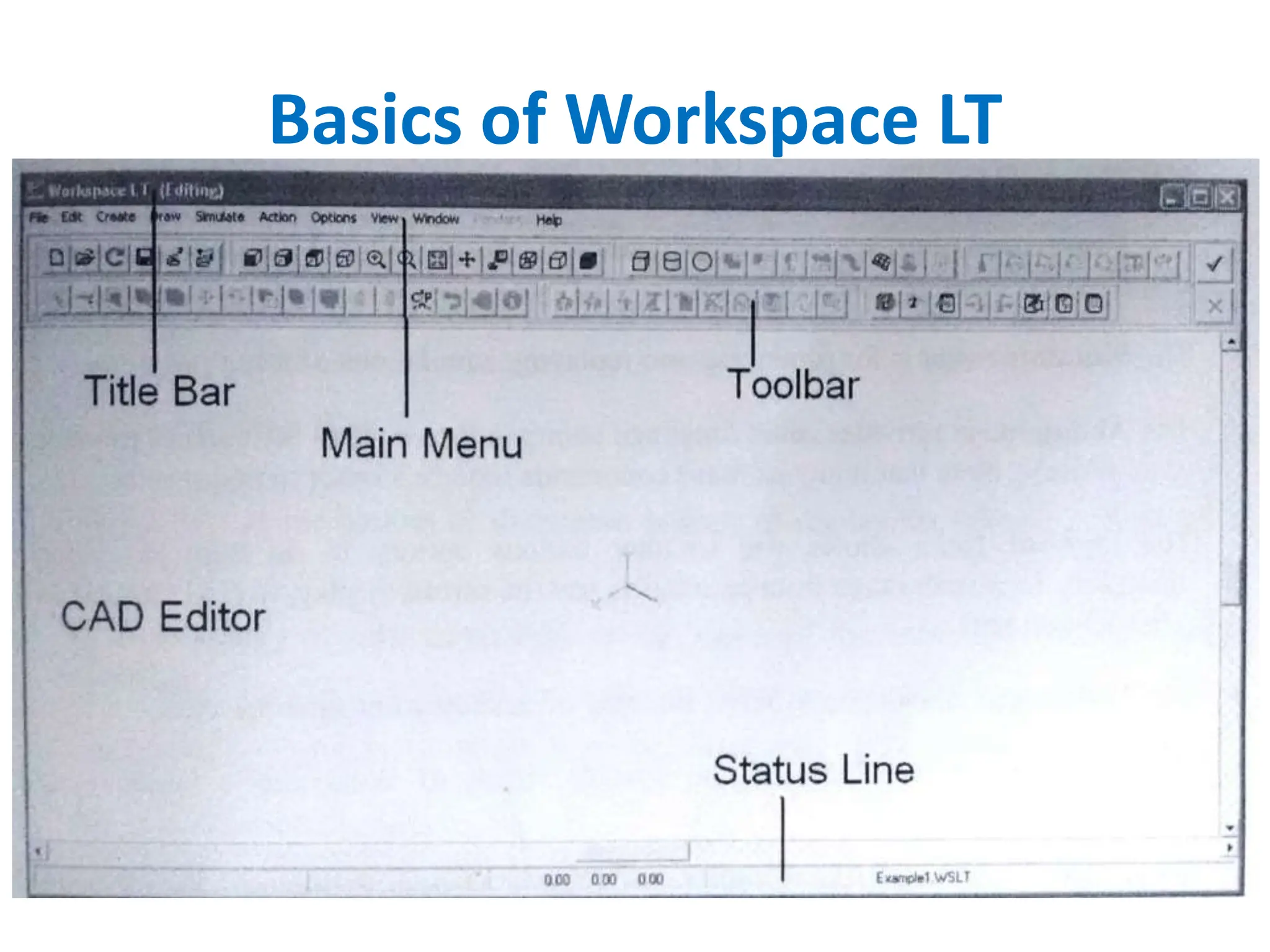

The document discusses a lab session on robot control using teach pendants, covering robot programming, the teach pendant method, and the features and benefits of Workspace LT software. It includes details on types of teach pendants, their advantages and disadvantages, and the capabilities of Workspace LT for offline programming and simulation in educational settings. Additionally, it specifies system requirements for installing Workspace LT and mentions various robot programming languages supported.