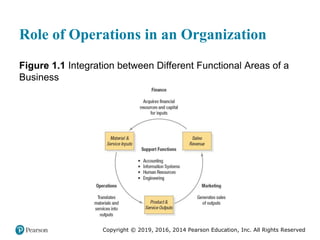

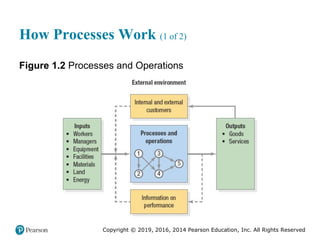

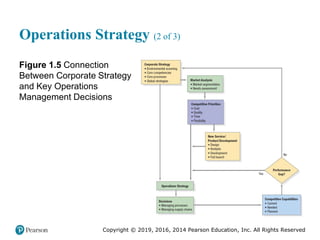

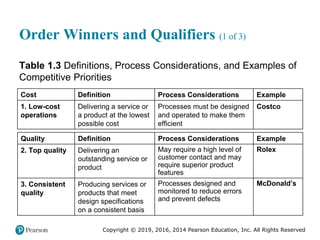

This document provides an overview of operations management and supply chain management concepts from the textbook "Operations Management: Processes and Supply Chains". It defines key terms like operations, processes, competitive priorities and capabilities. It also describes the role of operations in an organization and how corporate strategy, market analysis and operations strategy are connected. Finally, it identifies nine competitive priorities used in operations strategy and discusses how firms can develop capabilities in cost, quality, time and flexibility.

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

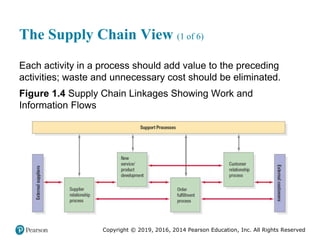

The Supply Chain View (2 of 6)

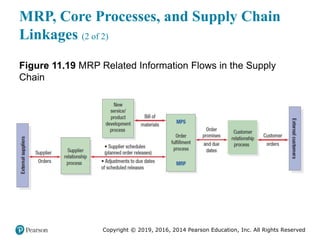

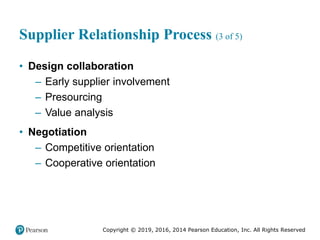

Supplier relationship process – A process that selects the

suppliers of services, materials, and information and facilitates

the timely and efficient flow of these items into the firm

Figure 1.4 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-15-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

The Supply Chain View (3 of 6)

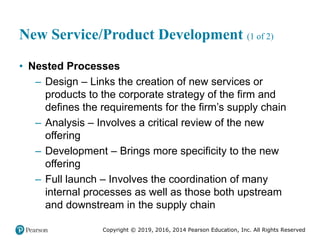

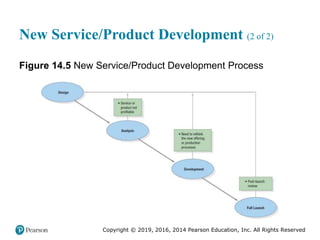

New service/product development – A process that designs and

develops new services or products from inputs received from

external customer specifications or from the market in general

through the customer relationship process

Figure 1.4 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-16-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

The Supply Chain View (4 of 6)

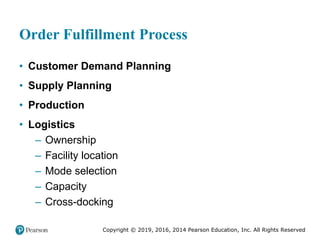

Order fulfillment process – A process that includes the activities

required to produce and deliver the service or product to the

external customer

Figure 1.4 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-17-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

The Supply Chain View (5 of 6)

Customer relationship process – A process that identifies,

attracts and builds relationships with external customers and

facilitates the placement of orders by customers (customer

relationship management)

Figure 1.4 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-18-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

The Supply Chain View (6 of 6)

Support Processes - Processes like Accounting, Finance,

Human Resources, Management Information Systems and

Marketing that provide vital resources and inputs to the core

processes

Figure 1.4 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-19-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Order Winners and Qualifiers (2 of 3)

Table 1.3 [continued]

Time Definition Process Considerations Example

4. Delivery speed Quickly filling a

customer’s order

Design processes to reduce

lead time

Netflix

5. On-time delivery Meeting delivery-time

promises

Planning processes used to

increase percent of customer

orders shipped when

promised

United

Parcel

Service

(UPS)

6. Development

speed

Quickly introducing a

new service or a

product

Process involve cross-

functional integration and

involvement of critical

external suppliers

Zara](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-28-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Order Winners and Qualifiers (3 of 3)

Table 1.3 [continued]

Flexibility Definition Process Considerations Example

7. Customization Satisfying the unique

needs of each

customer by

changing service or

product designs

Processes typically have

low volume, close customer

contact, and can be easily

reconfigured to meet

unique customer needs

Ritz Carlton

8. Variety Handling a wide

assortment of

services or products

efficiently

Processes are capable of

larger volumes than

processes supporting

customization

Amazon.com

9. Volume

flexibility

Accelerating or

decelerating the rate

of production of

services or products

quickly to handle

large fluctuations in

demand

Processes must be

designed for excess

capacity and excess

inventory

The United

States Postal

Service (USPS)](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-29-320.jpg)

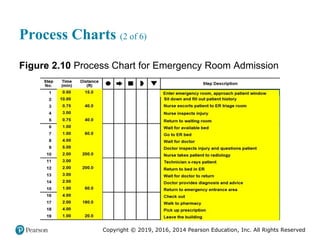

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Process Charts (3 of 6)

Figure 2.10 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-83-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Process Charts (4 of 6)

Figure 2.10 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-84-320.jpg)

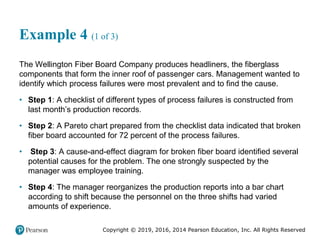

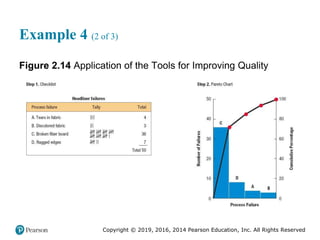

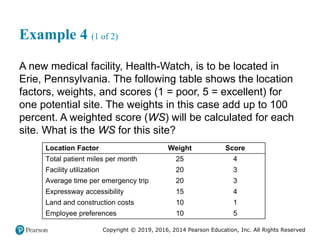

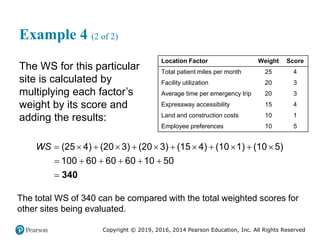

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

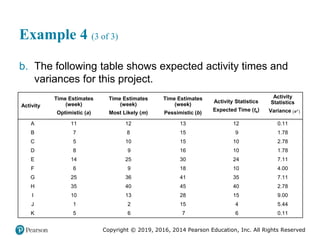

Example 4 (3 of 3)

Figure 2.14 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-97-320.jpg)

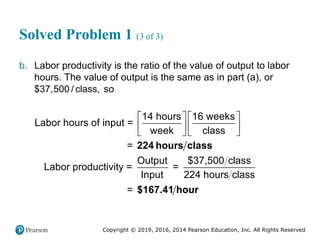

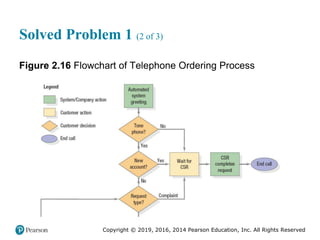

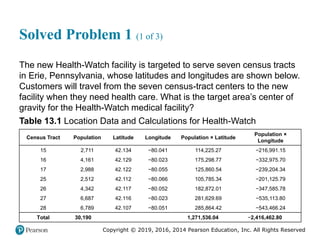

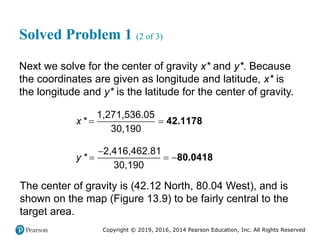

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

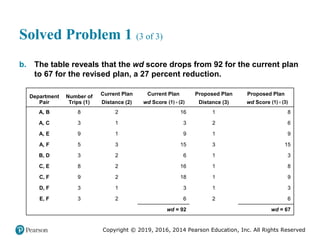

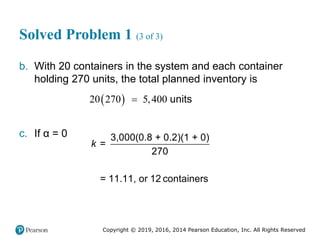

Solved Problem 1 (3 of 3)

Figure 2.16 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-104-320.jpg)

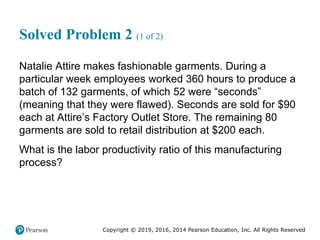

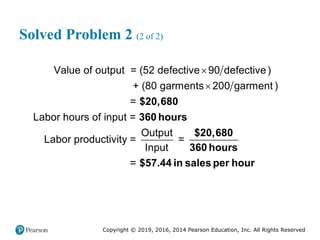

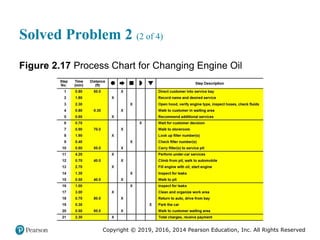

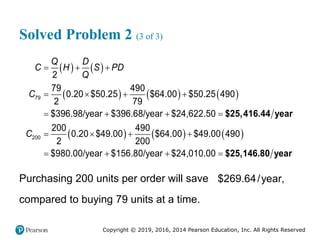

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

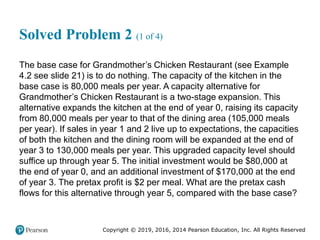

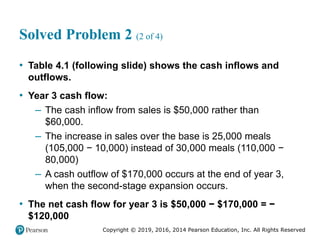

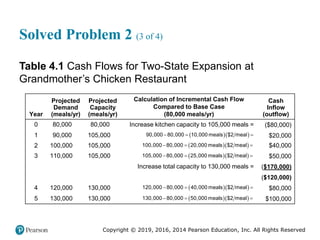

Solved Problem 2 (3 of 4)

Figure 2.17 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-107-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Control Charts (3 of 7)

(b) Run – Take action

Figure 3.8 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-141-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Control Charts (4 of 7)

(c) Sudden change – Monitor

Figure 3.8 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-142-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Control Charts (5 of 7)

(d) Exceeds control limits – Take action

Figure 3.8 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-143-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Process Capability (3 of 6)

(b) Process is not capable

Figure 3.13 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-170-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Solved Problem 2 (5 of 6)

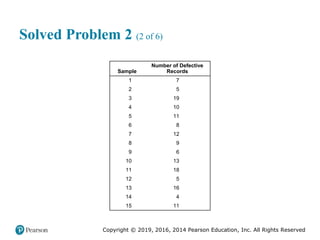

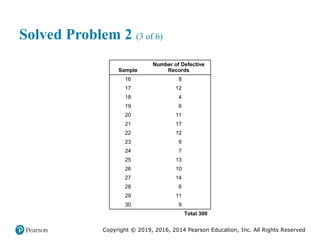

a. From the table, the supervisor knows that the total number of

defective records is 300 out of a total sample of 7,500 [or 30(250)].

Therefore, the central line of the chart is

300

= = 0.04

7,500

p

The control limits are:

(1 ) 0.04(0.96)

UCL = + z = 0.04 + 3 = 0.077

250

(1 ) 0.04(0.96)

LCL = = 0.04 3 = 0.003

250

p

p

p p

p

n

p p

p z

n](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-190-320.jpg)

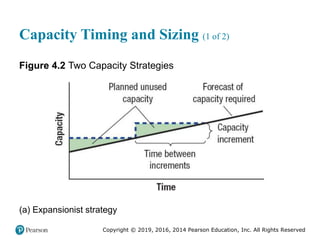

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Capacity Timing and Sizing (2 of 2)

Figure 4.2 [continued]

(b) Wait-and-see strategy](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-209-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Step 1 - Estimate Capacity Requirements (1 of 2)

For one service or product processed at one operation with a one year time

period, the capacity requirement, M, is

Processinghours required for year's demand

Capacity requirement =

Hours available from a single capacity unit

(such as an employee or machine) per year,

after deducting desired cushion

[1 ( 100)]

Dp

M

N C

where

D = demand forecast for the year (number of customers served or units

produced)

p = processing time (in hours per customer served or unit produced)

N = total number of hours per year during which the process operates

C = desired capacity cushion (expressed as a percent)

M = the number of input units required](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-212-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Step 1 - Estimate Capacity Requirements (2 of 2)

Setup times (time required to change a process or an operation

from making one service or product to making another) may be

required if multiple products are produced

Processing and setup hours required for year s demand,

summed over all services or products

Capacity requirement =

Hours available from a single capacity unit per year,

after deducting desired cushion

M

product 1 product 2 product

[ ( ) ] [ ( ) ] [ ( ) ]

[1 ( 100)]

n

Dp D Q s Dp D Q s Dp D Q s

N C

Where

Q = number of units in each lot

s = setup time in hours per lot](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-213-320.jpg)

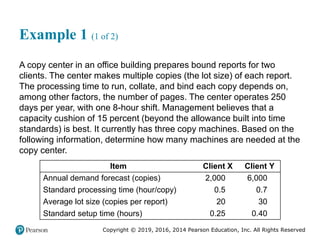

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 1 (2 of 2)

product 1 product 2 product n

client X client Y

[ ( ) ] [ ( ) ] [ ( ) ]

[1 ( 100)]

[2,000(0.5) (2,000 20)(0.25)] [6,000(0.7) (6,000 30)(0.40)]

[(250 day year)(1 shift day)(8 hours shift)][1.0 (15 100

Dp D Q s Dp D Q s Dp D Q s

M

N C

)]

5,305

1,700

3.12

Rounding up to the next integer gives a requirement of four

machines.](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-215-320.jpg)

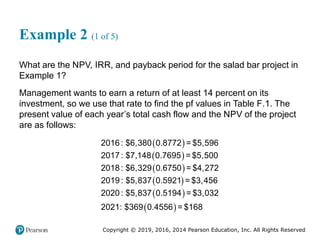

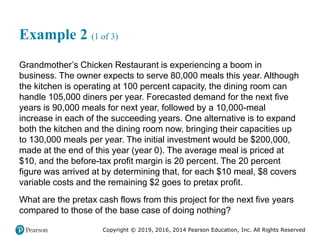

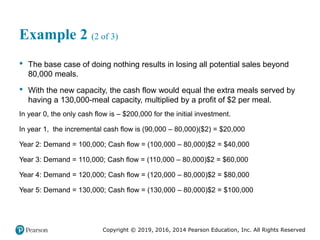

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 2 (3 of 3)

• The owner should account for the time value of money,

applying such techniques as the net present value or internal

rate of return methods (see Supplement F, “Financial

Analysis,” in MyOMLab).

• For instance, the net present value (NPV) of this project at a

discount rate of 10 percent is calculated here, and equals

$13,051.76.

$13,051.76

2

3 4 5

200,000 [(20,000 1.1)] [40,000 (1.1) ]

[60,000 (1.1) ] [80,000 (1.1) ] [100,000 (1.1) ]

$200,000 $18,181.82 $33,057.85 $45,078.89

$54,641.07 $62,092.13

NPV

](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-220-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

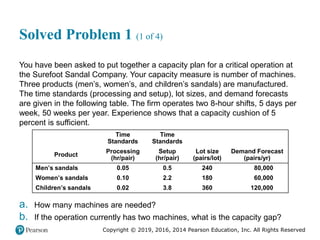

Solved Problem 1 (2 of 4)

a. The number of hours of operation per year, N, is N = (2

shifts/day)(8 hours/shifts) (250 days/machine-year) = 4,000

hours/machine-year

The number of machines required, M, is the sum of machine-

hour requirements for all three products divided by the

number of productive hours available for one machine:

men women children

[ ( ) ] [ ( ) ] [ ( ) ]

[1 ( 100)]

[80,000(0.05) (80,000 240)0.5] [60,000(0.10) (60,000 180)2.2]

[120,000(0.02) (120,000 360)3.8]

4,000[1 (5 100)]

14,567 hours year

3,800 hours machin

Dp D Q s Dp D Q s Dp D Q s

M

N C

e year

3.83 or 4 machines](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-225-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Solved Problem 2 (4 of 4)

For comparison purposes, the NPV of this project at a discount

rate of 10 percent is calculated as follows, and equals negative

$2,184.90.

$2,184.90

2

3 4 5

80,000 (20,000 1.1) [40,000 (1.1) ]

[120,000 (1.1) ] [80,000 (1.1) ] [100,000 (1.1) ]

$80,000 $18,181.82 $33,057.85 $90,157.77

$54,641.07 $62,092.13

NPV

• On a purely monetary basis, a single-stage expansion seems

to be a better alternative than this two-stage expansion.

• However, other qualitative factors as mentioned earlier must

be considered as well.](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-231-320.jpg)

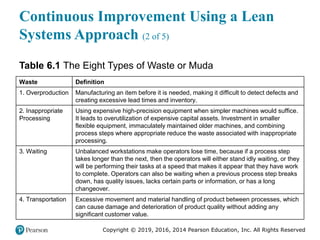

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Continuous Improvement Using a Lean

Systems Approach (3 of 5)

Table 6.1 [continued]

Waste Definition

5. Motion Unnecessary effort related to the ergonomics of bending, stretching, reaching,

lifting, and walking. Jobs with excessive motion should be redesigned.

6. Inventory Excess inventory hides problems on the shop floor, consumes space,

increases lead times, and inhibits communication. Work-in-process inventory is

a direct result of overproduction and waiting.

7. Defects Quality defects result in rework and scrap and add wasteful costs to the system

in the form of lost capacity, rescheduling effort, increased inspection, and loss

of customer goodwill.

8. Underutilization

of Employees

Failure of the firm to learn from and capitalize on its employees’ knowledge and

creativity impedes long-term efforts to eliminate waste.](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-297-320.jpg)

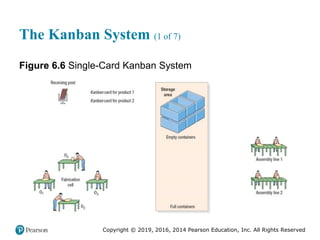

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

The Kanban System (2 of 7)

Figure 6.6 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-312-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

The Kanban System (3 of 7)

Figure 6.6 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-313-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

The Kanban System (4 of 7)

Figure 6.6 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-314-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

The Kanban System (5 of 7)

Figure 6.6 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-315-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

The Kanban System (6 of 7)

Figure 6.6 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-316-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

The Kanban System (7 of 7)

Figure 6.6 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-317-320.jpg)

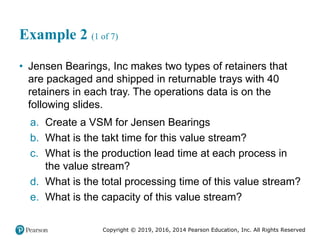

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 2 (3 of 7)

Table 6.3 [continued]

Overall Process Attributes

Average demand: 3,200/week (1,000 “L”; 2,200 “S”)

Batch size: 40

Number of shifts per day: 1

Availability: 8 hours per shift with two 30-minute lunch breaks

Customer Shipments One shipment of 3,200 units each week in trays of 40 pieces

Information Flow All communications from customer are electronic:

180/90/60/30/day Forecasts

Daily Order

All communications to supplier are electronic

4-Week Forecast

Weekly Fax

There is a weekly schedule manually delivered to Press, Pierce & Form, and

Finish Grind and a Daily Ship Schedule manually delivered to Shipping

All material is pushed](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-330-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

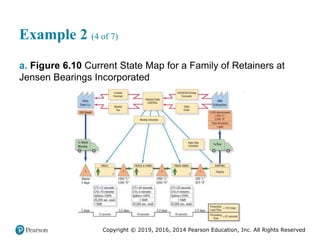

Example 2 (5 of 7)

b. Daily Demand

[(1,000 + 2,200) pieces/week]/5 days = 640 pieces per day

Daily Availability

(7 hours/day) × (3,600 seconds per hour) = 25,200

seconds per day

Takt Time

Daily availability 25,200

= = =

Daily Demand 640

39.375 seconds per piece](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-332-320.jpg)

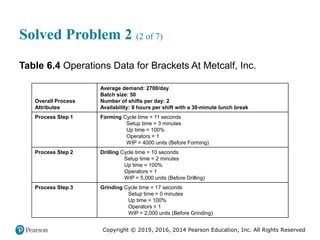

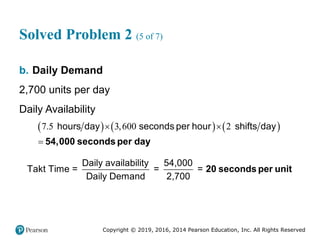

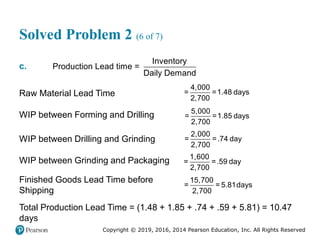

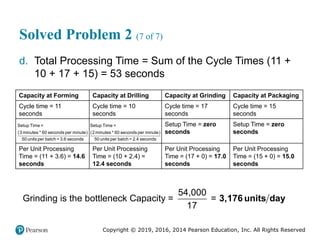

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Solved Problem 2 (3 of 7)

Table 6.4 [continued]

Overall Process

Attributes

Average demand: 2700/day

Batch size: 50

Number of shifts per day: 2

Availability: 8 hours per shift with a 30-minute lunch break

Process Step 4 Packaging Cycle time = 15 seconds

Setup time = 0 minutes

Up time = 100%

Operators = 1

WIP = 1,600 units (Before Packaging)

WIP = 15,700 units (Before Shipping)

Customer Shipments One shipment of 13,500 units each week

Information Flow All communications with customer are electronic

There is a weekly order release to Forming

All material is pushed](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-345-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 2 (4 of 6)

Figure 7.3 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-370-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 2 (5 of 6)

Figure 7.3 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-371-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 2 (6 of 6)

Figure 7.3 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-372-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

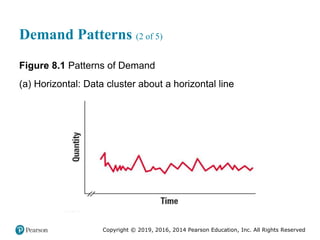

Demand Patterns (3 of 5)

Figure 8.1 [continued]

(b) Trend: Data consistently increase or decrease](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-427-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Demand Patterns (4 of 5)

Figure 8.1 [continued]

(c) Seasonal: Data consistently show peaks and valleys](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-428-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Demand Patterns (5 of 5)

Figure 8.1 [continued]

(d) Cyclical: Data reveal gradual increases and decreases over

extended periods](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-429-320.jpg)

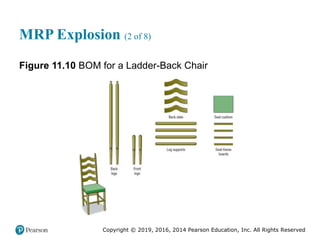

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

MRP Explosion (3 of 8)

Figure 11.10 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-653-320.jpg)

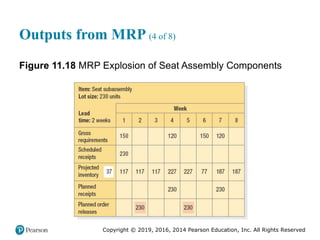

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Outputs from MRP (5 of 8)

Figure 11.18 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-674-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Outputs from MRP (6 of 8)

Figure 11.18 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-675-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Outputs from MRP (7 of 8)

Figure 11.18 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-676-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Solved Problem 3 (4 of 5)

Figure 11.27 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-703-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Solved Problem 3 (5 of 5)

Figure 11.27 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-704-320.jpg)

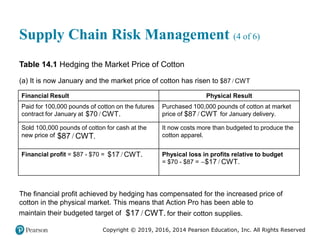

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Supply Chain Risk Management (5 of 6)

Table 14.1 [continued]

(b) It is now June and the market price of cotton has dropped to /

$65 CWT.

Financial Result Physical Result

Paid $70 per C W T for 100,000 pounds of cotton

on the futures contract for the month of June.

Purchased 100,000 pounds of cotton at the

market price of $65 per C W T for June delivery.

Sold 100,000 pounds of cotton for cash at the

new price of $65 per C W T.

It is now less expensive to produce the cotton

apparel.

Financial loss = $65 - $70 = $5 per C W T. Physical loss in profits relative to budget

= $70 - $65 = $5 per C W T.

The financial loss is balanced by the increase in physical profits. Active Pro has

achieved the budgeted cost of / .

$70 CWT

/ .

$5 CWT

/ .

$5 CWT

/

$65 CWT.

/

$65 CWT

/

$70 CWT](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-841-320.jpg)

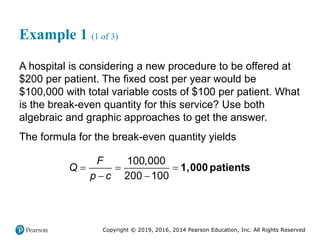

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

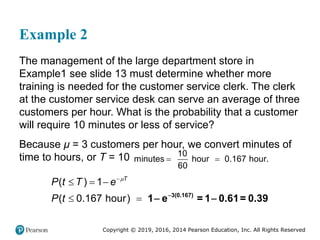

Example 2

If the most pessimistic sales forecast for the proposed

service from Figure A.1 was 1,500 patients, what would be

the procedure’s total contribution to profit and overhead per

year?

( ) ( ) [ (

+ = 200 1,500 100,000 +100 1,500

= $

)

50,000

]

pQ F cQ](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-925-320.jpg)

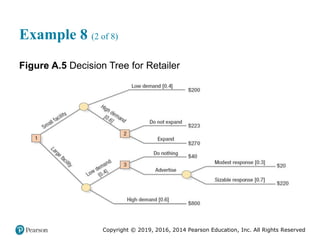

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 8 (3 of 8)

Figure A.5 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-948-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 8 (4 of 8)

Figure A.5 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-949-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 8 (5 of 8)

Figure A.5 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-950-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 8 (6 of 8)

Figure A.5 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-951-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 8 (7 of 8)

Figure A.5 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-952-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 8 (8 of 8)

Figure A.5 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-953-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Solved Problem 1 (4 of 4)

b. Total profit contribution = Total revenue − Total cost

[ ]

= +

=15(10,000) 56,000 + 7(10,000)

= $

( )

24,000

pQ F cQ](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-957-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

Example 1

• Management is redesigning the customer service process in a large

department store.

• Accommodating four customers is important.

• Customers arrive at the desk at the rate of two customers per hour.

• What is the probability that four customers will arrive during any

hour?

In this case customers per hour, T = 1 hour, and n = 4 customers. The

probability that four customers will arrive in any hour is

4

2(1) 2

4

[2(1)] 16

0.090

4! 24

P e e

](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-979-320.jpg)

![Copyright © 2019, 2016, 2014 Pearson Education, Inc. All Rights Reserved

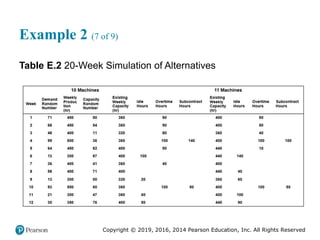

Example 2 (8 of 9)

Table E.2 [continued]](https://image.slidesharecdn.com/krajewskiom1201-231029185205-c0880f92/85/krajewski_om12-_01-pptx-1134-320.jpg)