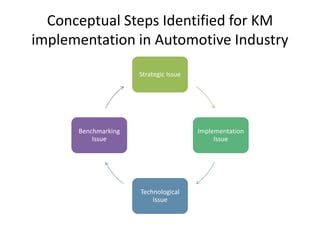

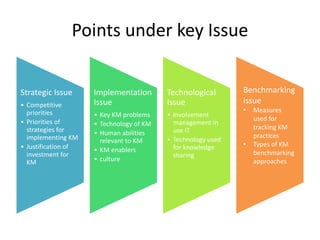

1. The document discusses key issues in implementing knowledge management in the automobile industry, including strategic issues, implementation issues, technological issues, and benchmarking issues.

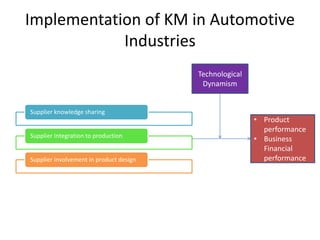

2. It provides examples of how knowledge management is used in automotive industries, such as supplier knowledge sharing, supplier integration in production, and supplier involvement in product design.

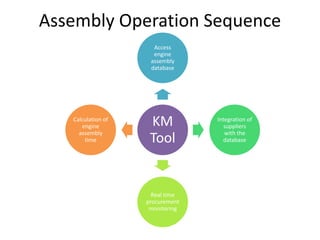

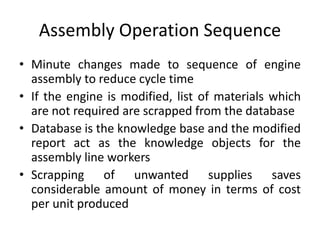

3. An assembly operation sequence knowledge management tool is described that provides assembly workers access to an engine assembly database to reduce cycle times and save costs by scrapping unwanted supplies.