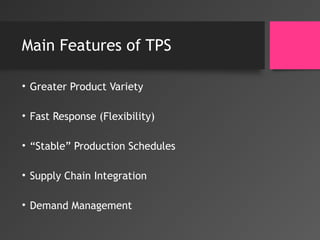

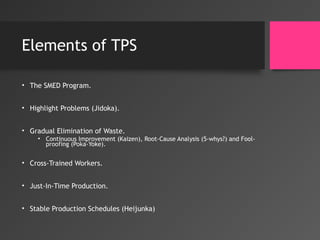

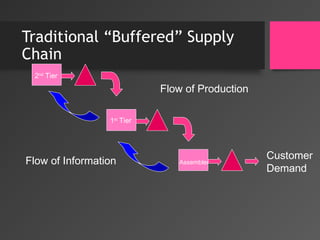

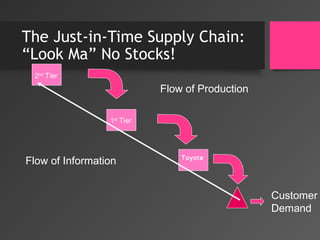

This document discusses the Toyota Production System and its transition from mass production to lean manufacturing. It provides background on Toyota as the world's largest automaker. The key aspects of the Toyota Production System discussed are just-in-time production and supply chain integration, which aim to eliminate waste through continuous improvement. Suppliers are expected to provide frequent, small deliveries with high reliability and participate in long-term relationships focused on productivity and quality gains.